Optical fiber MEMS microphone array acoustic detection plate and system

A microphone array and microphone technology, which is applied in the direction of measuring ultrasonic/sonic/infrasonic waves, measuring devices, utilizing wave/particle radiation, etc., can solve the problems of limited application scenarios, high manufacturing process requirements, complex structure, etc., and achieve easy preparation and assembly, Improved sensitivity and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

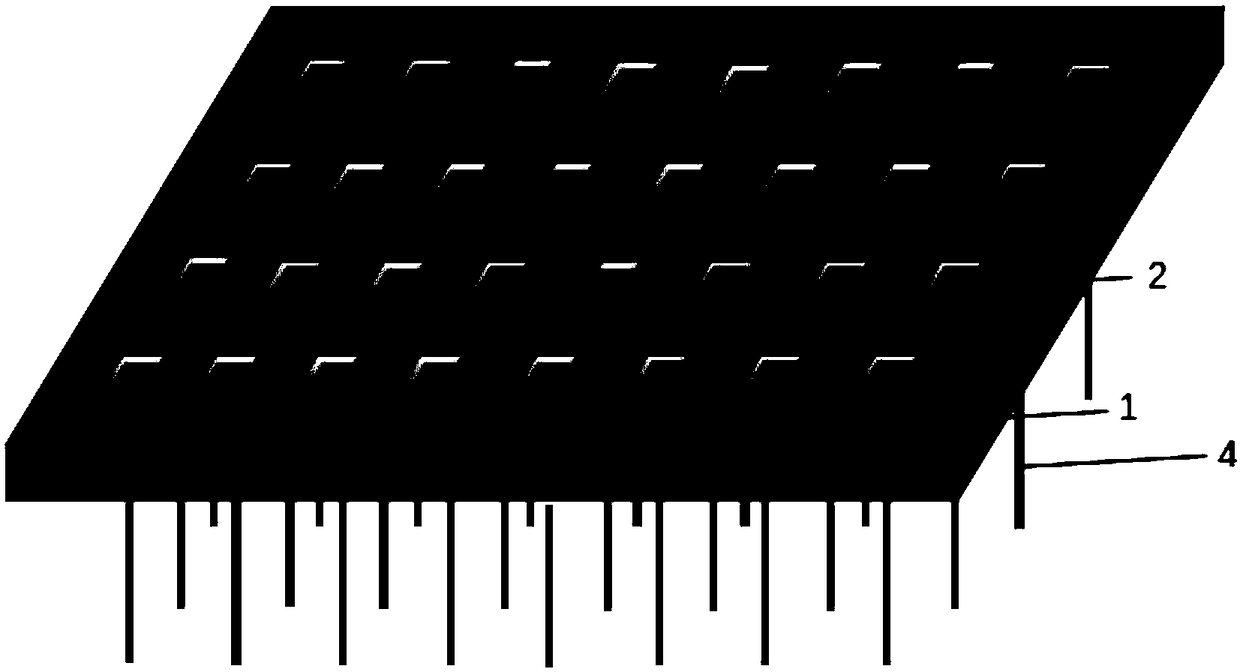

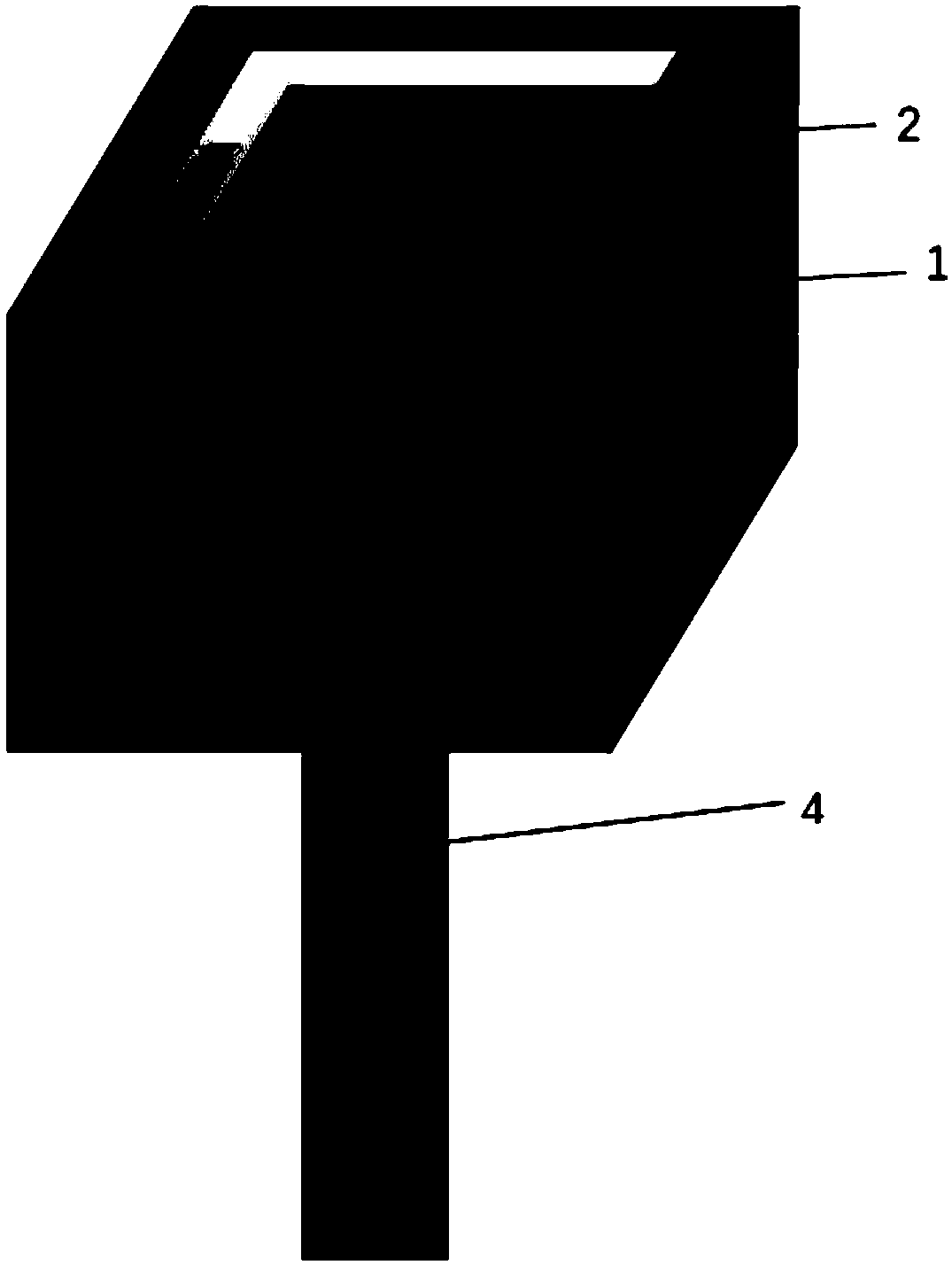

[0029] The present embodiment provides a kind of optical fiber MEMS microphone array acoustic detection plate, its structure is as follows figure 1 As shown, it is composed of optical fiber MEMS microphone acoustic wave sensors distributed in a 4*8 array; the structure of optical fiber MEMS microphone acoustic wave sensors is as follows figure 2 Shown: including substrate 1, MEMS diaphragm 2, capillary glass tube 3, optical fiber 4;

