Anti-microbial fabric

An antibacterial fabric and fabric technology, applied in the field of fabrics, can solve the problems of inconspicuous antibacterial effect, low comfort, and poor antibacterial effect, and achieve good antibacterial effect, excellent antibacterial and sterilizing performance, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

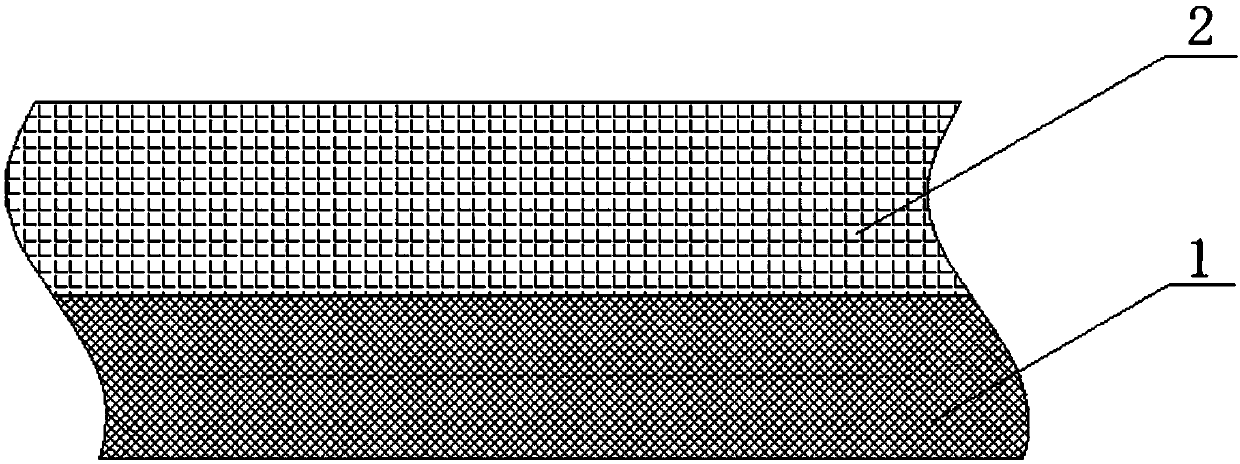

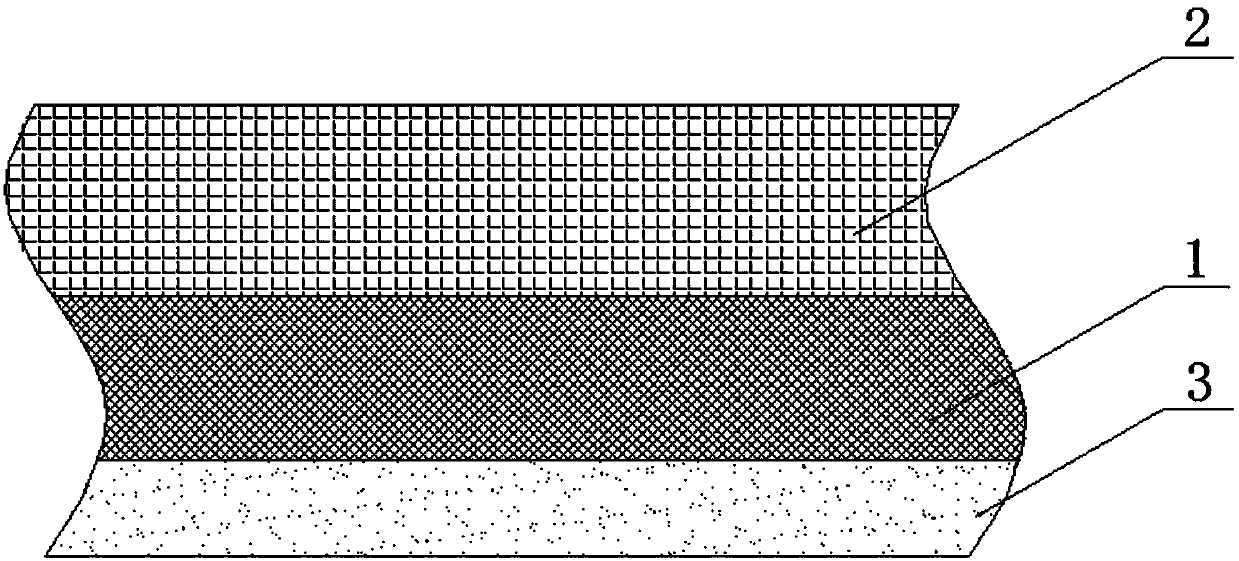

[0021] This embodiment provides a kind of antibacterial fabric, and this fabric is inner layer fabric 1 and outer layer fabric 2 successively from inside to outside, and inner layer fabric 1 and outer layer fabric 2 are laminated and connected by the mode of yarn sewing; The inner layer fabric 1 is a plain weave structure woven with bamboo charcoal fiber as the warp yarn and graphene inner warming fiber as the weft yarn, the warp density of the warp yarn is 196 / 10cm, and the weft density of the weft yarn is 158 / 10cm; the outer fabric 2 is composed of The concave-convex honeycomb mesh structure formed by the rib weave and the tuck weave, the rib weave is on the bottom, the tuck weave is on the top, the hanging arcs of the two adjacent tuck coils of the tuck weave overlap, and the rib weave and the tuck weave are formed by double twisting Yarn, and twisted yarn is made of kapok fiber yarn and hollow polyester yarn and twisted.

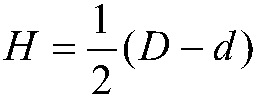

[0022] The thickness of the inner fabric 1 is 0.25...

Embodiment 2

[0024] The difference between embodiment 2 and embodiment 1 is that the thickness of the inner fabric 1 is 0.25mm, and the thickness of the outer fabric 2 is 0.30mm.

Embodiment 3

[0026] The difference between embodiment 3 and embodiment 1 is that the thickness of the inner fabric 1 is 0.30mm, and the thickness of the outer fabric 2 is 0.35mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com