A silicon rod growth rate prediction model in polysilicon reduction furnace is presented

A growth rate and prediction model technology is applied in the field of silicon rod growth rate prediction model in polysilicon reduction furnace, which can solve the problems of complex reaction, large energy loss and limited output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

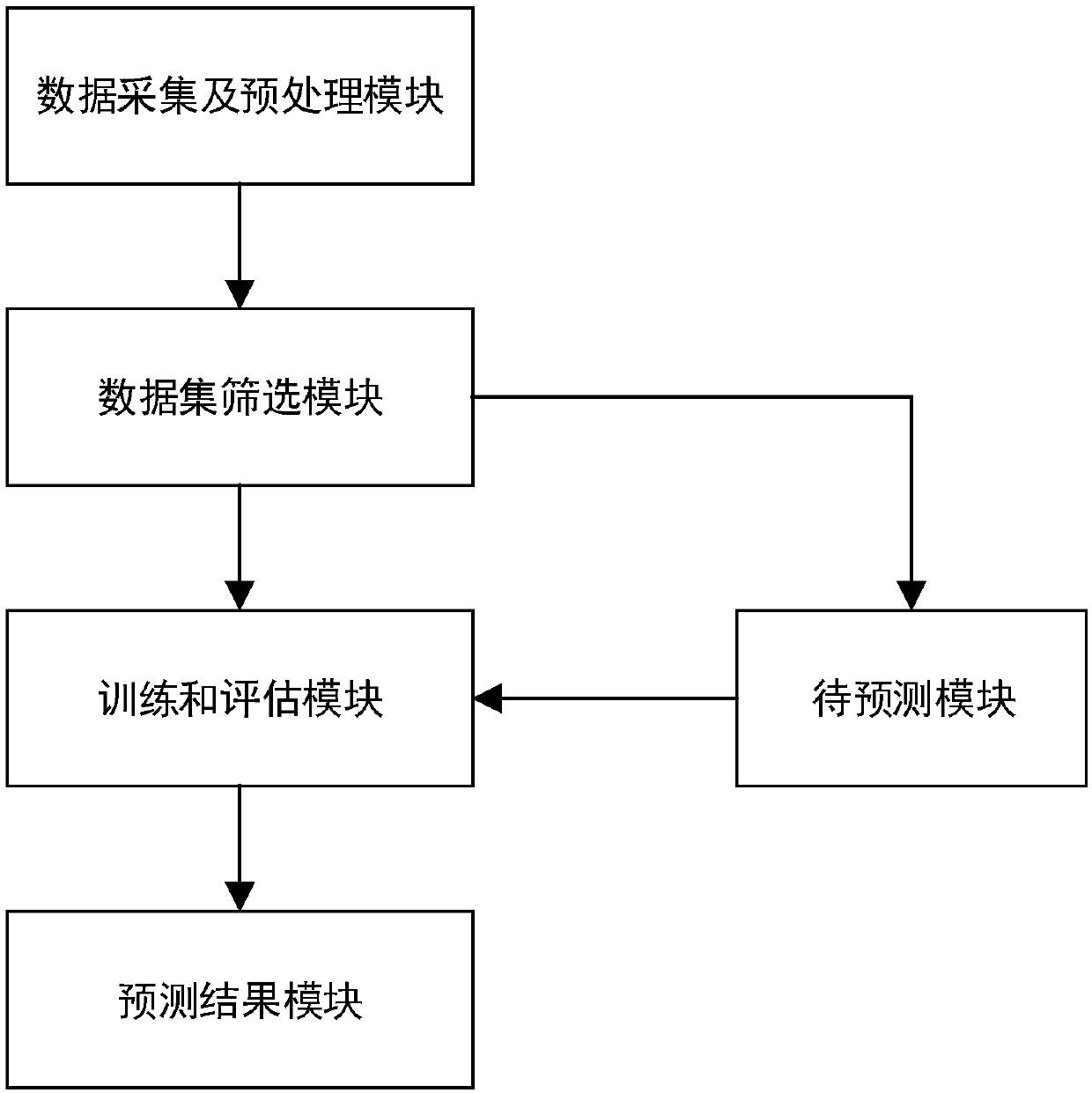

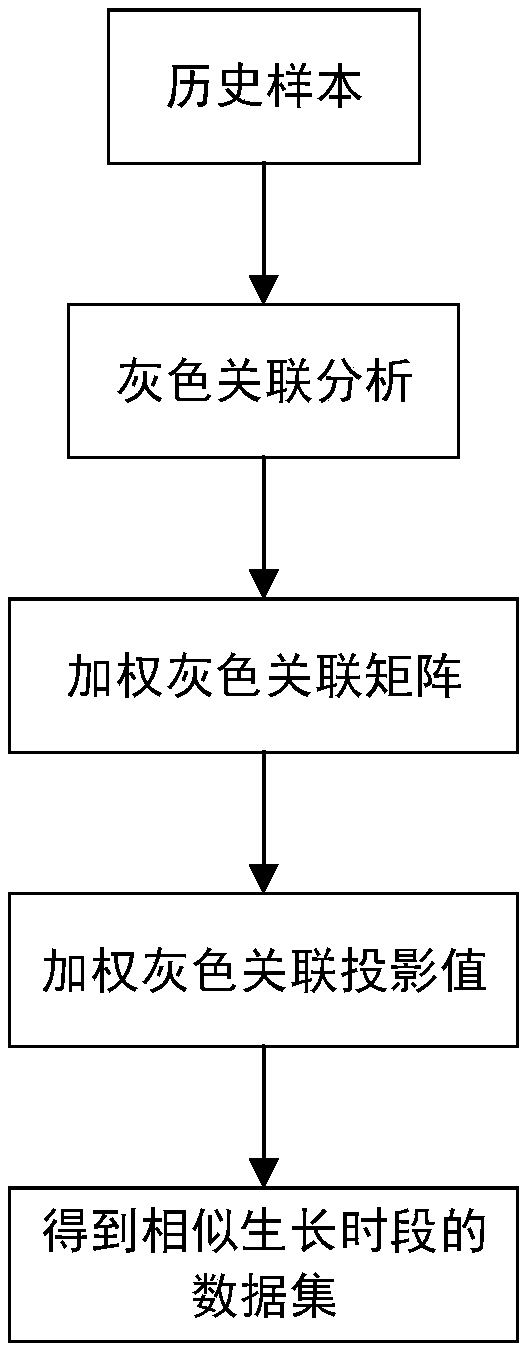

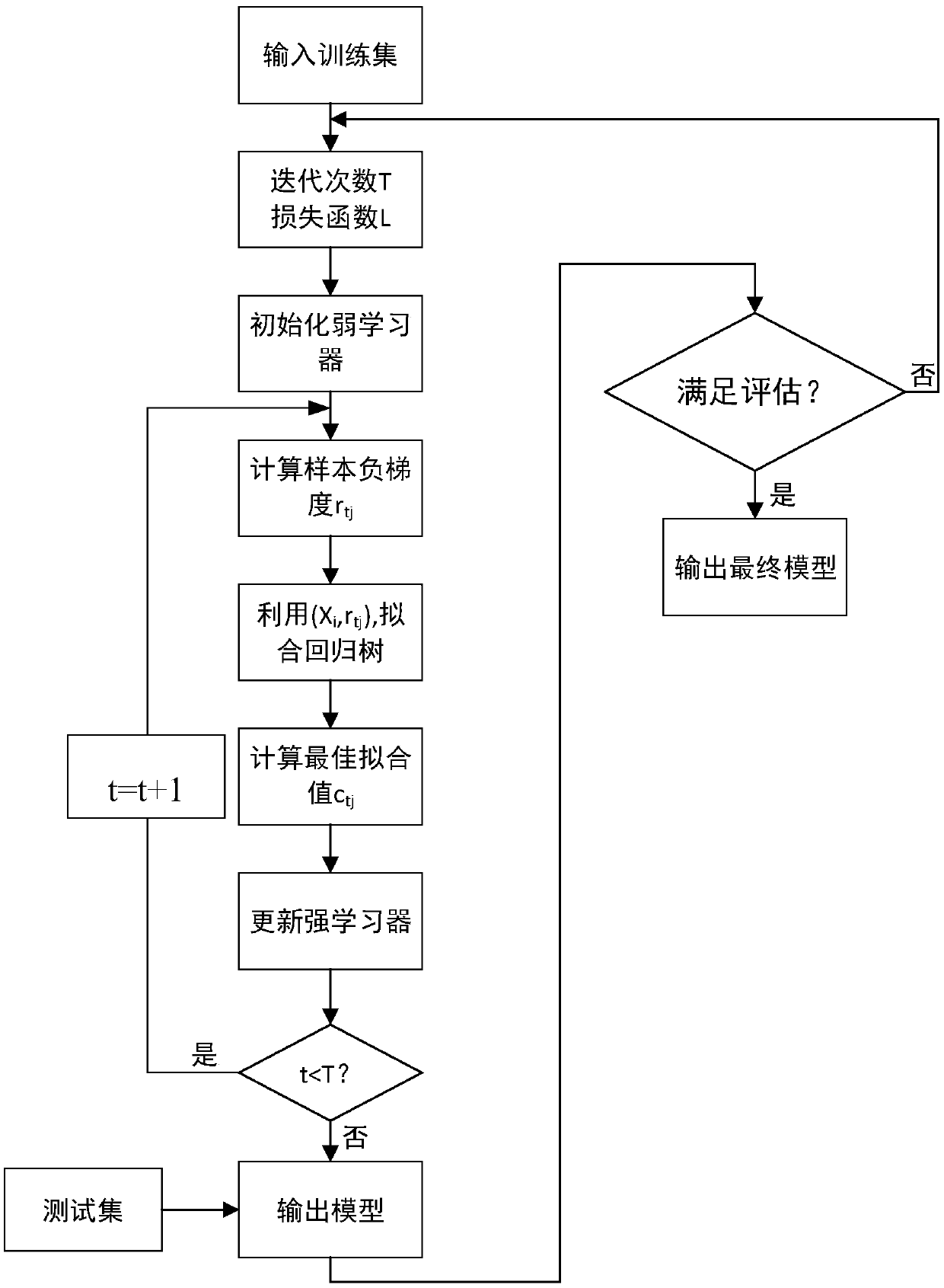

[0080] The idea of the present invention is to set up a predictive model of the growth rate of silicon rods in a polysilicon reduction furnace, and construct a plurality of inputs (such as pressure in the furnace, the speed of intake air, the feed amount of hydrogen and trichlorosilane, the diameter of silicon rods) etc.), the prediction model of a single output (growth rate of silicon rods), provides guidance for optimizing the coupling problem of process parameters, obtains a high and stable growth rate while ensuring quality, and improves production efficiency.

[0081] The invention discloses a silicon rod growth rate estimation model in a polysilicon reduction furnace, which includes the following modules:

[0082] 1. Data acquisition and preprocessing module

[0083] It is used to collect data related to the growth rate of silicon rods through sensors, construct a data set, and perform data cleaning on the collected data. specifically:

[0084] 1.1 Data collection

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com