Mine protecting suit fabric with synergetic functions of bacteria resisting, static resisting, toxic gas monitoring and dust poison filtering and preparation method thereof

A poisonous gas, anti-static technology, applied in protective clothing, clothing, clothing, etc., can solve problems such as unsuitable for mine protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

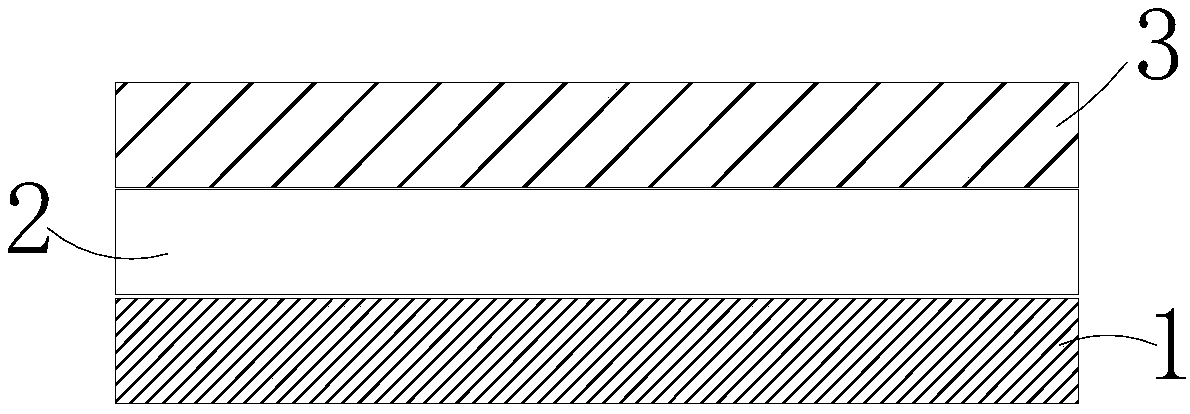

[0081] This embodiment discloses figure 1 The preparation process of the main protective fabric shown is as follows:

[0082] Such as figure 1 As shown, the main protective fabric includes an antistatic breathable base fabric layer 1, an MXene-based filter layer 2, and an antistatic hydrophobic layer 3 from the inside to the outside, and the preparation process of each layer is as follows:

[0083] Ti 3 C 2 T x Material preparation: the precursor material Ti was etched with a mixed solution of LiF and HCl (32wt%) with a mass ratio of 3:7 3 AlC 2 Medium element Al, the temperature is 30°C, and the reaction time is 60h. After the reaction is fully completed, centrifuge at 3500 rpm for 4 times until neutral, and the two-dimensional layered Ti can be obtained. 3 C 2 T x Material.

[0084] Prepare antistatic breathable base cloth layer: get each mass ratio and be respectively bamboo fiber: flax: ice silk=4:1:3 component weaves blended yarn, gets part blended yarn and above...

Embodiment 2

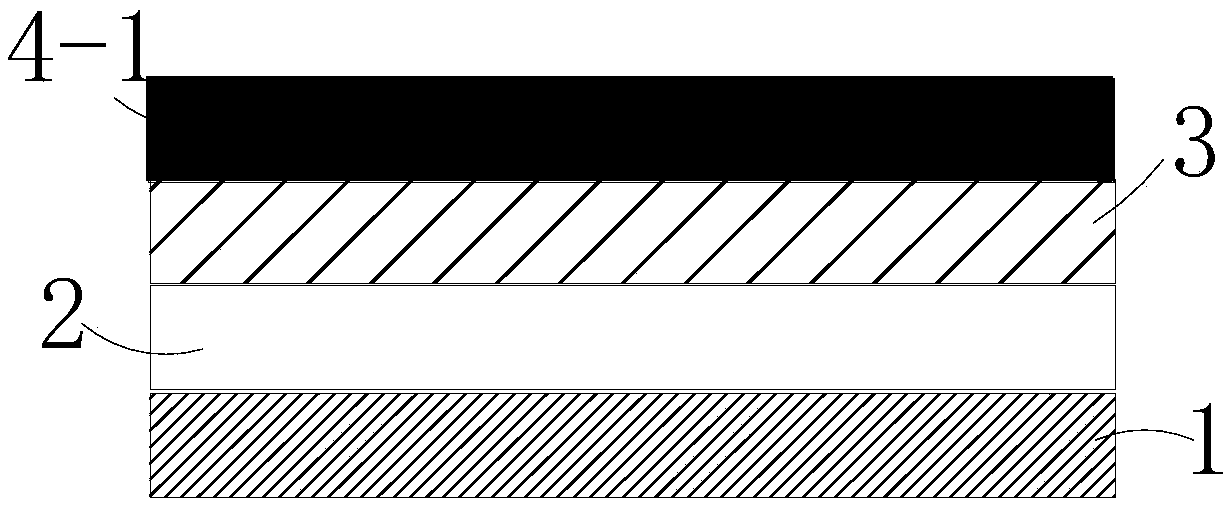

[0089] This embodiment discloses figure 2 The preparation process of the protective fabric with good bactericidal effect shown is as follows:

