Elastic double-layer tubular tissue engineering scaffold with multistage porous structure and preparation method thereof

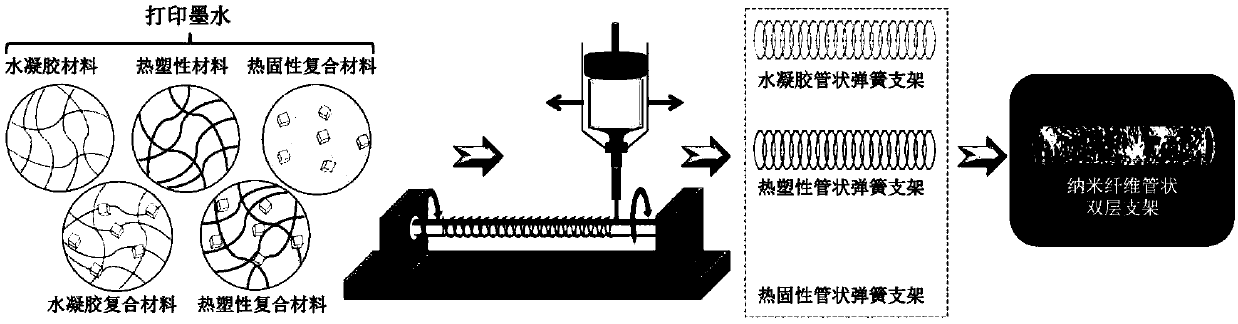

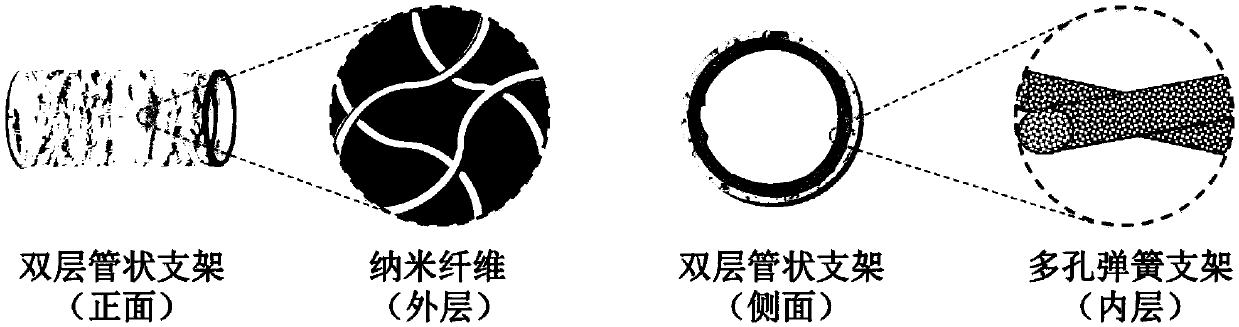

A technology of tissue engineering scaffolds and pore structures, which can be applied in tissue regeneration, pharmaceutical formulations, additive processing, etc. It can solve the problems that FDM is difficult to directly print porous tubular scaffolds, and achieve good application prospects and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

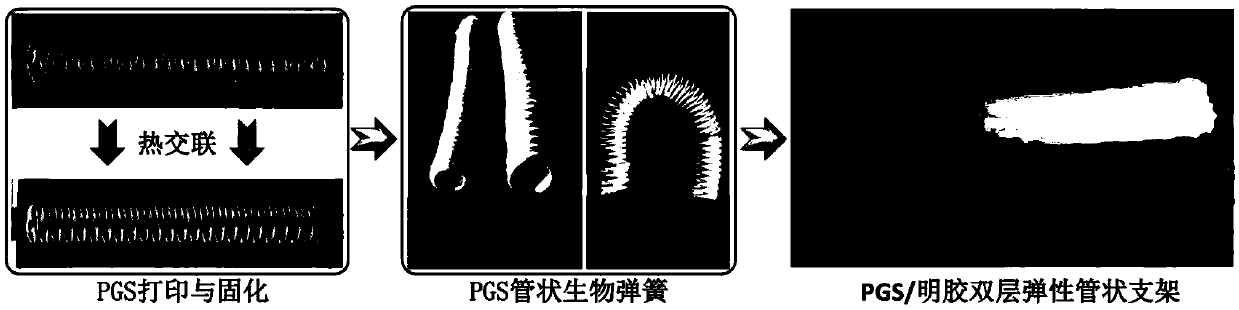

Embodiment 1

[0041] 1. Preparation process

[0042] 1.1 Printing material preparation

[0043] The mixing parameters of PGS prepolymer (Pre-PGS) and salt particles directly determine the extrudability, initial shape stability, high-temperature curing shape retention and pore structure of the scaffold during printing, which indirectly determine the performance of the scaffold. Including mechanical properties and biodegradability. Dissolve 10g Pre-PGS in 10ml acetone to form a viscous solution; put NaCl in a pulverizer and grind it, and pass through a sieve to get salt particles with a diameter less than 38μm; add salt particles and Pre-PGS at a mass ratio of 1:2 Mix 20g evenly, let the acetone volatilize slightly, then put it in a vacuum oven at 30°C for 24 hours to remove the acetone;

[0044] 1.2 4-axis 3D printing of Pre-PGS fiber interwoven tubular structure

[0045] A mixture of Pre-PGS and NaCl particles was loaded into the cartridge. Set extrusion chamber temperature and nozzle t...

Embodiment 2

[0063] 1. Preparation process

[0064] 1.1 4-axis printing of tubular structures interwoven with PCL fibers

[0065] The thermoplastic PCL polymer pellets were charged into the barrel. Set the extrusion chamber temperature and nozzle temperature to 180°C. Choose a 23G needle and print a length of 6 cm. Set the XY axis movement speed V m 1mm / s, T-axis extrusion speed V e is 0.0005mm / s. Choose a different diameter D r The PTFE round rod (2mm, 4mm, 10mm) is installed on the rotatable receiving platform as the receiver. Adjust the distance between the nozzle and the receiver to be 3mm, and the rotation speed to be 20r / min. The composite material is extruded in a line shape and deposited on the surface of the round rod. With the movement of the nozzle, a spiral structure is printed on the surface of the round rod. After reciprocating printing for 5 times (or multiple times), a fiber-interwoven tubular structure with different diameters is formed. Figure 8 .

[0066] 1.2 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com