Technological method for improving thermal fatigue performance of aluminum alloy material

A technology of aluminum alloy material and process method, applied in the direction of metal material coating process, coating, etc., can solve the problem that the cladding layer is easy to fall off, affects the improvement of the thermal fatigue performance of the aluminum alloy, and affects the effect of the laser cladding layer on the aluminum alloy. surface strengthening and other issues, to expand the application field and improve the thermal fatigue performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

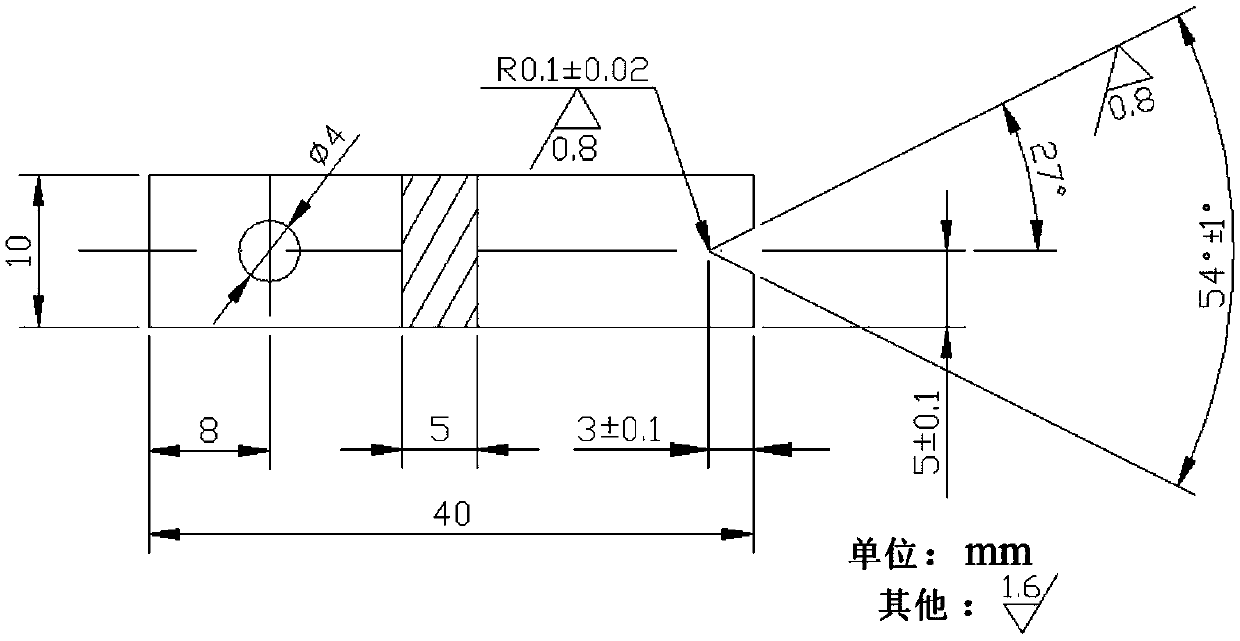

Image

Examples

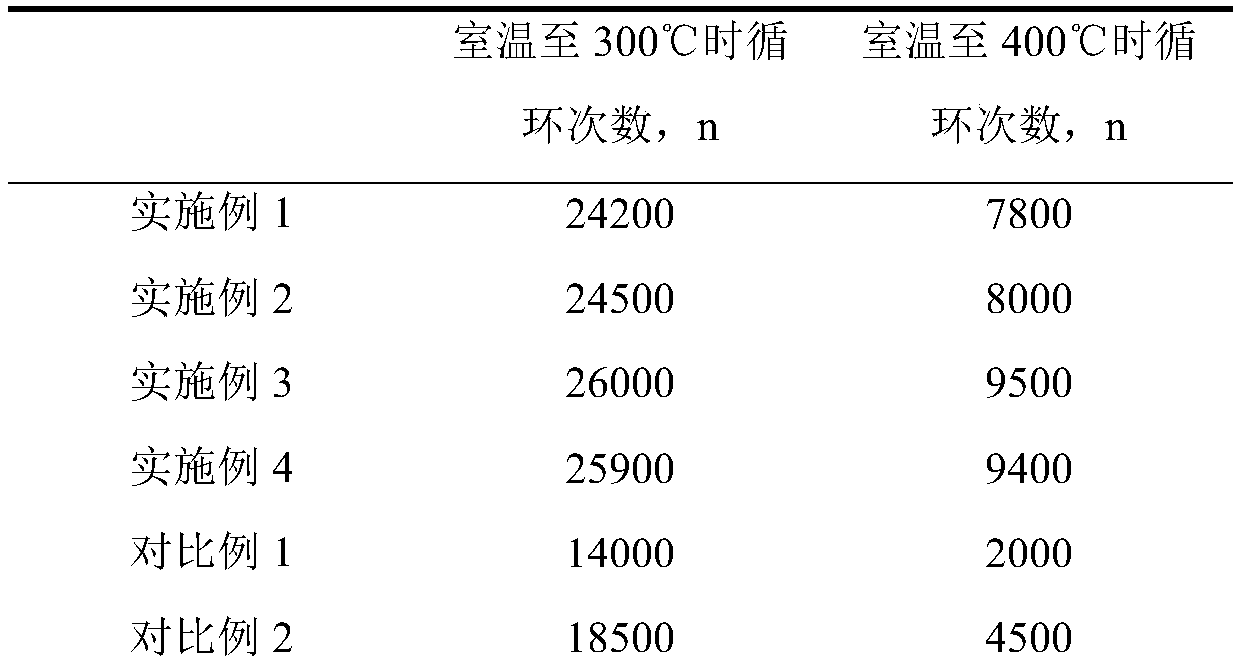

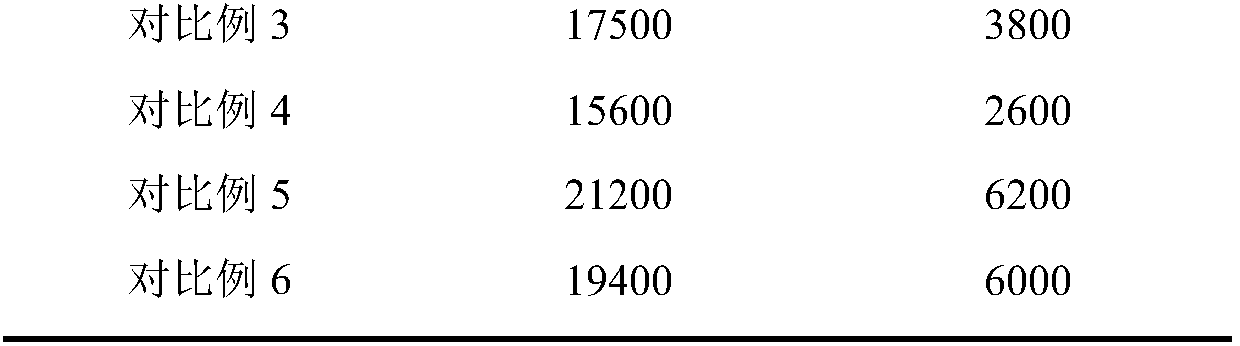

Embodiment 1

[0026]The aluminum alloy is selected from commercially available A356 cast aluminum alloy. The strengthening treatment is carried out according to the following steps: step (1): blackening treatment on the surface of the aluminum alloy. First sanded and polished, then immersed in 8% NaOH solution and etched for 3 min to remove the surface Al 2 o 3 Contaminants such as films and other oil stains are finally cleaned with alcohol and then air-dried for later use; step (2): preparation of cladding powder. The chemical composition of Ni-based powder is calculated by mass percentage, Cr is 13%, Si is 3%, Ti is 2%, B is 2%, Y 2 o 3 3%, CeO 2 3%, La 2 o 3 2%, Nd 2 o 3 is 1%, Co is 1%, C is 0.5%, Mn is 0.5%, SrO is 0.1%, Fe is 2%, and the balance is Ni. Grinding and mixing the above powder in a vacuum ball mill for 10 minutes, the particle size of the powder is 250-400 mesh, and the shape is spherical or nearly spherical; step (3): laser cladding process. The fiber laser is u...

Embodiment 2

