Method for detecting chromium content in surface of cold rolled tin-plated steel sheet

A technology of element content and detection method, applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problem that the content of chromium hydroxide and chromium oxide cannot be accurately measured, achieve quality improvement, simple and easy method, and avoid measurement errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiments.

[0021] A method for detecting the content of chromium on the surface of cold-rolled tin-plated steel sheet comprises the following steps:

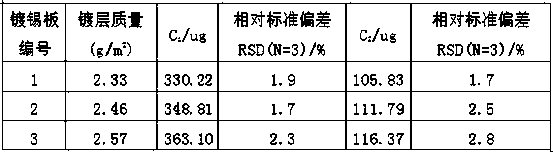

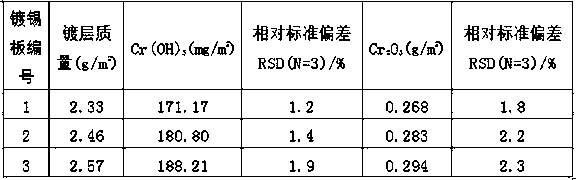

[0022] (1) The quality of three kinds of coatings is 2.33, 2.46 and 2.57 g / m respectively 2 The tinned plate is the sample to be tested. For sampling, two samples with a size of 3.5cm×3.5cm are continuously cut from the non-polluting and rust-free cold-rolled tinned steel plate to be tested, and one of the samples is sealed with acrylate glue. The side surface and four sides, the unsealed surface on the other side of the sample is the surface to be tested, and the two samples are respectively marked as sample 1 and sample 2; repeat this step twice, that is, take 3 parallel samples;

[0023] (2) Put sample 1 in a 300mL beaker, add 100±5mL dilute sulfuric acid solution with a concentration of 6:5 into the beaker to immerse the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com