Dyeing auxiliary for disperse dye and application thereof in assistance for disperse dye in process of dyeing wool

A technology of dyeing auxiliaries and disperse dyes, applied in dyeing method, textile and papermaking, etc., can solve the problems of high cost, complicated extraction and processing, and achieve the effect of low cost, strong solubilization and dyeing effect, and increase of cloud point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

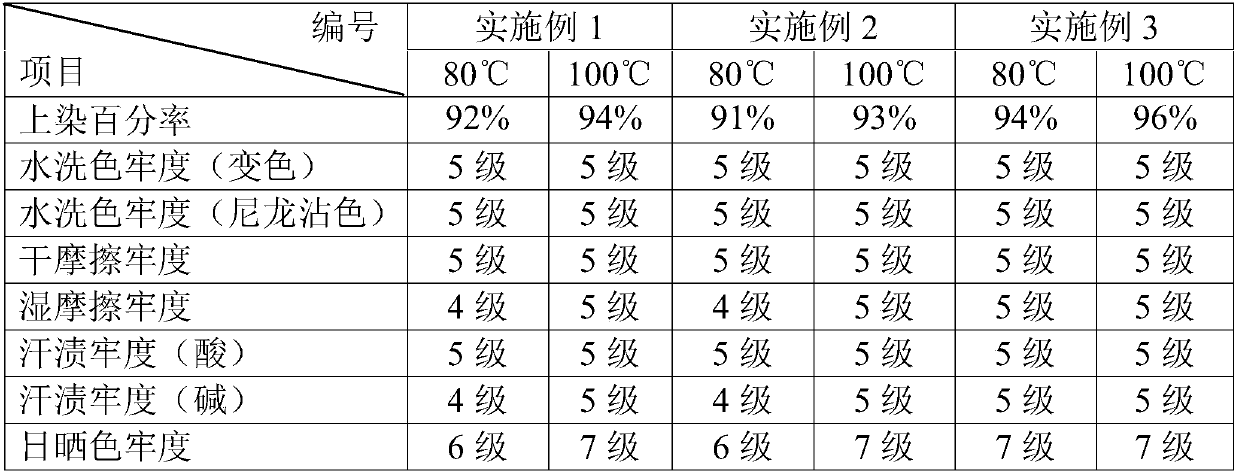

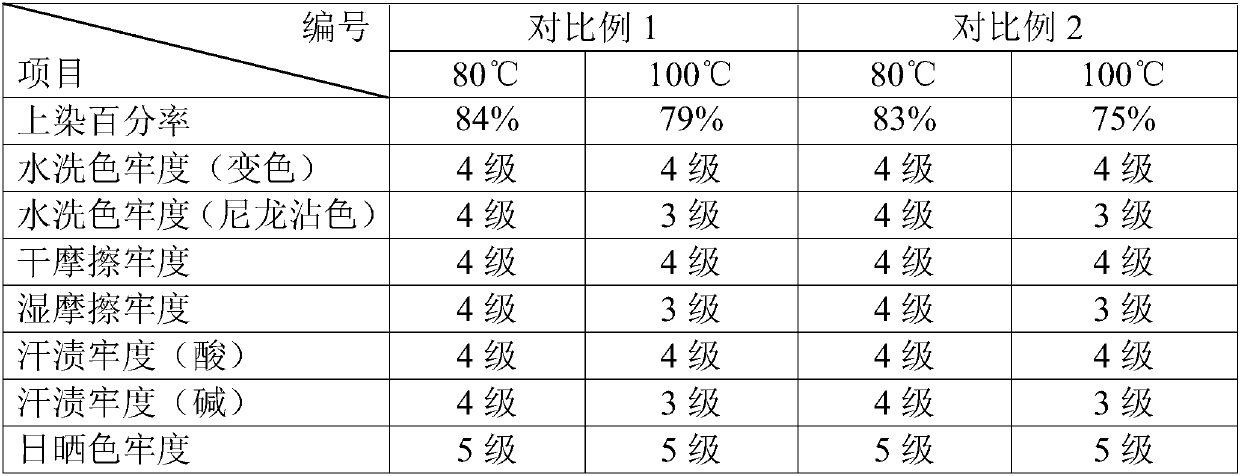

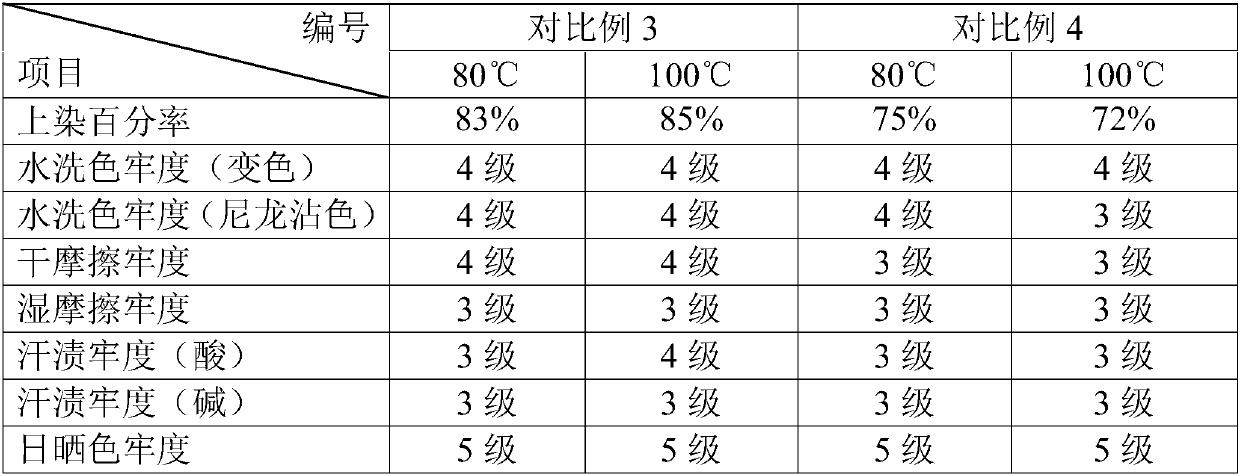

Embodiment 1

[0030] A disperse dye dyeing auxiliary in the present embodiment, in terms of mass fraction, the disperse dye dyeing auxiliary includes the following components: Pingpingjia O-15 40%, triethylene glycol monobutyl ether 5%, octadecyl beet Alkali 7%, Cetylpyridinium Bromide 2%, Polyamide Polyamine Epichlorohydrin 6%, Chitosan 4%, Poloxamer L65 3%;

[0031] Wherein, the average molecular weight of polyamide polyamine epichlorohydrin is 8000D;

[0032] The degree of deacetylation of chitosan is 75%, and the average molecular weight is 4000D.

[0033] Dyeing wool with the above-mentioned disperse dyeing auxiliaries and disperse red M-BL, including:

[0034] (1) Make wool into rolls, soak in 2g / L hexamethylenediamine liquid for 20min, wash with deionized water, and set aside;

[0035] (2) Mix disperse dye dyeing auxiliaries and disperse dyes at a mass ratio of 1:3, add water to 1000mL, make the concentration of disperse dye dyeing auxiliaries in the dye bath 4g / L, and use glacial ...

Embodiment 2

[0040] A disperse dye dyeing auxiliary in the present embodiment, in terms of mass fraction, the disperse dye dyeing auxiliary includes the following components: Pingpingjia O-30 60%, triethylene glycol monobutyl ether 8%, octadecyl beet Alkali 3%, cetylpyridinium bromide 4%, polyamide polyamine epichlorohydrin 8%, chitosan 2%, poloxamer F68 9%;

