High-temperature air source heat pump suitable for ultra-low-temperature environment

A high-temperature air and source heat pump technology, which is applied to fluid heaters, lighting and heating equipment, and compressors with cascade work, etc., can solve the problem of insufficient heat supply, unstable operation of air source heat pumps, and changes in thermal properties, etc. problems, to achieve the effect of improving heating capacity and energy efficiency, solving insufficient heat supply, and reducing exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0023] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein. The size and thickness of each component shown in the drawings are arbitrarily shown, and the present invention does not limit the size and thickness of each component.

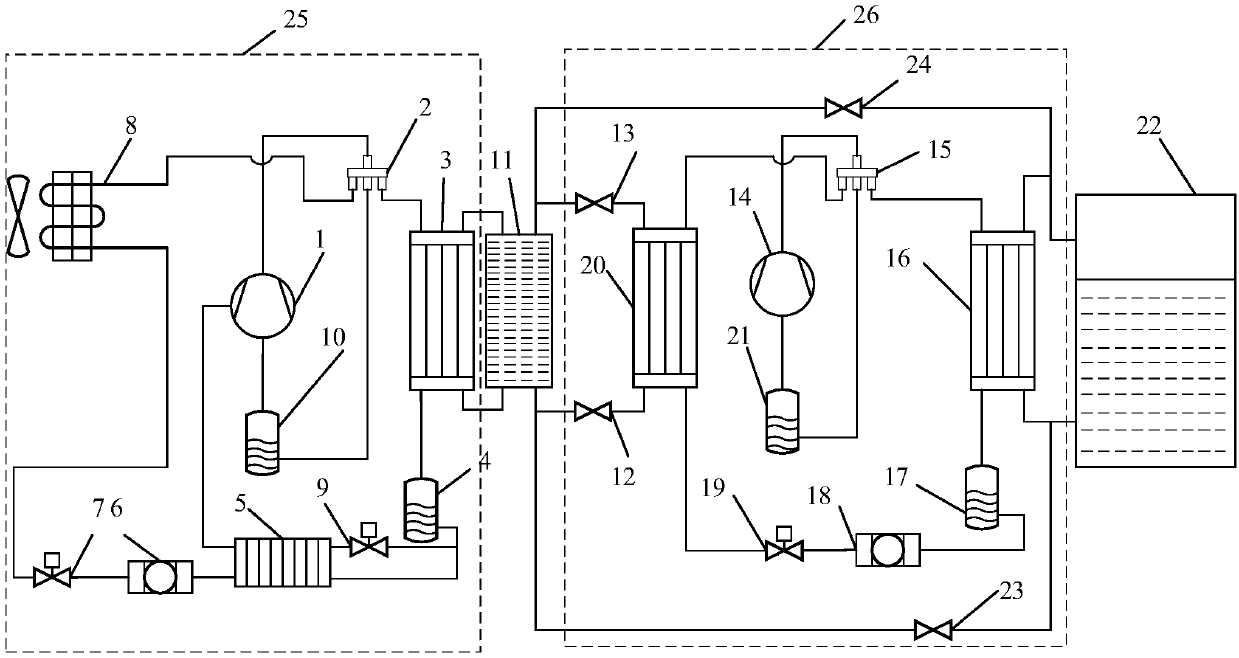

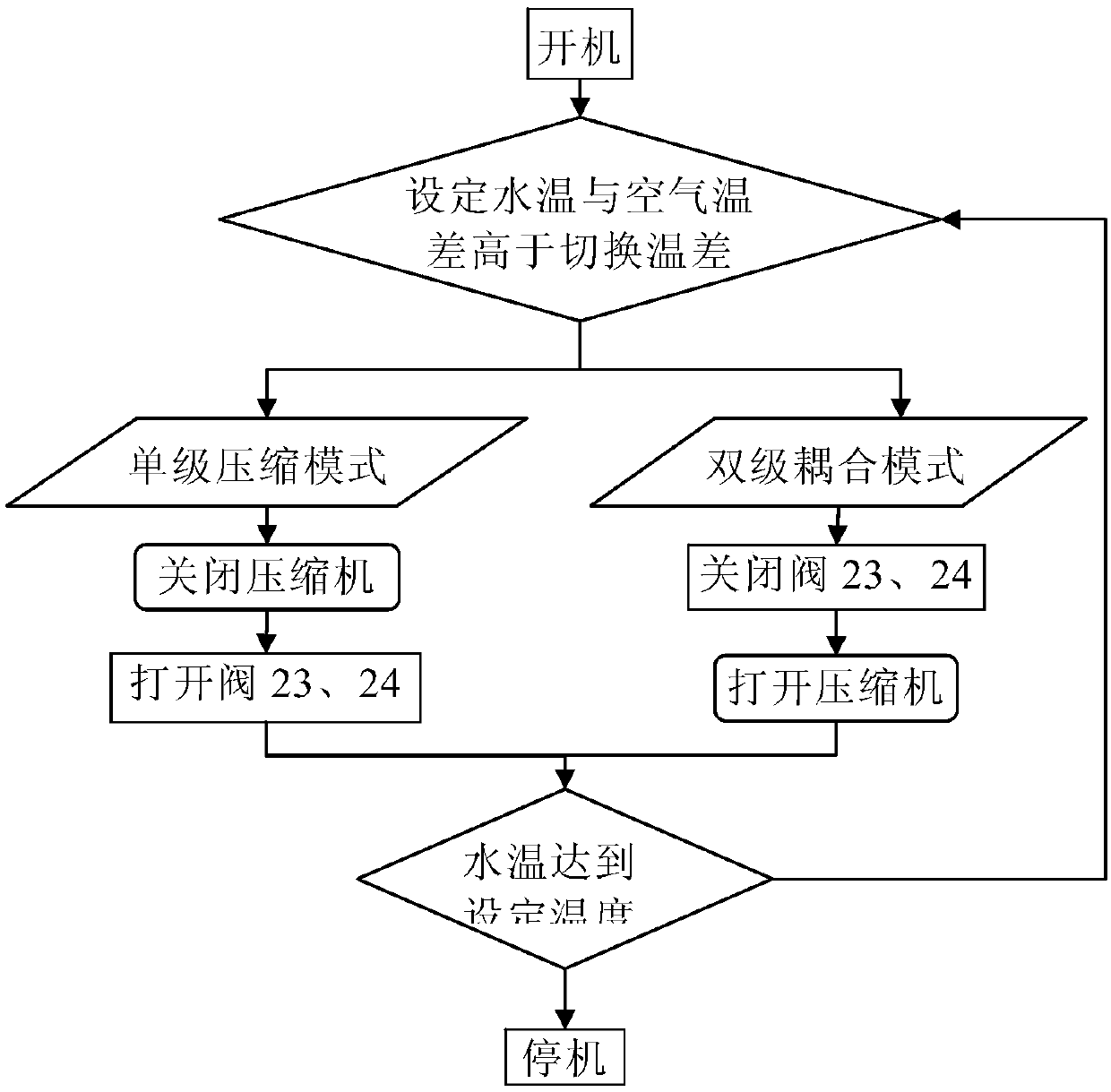

[0024] Such as figure 1 as shown, figure 1It is a structural schematic diagram of a preferred embodiment of the present invention. Wherein, the air source heat pump is composed of a first air source system 25, a second air source system 26, an intermediate heat exchanger 11 and a water tank 22, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com