Ti-containing austenitic stainless steel submerged arc sintering flux and preparation method

A technology of austenitic stainless steel and sintered flux, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of ugly welding bead surface, uneven weld edge, poor slag removal performance, etc., and achieve slag removal performance. Good, the surface of the weld bead is beautiful, and the effect of improving the slag removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] by CaF 2 5kg, SiO 2 25kg; Al 2 o 3 28kg; CaO 12kg; ZrO 2 3kg; 3 AlF 6 13kg; NaF8kg, Na 2 O 0.5kg; K 2 O 1.0kg; Fe 2 o 3 0.5kg; S 0.06kg; P 0.04kg, put all kinds of powder in the mixer, stir and mix evenly, add 20kg of potassium silicate to mix and granulate, then bake at 180°C, sinter at 760°C, and sieve. That is, a flux product is obtained.

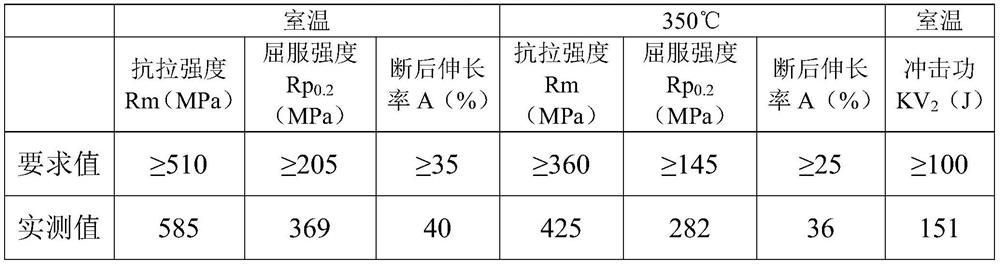

[0032] Table 1 shows the mechanical properties data of deposited metal (after 1050±10℃×3h+water cooling).

[0033] Table 1 Deposited metal mechanical properties data

[0034]

Embodiment 2

[0036] by CaF 2 8kg, SiO 2 22kg; Al 2 o 3 29kg; CaO 12kg; ZrO 2 3kg; 3 AlF 613kg; NaF10kg, NaF 2 O 0.5kg; K 2 O 1.0kg; Fe 2 o 3 0.5kg; S 0.06kg; P 0.04kg, put the powder in the mixer, stir and mix evenly, add 22kg of sodium water glass to mix and granulate, then bake at 180°C, sinter at 760°C, and sieve. That is, a flux product is obtained.

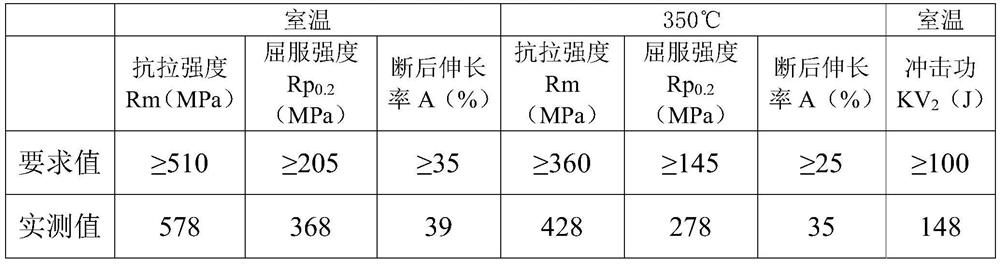

[0037] Table 2 shows the mechanical properties data of deposited metal (after 1050±10℃×3h+water cooling).

[0038] Table 2 Deposited metal mechanical properties data

[0039]

Embodiment 3

[0041] by CaF 2 6kg, SiO 2 25kg; Al 2 o 3 28kg; CaO 12kg; ZrO 2 4kg; 3 AlF 6 14kg; NaF8kg, Na 2 O 0.5kg; K 2 O 1.0kg; Fe 2 o 3 0.5kg; S 0.06kg; P 0.04kg ratio Put the powder in the mixer, stir and mix evenly, add 18kg of potassium sodium water glass to mix and granulate, then bake at 180°C, sinter at 760°C, and sieve , that is, the flux product is obtained.

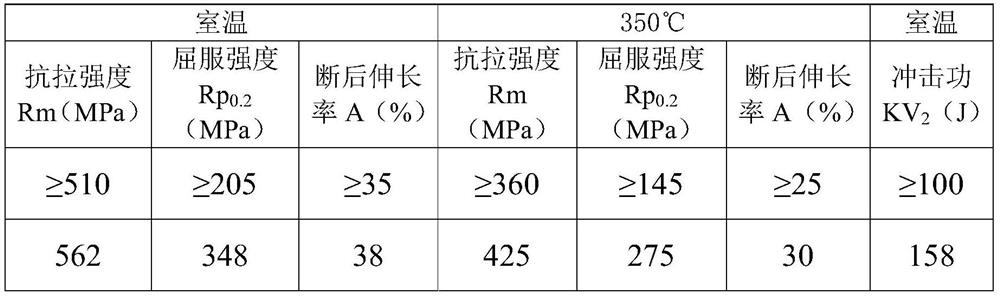

[0042] Table 3 shows the mechanical properties data of deposited metal.

[0043] Table 3 Deposited metal mechanical properties data

[0044]

[0045] The flux products of Examples 1-3 are matched with corresponding welding wires, and the welding process performance is good, the slag is easy to remove, and the mechanical properties meet the technical requirements.

[0046] In Examples 1-3, the welding base material is Ti-containing austenitic stainless steel. In the present invention, unless otherwise specified, % refers to mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com