High-efficiency steelmaking process for steelmaking furnace

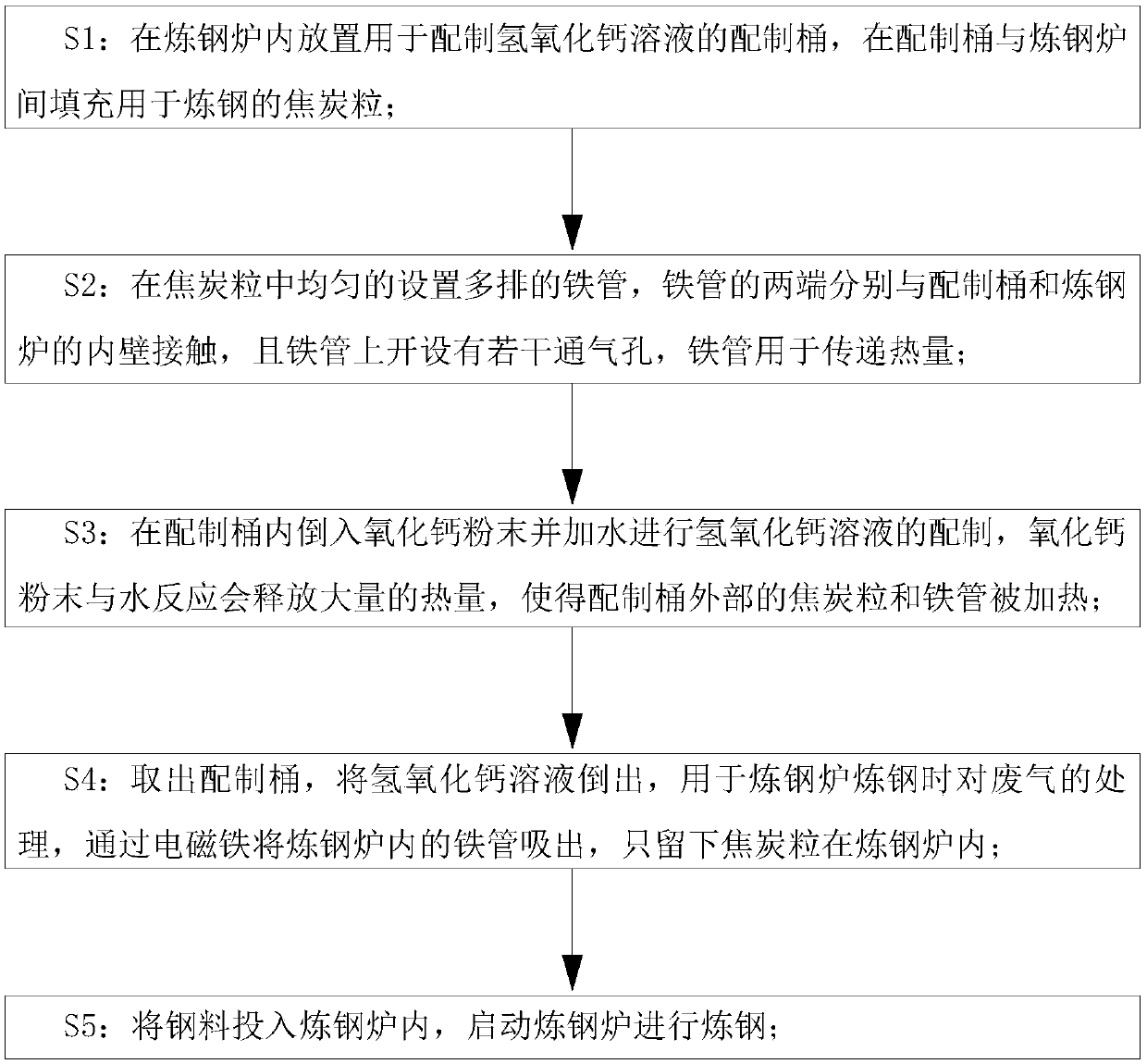

A technology of steelmaking furnace and process, which is applied in the field of high-efficiency steelmaking process of steelmaking furnace, which can solve the problems of excessive coke particles and affecting the combustion of coke particles, and achieve the effects of improving absorption effect, improving steelmaking efficiency, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

