In-situ dimensional measurement method and device for parts

A technology for measuring devices and parts, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unrealistic measurement, low efficiency of contact method, and difficulty in guaranteeing processing accuracy, etc., to achieve easy system maintenance and upgrade, and small imaging distortion , Improve the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

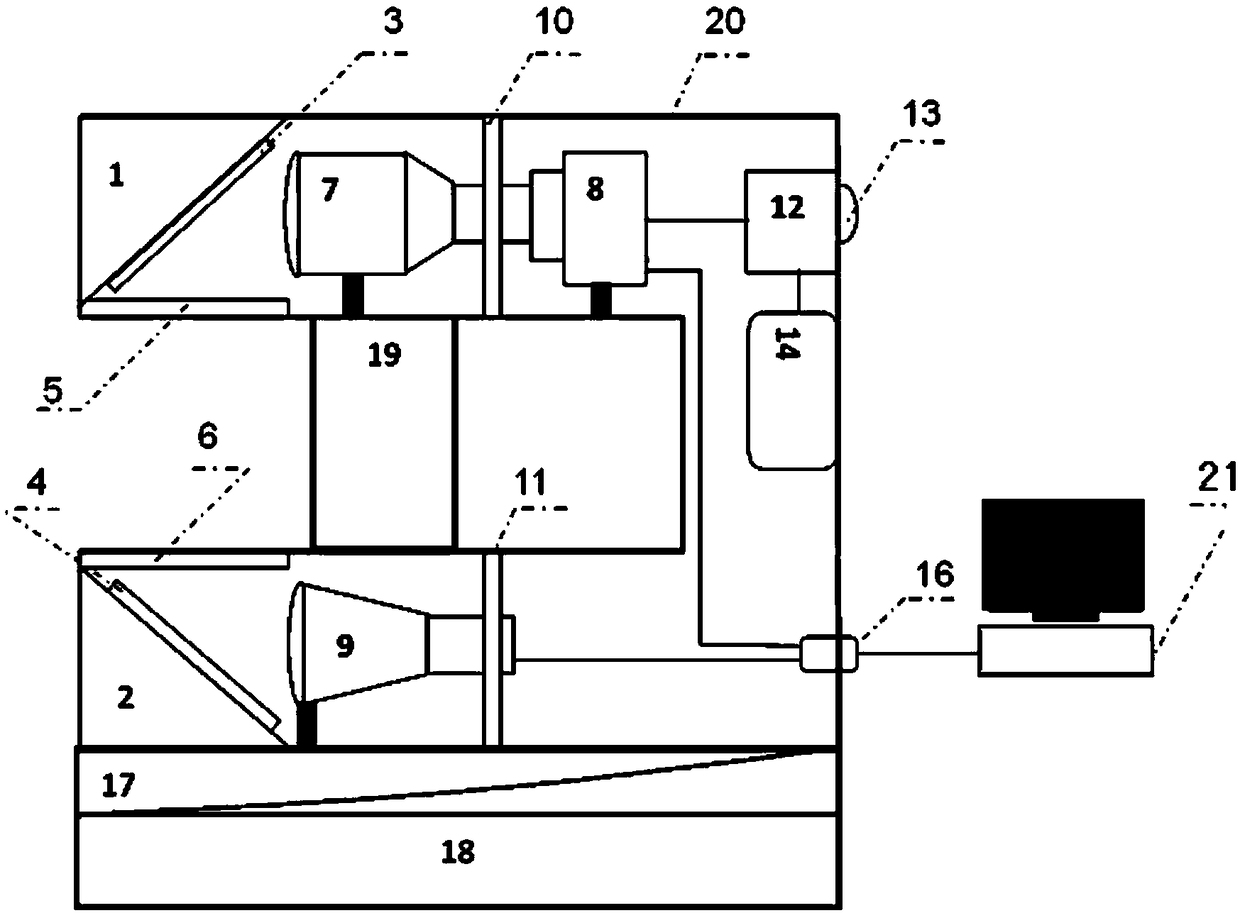

[0045] The composition of an in-situ size measuring device for parts includes: mirror frame A1, mirror frame B2, mirror A3, mirror B4, glass sheet A5, glass sheet B6, telecentric lens 7, image sensor 8, telecentric light source 9. Isolation frame A10, isolation frame B11, trigger controller 12, trigger button 13, battery 14, electrical interface 16, pitch and yaw adjustment platform 17, vertical translation platform 18, support column 19, equipment housing 20 and computer 21, The installation and position relationship of the above components are as follows:

[0046] Reflector A3 and reflector B4 are respectively installed on reflector frame A1 and reflector frame B2, the reflectivity of reflector A3 and reflector B4 is 90%, and the angle adjustment range of reflector frame A1 and reflector frame B2 is ±3°, the minimum adjustment angle is 1', with locking function, mirror frame A1, mirror frame B2, glass sheet A5, glass sheet B6, telecentric lens 7, image sensor 8, telecentric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com