Patents

Literature

194 results about "Gradient boosting decision tree" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Primer on Gradient Boosted Decision Trees. Gradient boosted decision trees are an effective off-the-shelf method for generating effective models for classification and regression tasks. Gradient boosting is a generic technique that can be applied to arbitrary 'underlying' weak learners - typically decision trees are used.

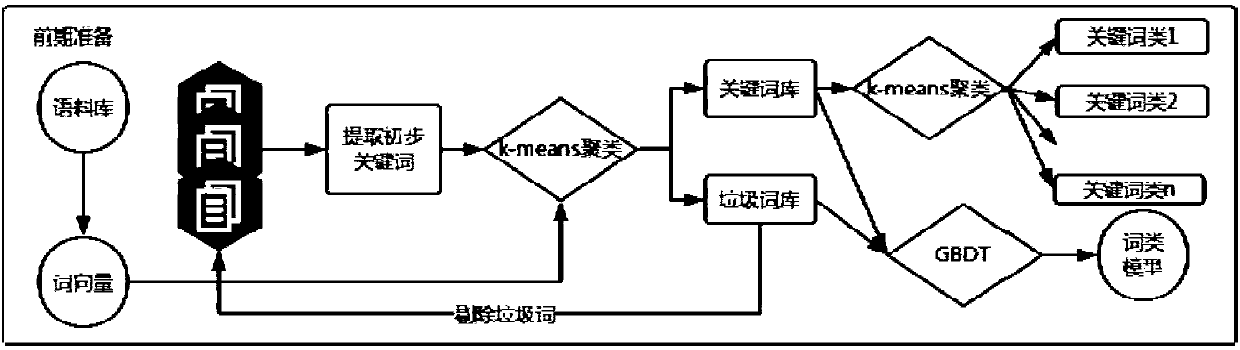

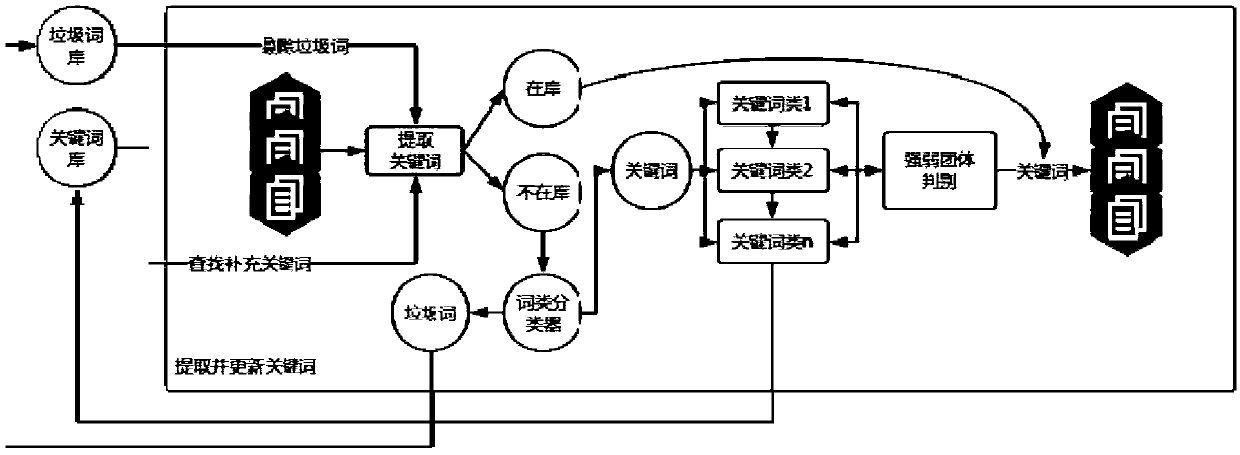

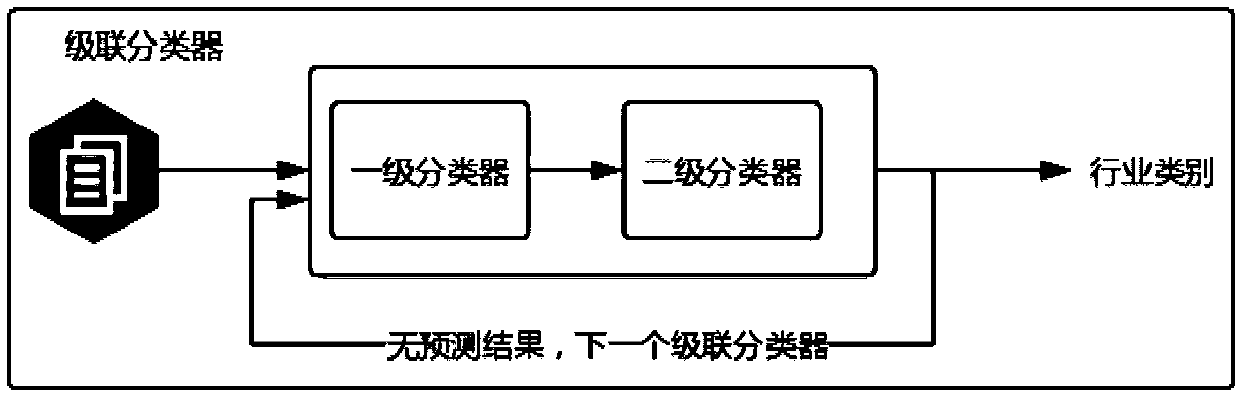

Enterprise industry classification method

ActiveCN107944480ASolve the tedious problem of manual classificationSolve classification problemsCharacter and pattern recognitionLearning basedCluster algorithm

The invention discloses an enterprise industry classification method. According to the method, main business keywords of enterprises are effectively extracted by utilizing semi-supervised learning-based image split clustering algorithm, the extracted keywords are used as features on the basis of a gradient enhancement decision-making tree, and a training cascade classifier is used for classifyingthe enterprises according to industries, so that the problem that artificial classification is tedious is solved. The method specifically comprises the following steps of: 1) extracting main businesskeywords of enterprises by utilizing a word vector and a semi-supervised image split clustering algorithm, getting rid of junk words and constructing a keyword library; and 2) inputting the extractedkeywords which are taken as features into a training cascade classifier, the enterprises are classified by each level of classifier, and the unclassified enterprises are classified according to the next level of classifier. According to the method, keywords can be automatically constructed, updated and classified, the problem of classifying millions and millions of enterprise industries is solved,and the problem of artificial labelling is effectively solved.

Owner:广州探迹科技有限公司

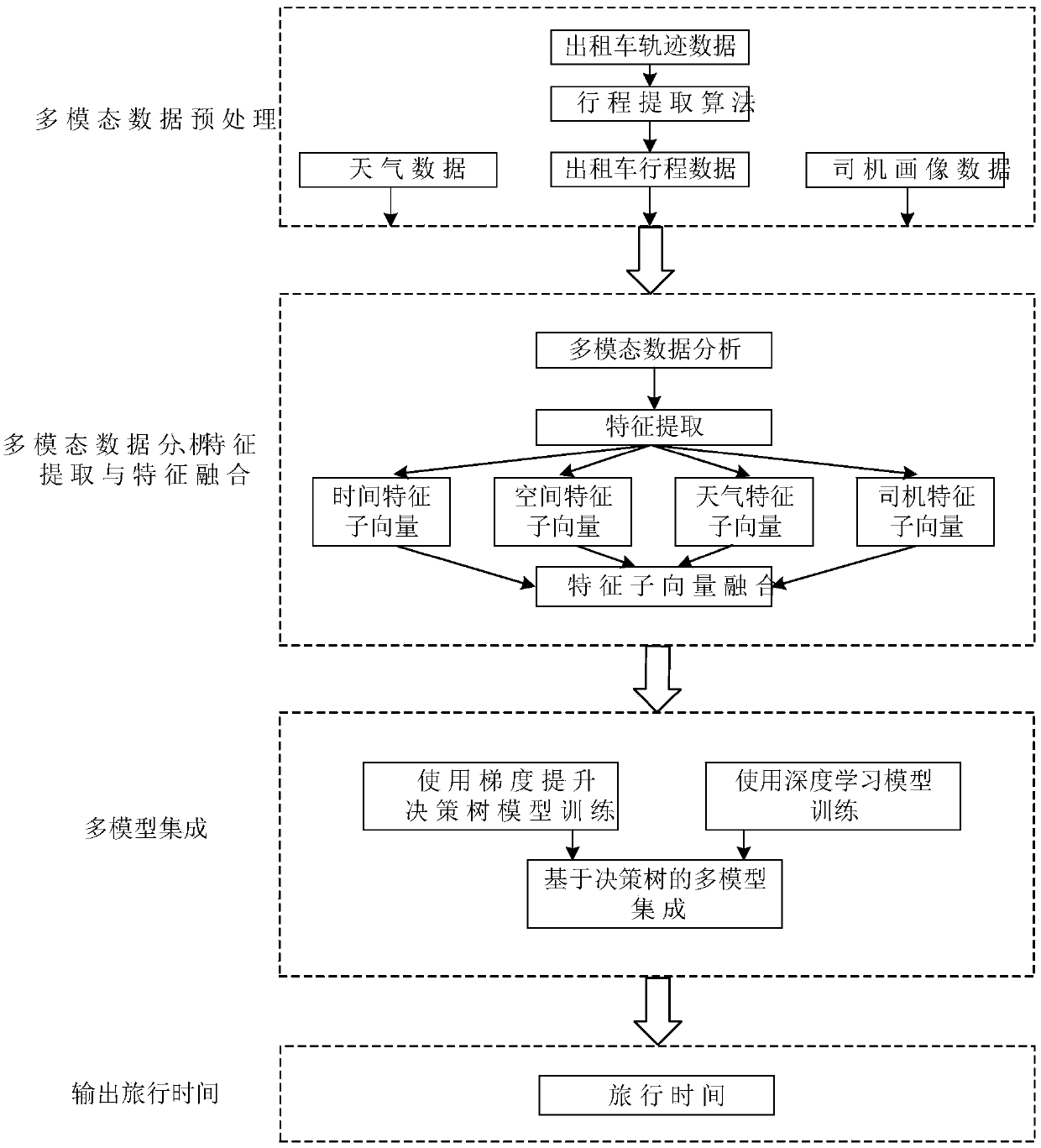

A travel time prediction method based on multi-modal data fusion and multi-model integration

ActiveCN109670277AReduce computational costFast operationForecastingDesign optimisation/simulationNetwork modelGps trajectory

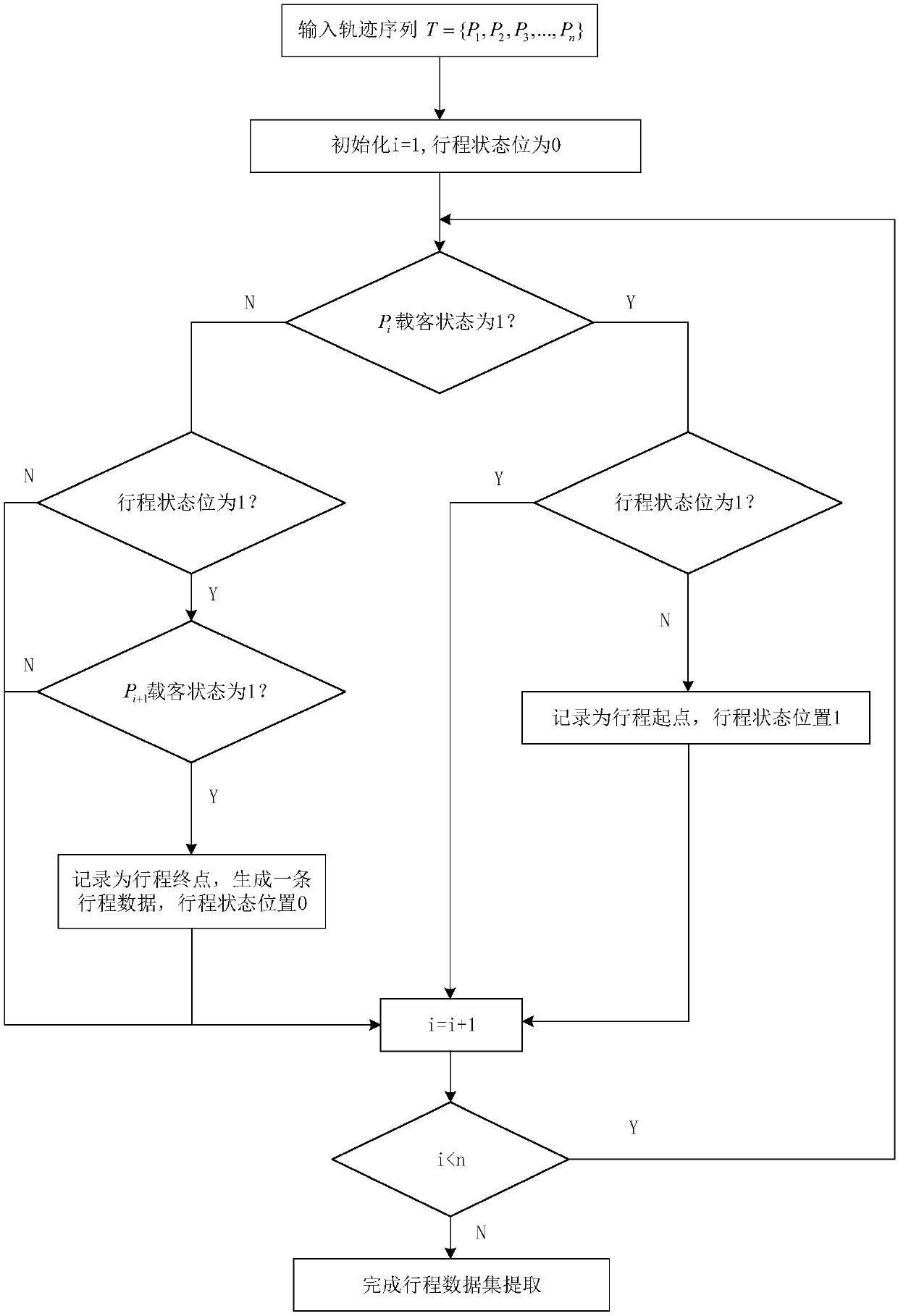

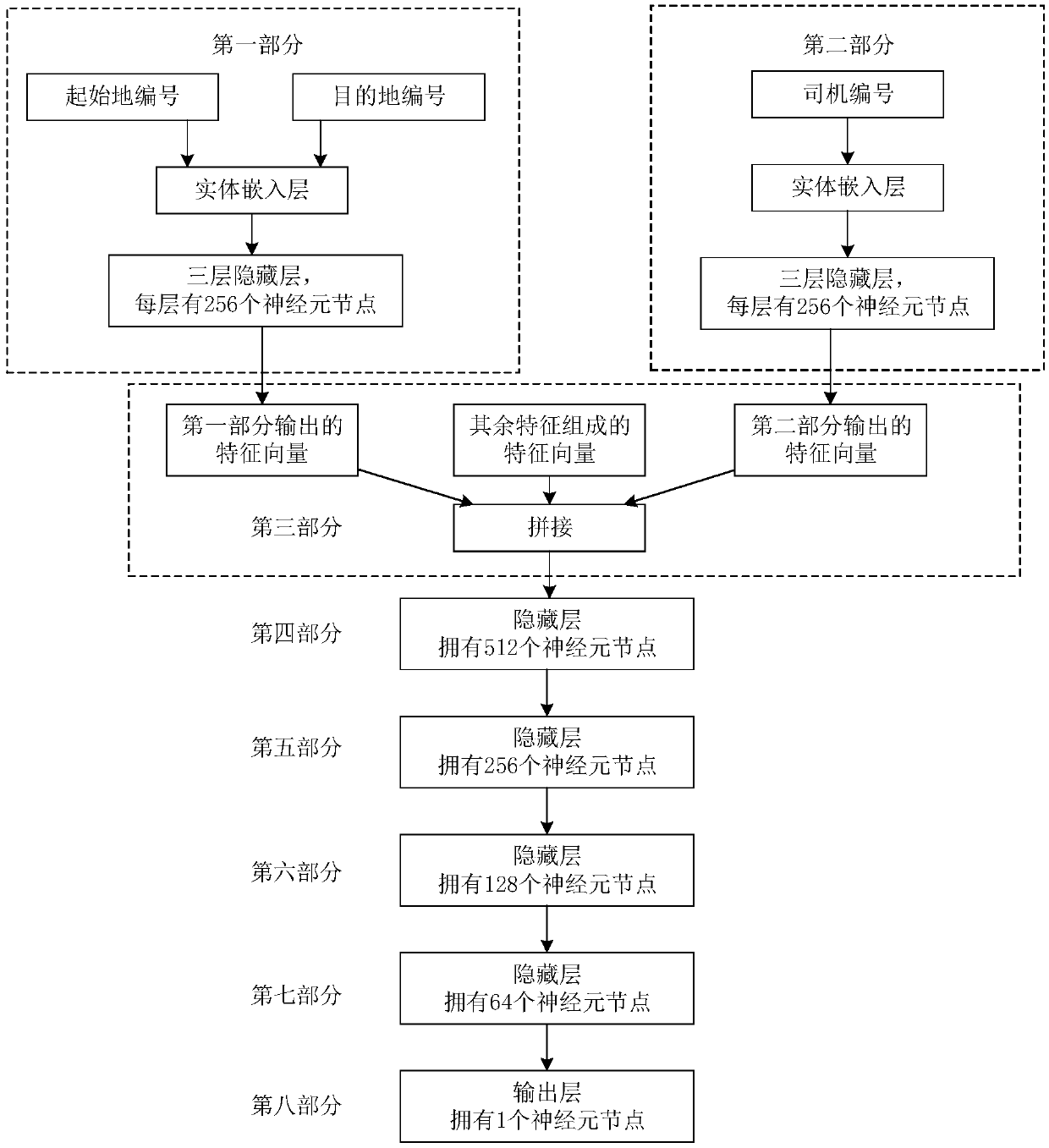

The invention discloses a travel time prediction method based on multi-modal data fusion and multi-model integration. The travel time prediction method comprises a multi-modal data preprocessing module which extracts taxi travel data from taxi GPS track data according to the passenger carrying state; a multi-modal data analysis, feature extraction and feature fusion module which is used for extracting corresponding feature sub-vectors from the fields of taxi track data, weather data, driver portrait data and the like and completing feature splicing; and a multi-model integration module which is used for respectively establishing a gradient improvement decision tree model and a deep neural network model, and integrating prediction results of the models by using the decision tree model. According to the travel time prediction method, by fusing the multi-modal data such as taxi track data, weather data and driver portrait data, the factors influencing travel time are fully extracted and mined, and an integrated model based on a decision tree is established, so that higher travel time prediction accuracy is obtained at lower calculation cost.

