System and method for removing CO (carbon monoxide) in hydrogen gas of proton exchange membrane fuel battery

A proton exchange membrane and fuel cell technology, applied in fuel cells, electrical components, separation methods, etc., can solve problems such as excessive CO content, and achieve the effect of reducing performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

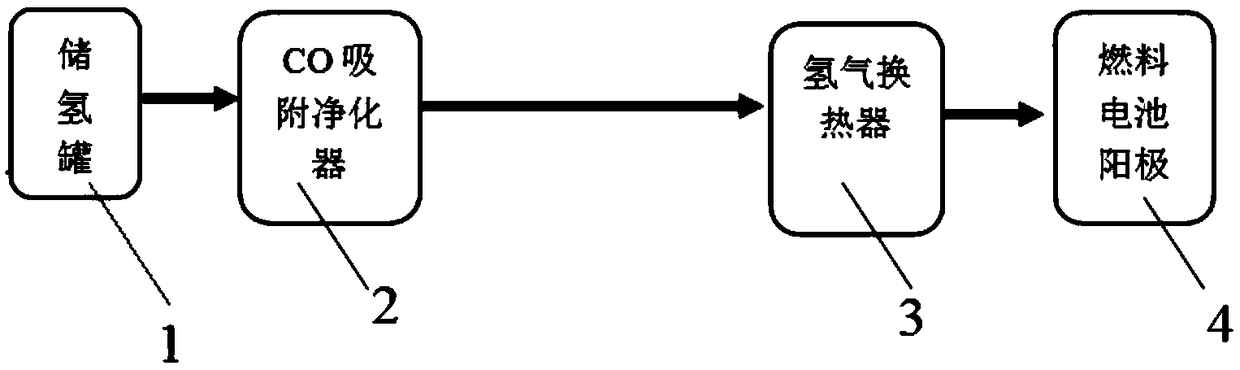

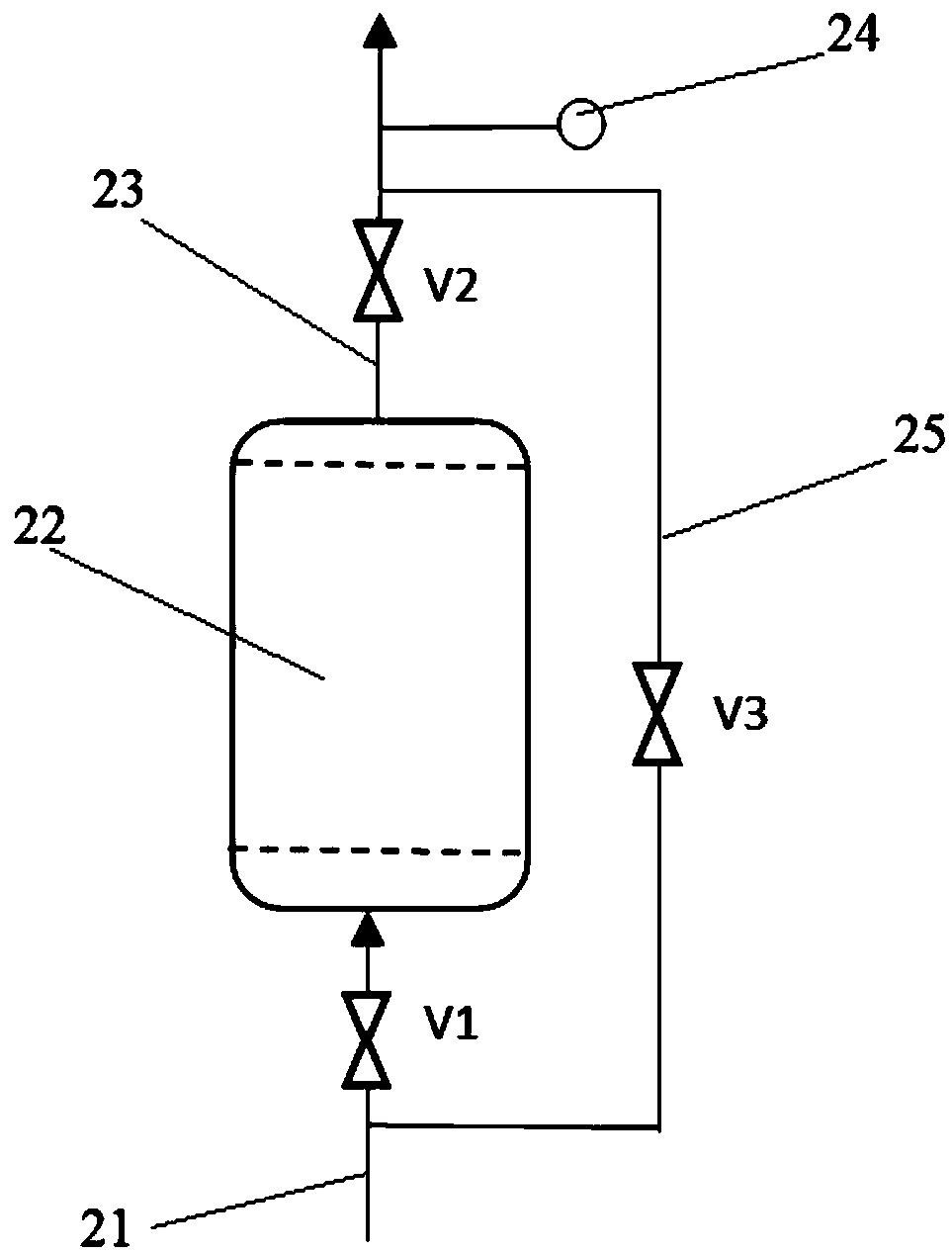

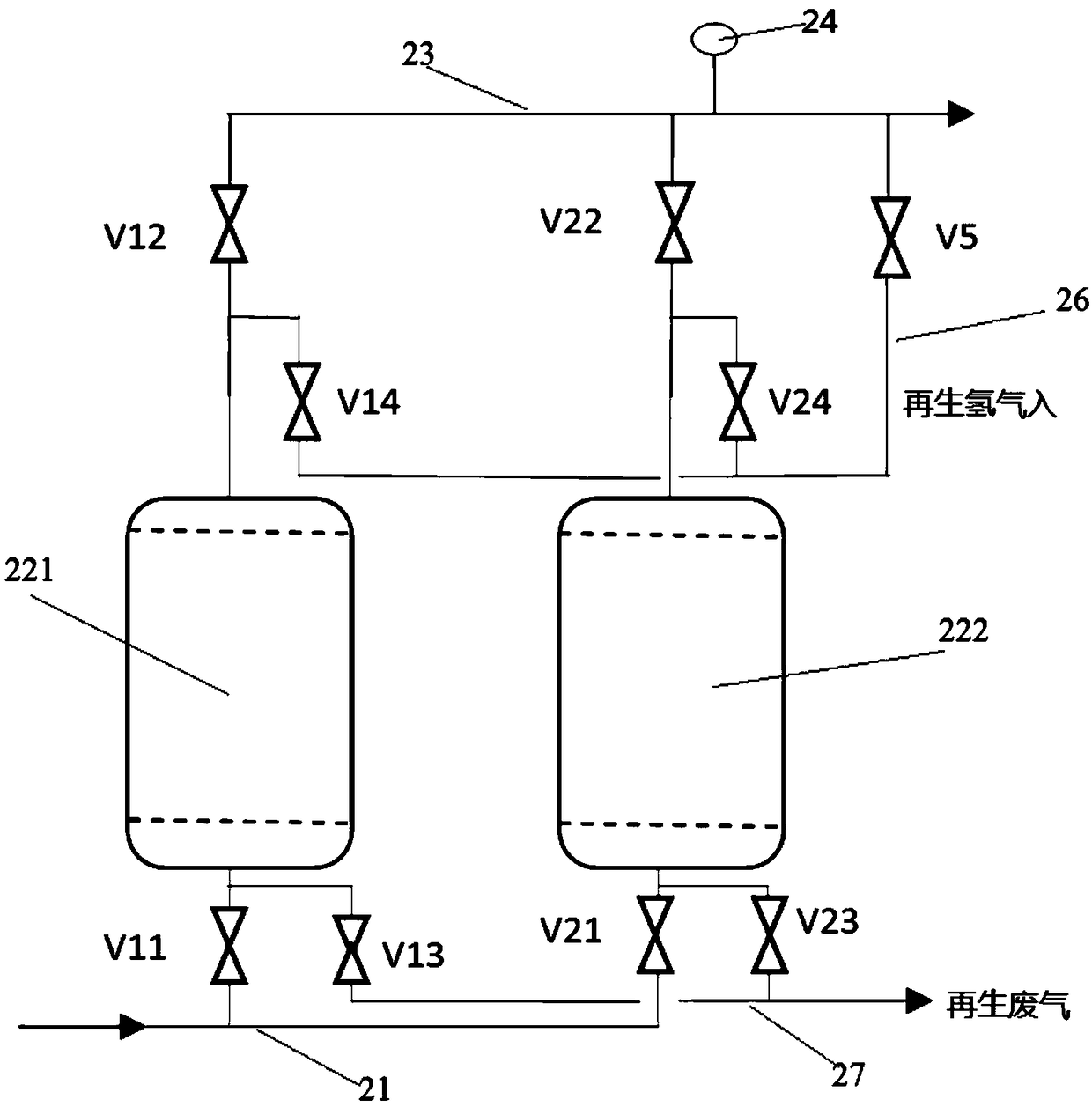

[0033] A CO removal system supporting a 1kW hydrogen fuel cell is as follows: figure 1 and figure 2 shown. The system includes a hydrogen storage tank 1, a CO adsorption purifier 2, a hydrogen heat exchanger 3, and a fuel cell anode 4 connected in sequence, wherein the CO adsorption purifier 2 includes a hydrogen inlet pipeline 21, an inlet pipeline control valve V1, an adsorption device 22, a purified hydrogen outlet pipeline 23, an outlet pipeline control valve V2 and a CO detection probe 24 located on the purified hydrogen outlet pipeline 23, the hydrogen inlet pipeline 21 communicates with the inlet of the hydrogen storage tank 1 and the adsorber 22, and the purified hydrogen outlet The pipeline 23 communicates with the outlet of the adsorber 22 and the hydrogen heat exchanger 3. The adsorber 22 is filled with an activated carbon-loaded copper adsorbent with a volume of 0.2 liters. Bypass line 25 for valve V3.

[0034] When working, open the control valves V1 and V2, c...

Embodiment 2

[0036] A CO removal system supporting a 30kW hydrogen fuel cell is as follows: figure 1 and figure 2 shown. It consists of an adsorber and related devices. The adsorber is filled with X-type molecular sieve-loaded copper adsorbent with a volume of 5 liters. The CO removal system and hydrogen purification process and operation steps are the same as in Example 1.

Embodiment 3

[0038] The CO removal system for a 300kW hydrogen fuel cell is as follows: figure 1 and figure 2 shown. It consists of an adsorber and related devices. The adsorber is filled with MCM mesoporous material-loaded copper adsorbent with a volume of 100 liters. The CO removal system and hydrogen purification process and operation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com