Metal mineral separation flotation process

A technology of metal minerals and technology, which is applied in the field of separation and flotation of metal minerals, can solve the problems of low flotation efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

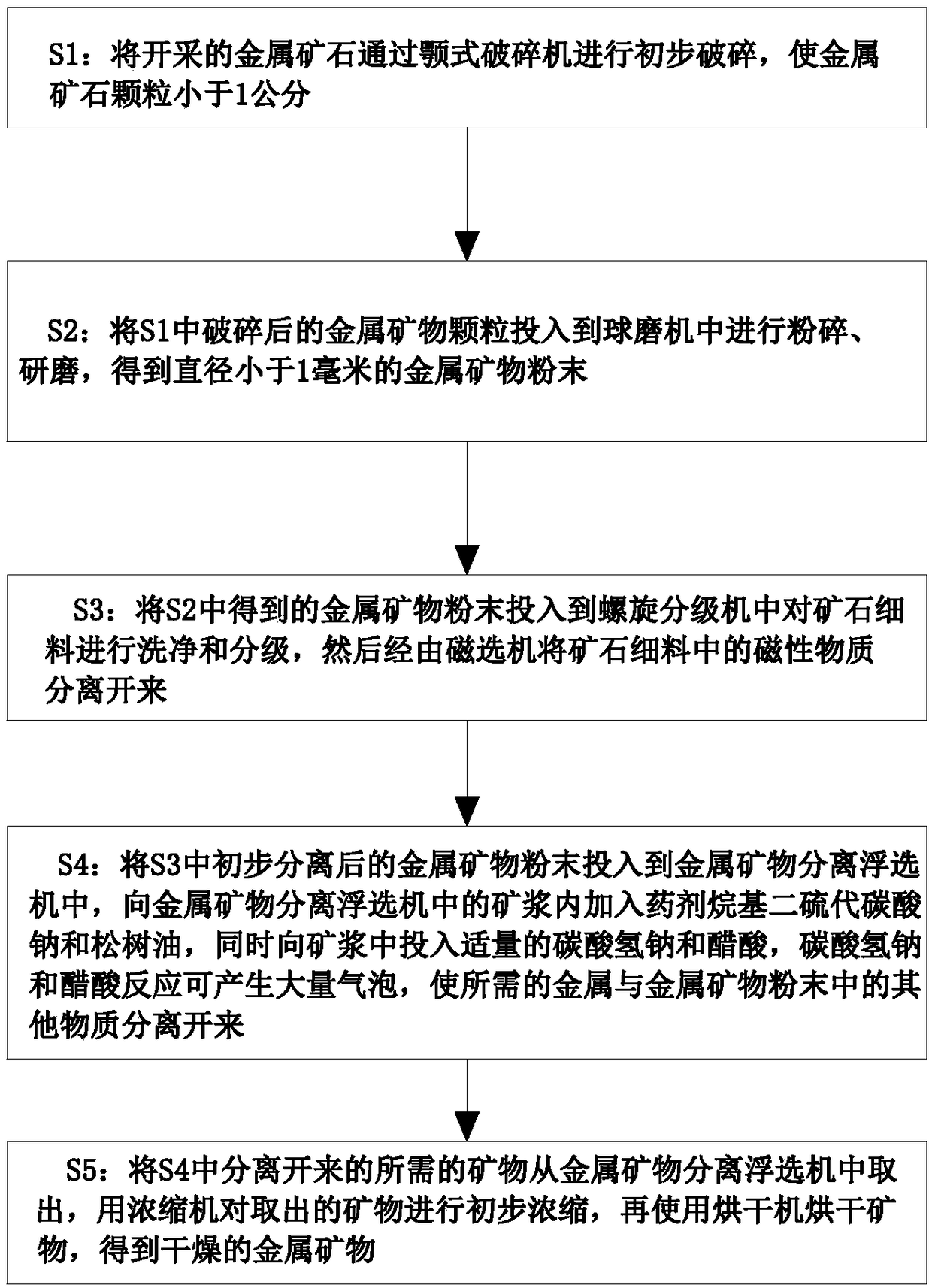

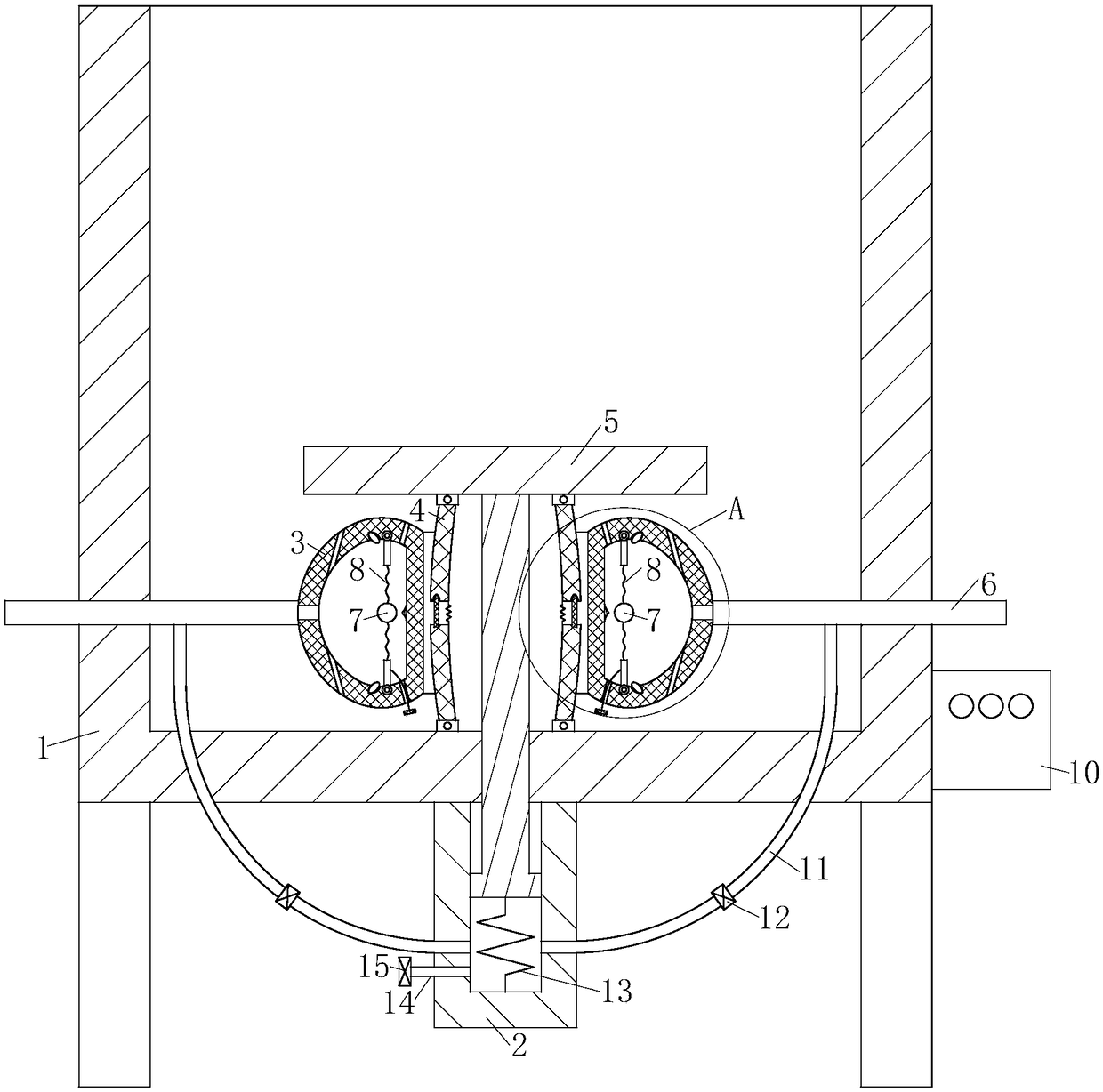

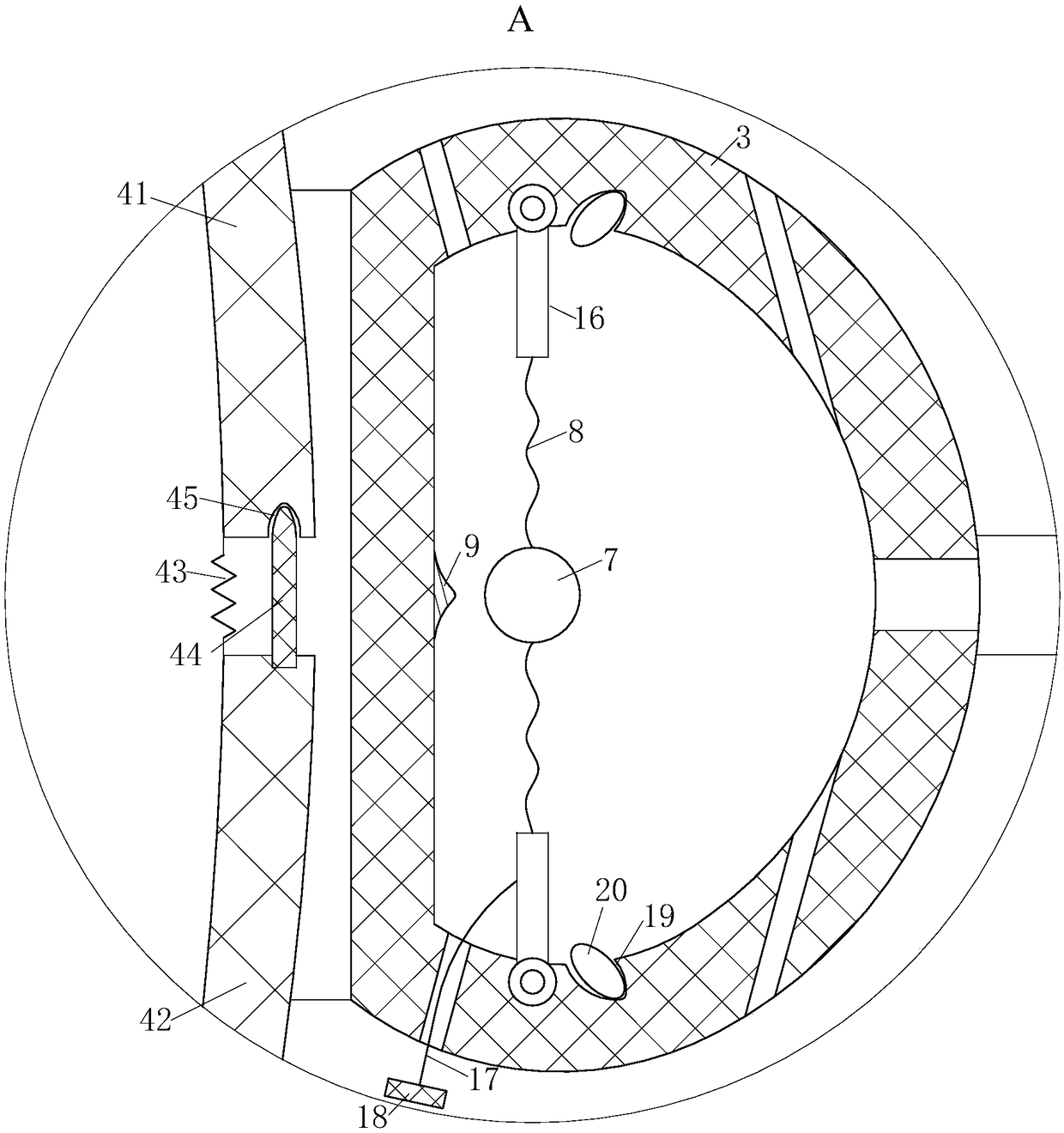

[0025] use Figure 1 to Figure 3A metal mineral separation flotation process of the present invention is described as follows.

[0026] Such as Figure 1 to Figure 3 Shown, a kind of metal mineral separation flotation process of the present invention, this process comprises the steps:

[0027] S1: Preliminarily crush the mined metal ore through a jaw crusher, so that the diameter of the metal ore particles is less than 1 cm, which is convenient for grinding;

[0028] S2: Put the crushed metal mineral particles in S1 into a ball mill for crushing and grinding to obtain metal mineral powder with a diameter of less than 1 mm, which is beneficial to the flotation of minerals;

[0029] S3: Put the metal mineral powder obtained in S2 into a spiral classifier to clean and classify the metal mineral powder, and then separate the magnetic substances in the metal mineral powder through a magnetic separator. The magnetic susceptibility coefficient is different to separate different mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com