Owner:NANJING UNIV OF POSTS & TELECOMM

Hyperspectral image classification based on gradient lifting decision tree and semi-supervise algorithm integration

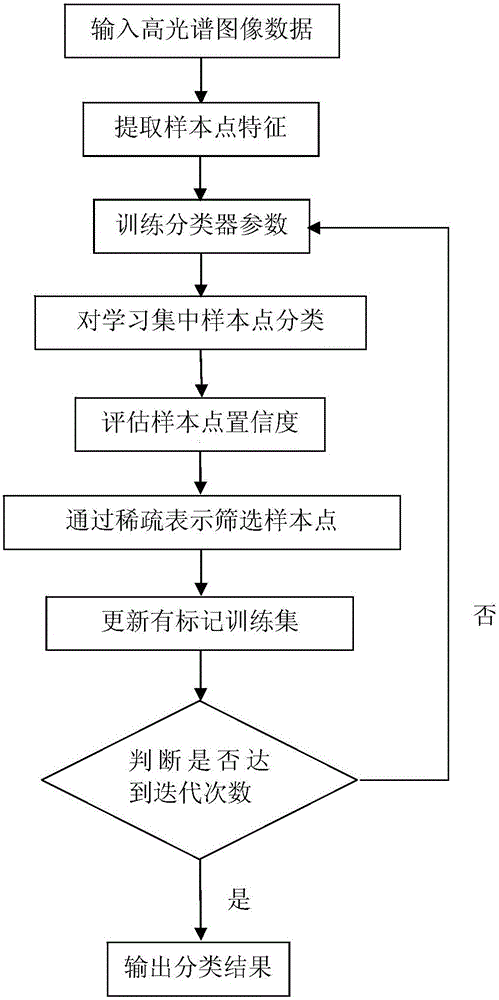

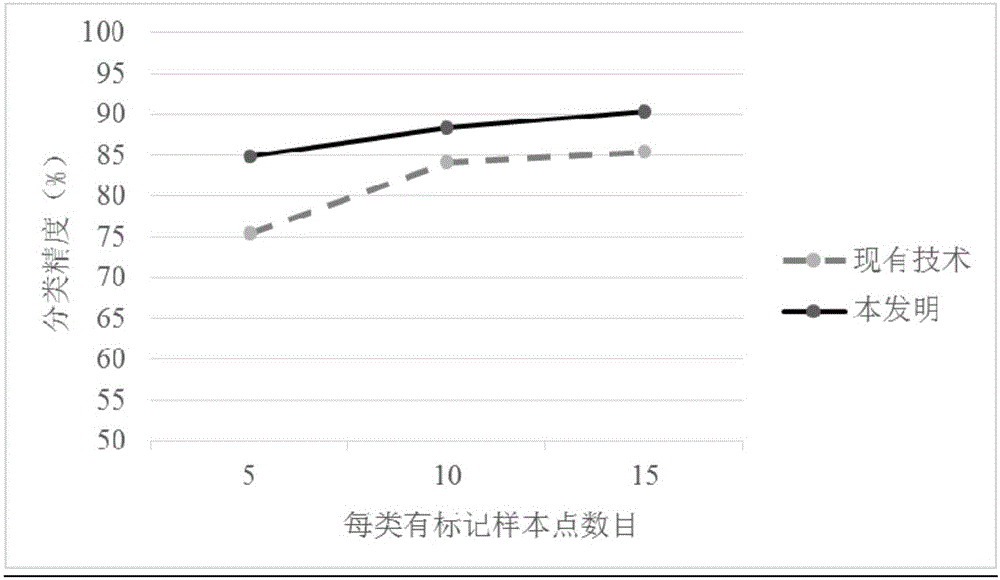

The invention discloses a hyperspectral image classification based on gradient lifting decision tree and semi-supervise algorithm integration in order to solve the technical problem that hyperspectral image classification based on active learning and semi-supervise learning is low in classification precision. Hyperspectral image classification includes the steps that firstly, hyperspectral image data is input; secondly, features of sample points are extracted; thirdly, parameters of a gradient lifting decision tree classifier are trained; fourthly, massed learning sample points are classified; fifthly, the confidence degree of the sample points are assessed; sixthly, the sample points are screened through sparse representation; seventhly, a marked training set is updated; eighthly, a classification result is output. Assessment is conducted on the confidence degree of the unmarked sample points through the prediction result of the classifier and sparse representation, according to the confidence degree of the unmarked sample points, the sample points are divided into two sets for different kinds of processing, burdens for manual marking are reduced while classification precision is improved, and hyperspectral image classification can be used in the fields of geological survey, atmospheric pollution and like.

Owner:XIDIAN UNIV

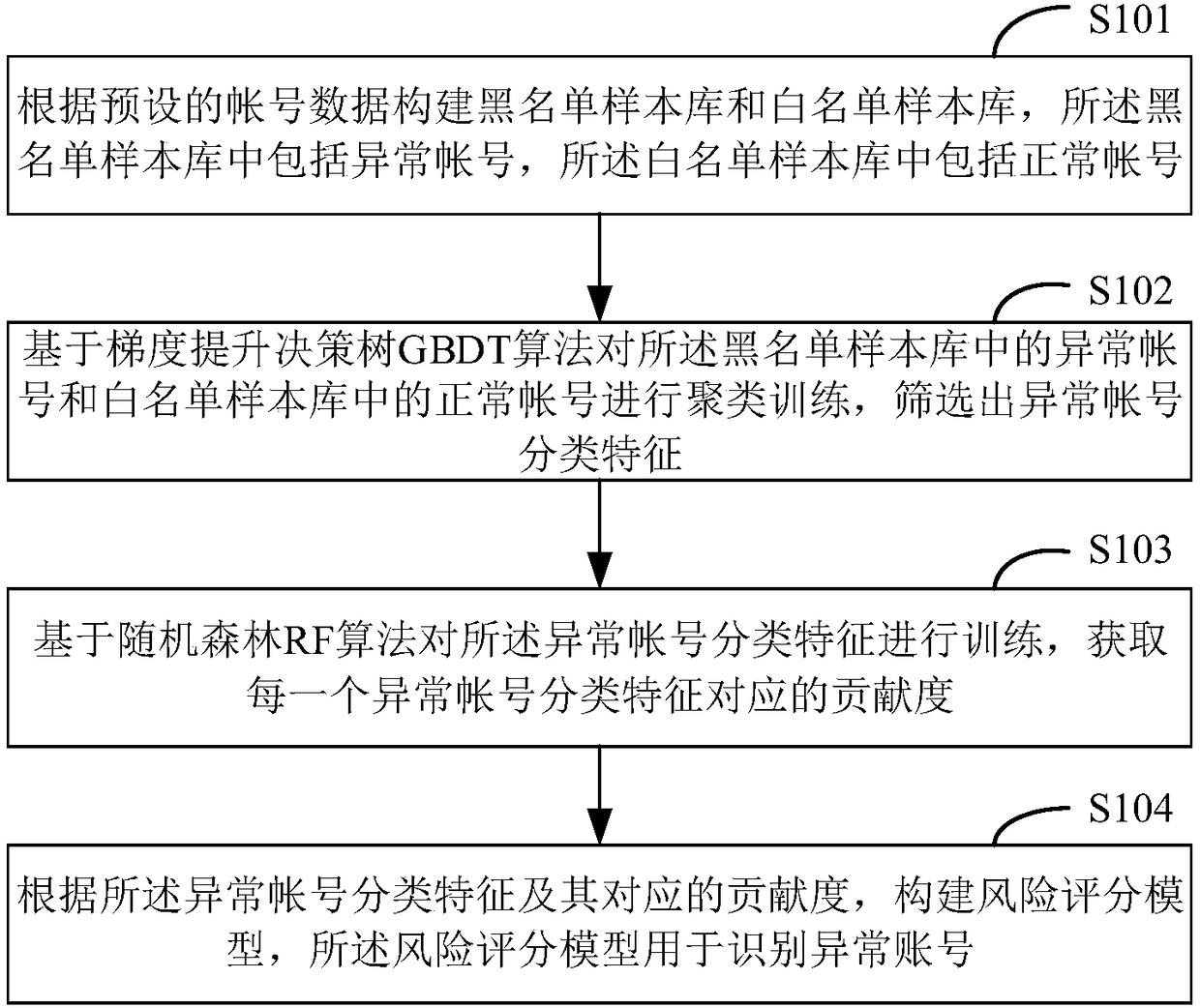

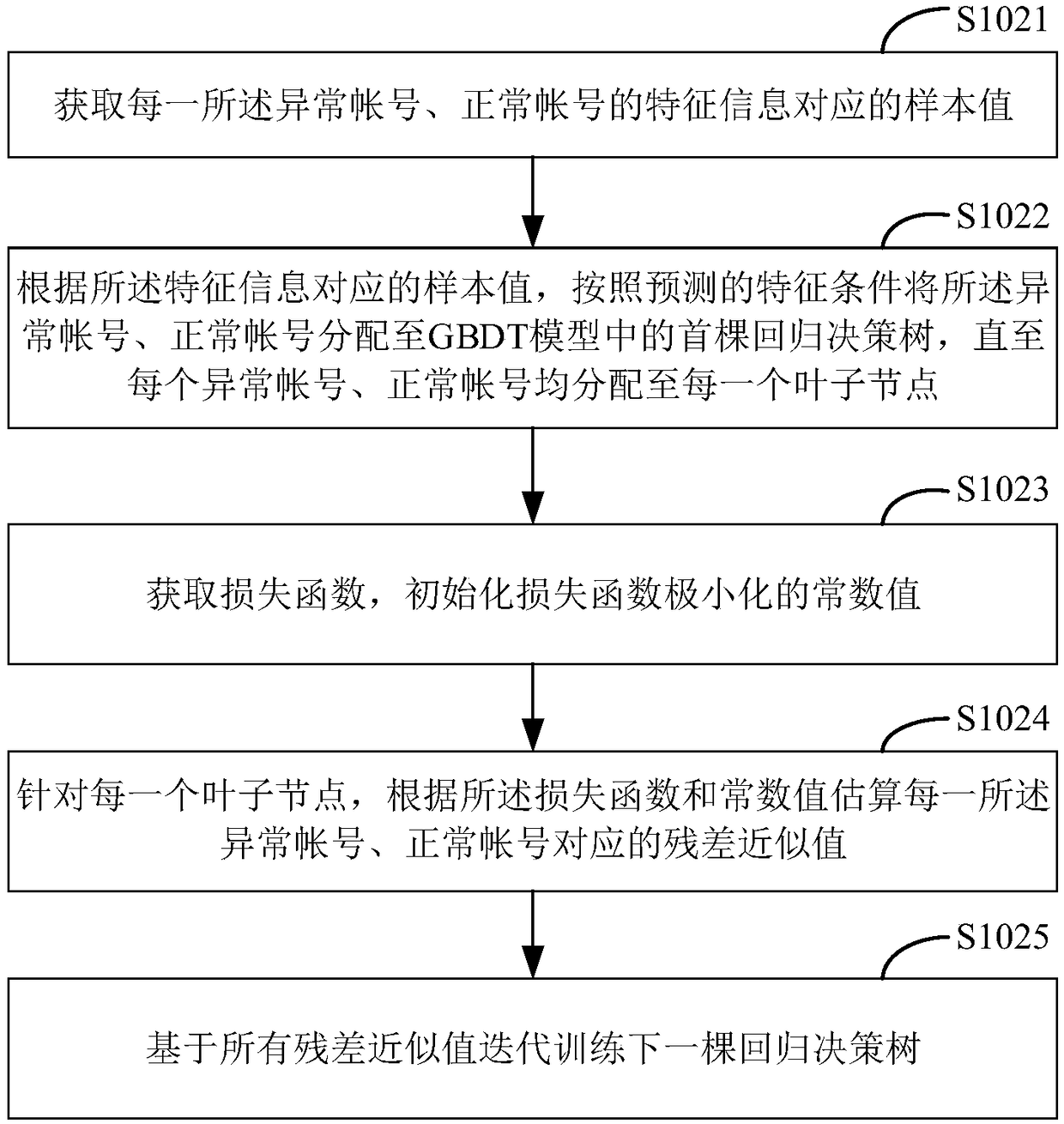

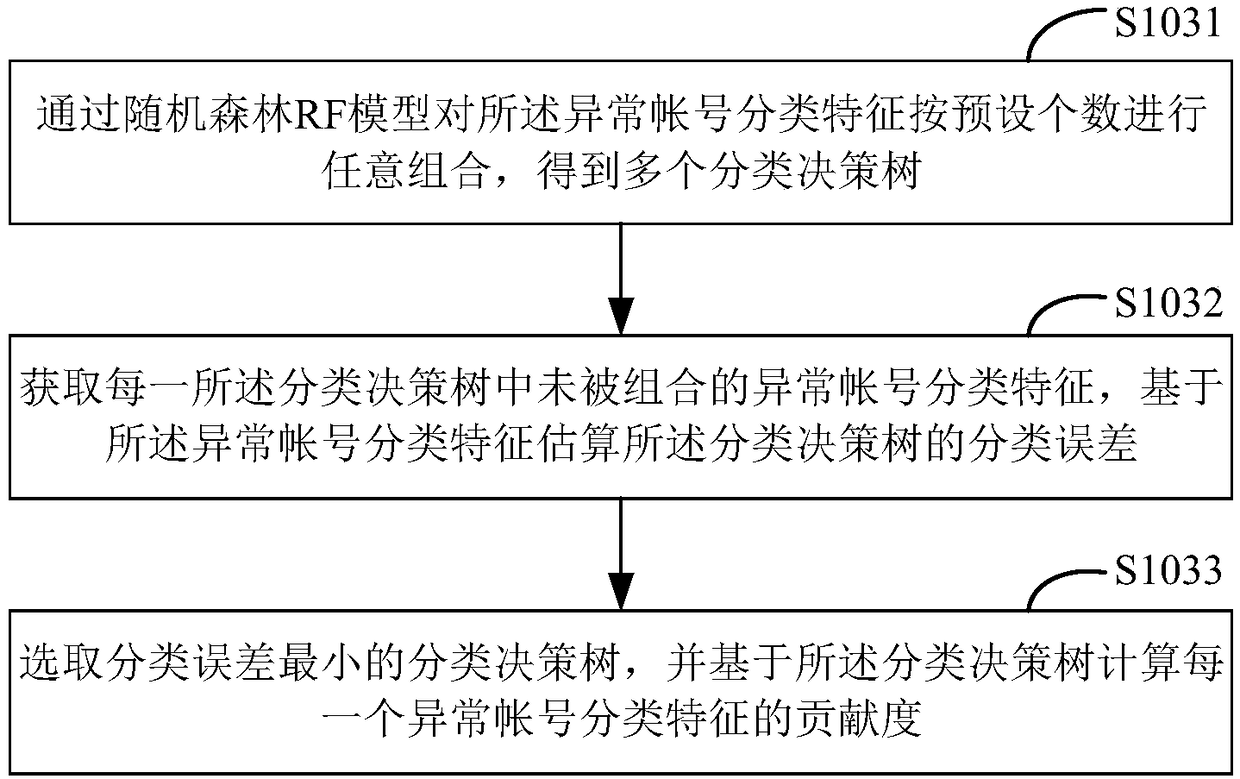

Risk scoring model construction method, device, storage medium and terminal

InactiveCN108269012AQuality improvementImprove calculation accuracyFinanceCharacter and pattern recognitionAlgorithmComputer terminal

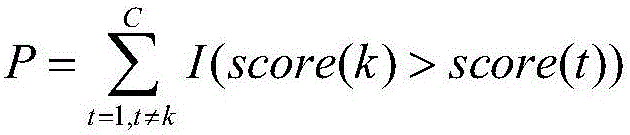

The present invention provides a risk scoring model construction method. The construction method includes the following steps that: a blacklist sample library and a whitelist sample library are constructed according to preset account data, wherein the blacklist sample library includes abnormal accounts, and the whitelist sample library includes normal accounts; cluster training is performed on theabnormal accounts in the blacklist sample library and the normal accounts in the whitelist sample library on the basis of a gradient boosting decision tree (GBDT) algorithm, and abnormal account classification features are screened out; the abnormal account classification features are trained on the basis of a random forest (RF) algorithm, and a contribution degree corresponding to each abnormalaccount classification feature is obtained; and a risk scoring model is constructed according to the abnormal account classification features and the contribution degrees corresponding to the abnormalaccount classification features, and the risk scoring model is used for identifying the abnormal accounts. The risk scoring model constructed by the method of the invention improves the timeliness ofclearing the abnormal accounts, reduces noise interferences caused by the abnormal accounts, and improves the calculation precision of many indicators of APPs.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

Commodity purchase prediction modeling method

InactiveCN107392644APracticalGuaranteed robustnessMachine learningMarketingPersonalizationPredictive modelling

The invention discloses a commodity purchase prediction modeling method. The method comprises the steps that a purchase record marking training sample is used to predict whether to purchase or not; a sliding window commodity purchase sample is constructed; commodity purchase features are designed based on a time preference; a gradient improvement decision tree algorithm is used for training prediction; after the sample and the features are constructed, feature processing and selection need to be performed, and then the features are input into the gradient improvement decision tree algorithm for training prediction; and feature selection indicators include feature value distribution and relevancy, feature information gains, feature calling frequency, influences of feature knockout, etc. Ordering is performed on feature importance by integrating the indicators, and redundant features with low importance are eliminated. According to the method, a sliding window sample construction method and a feature system based on the time preference are proposed, the accuracy of a commodity purchase prediction model is effectively improved, and the method is used for realizing commodity personalized recommendation in a big data background to precisely recommend proper commodities to a user at a proper time and a proper place.

