Asymmetric heat conducting flow passage based tar cooling and collecting device

A technology of collecting device and warm runner, which is applied in the petroleum industry, gas purification of condensed non-gaseous materials, purification/transformation of combustible gas, etc. It can solve the problem of gas short-circuit heat transfer and tar collection effect, large heat exchanger size and complex pipeline and other issues, to achieve the effect of increasing the contact probability and residence time, large contact area, and enhancing the exchange of cold energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The tar cooling and collecting device based on the asymmetric temperature-conducting flow channel involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0051]

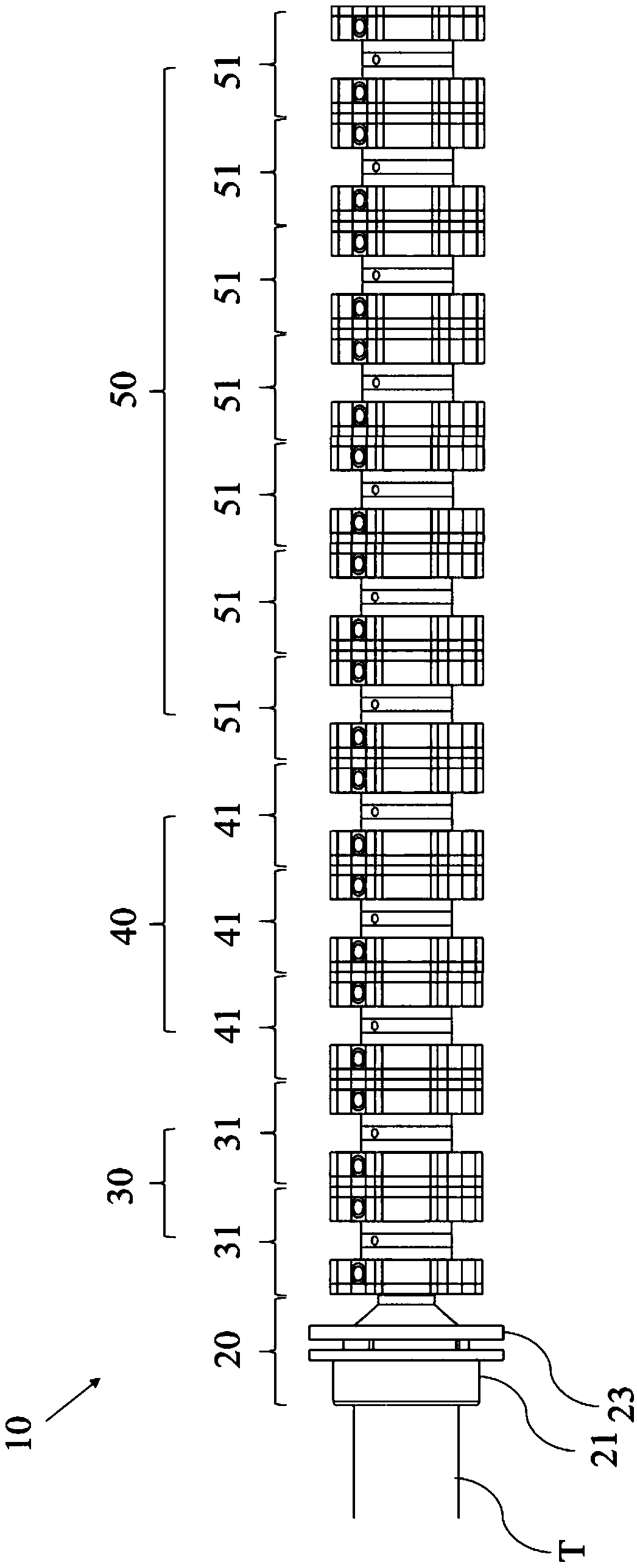

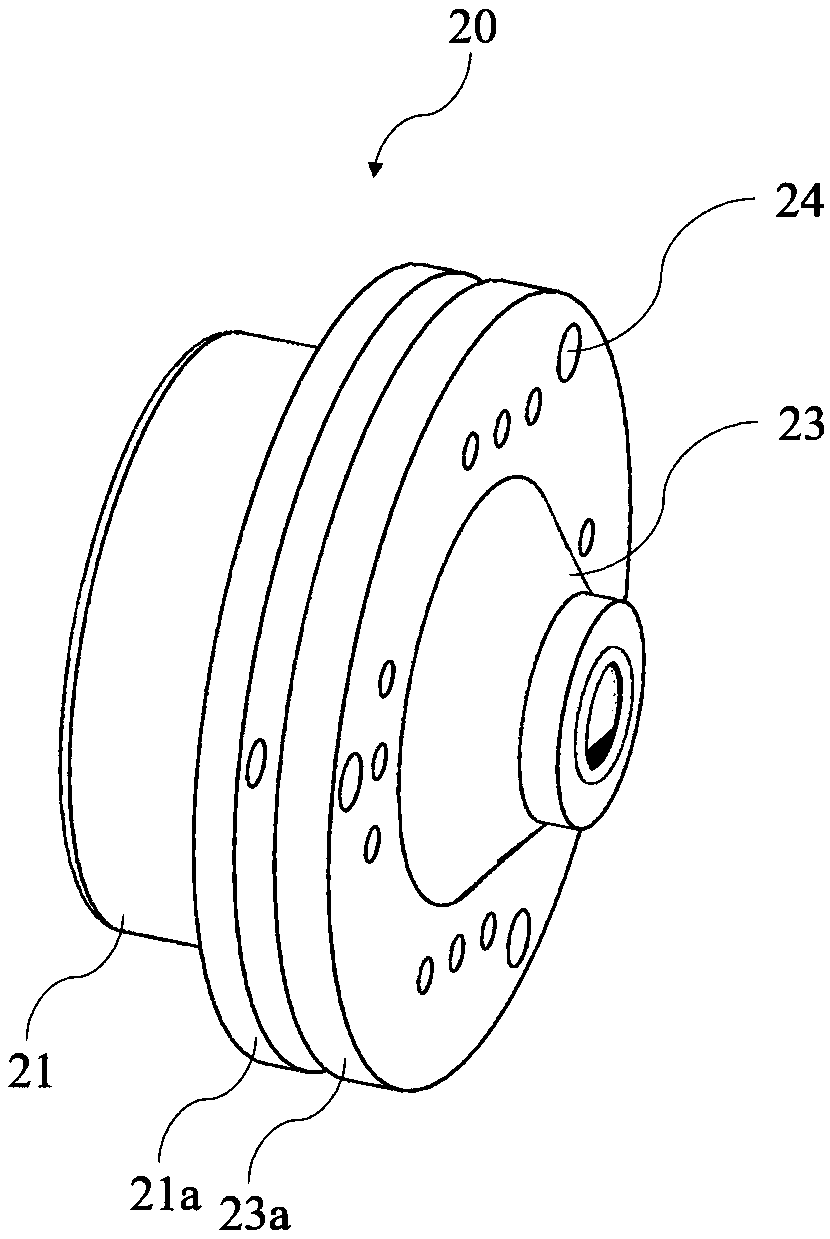

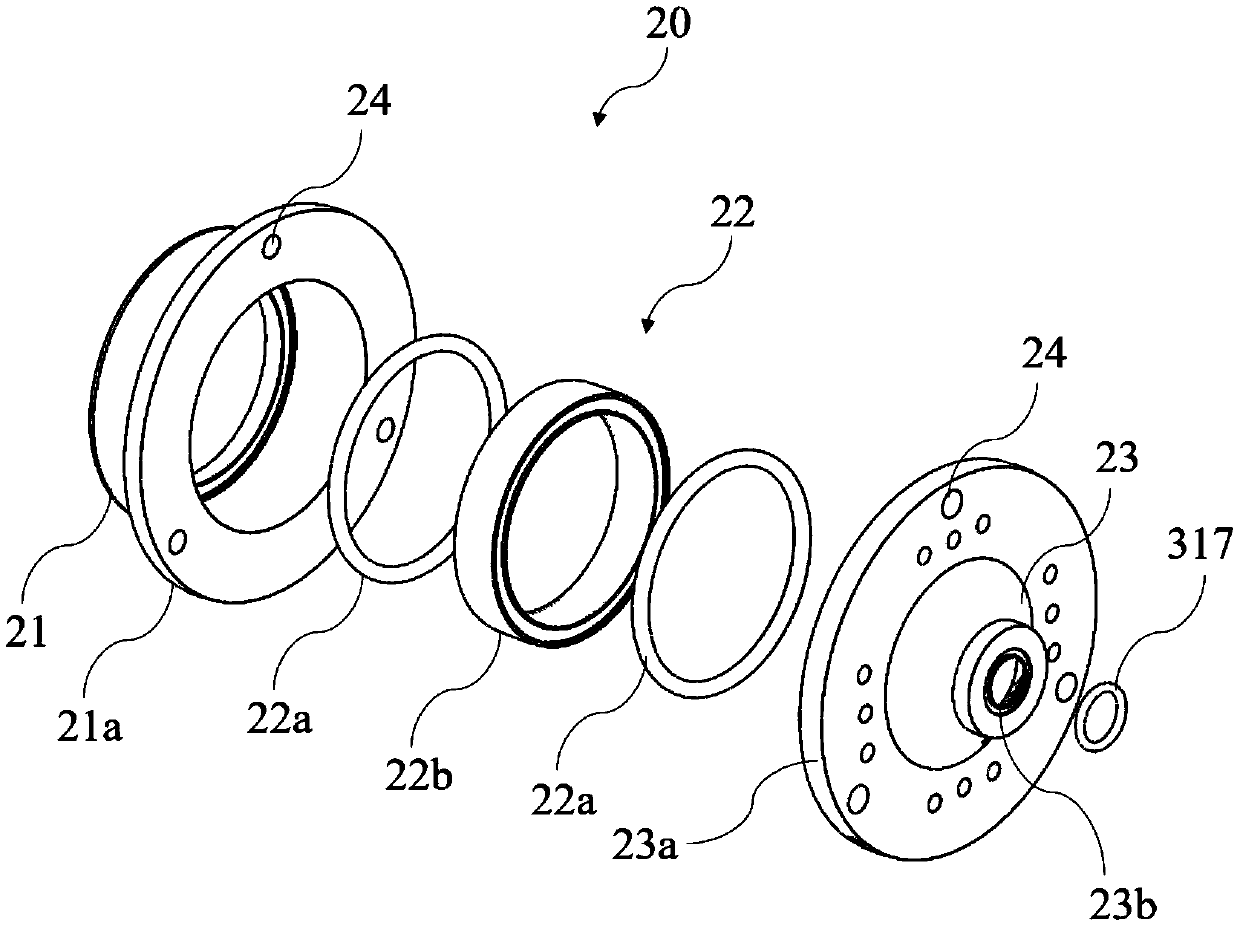

[0052] Such as Figures 1 to 15 As shown, the tar cooling and collecting device 10 based on the asymmetric temperature-guiding flow channel is connected with the tar delivery pipeline T, condenses the high-temperature pyrolysis gas delivered from the pipeline T and collects the liquefied tar. The tar cooling and collecting device 10 based on the asymmetric temperature guide flow channel includes a pipeline connection module 20, a high-temperature section refrigeration assembly 30, a medium-temperature section refrigeration assembly 40, a low-temperature section refrigeration assembly 50, three sets of temperature measuring components 60, and three sets of cooling liquid supply components 70 . Three sets of power regulating components 80 and temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com