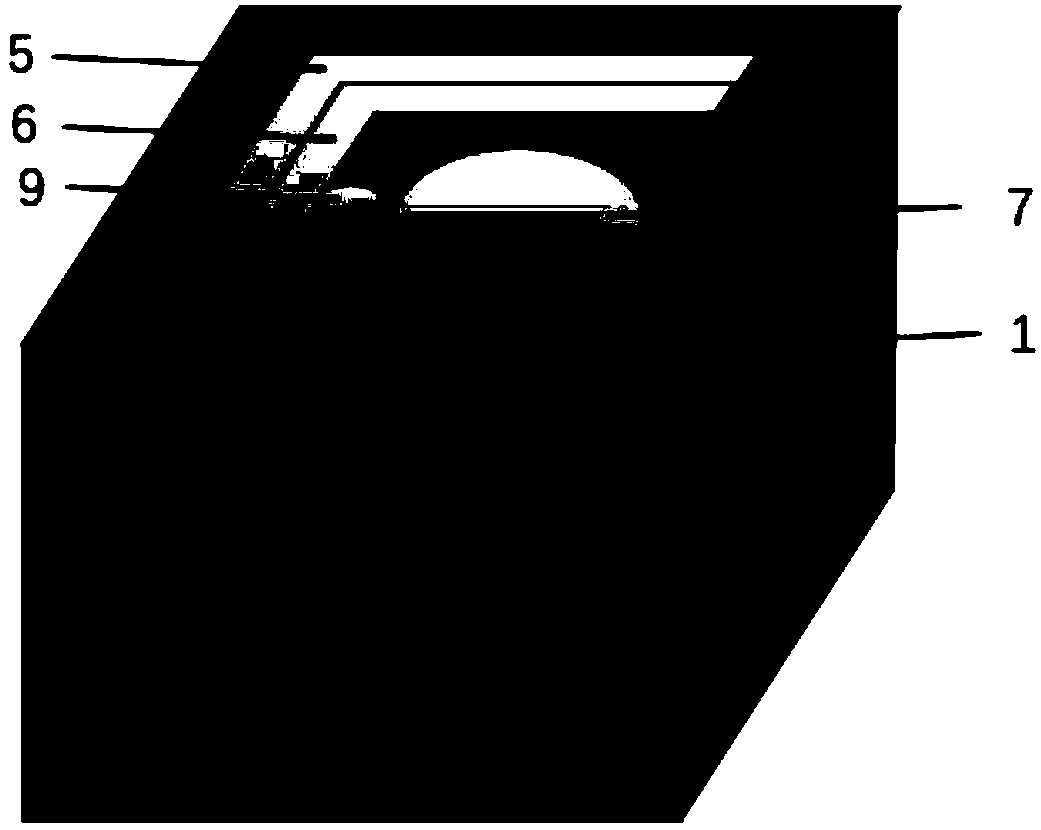

[0030] A first-level groove 5 is formed at the center of the upper surface of the substrate 1, a second-level groove 6 is formed at the center of the bottom of the first-level groove, and an optical fiber hole 7 through the substrate is formed at the center of the bottom of the second-level groove; The lower surface of the substrate 1 is provided with a ventilation hole 9 to allow the air to circulate between the second-level groove 6 and the outside world; image 3 , Figure 4 shown;

[0031] The upper surface of the MEMS diaphragm has perio...

Embodiment 2

[0037] The present embodiment provides a kind of detection system that comprises the optical fiber MEMS microphone array acoustic detection plate in embodiment 1, such as Figure 12 As shown; including ASE light source, coupler, optical fiber MEMS microphone array acoustic detection board, 32 circulators, 32 photodetectors and FPGA, it is characterized in that the optical fiber MEMS microphone array acoustic detection board includes 32 optical fiber MEMS microphone acoustic wave sensors , each optical fiber MEMS microphone acoustic wave sensor circulator is connected to a circulator through optical brazing, and the circulator is connected to a photodetector; the laser light emitted by the ASE light source is first divided into 4 equal-proportion laser beams through a 1*4 coupler, and each laser beam is then After passing through the 1*4 coupler, a total of 16 equal-proportion laser beams are separated at this time, and each laser beam passes through a 1*2 coupler, and a total o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com