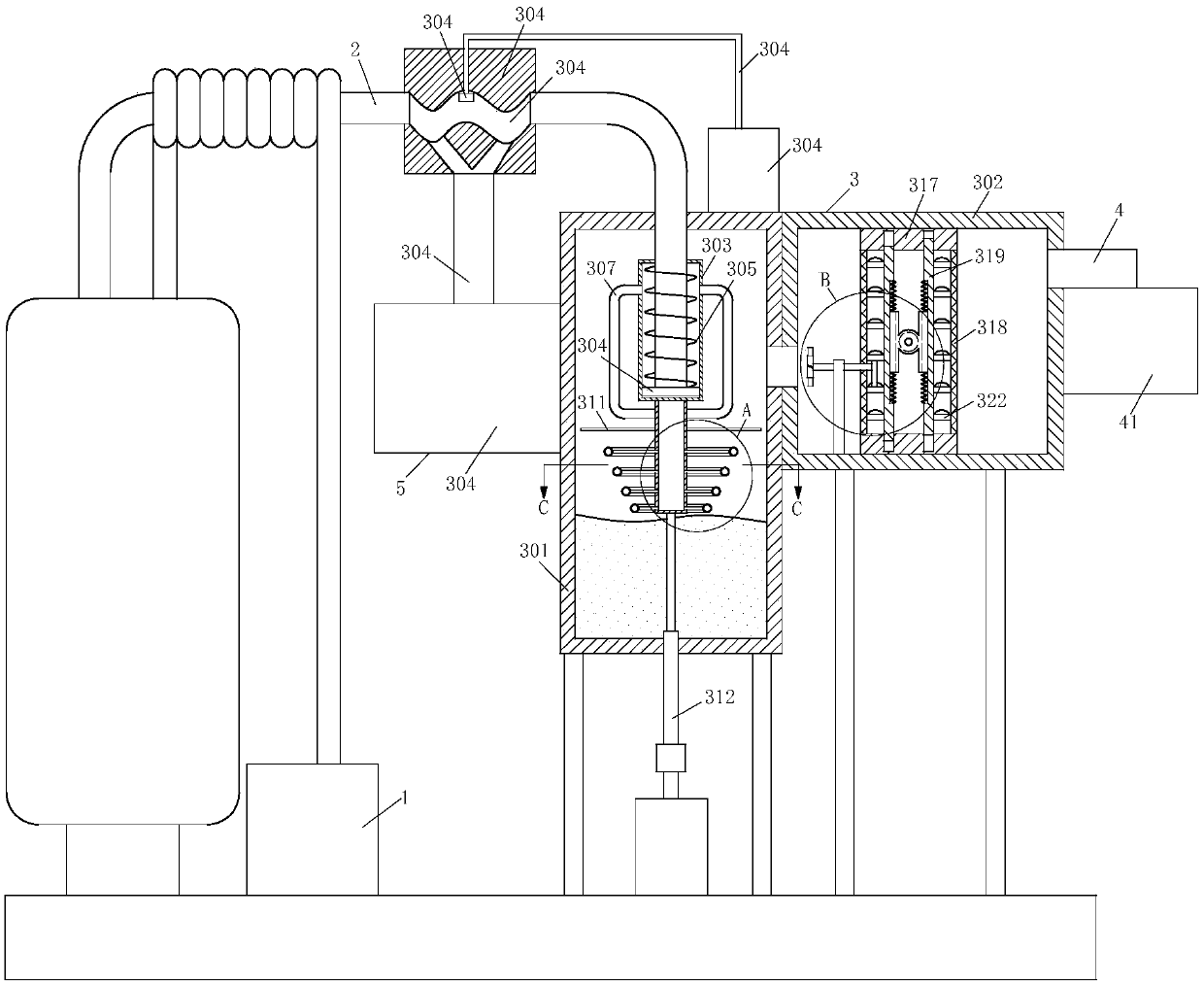

[0041]As an embodiment of the present invention, the dust processing unit 5 includes a dust processing box 51, a W-shaped channel 52, a sewage pipe 53, a dust collection box 54, a spray head 55, a spray pipe 56, a water tank 57 and a water pump; The dust collection box 54 is arranged on the side wall of the No. 1 treatment box 301, and one end of the blowdown pipe 53 is arranged through the dust treatment box 51, and the other end of the blowdown pipe 53 is arranged at the bottom of the dust treatment box 51; The dust treatment box 51 is arranged on the smoke exhaust pipe 2, and a W-shaped channel 52 is arranged in the dust treatment box 51. In the diversion hole of the sewage, the upper side of the W-shaped passage 52 is provided with a spray head 55; It is connected with a water pump; the water pump is arranged in the water tank 57, and the water pump is used to supply water to the nozzle; the water tank 57 is arranged on the top of the No. 1 treatment tank 301. Start the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com