[0090] Such as figure 2 As shown, the main protective fabric consists of an antistatic breathable base fabric layer 1, an MXene-based filter layer 2, an antistatic hydrophobic layer 3, and a bactericidal layer 4-1 from the inside to the outside, and the preparation process of each layer is as follows:

[0091] Take Ti at a concentration of 0.5 mg / mL 3 C 2 T x The solution is mixed with the silver nanowire bactericide of 2 mg / mL to form a uniformly dispersed mixed solution, and the mixed solution is sprayed on the surface of the main body protective fabric prepared in Example 1, and after drying, a bactericidal layer with a thickness of 1 mm is obtained and has a good bactericidal effect. Protective fabric.

[0092] Wherein, the mixed liquid can also be 10 mg / mL hexagonal boron nitride and 10 mg / mL silver nanowire fungicide.

[...

Embodiment 3

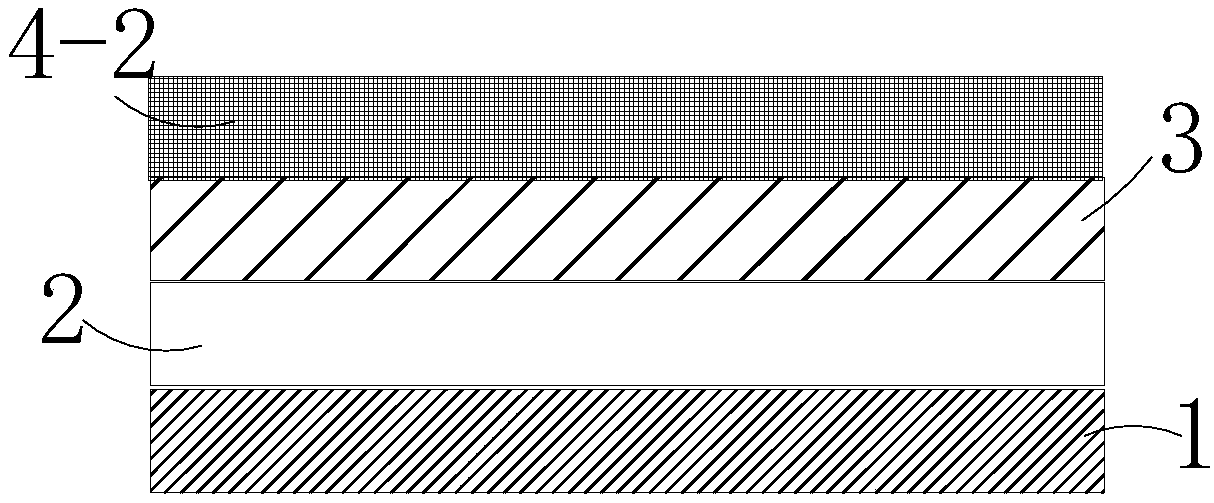

[0096] This embodiment discloses image 3 The preparation process of the protective fabric with gas-sensitive discoloration function shown is as follows:

[0097] Such as image 3 As shown, the main protective fabric consists of an antistatic breathable base fabric layer 1, an MXene-based filter layer 2, an antistatic hydrophobic layer 3, and an aerochromic layer 4-2 from the inside to the outside, and the preparation process of each layer is as follows:

[0098] One side of the base fabric was coated with a mixed solution consisting of 0.1 mg / mL h-BN, polydimethylsiloxane (PDMS), 2 mg / mL Prussian blue, and 0.1 mg / mL silicone hydrophobic agent, and after drying, a gas The aerochromic layer is composed of the aerochromic layer and the main protective fabric prepared in Example 1 to obtain a protective fabric with gas-sensitive discoloration function.

[0099] Among them, the mixed liquid is 5 mg / mL h-BN, polydimethylsiloxane (PDMS), 15 mg / mL trimanganese tetraoxide, and 0.1 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com