Formaldehyde absorbing type parquet plywood base material and preparation method thereof

A technology for solid wood composite flooring and plywood, applied in the fields of aldehyde/ketone condensation polymer adhesives, wood treatment, wood heat treatment, etc., can solve the problems of high cost of dispersion components, high preparation cost, and no value for popularization and application , to achieve significant formaldehyde effect and stable formaldehyde effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] 1 Main research content

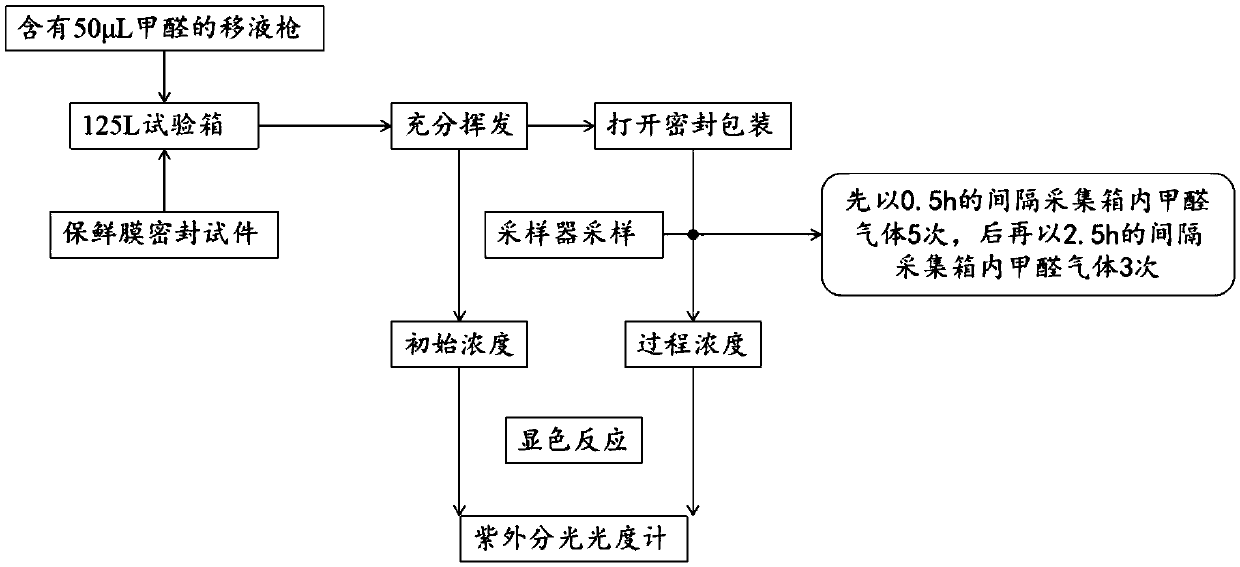

[0035] Research plan: choose poplar veneer as the test material, first conduct heat treatment with different processes, then heat-press the veneer after heat treatment into multi-layer plywood for floor substrates, test the adsorption effect of the substrate on formaldehyde, and evaluate Heat treatment process, and finally obtain the best veneer heat treatment process for adsorbing formaldehyde as the subsequent floor substrate heat treatment process.

[0036] When studying the chemisorption of floor substrates, firstly add different chemisorbents to the adhesive, such as amino chitosan, 2-imidazolidinone and the equal ratio mixture of the two. Modification is carried out to increase the adsorption performance of the glue to formaldehyde, and then a preliminary test is carried out. On the basis of determining the relationship between the amount of each chemical adsorbent and the adsorption effect, the ratio and formula of the chemical adsorbent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com