Rice storage method

A rice and storage silo technology, which is applied to the preservation of edible seeds, the preservation of seeds through pressure changes, and the preservation of seeds through radiation/electrical treatment, etc. problems, to achieve the effects of inhibiting the formation of coatings, high energy utilization, and reducing running water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

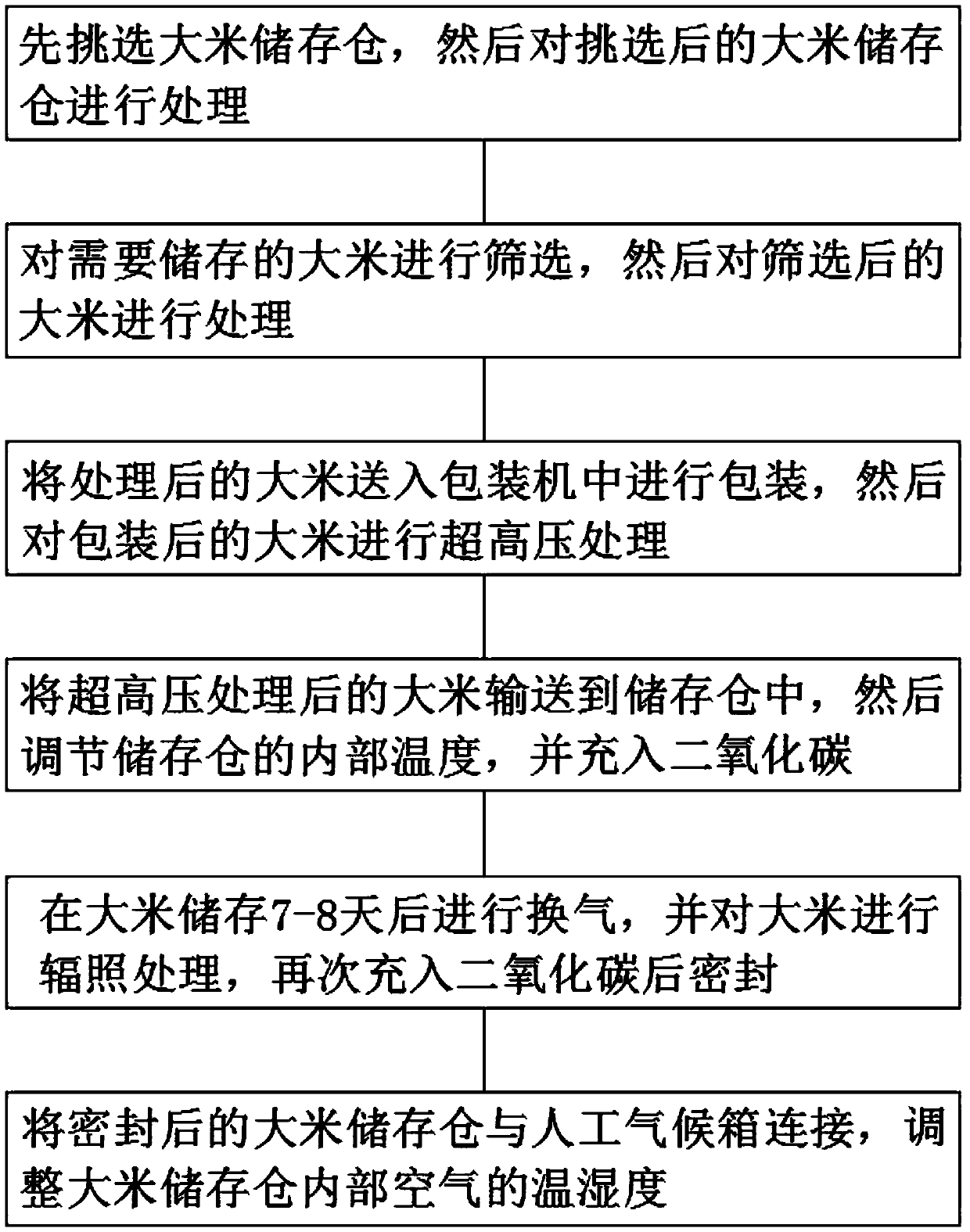

Method used

Image

Examples

Embodiment 1

[0032] (1), first select the rice storage bin, and then process the rice storage bin. The processing of the rice storage bin includes cleaning and disinfection. The processing steps of the rice storage bin are as follows:

[0033] ①. Use a high-pressure spray gun to rinse the surface of the rice storage bin, then open the door of the rice storage bin and let it stand for 2 days;

[0034] ②, and then spray the disinfectant solution into the rice storage bin after washing, and the concentration ratio of the disinfectant solution and water is 1:9;

[0035] ③. Fumigate the sterilized rice storage warehouse, and use aluminum phosphide as the fumigant; ventilate after 6-8 days of fumigation, and ventilate for 3 days;

[0036] (2) Send the rice that needs to be stored into the vibrating screening machine for screening, and then process the screened rice. The processing of rice includes controlling the water content of rice and sterilization. Rice microwave sterilization machine and u...

Embodiment 2

[0045] (1), first select the rice storage bin, and then process the rice storage bin. The processing of the rice storage bin includes cleaning and disinfection. The processing steps of the rice storage bin are as follows:

[0046] ①. Use a high-pressure spray gun to rinse the surface of the rice storage bin, then open the door of the rice storage bin and let it stand for 2 days;

[0047] ②, and then spray the disinfectant solution into the rice storage bin after washing, and the concentration ratio of the disinfectant solution and water is 1:9;

[0048]③. Fumigate the sterilized rice storage warehouse, and use aluminum phosphide as the fumigant; ventilate after 6-8 days of fumigation, and ventilate for 3 days;

[0049] (2) Send the rice that needs to be stored into the vibrating screening machine for screening, and then process the screened rice. The processing of rice includes controlling the water content of rice and sterilization. Rice microwave sterilization machine and ul...

Embodiment 3

[0058] (1), first select the rice storage bin, and then process the rice storage bin. The processing of the rice storage bin includes cleaning and disinfection. The processing steps of the rice storage bin are as follows:

[0059] ①. Use a high-pressure spray gun to rinse the surface of the rice storage bin, then open the door of the rice storage bin and let it stand for 2 days;

[0060] ②, and then spray the disinfectant solution into the rice storage bin after washing, and the concentration ratio of the disinfectant solution and water is 1:9;

[0061] ③. Fumigate the sterilized rice storage warehouse, and use aluminum phosphide as the fumigant; ventilate after 6-8 days of fumigation, and ventilate for 3 days;

[0062] (2) Send the rice that needs to be stored into the vibrating screening machine for screening, and then process the screened rice. The processing of rice includes controlling the water content of rice and sterilization. Rice microwave sterilization machine and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com