Owner:SOUTH CHINA UNIV OF TECH

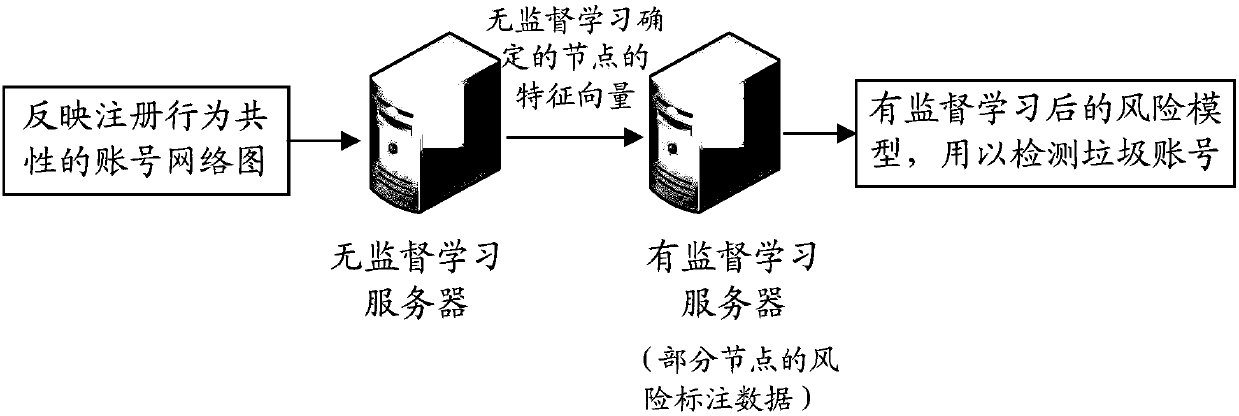

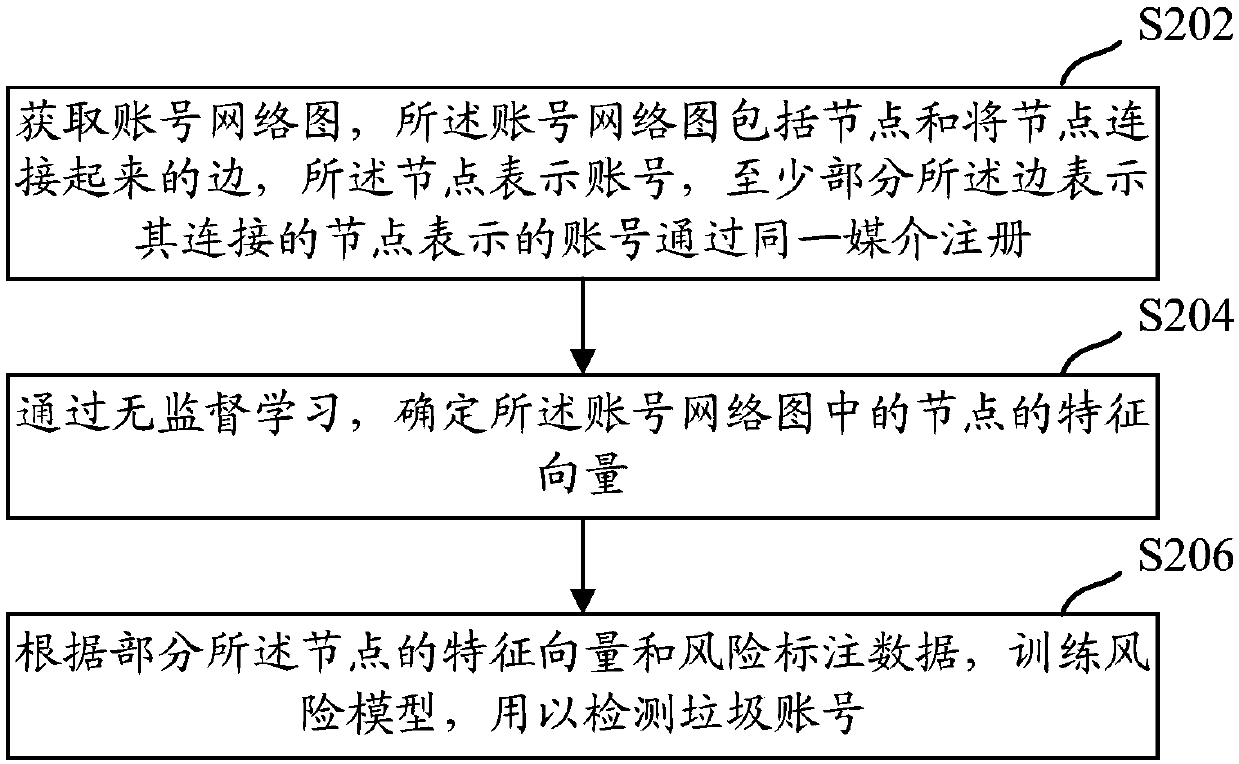

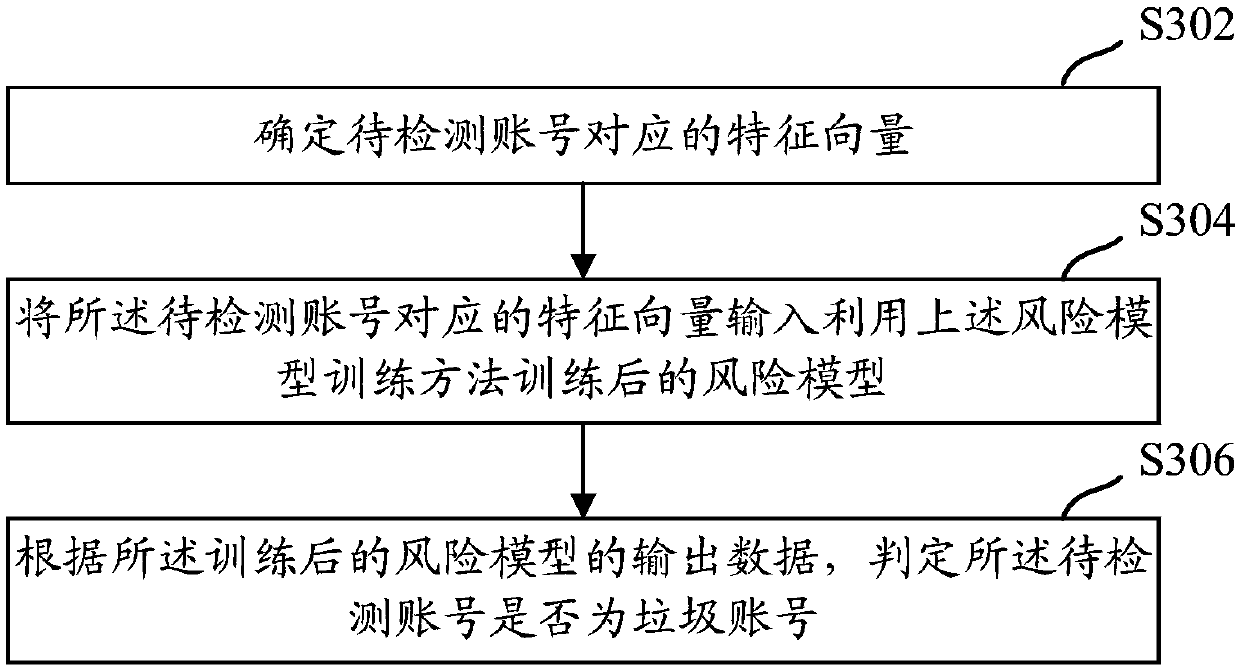

Risk model training and junk account detection method, device and equipment

ActiveCN108418825AEfficient and Accurate TrainingTraining accuratelyData switching networksNODALFeature vector

The embodiment of the invention discloses a risk model training and junk account detection method, device and equipment. The risk model training method comprises the following steps: acquiring an account network diagram, wherein the account network diagram includes nodes and edges connecting the nodes, the nodes represent accounts, and at least part of the edges represent that the accounts represented by the nodes connected with the at least part of the edges are registered through the same medium; determining a characteristic vector of the nodes through unsupervised learning; and training a risk model through supervised learning according to the determined characteristic vector. According to the risk model training method provided by the invention, a junk account is detected by using thetrained risk model, wherein the risk model is a GBDT (Gradient Boosting Decision Tree) classifier and the like.

Owner:ADVANCED NEW TECH CO LTD

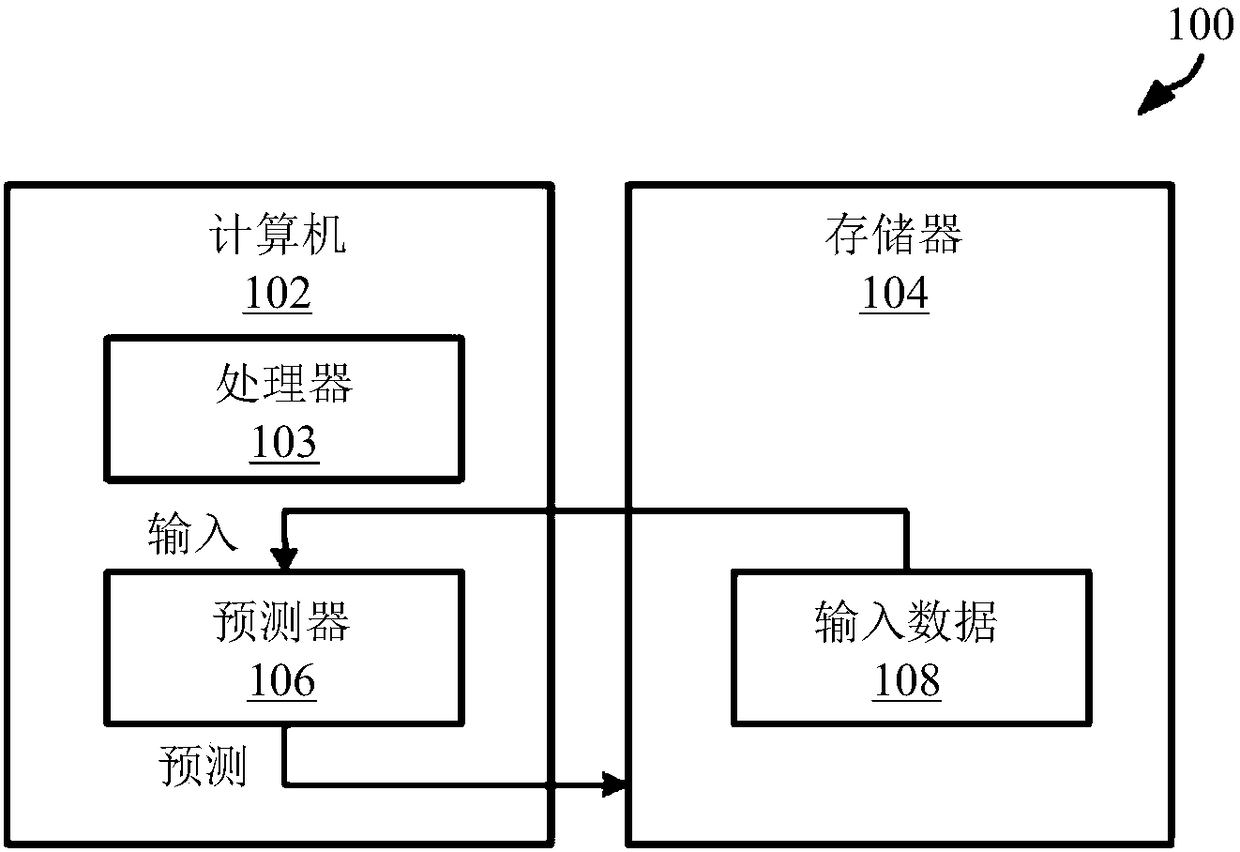

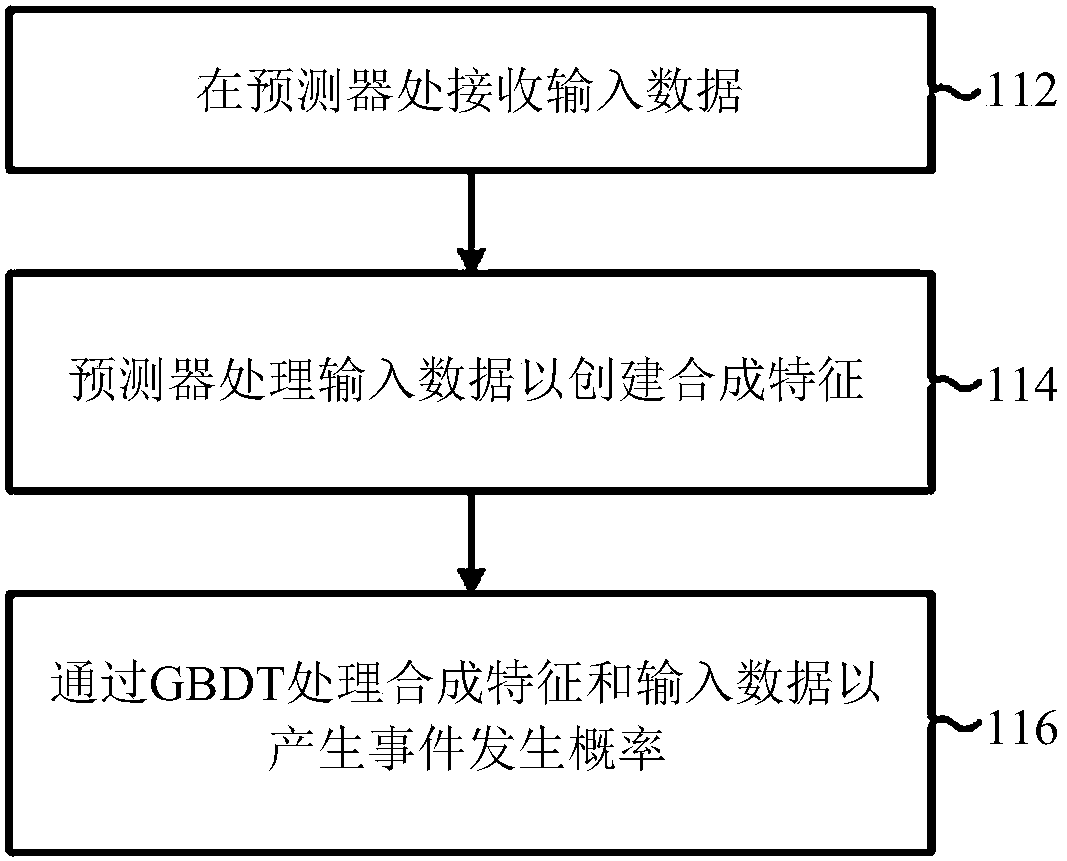

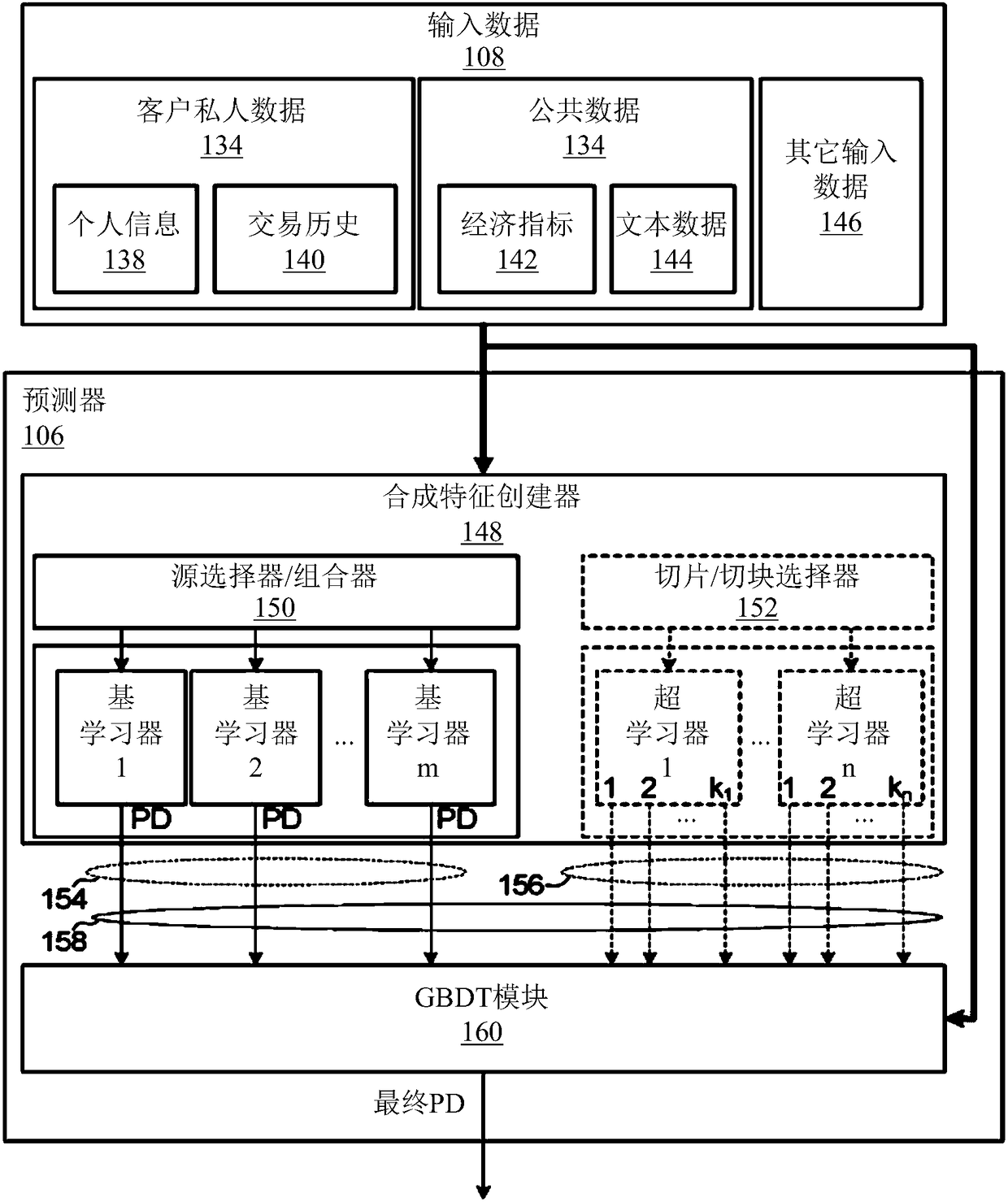

System and method for prediction using synthetic features and gradient boosted decision tree

A machine learning system and method are disclosed in which a plurality of synthetic features are created from input data, and a gradient boosted decision tree algorithm is then executed by the computer to process both the synthetic features and at least some of the input data to produce an output that is a probability.

