Multi-water-source steam or hot water generation method and device

A generation method and multi-water source technology, applied in the direction of steam generation, cleaning heat transfer devices, steam boilers, etc., can solve the problems of large boiler damage, high cost, corrosion, etc., to prevent damage and scaling, reduce operating costs, and operate Convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

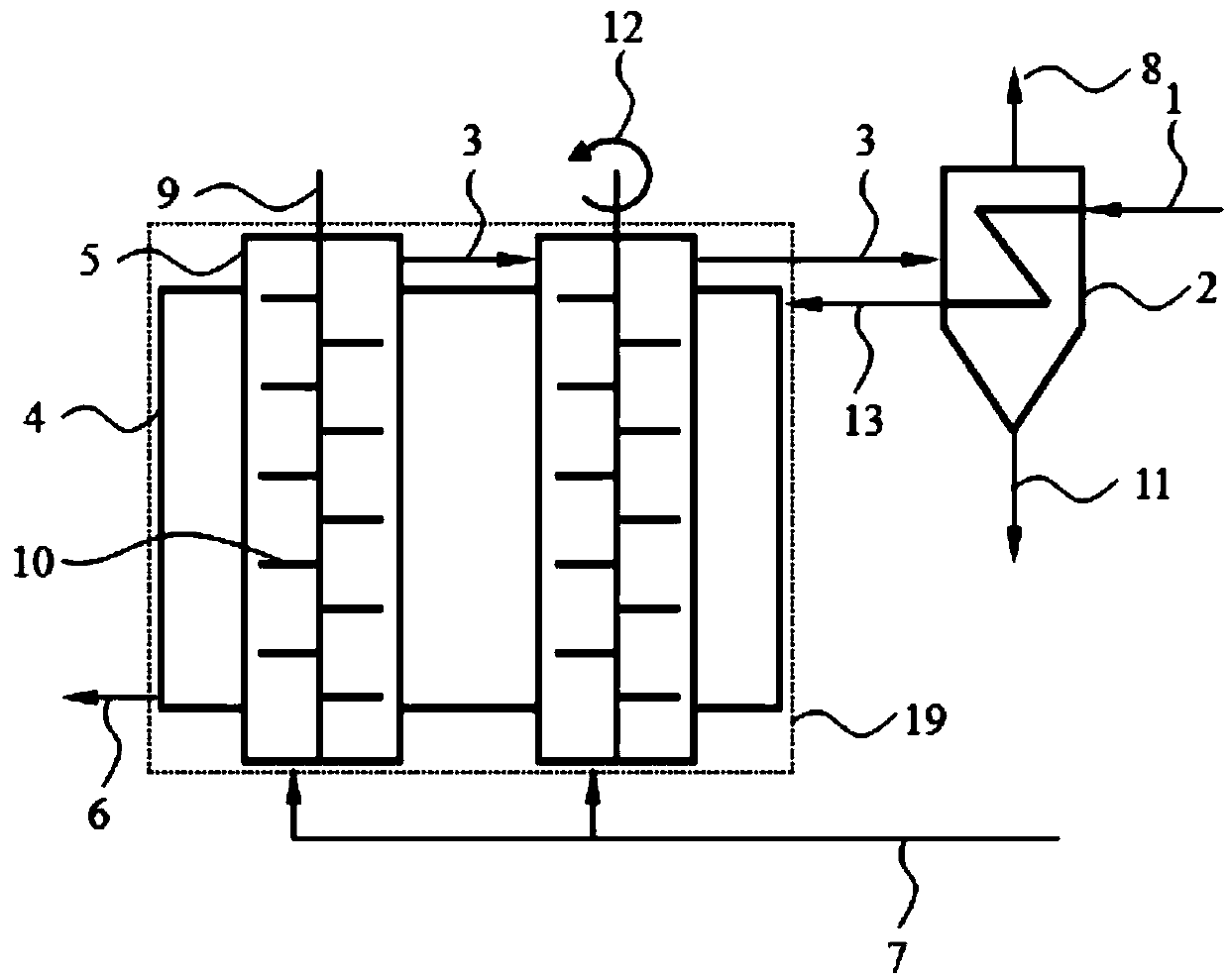

[0034] Use waste water to produce steam 2~3t / h, such as figure 1 , a multi-water source steam generating device, the heat exchange structure of the main heat exchange device 19 is a water pipe 5, the diameter of the water pipe 5 is between 100 mm and 300 mm, the pipe length is 300 mm to 1000 mm, the inner wall of the pipe is smooth, and the water pipe is a smooth pipe, The light pipe with short pipe length and large pipe diameter can effectively prevent impurities in the waste water from depositing on the inner wall of the pipe, prevent scaling, and is easy to clean; the bottom of the water pipe 5 is connected to the water supply pipe 7, and the water supply pipe 7 There is a flow regulating valve inside, and the top of the water pipe 5 is provided with a heat exchange product collection pipe 3. When collecting steam, the heat exchange product collection pipe 3 is a steam collection pipe, and the water pipe 5 runs through the top and bottom of the box body 4 respectively, and t...

