Noise-reducing sound-absorbing inner wall insulation board

A technology for thermal insulation panels and interior walls, applied in thermal insulation, sound insulation, building components, etc., can solve problems such as unsatisfactory noise reduction and noise reduction, noise affecting neighbors, single function, etc., to eliminate brain fatigue, promote sleep, and reduce noise. The effect of sound-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

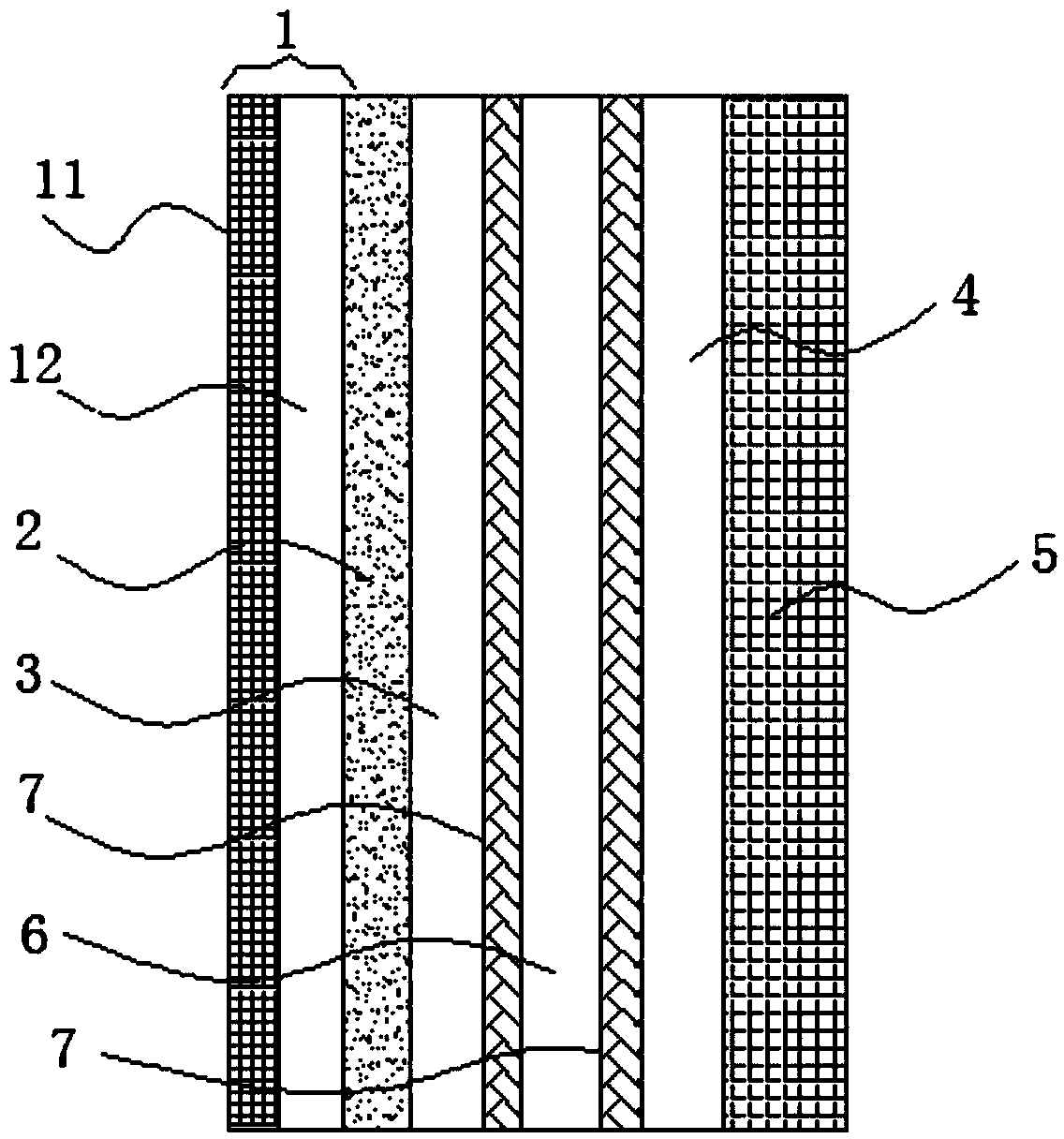

[0027] Embodiment: a kind of noise-reducing and sound-absorbing interior wall insulation board, such as figure 1 As shown, it includes a substrate 1, an insulating layer 2, a sound-absorbing layer 3, a protective layer, a sterilization layer 4 and a decorative layer 5;

[0028] The insulation layer is located on the surface of the base body, the sound-absorbing layer is located on the surface of the insulation layer, the protective layer is located on the surface of the sound-absorbing layer, the sterilization layer is located on the surface of the protective layer, the The decorative layer is located on the surface of the sterilization layer;

[0029] The sound-absorbing layer is a compressed sound-absorbing cotton layer, and the thickness of the sound-absorbing cotton layer is 0.5-1.1mm;

[0030] The protective layer includes an alkali-resistant fiberglass mesh 6, which is connected to the sound-absorbing layer through an anti-crack glue layer 7, and the other side of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com