[0029] The aluminum alloy is selected from commercially available A356 cast aluminum alloy. The strengthening treatment is carried out according to the following steps: step (1): blackening treatment on the surface of the aluminum alloy. First sanded and polished, and then immersed in 10% NaOH solution for 2 min to remove the surface Al 2 o 3 Contaminants such as films and other oil stains are finally cleaned with alcohol and then air-dried for later use; step (2): preparation of cladding powder. The chemical composition of Ni-based powder is calculated by mass percentage, Cr is 18%, Si is 5%, Ti is 3%, B is 3%, Y 2 o 3 4%, CeO 2 4%, La 2 o 3 3%, Nd 2 o 3 2%, Co 3%, C 0.8%, Mn 0.8%, SrO 0.3%, Fe 8%, and the balance Ni. Grinding and mixing the above powder in a vacuum ball mill for 30 minutes, the particle size of the powder is 150-300 mesh, and the shape is spherical or nearly spherical; step (3): laser cladding process. The fiber laser is used to carry out laser cla...

Embodiment 3

[0032] The aluminum alloy is selected from the commercially available 7075 deformed aluminum alloy. The strengthening treatment is carried out according to the following steps: step (1): blackening treatment on the surface of the aluminum alloy. First sanded and polished, then immersed in 8% NaOH solution and etched for 3 min to remove the surface Al 2 o 3 Contaminants such as films and other oil stains are finally cleaned with alcohol and then air-dried for later use; step (2): preparation of cladding powder. The chemical composition of Ni-based powder is calculated by mass percentage, Cr is 13%, Si is 3%, Ti is 2%, B is 2%, Y 2 o 3 3%, CeO 2 3%, La 2 o 3 2%, Nd 2 o 3 1%, Co 1%, C 0.5%, Mn 0.5%, SrO 0.1%, Fe 2%, and the balance Ni. Grinding and mixing the above powder in a vacuum ball mill for 10 minutes, the particle size of the powder is 250-400 mesh, and the shape is spherical or nearly spherical; step (3): laser cladding process. The fiber laser is used to carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com