4-axis 3D-printing tubular medical stent and preparation method thereof

A technology of 3D printing and printing tubes, applied in the field of medical stents, can solve problems such as difficulty in preparing thin-walled porous tubular stents, and achieve good application prospects, simple methods, and the effect of preventing thrombosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

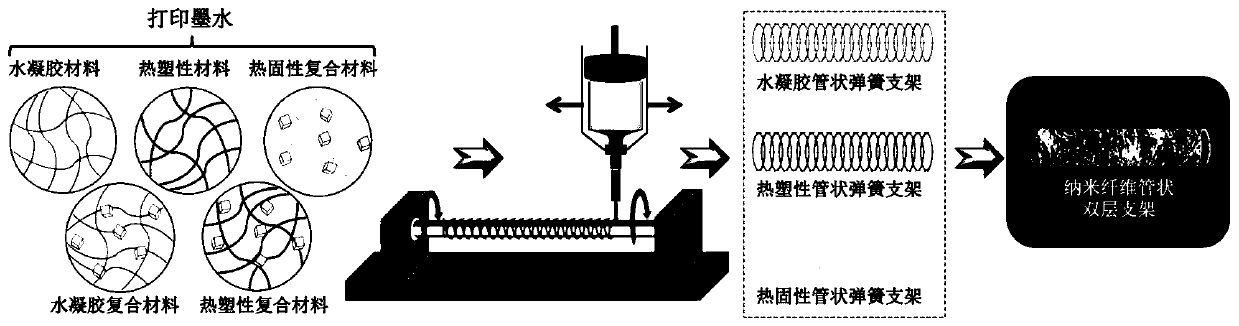

Method used

Image

Examples

preparation example Construction

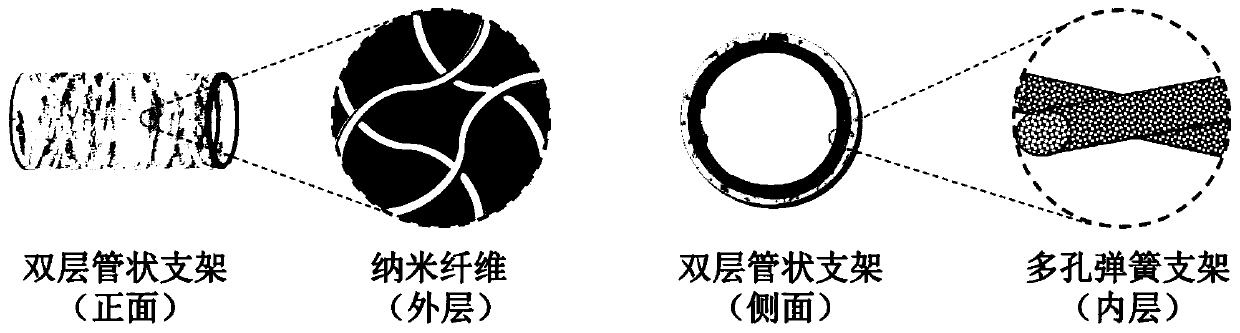

[0057] 1.4 Preparation of double-layer tubular scaffold

[0058] A gelatin / hexafluoroisopropanol solution (12%, w / v) was prepared as an electrospinning solution, drawn into a 5ml syringe, and installed on a microsyringe pump. The above-mentioned tubular PGS biological spring is threaded into a metal receiver of corresponding specifications, and installed on a rotating receiving device with adjustable speed. The injection rate is 1ml / h, and the uniform and continuous nanofibers are formed under the action of 12KV high-voltage static electricity. The rotating receiving device is placed 15cm below the electrospinning needle, and it is rotated and received at a rate of 30r / min. The nanofibers are deposited by electrostatic adsorption. And wrapped on the surface of the PGS tubular biospring, after receiving for 2 hours, a densely coated nanofiber layer is formed on the outer layer. After it was removed from the metal rod, it was placed in 5% glutaraldehyde / ethanol & aqueous soluti...

Embodiment 2

[0078] 1. Preparation process

[0079] 1.1 3D printing polycaprolactone (PCL) tubular scaffolds with different macroscopic shapes

[0080] The PCL with a molecular weight of 80,000 was preheated at 200°C for 30 minutes in the printer to make it fully melted, extruded into uniform fibers through a 22G needle at 180°C, and deposited on a rotating receiving device. Tubular stents with different morphological structures can be obtained by controlling the shape of the receiving device. The inner diameter of the printer heating cabin is (D e )18mm.

[0081] 1.2 3D printing of PCL tubular scaffolds with different microstructures

[0082] Under the above printing conditions, using the diameter (D r ) 5.14cm cylindrical receiving device, keep the extrusion rate (V e ) is 0.03mm / min, and the nozzle moving speed is (V m )1mm / s, print 5 times back and forth. Control the rotational speed n of the receiving device to be 10, 20, 30, 40 min / r, respectively.

[0083] 1.3 3D printed vas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com