Method of preparing cone-shaped optical fiber SERS probe by laser induced one-step lifting method

A tapered optical fiber, laser-induced technology, applied in Raman scattering, material excitation analysis, material analysis through optical means, etc., can solve the problems that are not suitable for the preparation of tapered optical fiber SERS probes, so as to ensure the repeatability of the preparation , high sensitivity, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

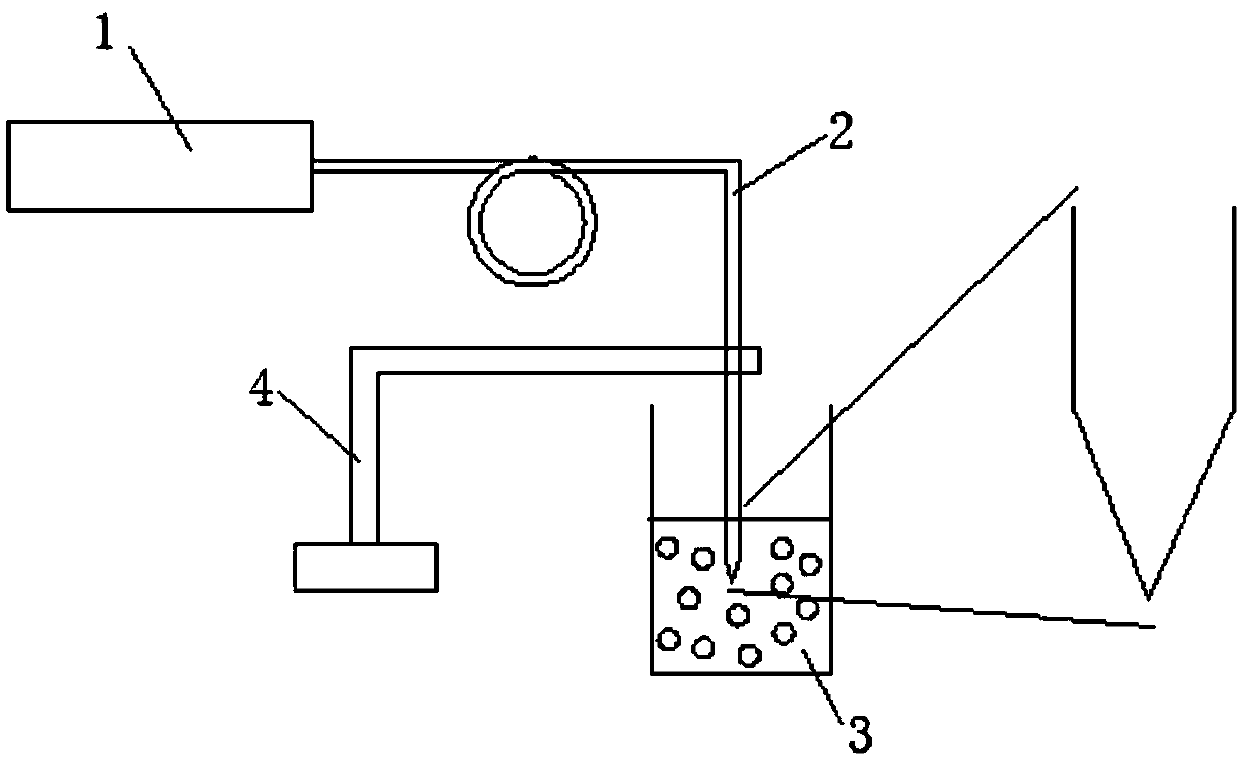

[0021] Such as figure 1 As shown, a method for preparing a tapered optical fiber SERS probe by a laser-induced one-step pulling method includes a laser 1, a tapered optical fiber 2, a noble metal nanoparticle sol 3 and a one-dimensional precision displacement platform 4. The tapered optical fiber One end of 2 is a flat end, and the other end is a tapered end. The flat end of the tapered optical fiber 2 is welded to the output pigtail of the laser 1, and the tapered end is inserted into the pre-prepared noble metal nanoparticle sol 3. The middle part of the tapered optical fiber Fixed on the moving end of the one-dimensional precision displacement platform 4; turn on the laser 1, and under the irradiation of the induced laser, use the one-dimensional precision displacement platform 4 to slowly pull the tapered end of the optical fiber from the noble metal nanoparticle sol 3 to the tapered end. The cone tip is located near the upper surface interface of the noble metal nanoparti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com