Owner:HUAWEI TECH CO LTD

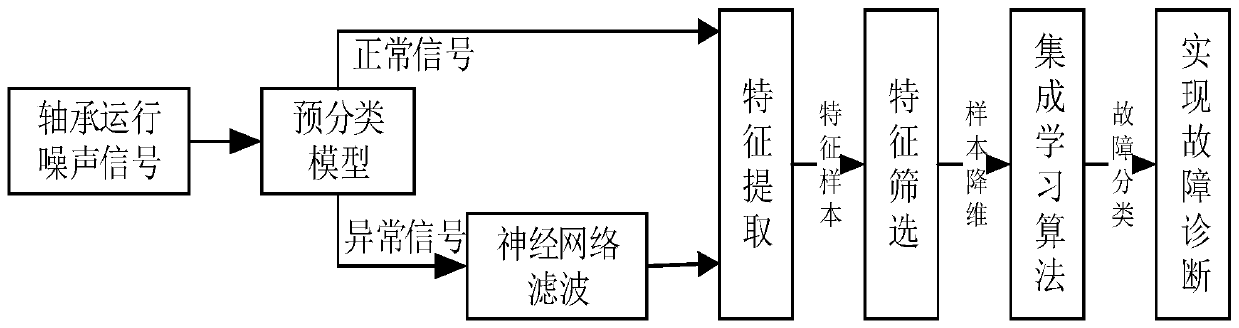

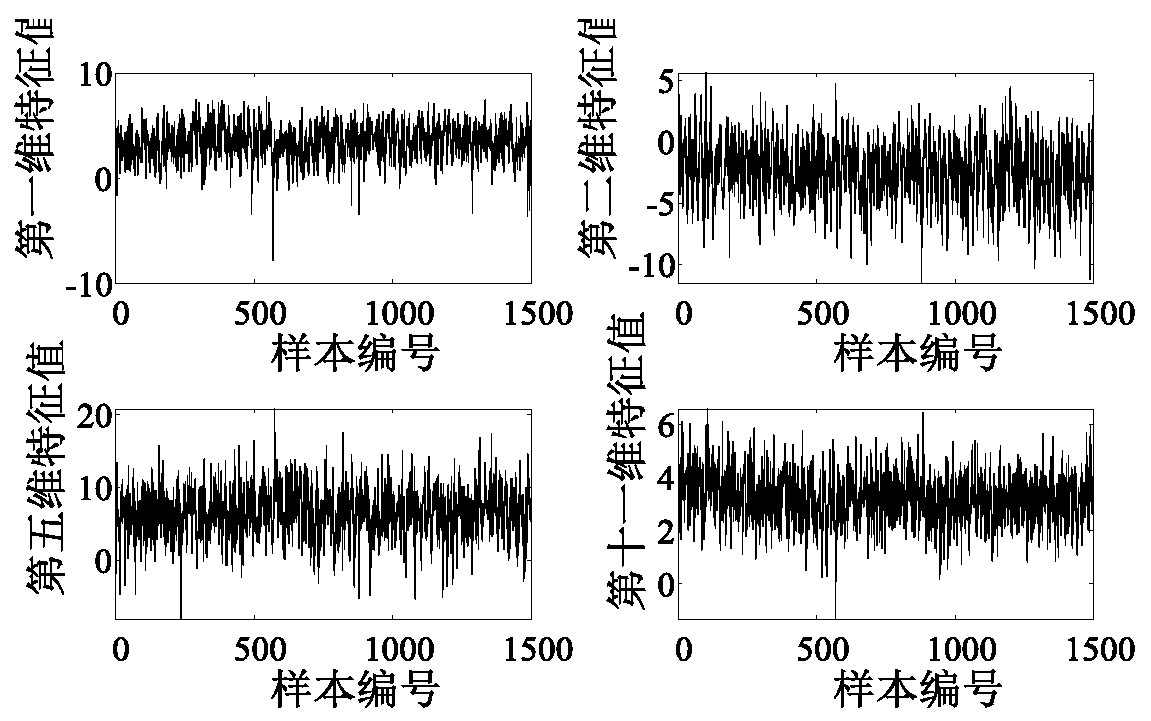

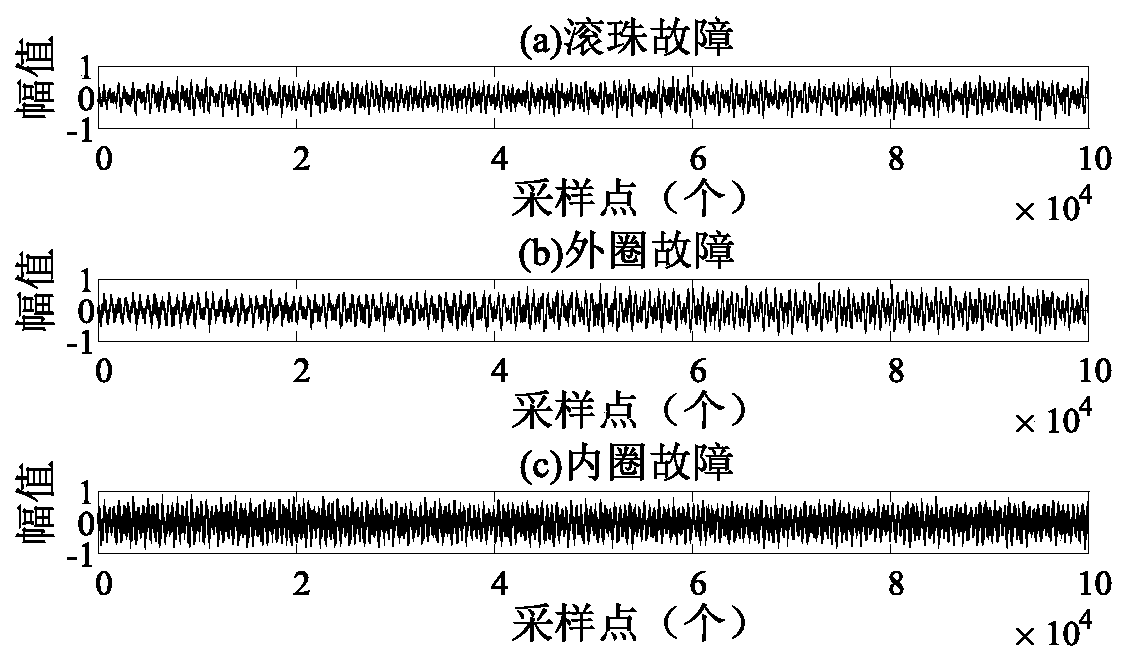

Noise diagnosis algorithm for rolling bearing faults of rotary equipment

ActiveCN110132598AEffective diagnosisEfficient detectionMachine part testingCharacter and pattern recognitionPrincipal component analysisEngineering

The invention discloses a noise diagnosis algorithm for rolling bearing faults of rotary equipment. Firstly, a sound pick-up device collects running noise signals of a rolling bearing, and the signalsare subjected to preliminary fault judgment through a bearing normality and anomaly pre-classification model based on an anomaly detection algorithm; secondly, according to a fault pre-judgment result, the abnormal signals (the faults occur) pass through a neural network filter to filter normal components in the signals of the bearing, the output net abnormal signals are connected to a subsequentfeature extraction module, and the normal signals (no faults occur) are directly connected to the feature extraction module; the feature extraction module extracts Mel-cepstrum coefficients (MFCC) ofthe signals to serve as eigenvectors, feature reconstruction is carried out by utilizing a gradient boosted decision tree (GBDT) to form composite eigenvectors, and principal component analysis (PCA)is used for carrying out dimensionality reduction on features; and finally, feature signals are input into an improved two-stage support vector machine (SVM) ensemble classifier for training and testing, and at last, high-accuracy fault type diagnosis is achieved. According to the algorithm, the bearing faults can be effectively detected and relatively high fault identification accuracy is kept;and the algorithm has relatively high effectiveness and robustness for detection and classification of the bearing faults.

Owner:CHINA UNIV OF MINING & TECH

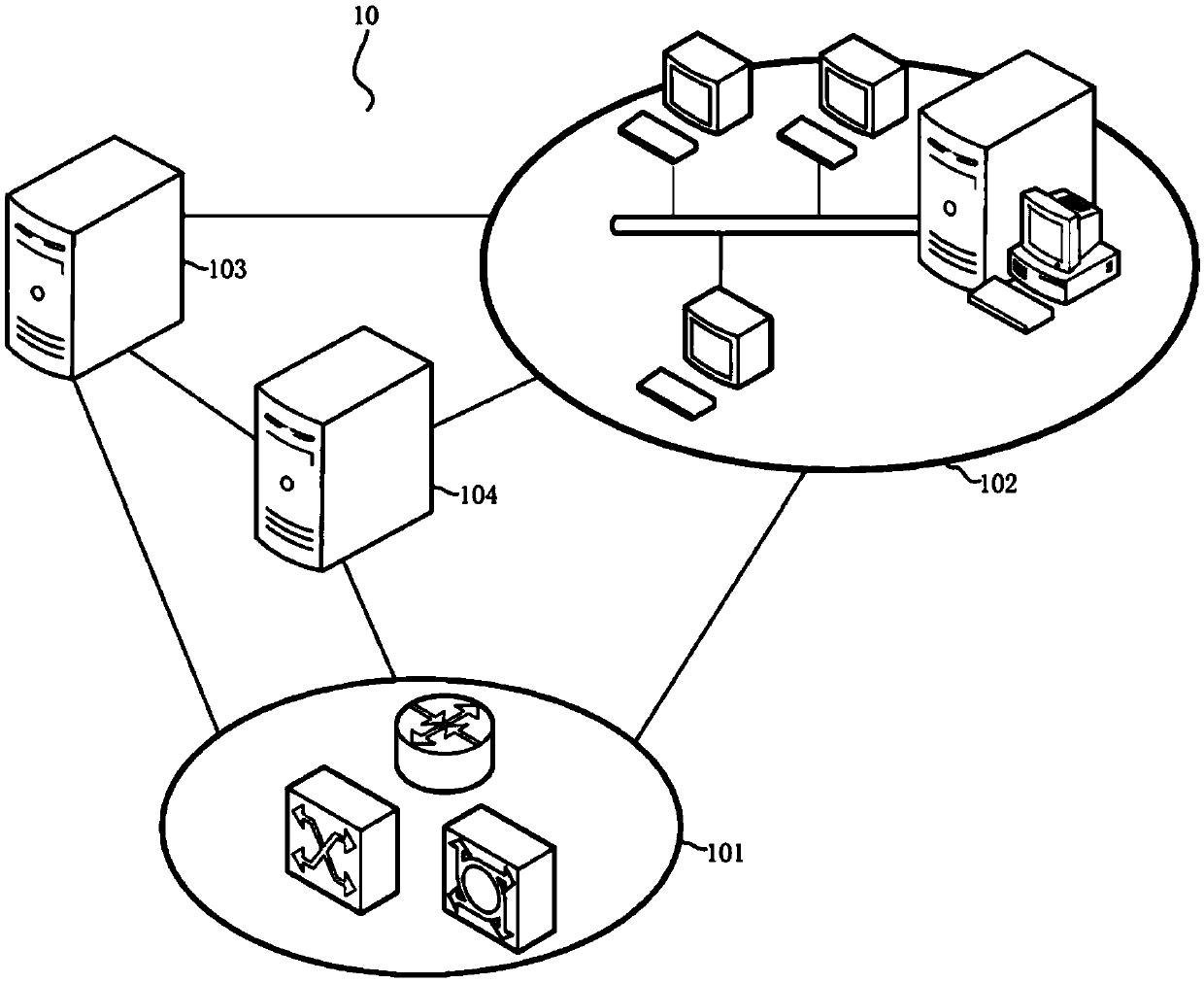

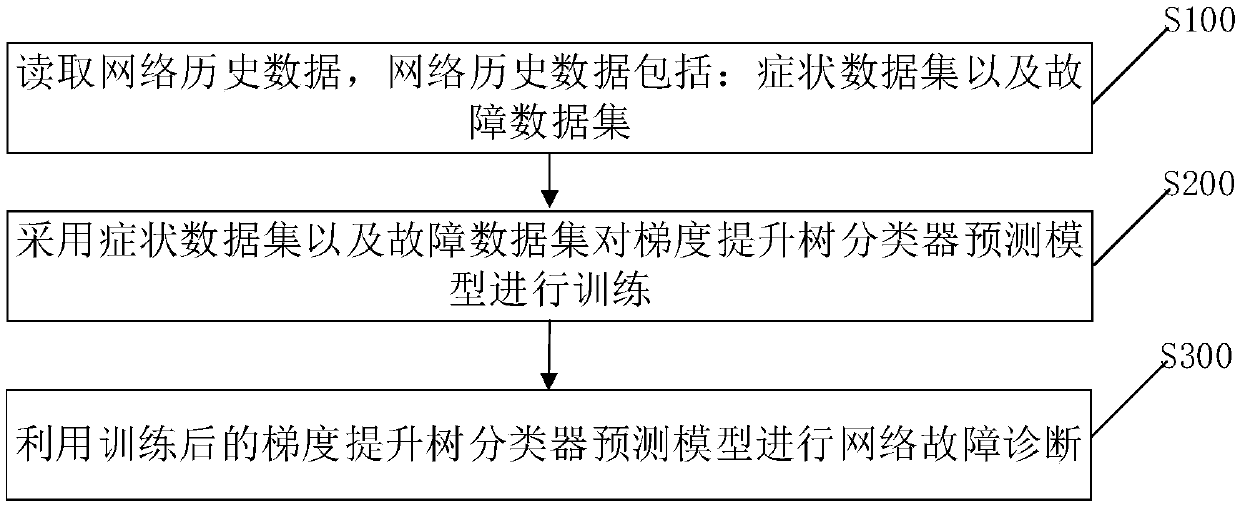

Network fault diagnosis methods and systems

InactiveCN109617715AImprove the accuracy of fault diagnosisReduce troubleshooting timeData switching networksData setDiagnosis methods

The invention provides network fault diagnosis methods and systems. A gradient boosting decision tree classifier prediction model is trained through adoption of a symptom data set and a fault data setin network history data. Network fault diagnosis is carried out through utilization of the trained gradient boosting decision tree classifier prediction model. Network fault diagnosis precision can be effectively improved. Network fault diagnosis time can be effectively reduced. The method and the system are applicable to diversified production scenes.

