Phenol pollutant removal system and method based on moving bed biofilm reactor

A moving bed biofilm and reactor technology, applied in the field of water treatment, can solve problems such as continuous consumption, and achieve the effect of ensuring sustainability and realizing in-situ recycling and regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

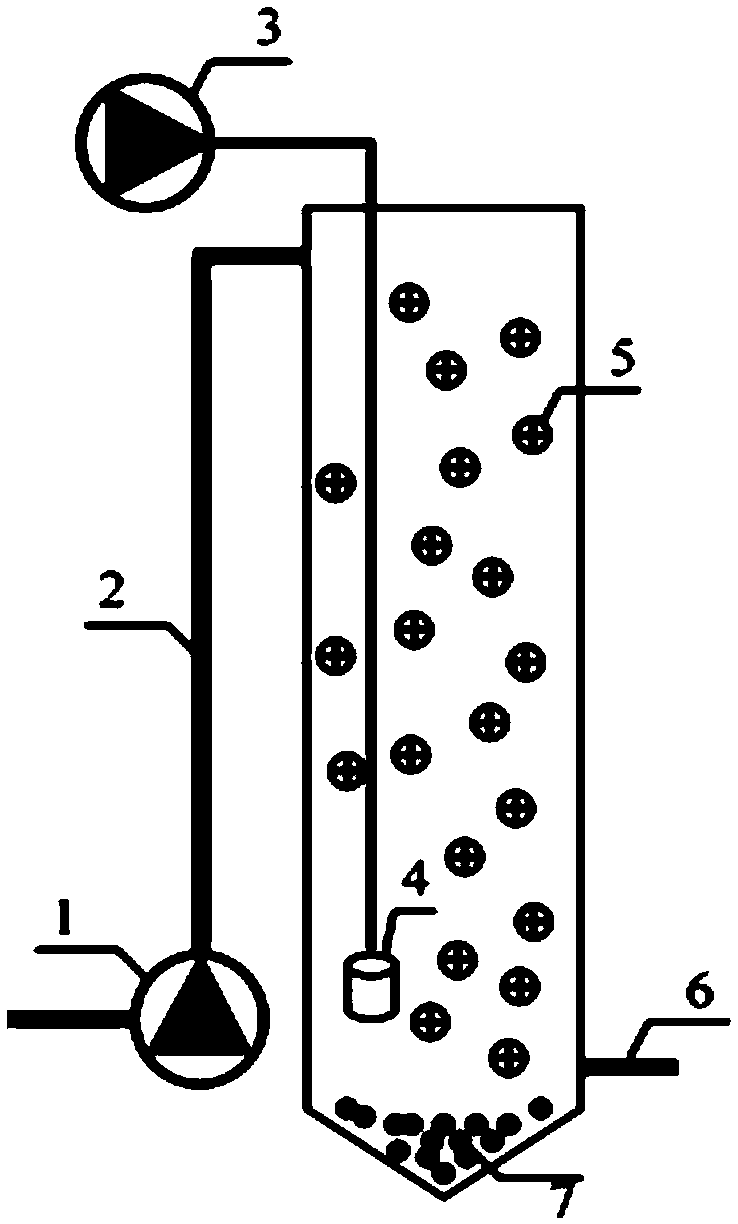

[0045] This embodiment discloses a phenolic pollutant removal system based on a moving bed biofilm reactor, and its structure is as attached figure 1 As shown, it includes a reactor, a water inlet pump 1, an aeration pump 3, and an aeration head 4. The water inlet at the upper end of the reactor is in communication with the water inlet pump 1 through a water inlet pipe 2, and a biofilm filler 5 is provided in the reactor. , The bottom of the reactor is provided with a biological manganese oxide 7, and an aeration head is provided in the reactor above the biological manganese oxide, and the aeration head is in communication with an aeration pump set above the reactor through a pipeline A water outlet is provided on the side wall of the reactor above the biological manganese oxide, and the water outlet is in communication with the water outlet pipe 6. The moving bed biofilm reactor can realize in-situ generation and recycling of biomanganese oxide.

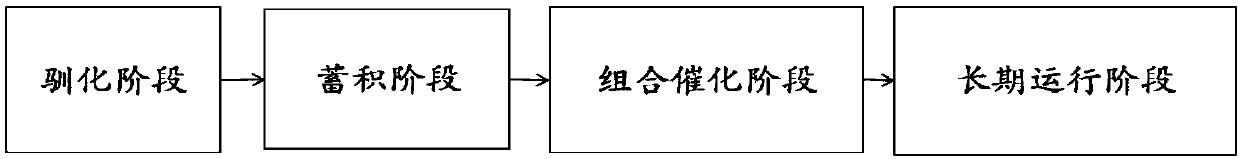

[0046] The steps of the phenol...

Embodiment 2

[0071] This example discloses a phenolic pollutant removal system based on a moving bed biofilm reactor. Based on Example 1, we set the hydraulic residence time of the entire reactor to 24h in Example 2.

[0072] 1. Wastewater treatment parameters

[0073] The wastewater is treated with simulated wastewater prepared in the laboratory. The main water quality indicators: COD 1500mg / L, NH 4 + -N90mg / L, phenol concentration 600mg / L, p-chlorophenol concentration 30mg / L.

[0074] 2. Wastewater treatment stage

[0075] The reactor was operated in sequential batch mode, and the hydraulic retention time was set to 24h. The other conditions are consistent with Example 1.

[0076] 3. The effect of reactor operation

[0077] After testing, the change of hydraulic retention time significantly affected the phenol removal performance of the combined system. Monitor the concentration of phenol in the effluent of the reactor (12h, 24h) and the concentration of p-chlorophenol in the effluent (6h, 12h) b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com