[0041] Wherein, the average molecular weight of polyamide polyamine epichlorohydrin is 12000D;

[0042]The degree of deacetylation of chitosan is 85%, and the average molecular weight is 5000D.

[0043] Dyeing wool with the above-mentioned disperse dyeing auxiliaries and disperse red M-BL, including:

[0044] (1) Make wool into rolls, soak in 2g / L hexamethylenediamine liquid for 20min, wash with deionized water, and set aside;

[0045] (2) Mix disperse dye dyeing auxiliaries and disperse dyes at a mass ratio of 1:3, add water to 1000mL, make the concentration of disperse dye dyeing auxiliaries in the dye bath 6g / L, and use glacial ...

Embodiment 3

[0050] A disperse dye dyeing auxiliary in the present embodiment, in terms of mass fraction, the disperse dye dyeing auxiliary includes the following components: Pingpingjia O-20 50%, triethylene glycol monobutyl ether 6%, octadecyl beet Alkali 5%, cetylpyridinium bromide 3%, polyamide polyamine epichlorohydrin 7%, chitosan 3%, poloxamer F68 6%;

[0051] Wherein, the average molecular weight of polyamide polyamine epichlorohydrin is 10000D;

[0052] The degree of deacetylation of chitosan is 80%, and the average molecular weight is 4000D.

[0053] Dyeing wool with the above-mentioned disperse dyeing auxiliaries and disperse red M-BL, including:

[0054] (1) Make wool into rolls, soak in 2g / L hexamethylenediamine liquid for 20min, wash with deionized water, and set aside;

[0055] (2) Mix disperse dye dyeing auxiliaries and disperse dyes at a mass ratio of 1:3, add water to 1000mL, make the concentration of disperse dye dyeing auxiliaries in the dye bath 5g / L, and use glacial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com