Owner:CHINA UNITECHS

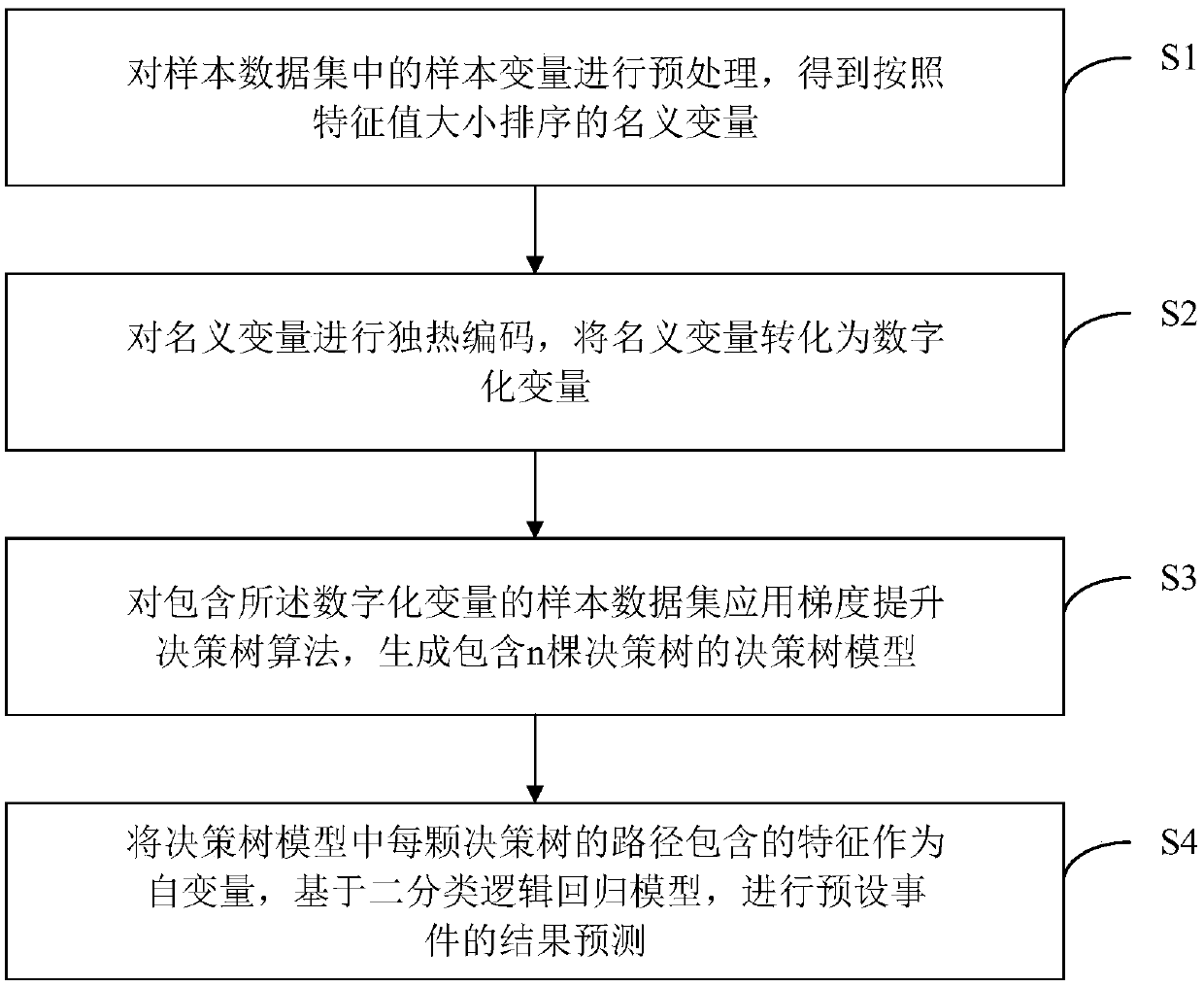

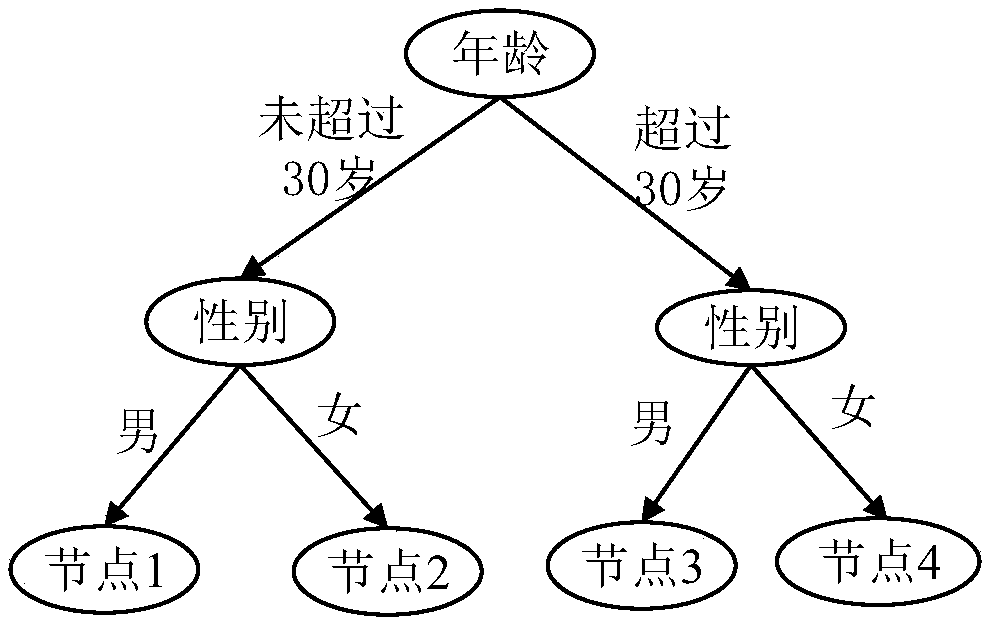

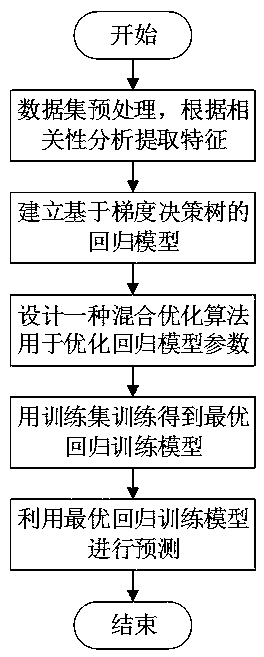

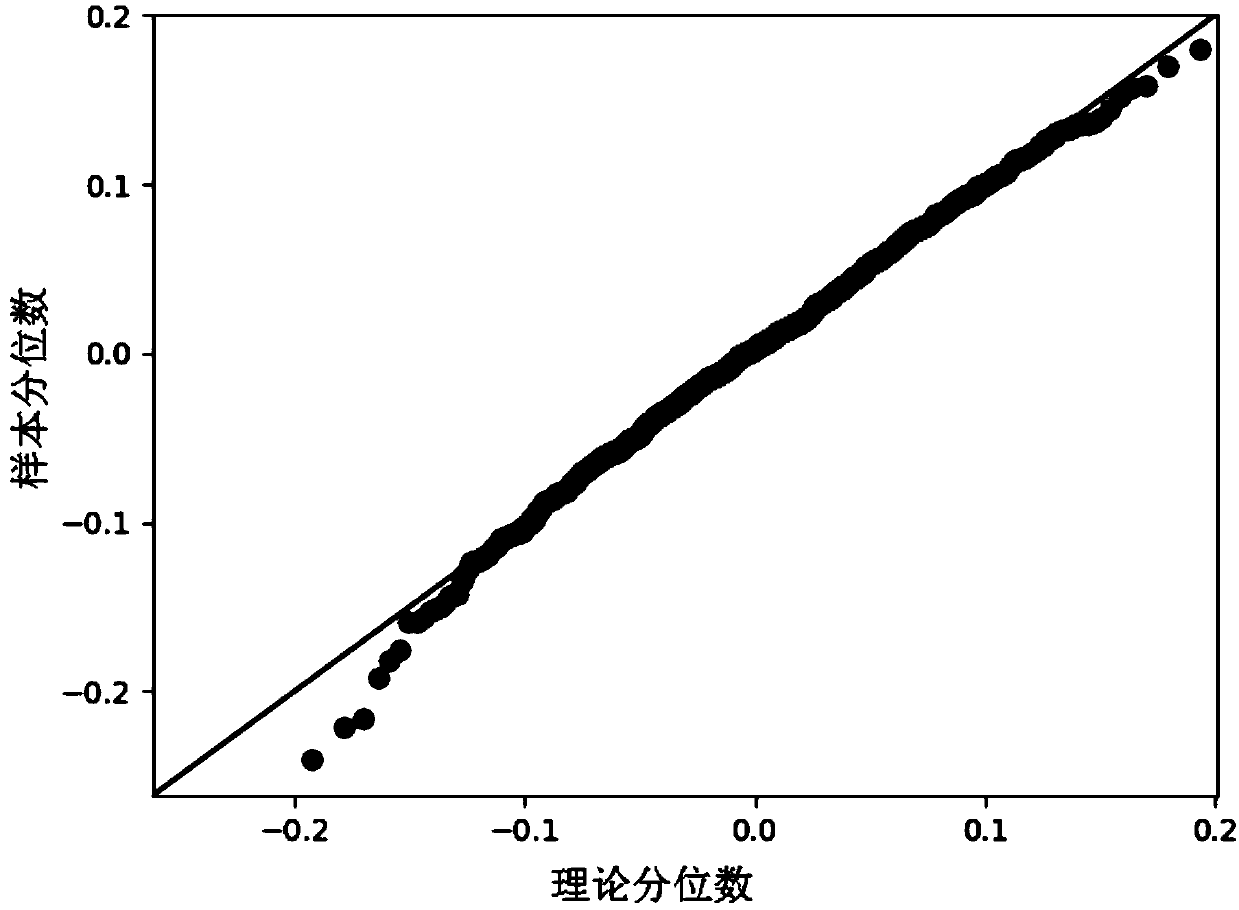

Data evaluation method and device, terminal equipment and storage medium

The invention discloses a data evaluation method and device, terminal equipment and a storage medium. The method comprises the following steps of carrying out preprocessing on sample variables in a sample data set in order to obtain nominal variables which are ordered according to the sizes of characteristic values; carrying out one-hot coding on the nominal variables which are ordered according to the sizes of the characteristic values, and converting the nominal variables into digital variables; applying a gradient lifting decision-making tree algorithm to the sample data set containing thedigital variables; generating a decision tree model comprising n decision trees; and acquiring combined characteristics by adopting the gradient lifting decision-making tree algorithm. The accuracy ofprediction of the combined characteristics of sample data is improved, and the efficiency of acquisition of the combined characteristics is also improved, so that the combined characteristics are used as input characteristics of a binary logic regression model to carry out prediction of a preset event result, and thus the complexity and the uncertainty of manual searching of the characteristics are avoided, the prediction accuracy of the sample data for the preset event result is improved, and meanwhile, the accuracy and the efficiency of sample data evaluation are also improved.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

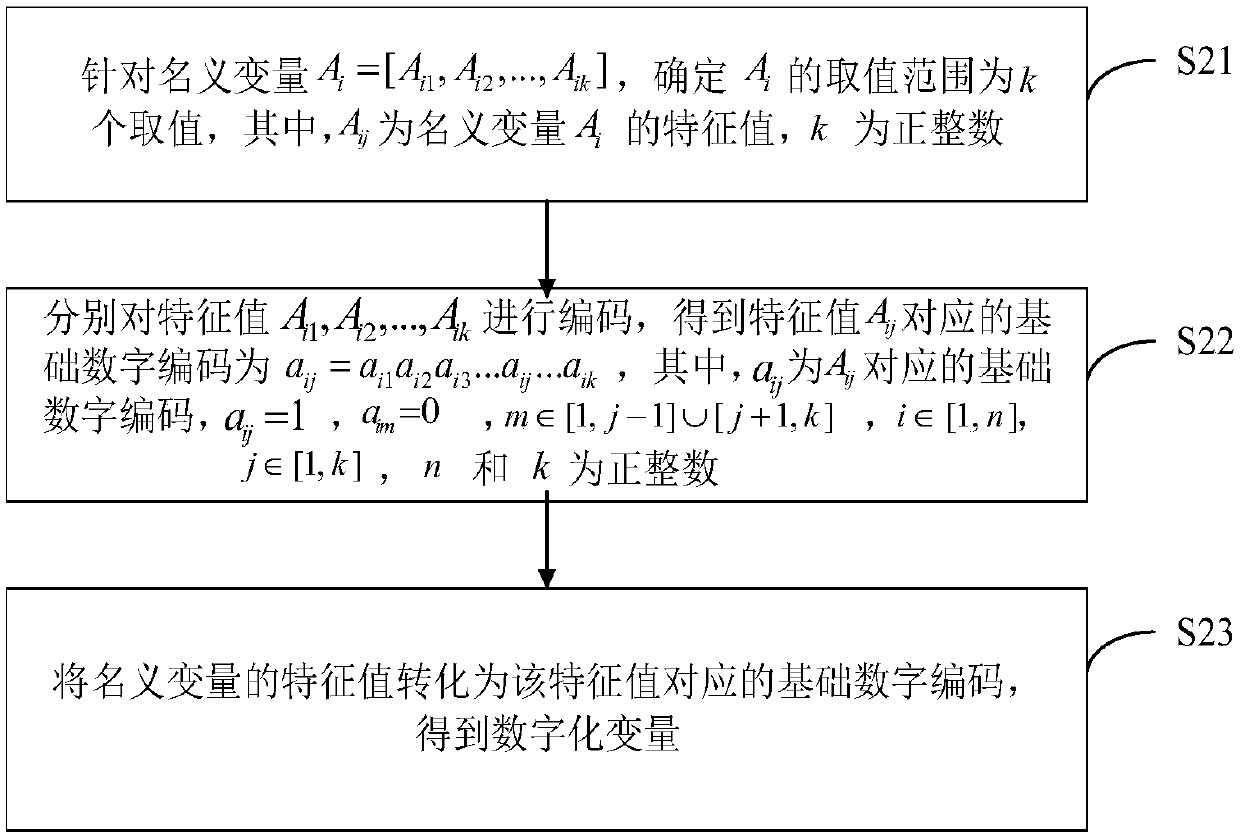

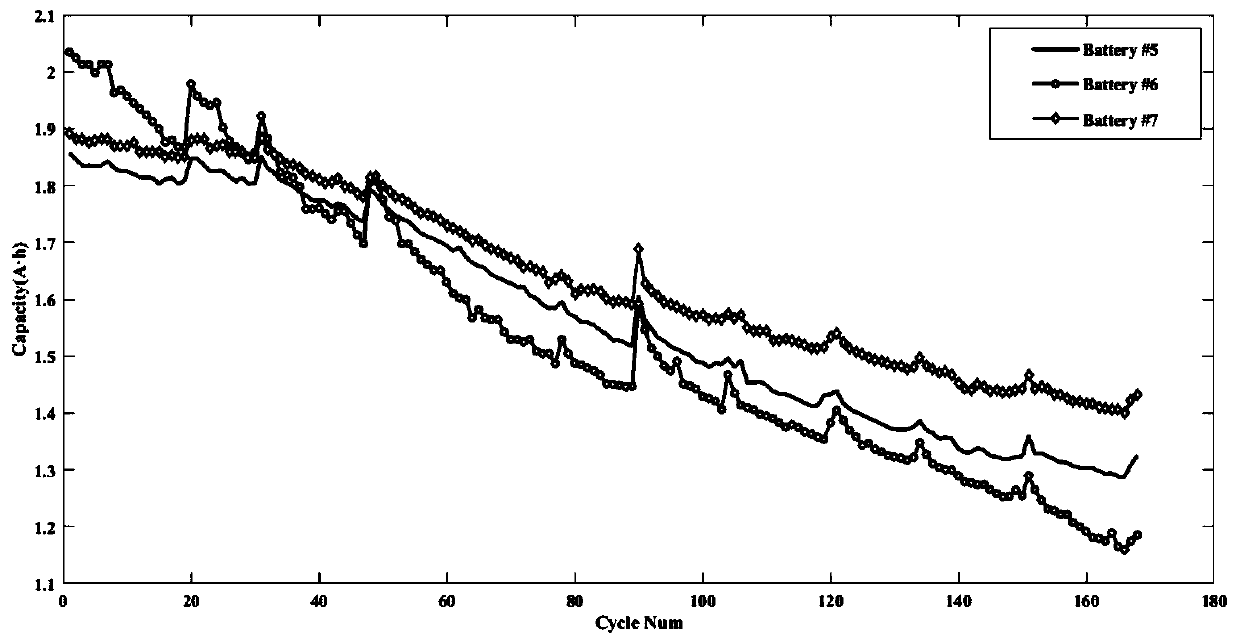

Lithium battery state-of-health estimation method

InactiveCN111044928AExcellence and StabilityHeight and stabilityElectrical testingAlgorithmEngineering

The invention relates to a lithium battery state-of-health estimation method, which comprises the following steps of: selecting battery capacity as a state variable, and extracting a plurality of characteristics as input and output data of a subsequent model according to correlation analysis so as to simulate an aging process of a lithium battery; dividing the sample data into a training set and atest set, establishing a regression model based on a gradient boosting decision tree, performing parameter optimization on the regression model, and performing sample training to obtain a mixed algorithm regression training model; and estimating the state-of-health of the lithium battery under the test set by using the mixed algorithm regression training model. The lithium battery state-of-health estimation method has the advantages of high precision, high generalization ability and the like, and can precisely and effectively estimate the state-of-health of the lithium battery.

Owner:FUZHOU UNIV

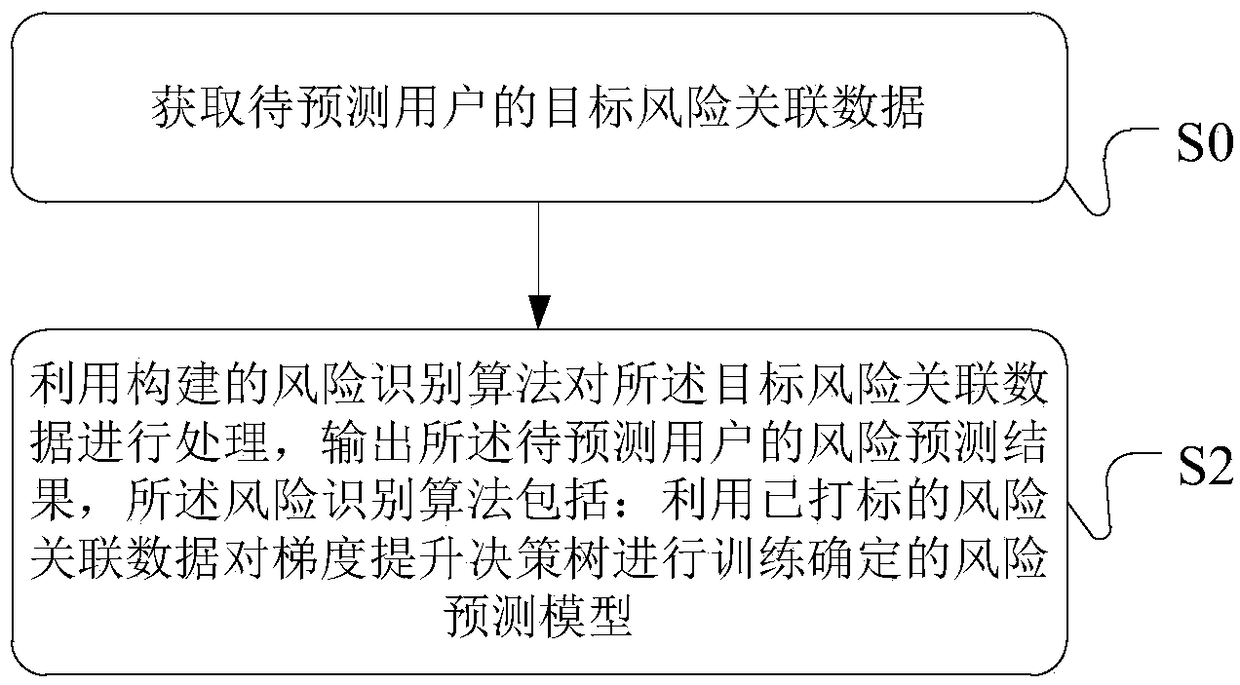

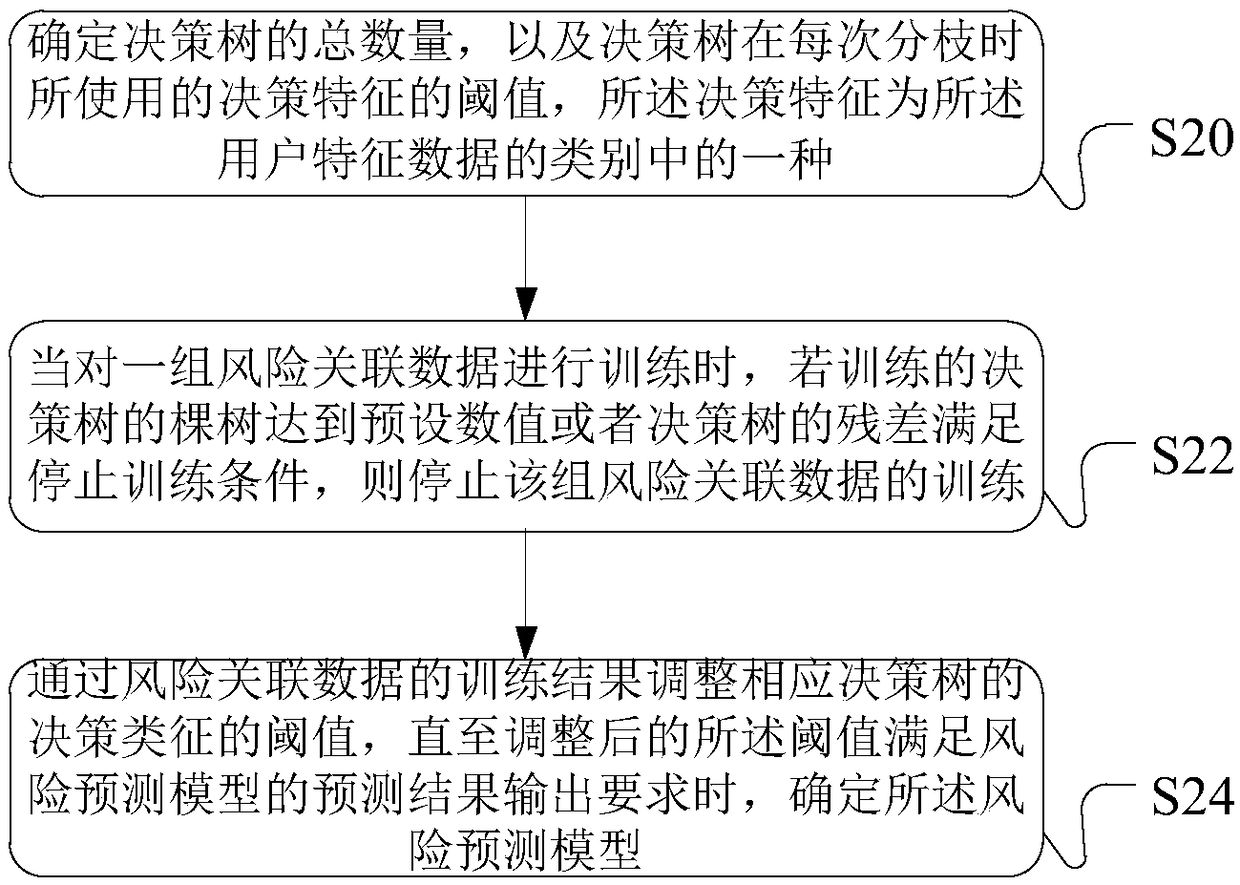

Processing method and device and processing equipment for insurance service risk prediction

InactiveCN108665175AImprove service experienceImprove accuracyFinanceCharacter and pattern recognitionService experienceLinear model

The embodiment of the invention discloses a processing method and device and processing equipment for insurance service risk prediction. According to the method, the gradient boosted decision tree canbe pre-used to construct a risk prediction module, and the risk prediction module can be trained by using marked risk associated data related to an insurance service; when the risk prediction moduletraining reaches prediction requirements, the risk prediction module can be used for online risk prediction, insurance service risk prediction is carried out on a to-be-tested user, and a prediction result is output. The provided method can reasonably effectively use multidimensional nonlinear variables in the insurance service; the risk prediction module based on a nonlinear relationship of the gradient boosted decision tree can have good compatibility of linear and nonlinear variables; compared with a conventional linear module, the accuracy of a prediction result is markedly improved, the deficiency of the conventional linear module is effectively remedied, and the service experience of the insurance service is improved.