Embodiment 2

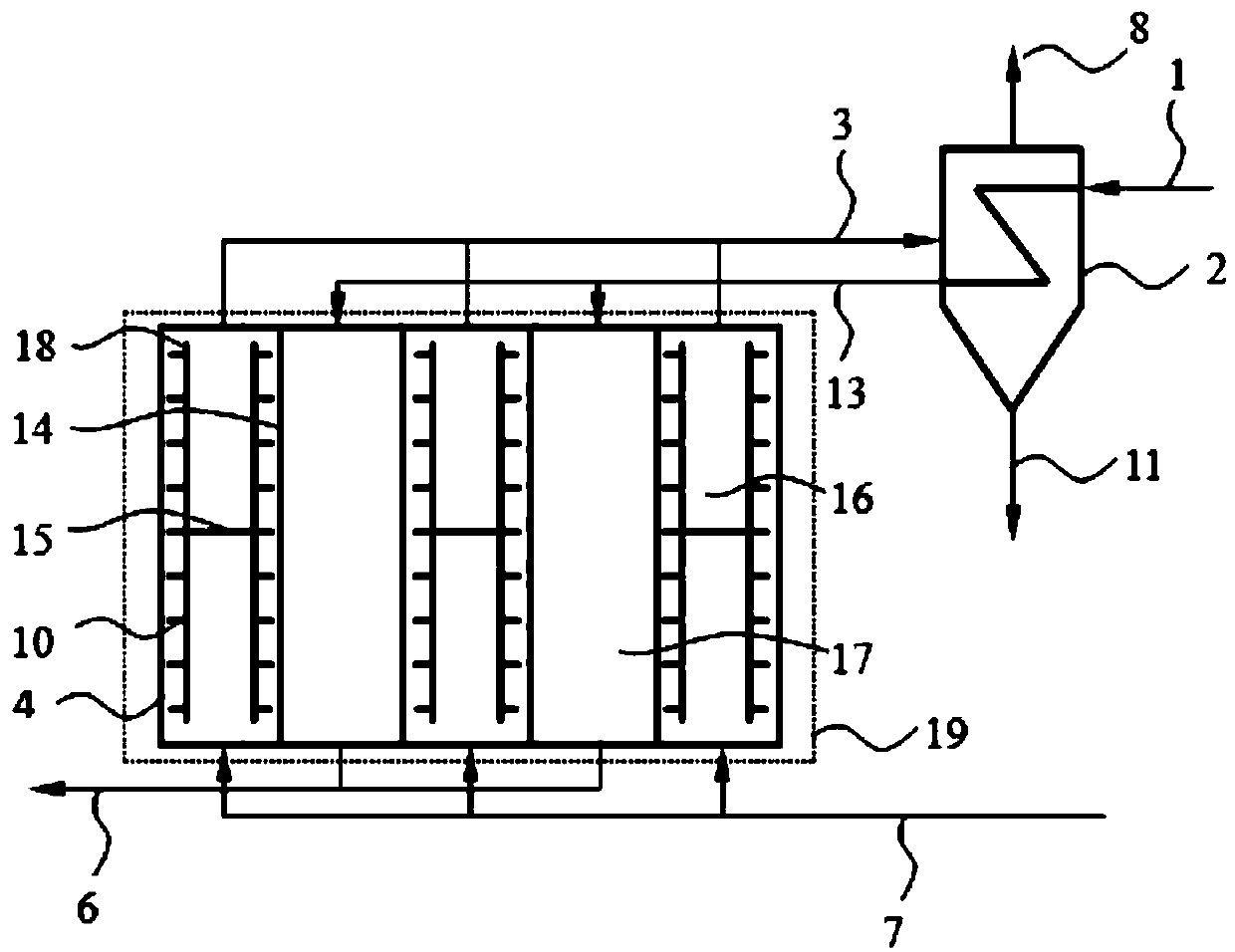

[0040] Use waste water to produce steam 4~5t / h, such as figure 2 , a steam generating device with multiple water sources, the heat exchange structure of the main heat exchange device 29 is that a plurality of metal plates 14 divide the box body 4 into a plurality of thin rectangular channels, which are respectively the water channel side and the heat source side channel, and the two channels alternate with each other, Hot and cold fluids flow and exchange heat in the channels on both sides of the metal plate 14; the distance between the metal plates 14 is between 80-200mm, the water depth of the rectangular channel is 300-800mm, and the metal plate 14 is rectangular with tiny corrugations on the surface The stainless steel metal plate can increase the heat exchange effect; the upper, lower, left, and right walls of the box are provided with grooves arranged reasonably, and the four sides of the metal plate 14 are embedded in the corresponding grooves in the box 4 for fixing; t...

Embodiment 3

[0046] Utilize waste water to produce hot water 2~3t / h, the hot water generating device of this embodiment sees figure 1, the difference from the steam generation device in Example 1 is that there is no steam-water separation and superheater device, the heat exchange product collection pipe is a hot water collection pipe, and the hot water is collected and directly flows out of the device for production use, and the rest of the structure and connections are the same as figure 1 The steam generating device in is basically the same. The heat exchange between the feed water and the heat source is different from that of Example 1 in that the feed water absorbs the heat source and releases heat and then rises in temperature, and the final temperature after the temperature rise is controlled not to exceed its boiling temperature. It can be controlled at 70°C to 80°C, the heat source is medium-high temperature steam, and the steam temperature is 450°C or 540°C.

[0047] The multi-so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap