Fluorescein dyeing method for modified acrylic staple fiber blended fabric

A dyeing method and technology of modified acrylic fibers, which can be used in dyeing methods, textiles and papermaking, dry cleaning fiber products, etc., can solve the problems of fluorescent yellow dyeing chroma and brightness that do not meet the standard requirements, and are conducive to industrial large-scale production. , Eliminate discoloration, the effect of simple dyeing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

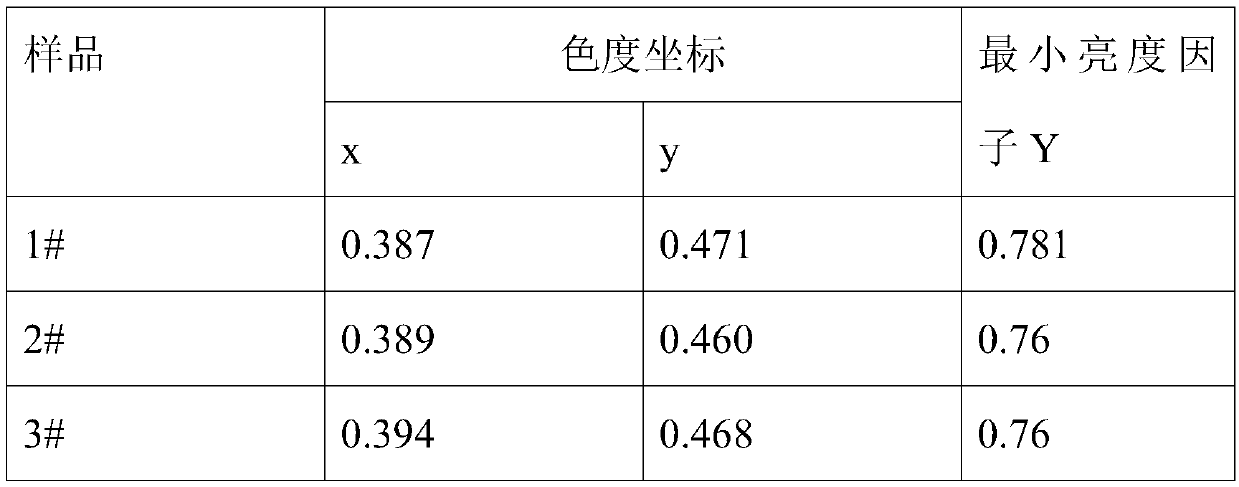

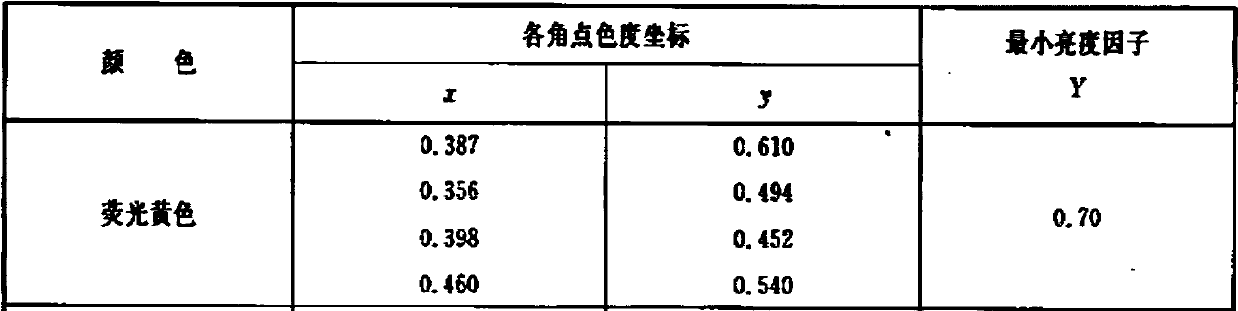

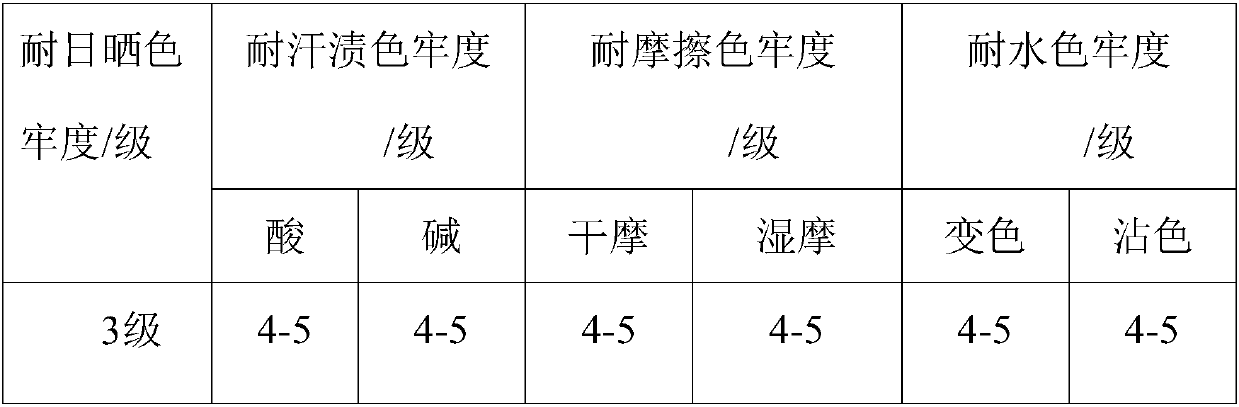

Examples

Embodiment 1

[0039] Step 1: Desizing the modified acrylic cotton fabric. Among them, the desizing enzyme concentration is 10g / L, the desizing agent is 5g / L, and the emulsifying and refining agent is 2g / L to form a desizing solution. The bath ratio is controlled at 1:10, and the temperature is raised to 100°C. After 90 minutes of heat preservation, hot water washing is obtained Desizing modified acrylic cotton blended fabric;

[0040] Step 2: Light bleaching the desized modified acrylic cotton blended fabric obtained in step 1. Among them, the hydrogen peroxide concentration is 10g / L, the hydrogen peroxide stabilizer is 2.5kg / L, the pH value is adjusted to 11, the temperature is raised to 50°C and kept for 60 minutes, and the light bleached fabric is obtained after washing with hot water;

[0041] Step 3: Place the fabric after light bleaching in a closed overflow machine, add bleaching solution, heat it up to 70°C and keep it warm for 90 minutes, then cool it down to room temperature natu...

Embodiment 2

[0047] Step 1: Desizing the modified acrylic cotton fabric. Among them, the desizing enzyme concentration is 25g / L, the desizing agent is 15g / L, and the emulsifying and refining agent is 10g / L to form a desizing solution. Pulp modified acrylic cotton blended fabric;

[0048] Step 2: Light bleaching the desized modified acrylic cotton blended fabric obtained in step 1. Among them, the concentration of 30% hydrogen peroxide is 20g / L, the hydrogen peroxide stabilizer is 3kg / L, the pH value is adjusted to 8, the temperature is raised to 80°C and kept for 45 minutes, and the light bleached fabric is obtained after washing with hot water;

[0049] Step 3: Put the fabric after light bleaching in a closed overflow machine, add bleaching solution, heat it up to 80°C and keep it warm for 60 minutes, then cool it down to room temperature naturally, wash it with overflow water, and then use a dechlorination agent to keep it warm at 95°C for 10 minutes Dechlorination; after dechlorinatio...

Embodiment 3

[0055] Step 1: Desizing the modified acrylic cotton fabric. Among them, the desizing enzyme concentration is 40g / L, the desizing agent is 20g / L, and the emulsifying and refining agent is 20g / L to form a desizing solution. The bath ratio is controlled to be 1:1, and the temperature is raised to 70°C. Desizing modified acrylic cotton blended fabric;

[0056] Step 2: Light bleaching the desized modified acrylic cotton blended fabric obtained in step 1. Among them, the concentration of 30% hydrogen peroxide is 30g / L, the hydrogen peroxide stabilizer is 4kg / L, the pH value is adjusted to 9, the temperature is raised to 90°C and kept for 30 minutes, and the light bleached fabric is obtained after washing with hot water;

[0057] Step 3: Place the fabric after light bleaching in a closed overflow machine, add bleaching solution, heat it up to 80°C and keep it warm for 60 minutes, then cool it down to room temperature naturally, wash it with overflow water, and then use a dechlorinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com