Owner:ADVANCED NEW TECH CO LTD

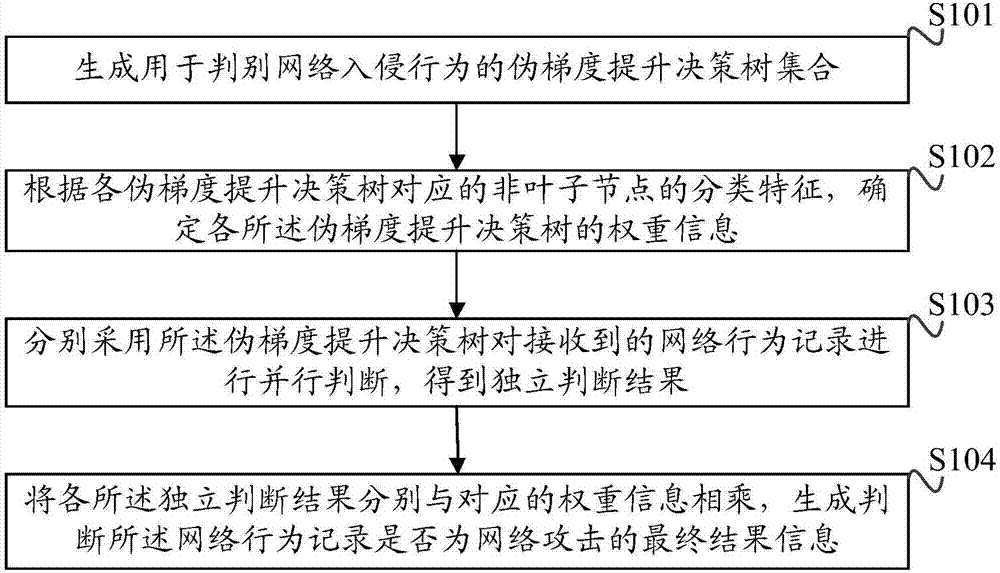

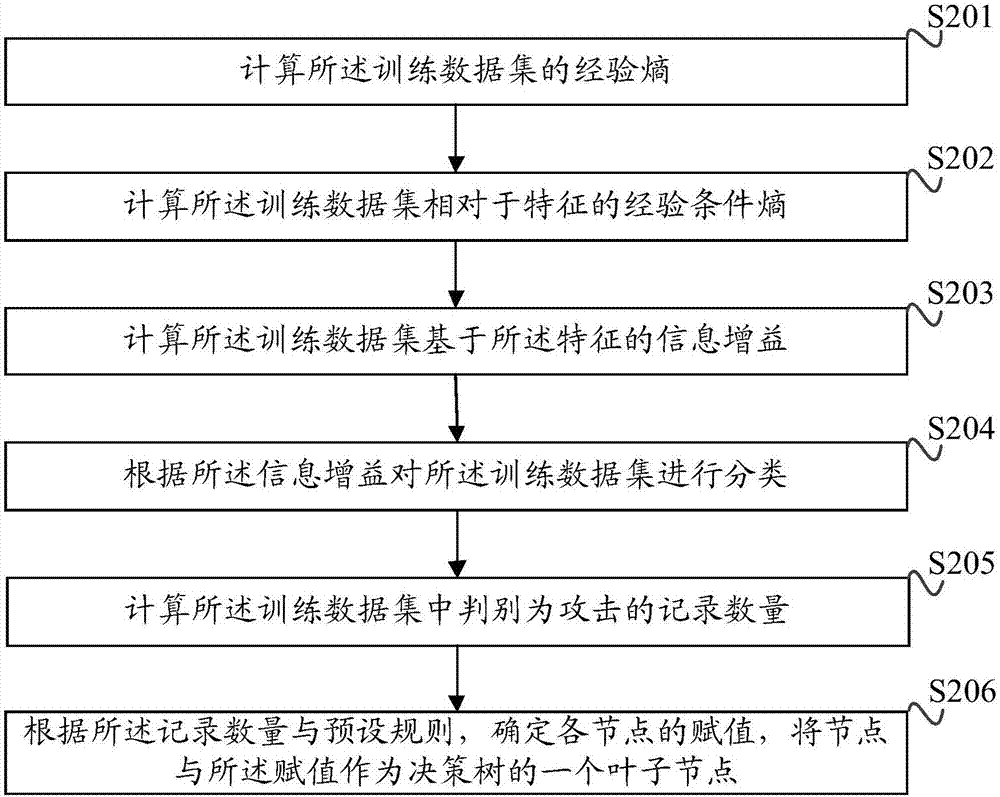

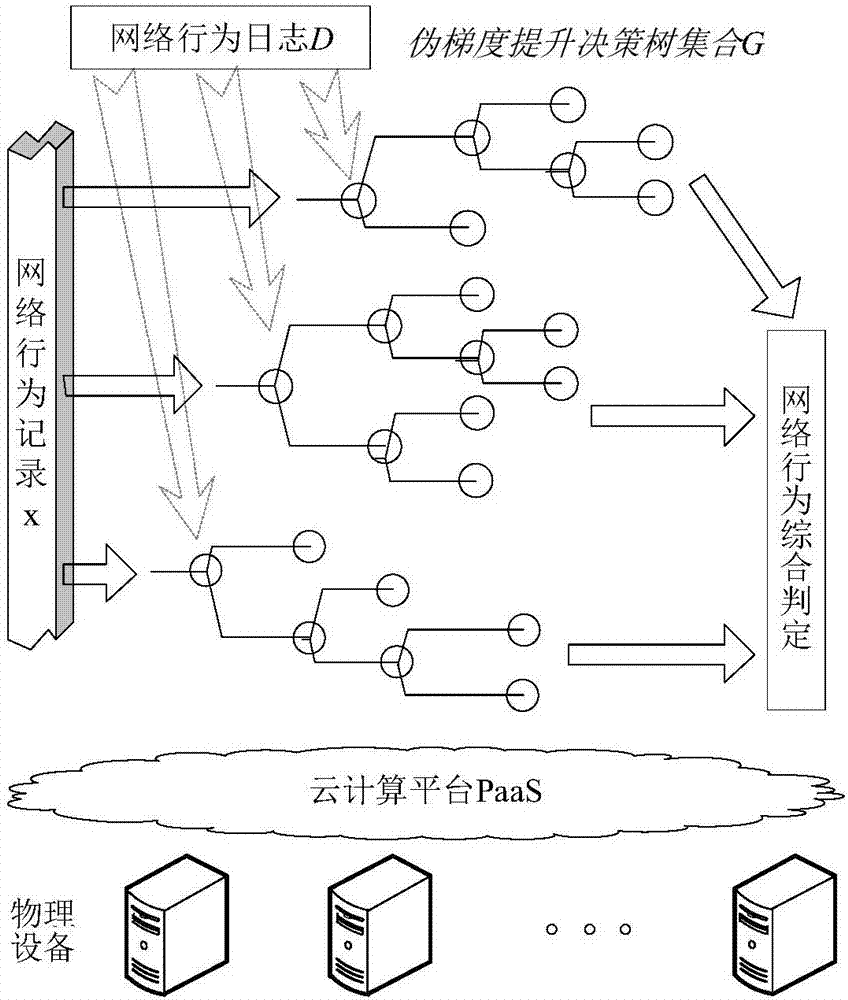

Cloud-computing oriented network intrusion detect method and system

ActiveCN106899440AImprove dynamic update operation speedImprove real-time performanceData switching networksNetwork behaviorNetwork attack

The invention discloses a cloud-computing oriented network intrusion detect method. The method comprises the steps of generating a pseudo-gradient promotion decision-making tree set for judging network intrusion behaviors; determining weight information of pseudo-gradient promotion decision-making trees according to classification features of non-leaf nodes corresponding to the pseudo-gradient promotion decision-making trees; carrying out parallel judgment on received network behavior records through adoption of the pseudo-gradient promotion decision-making trees, thereby obtaining independent judgment results; and multiplying the independent judgment results by the corresponding weight information, thereby generating final result information for judging whether the network behavior records are network attacks or not. The method and the system are characterized in simplicity, legibility, high distinguishing precision and high smart comprehensive processing capability. The pseudo-gradient promotion decision-making tree can be generated in a distributed parallel mode under a cloud computing environment. The dynamic update operation speed of the decision-making threes is improved, and the timeliness and accuracy of detecting new-type intrusion events by an IDS are improved.

Owner:SUZHOU UNIV

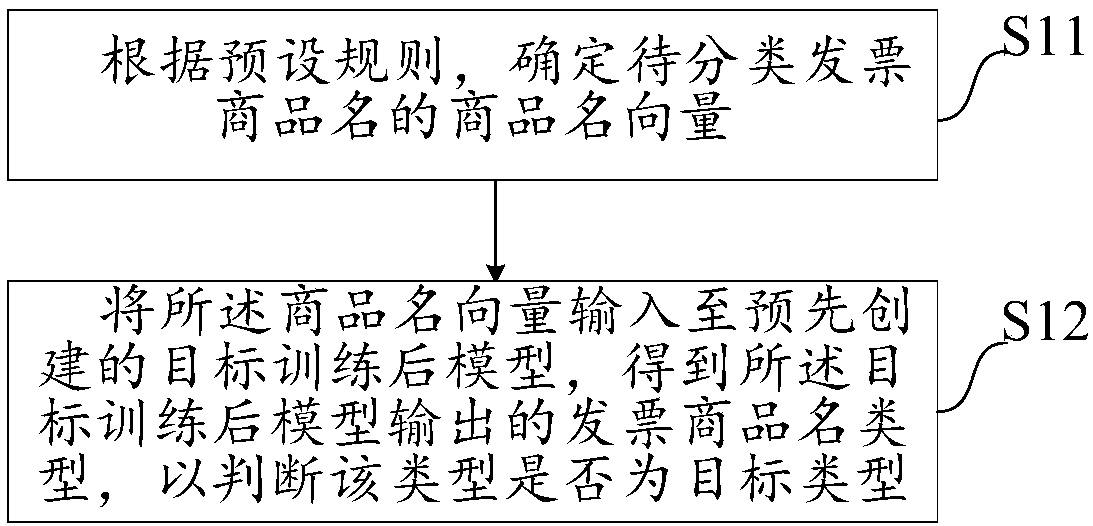

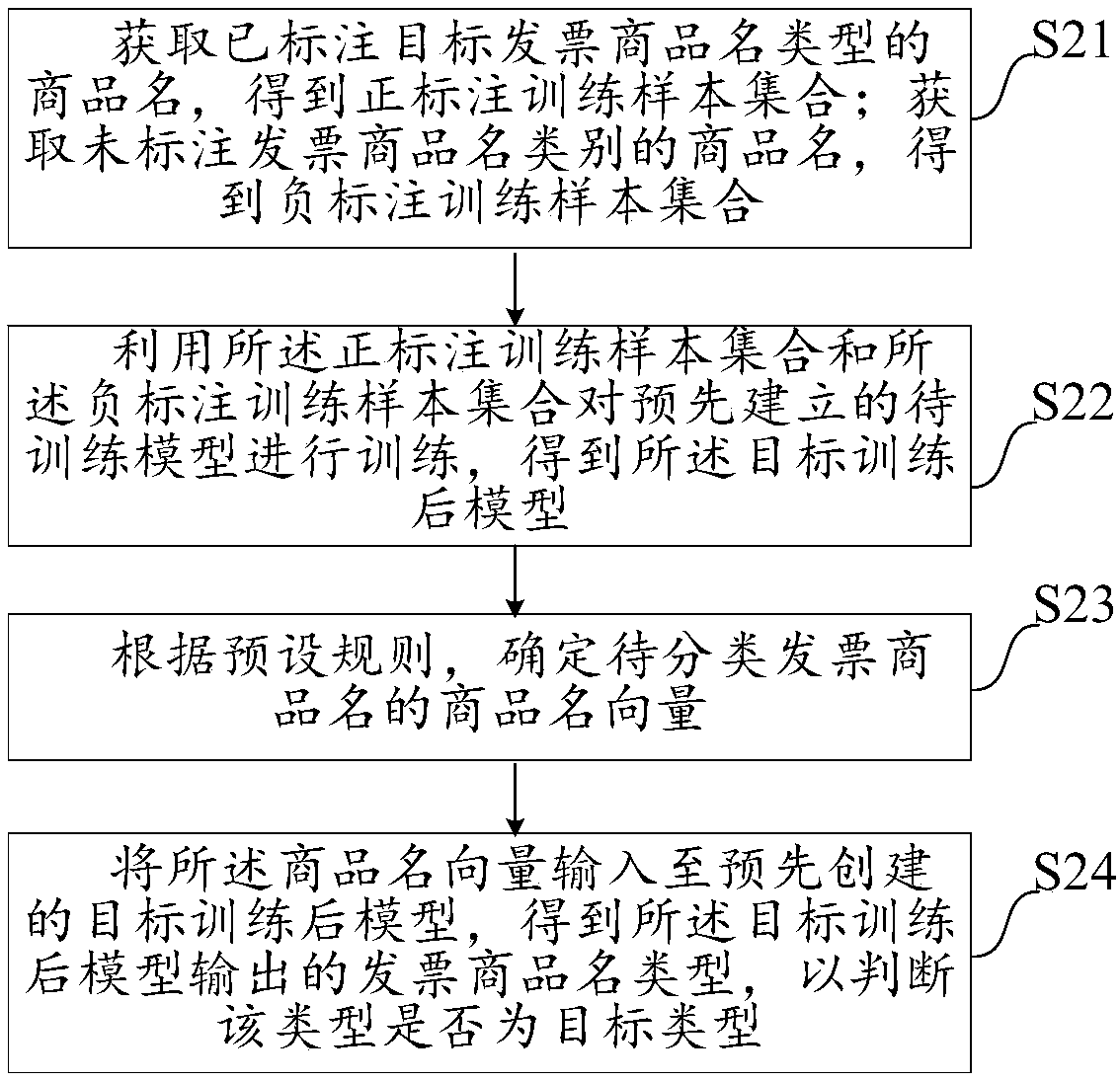

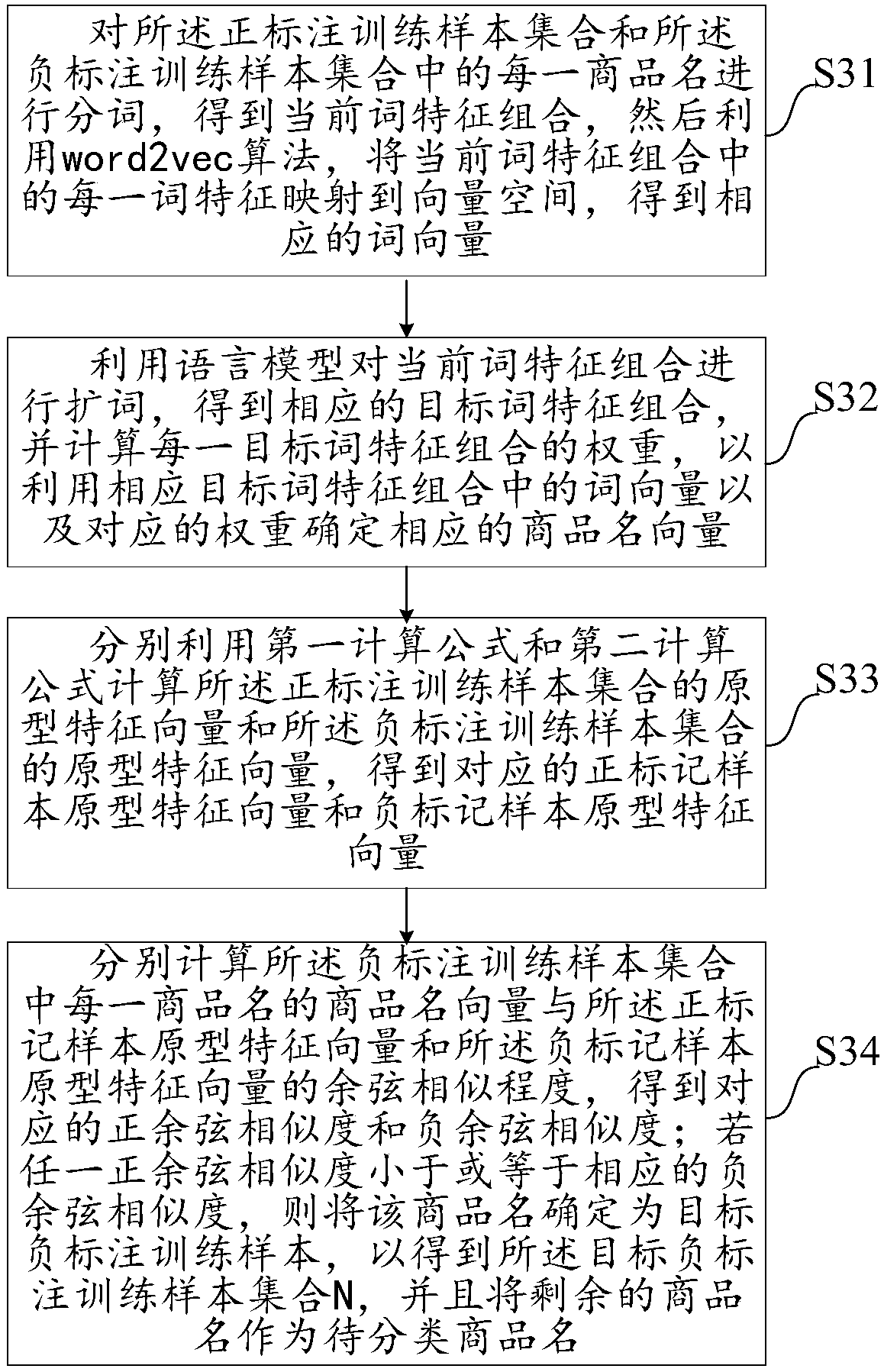

Invoice trade name classification method, system and equipment and computer readable storage medium

InactiveCN107871144AImprove accuracyReduce dependenceCharacter and pattern recognitionRocchio algorithmAlgorithm

The application discloses an invoice trade name classification method, system and equipment and a computer readable storage medium. The method comprises the following steps: determining the trade namevector of a to-be-classified invoice trade name based on preset rules; inputting the trade name vector to a pre-created target trained model to obtain an invoice trade name type output by the targettrained model, for judging if the type is a target type, wherein the target trained model is obtained by pre-utilizing target training samples to train a to-be-trained model created by the Extreme Gradient Boosting (XGBoost) model based on the gradient boosting decision tree, and the target training samples include training samples marked with target invoice trade name types and training samples obtained based on Rocchio algorithm and not marked with the trade name types. By using the invoice trade name classification method provided by the invention, the labour cost can be reduced and the accuracy of classification results can be obviously improved.

Owner:SERVYOU SOFTWARE GRP

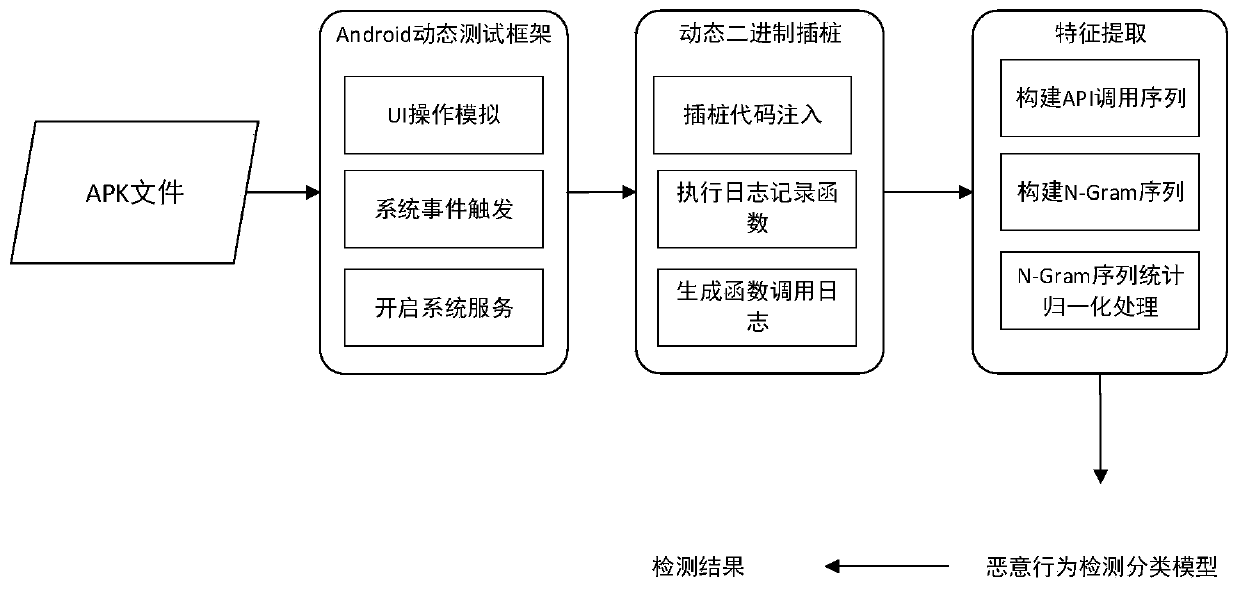

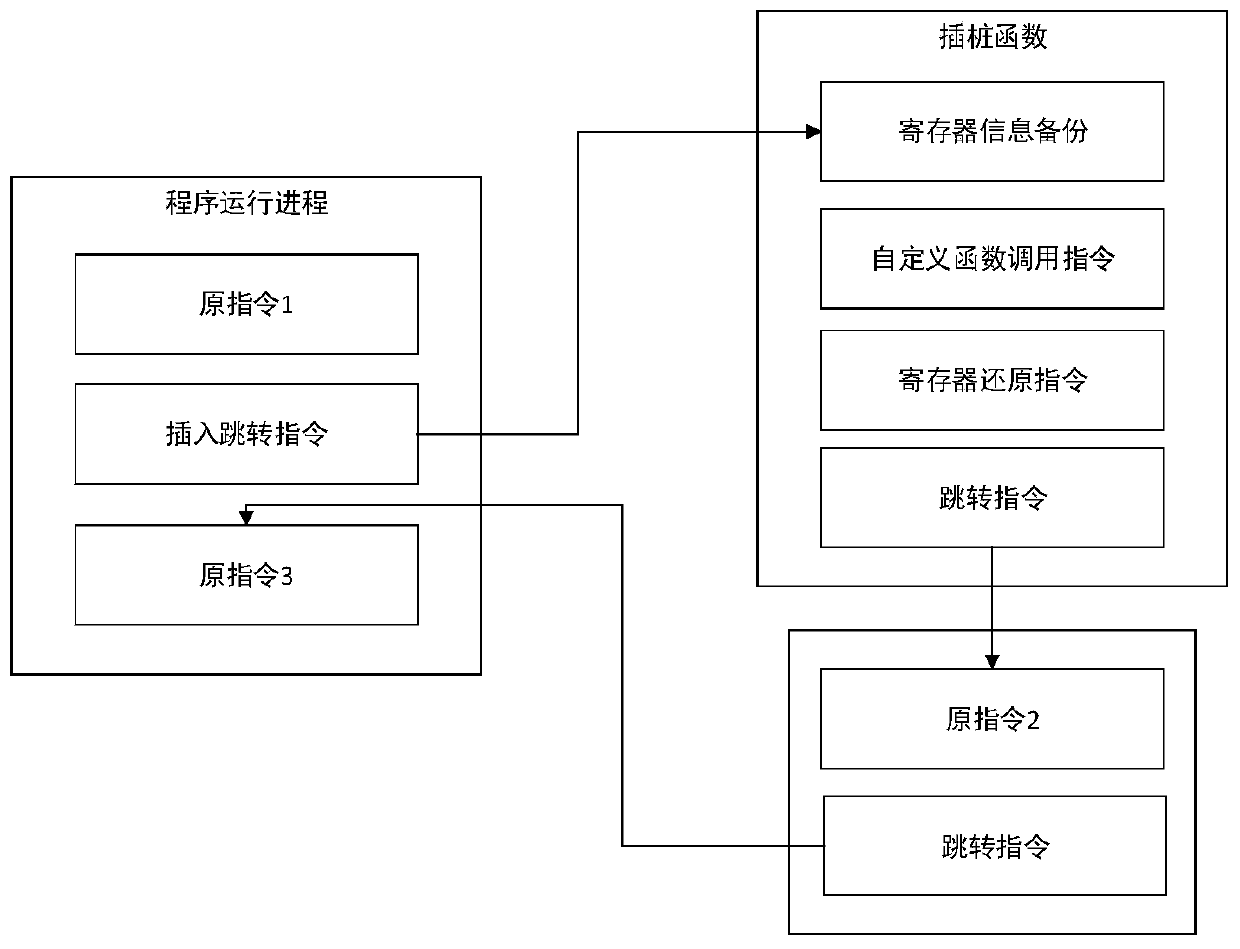

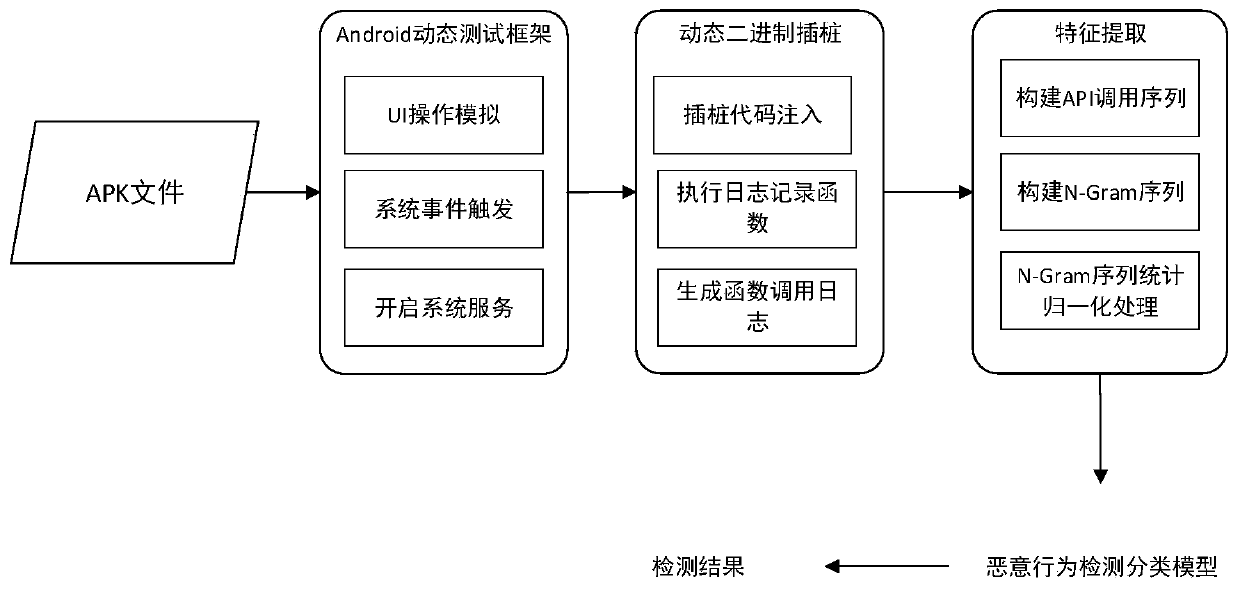

Android malicious behavior dynamic detection method based on binary dynamic instrumentation

InactiveCN109992968AImprove detection efficiencyImprove accuracyPlatform integrity maintainanceSoftware simulation/interpretation/emulationGranularityDynamic instrumentation

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

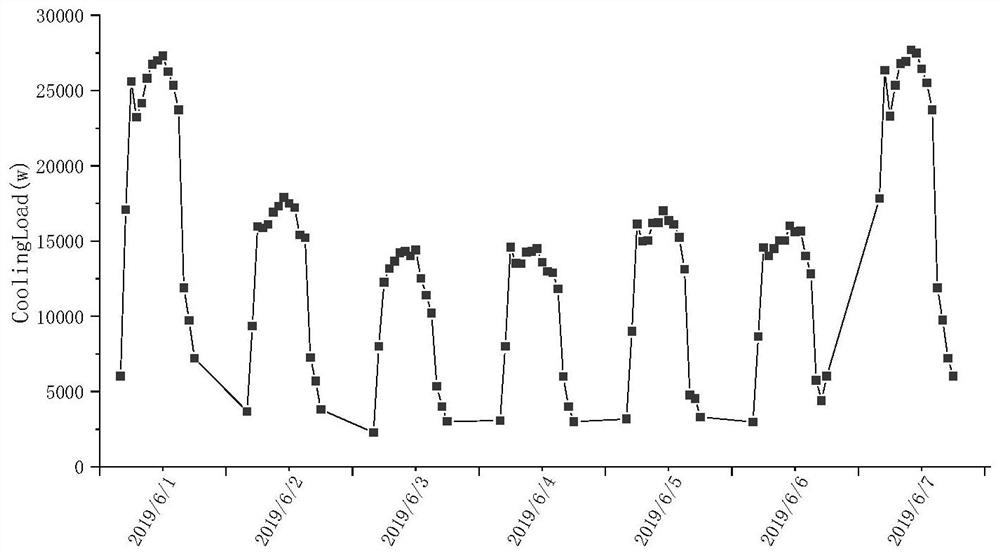

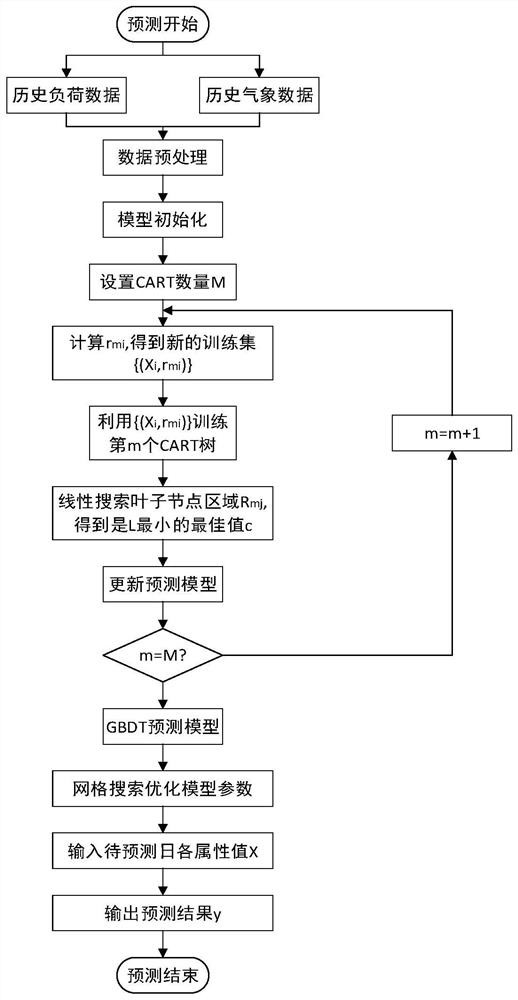

Shopping mall building air conditioner cooling load prediction method based on GBDT, storage medium and equipment

PendingCN112001439AFlexible handlingSolve the problem of requiring a large amount of data trainingForecastingCharacter and pattern recognitionSimulationEngineering

The invention discloses a shopping mall building air conditioner cooling load prediction method based on GBDT, a storage medium and equipment, and the method comprises: collecting cooling load data, and carrying out the normalization processing to serve as the cooling load energy consumption prediction; establishing a load prediction model based on a gradient lifting decision tree algorithm; inputting the preprocessed data into a prediction model for training, selecting a grid search-cross validation mode, and optimizing the three hyper-parameters with the maximum influence on the performanceof the GBDT model; establishing a final cold load prediction model by completing parameter optimization of the prediction model, and obtaining a predicted cold load curve according to the parameters and the structure of the prediction model; and evaluating the prediction performance of the prediction model, adopting the prediction error for evaluation, enabling the deviation between the true valueand the prediction value to form the prediction error, and completing mall building air conditioner cooling load prediction. The method has good prediction precision, universality and applicability,and is especially suitable for large public buildings with periodically changing cold loads.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

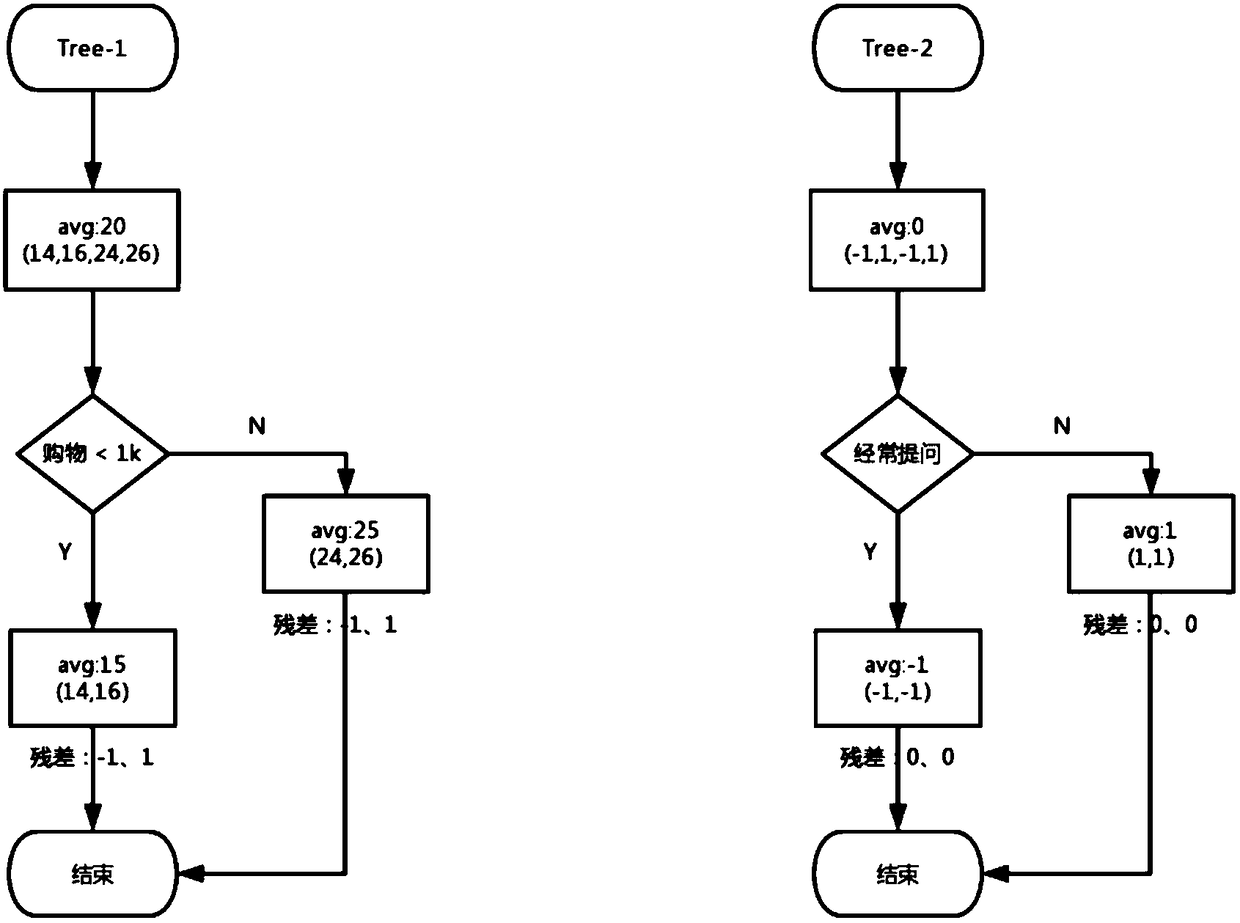

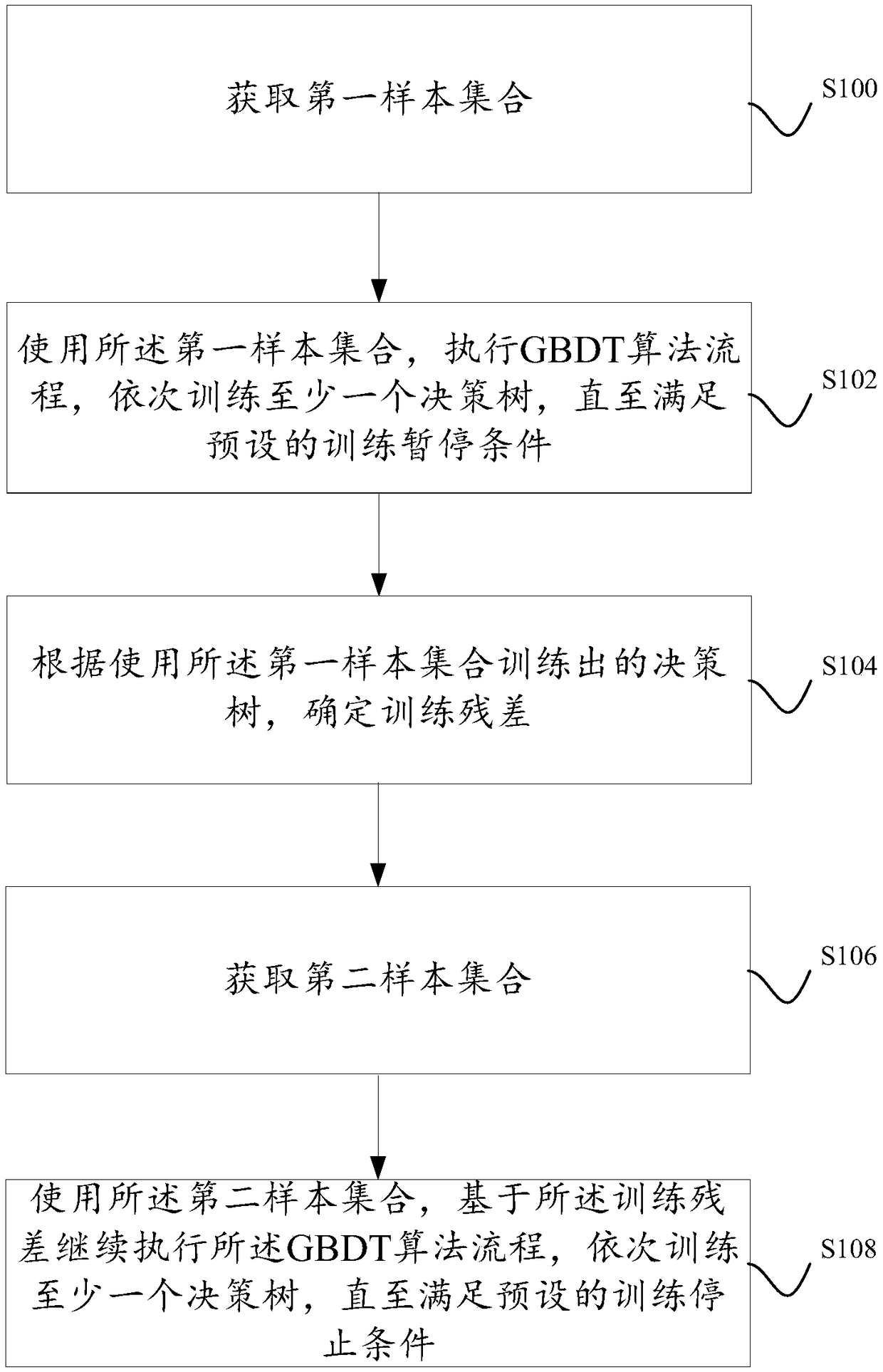

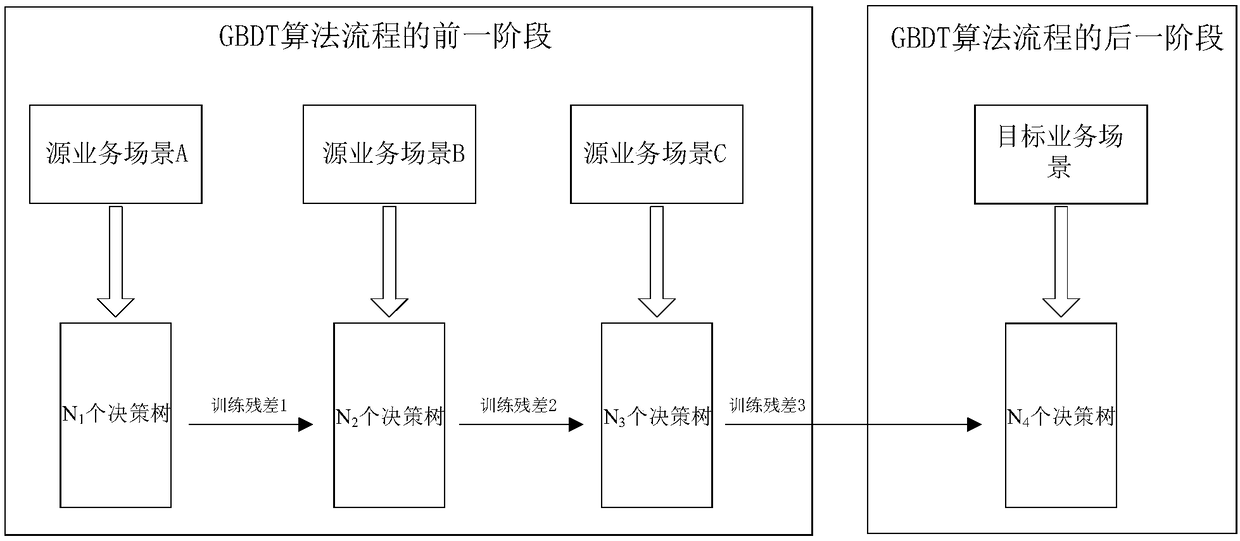

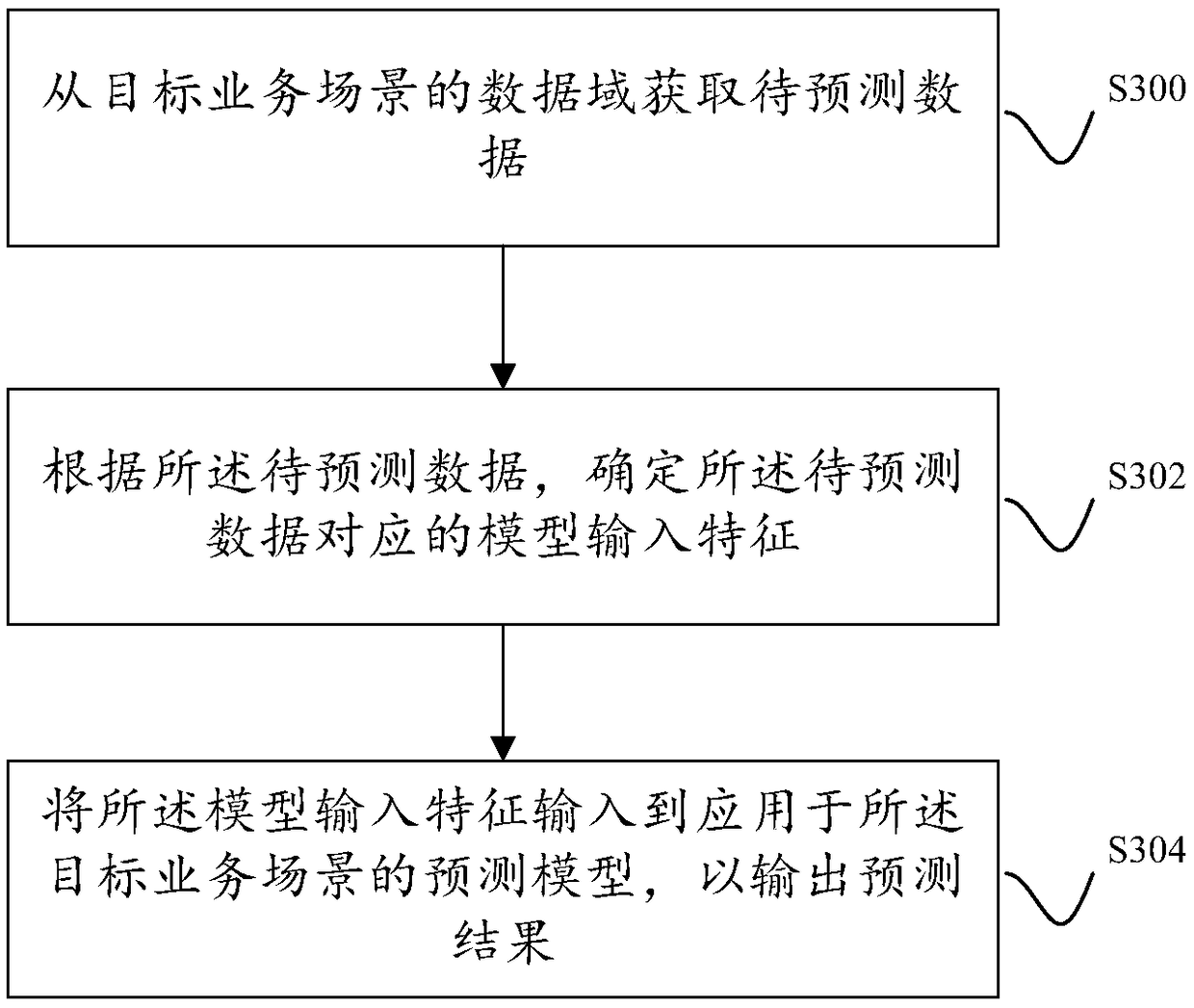

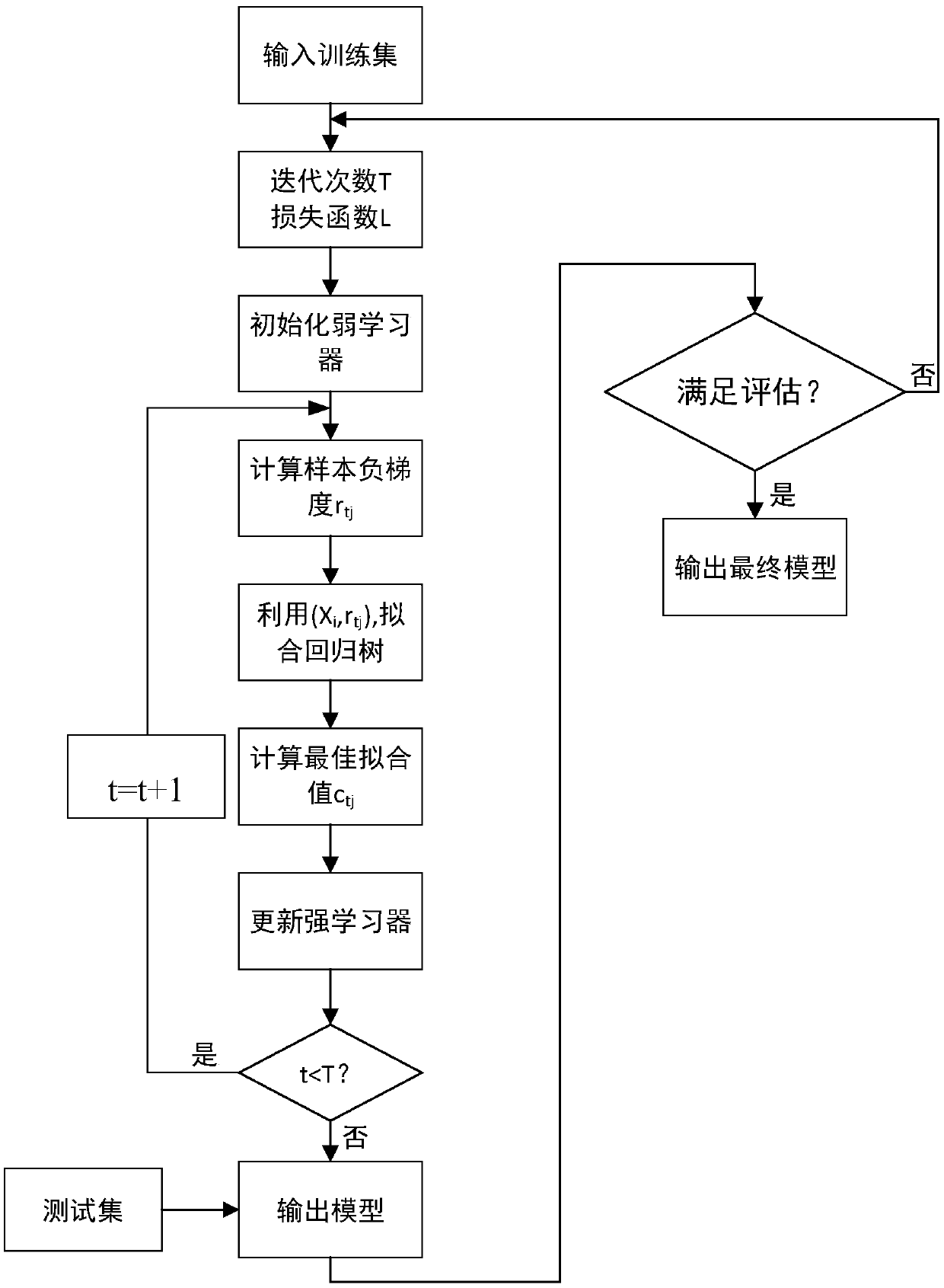

A method and apparatus for training a model based on a gradient lifting decision tree

InactiveCN109472296AThe effect is qualifiedExamples cannot be limitedEnsemble learningKernel methodsAlgorithmData domain

The invention discloses a model training method and a device based on a gradient lifting decision tree. A GBDT algorithm is divided into two phases. In the former phase, several decision trees are trained by obtaining labeled samples from the data domain of the business scenarios similar to the target business scenarios, and the training residuals generated after the training in the previous phaseare determined. At a later stage, that annotated sample are obtained from the data domain of the target business scenario, and a number of decision trees are continue to be trained based on the training residuals. Finally, the model applied to the target business scenario is actually integrated from the decision tree trained in the previous stage and the decision tree trained in the next stage.

Owner:ADVANCED NEW TECH CO LTD

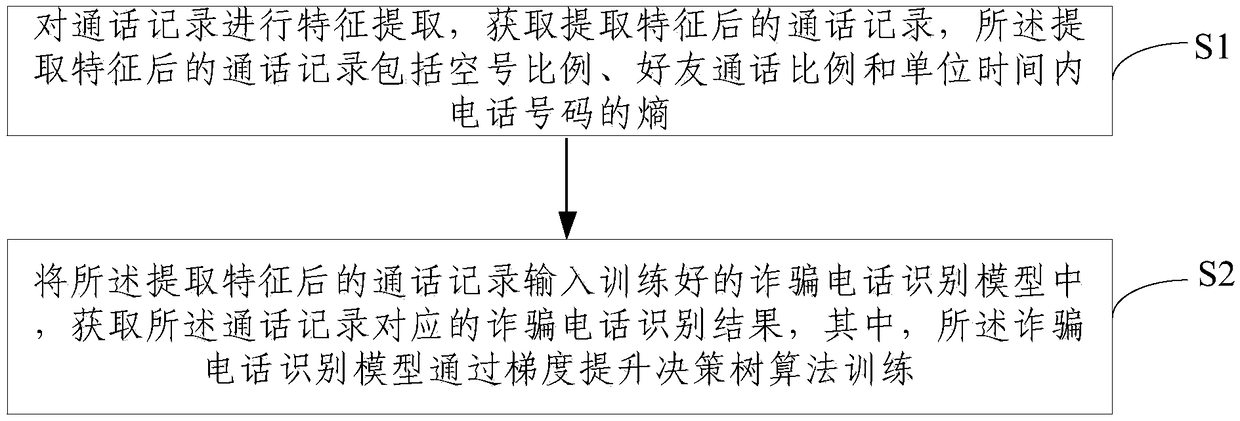

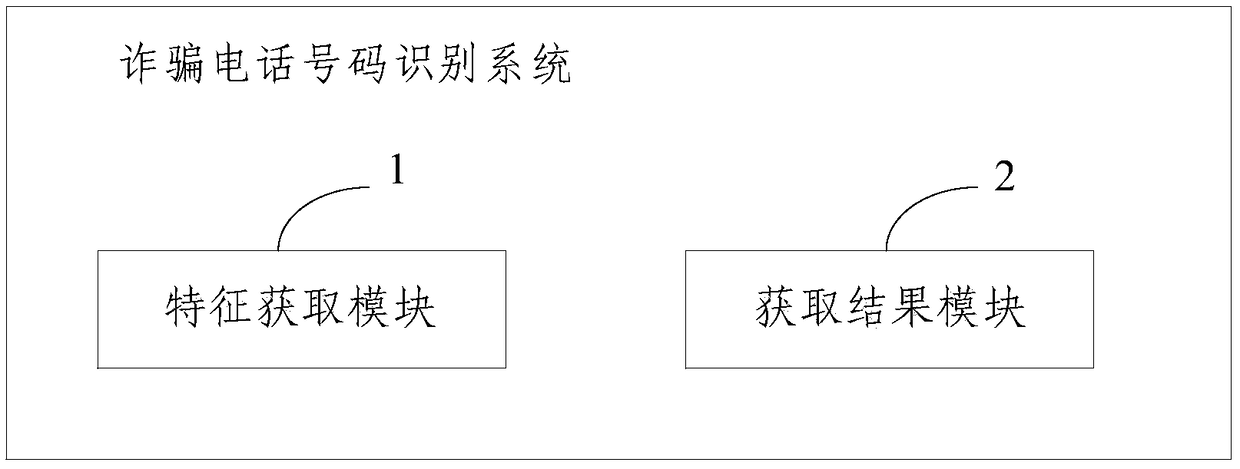

Fraudulent phone number identification method and system

ActiveCN108833720AIdentify meticulously and accuratelyAccurate identificationSupervisory/monitoring/testing arrangementsSecurity arrangementFeature extractionComputer science

The embodiment of the invention provides a fraudulent phone number identification method and system. The identification method comprises the following steps of carrying out characteristic extraction on a call record and obtaining the call record after characteristic extraction, wherein the call record after characteristic extraction includes a vacant number ratio, a friend call ratio, and the entropy of phone numbers in unit time; and inputting the call record after characteristic extraction into a trained fraudulent phone identification model, and acquiring a fraudulent phone identification result corresponding to the call record, wherein the fraudulent phone identification model is trained through a gradient lifting decision tree algorithm. By using the fraudulent phone number identification method and system, whether a phone number is a fraudulent phone number can be accurately identified; and through arranging the model trained through the gradient lifting decision tree algorithm,the fraudulent phone number can be precisely identified.

Owner:BEIJING UNIV OF POSTS & TELECOMM

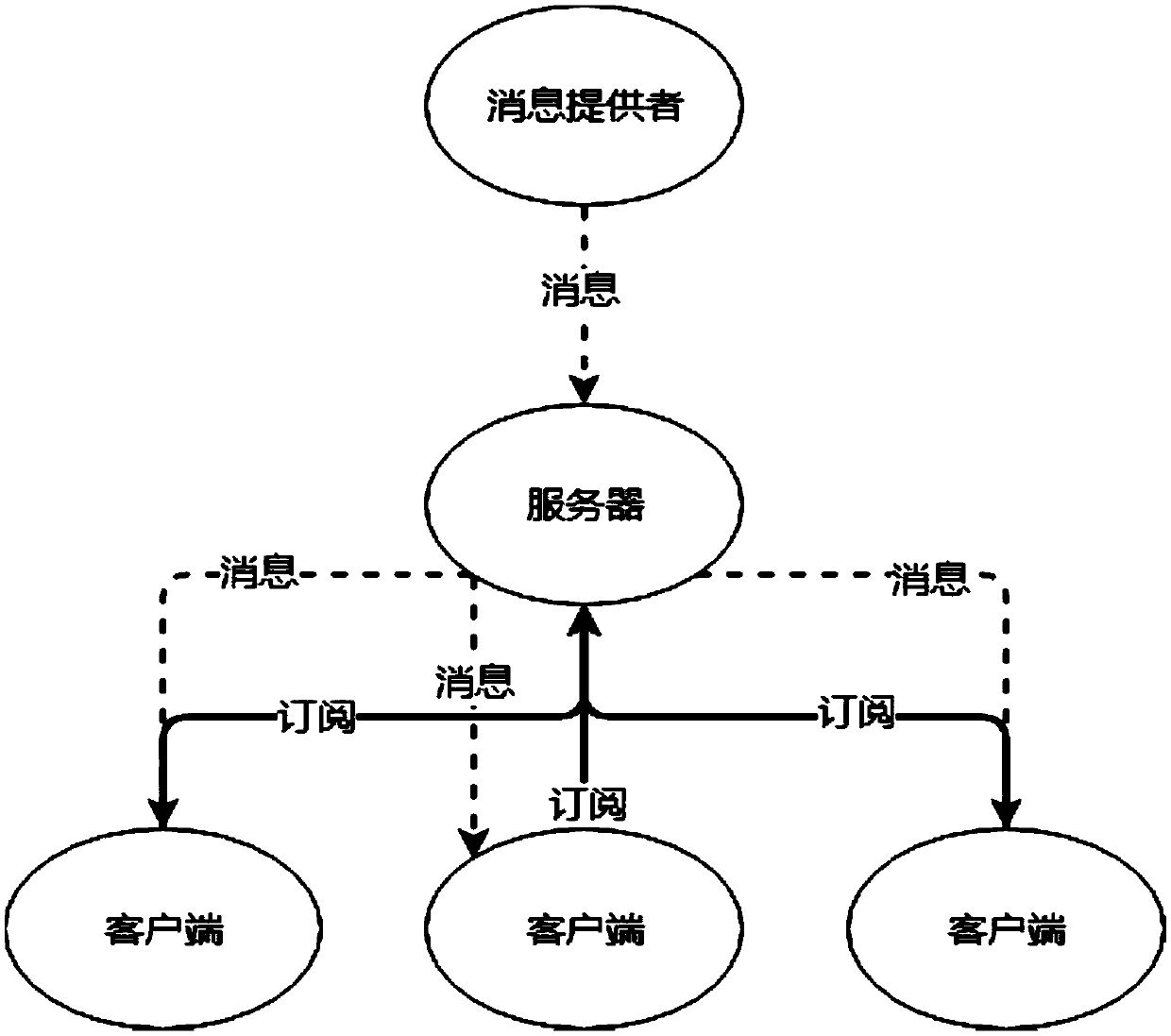

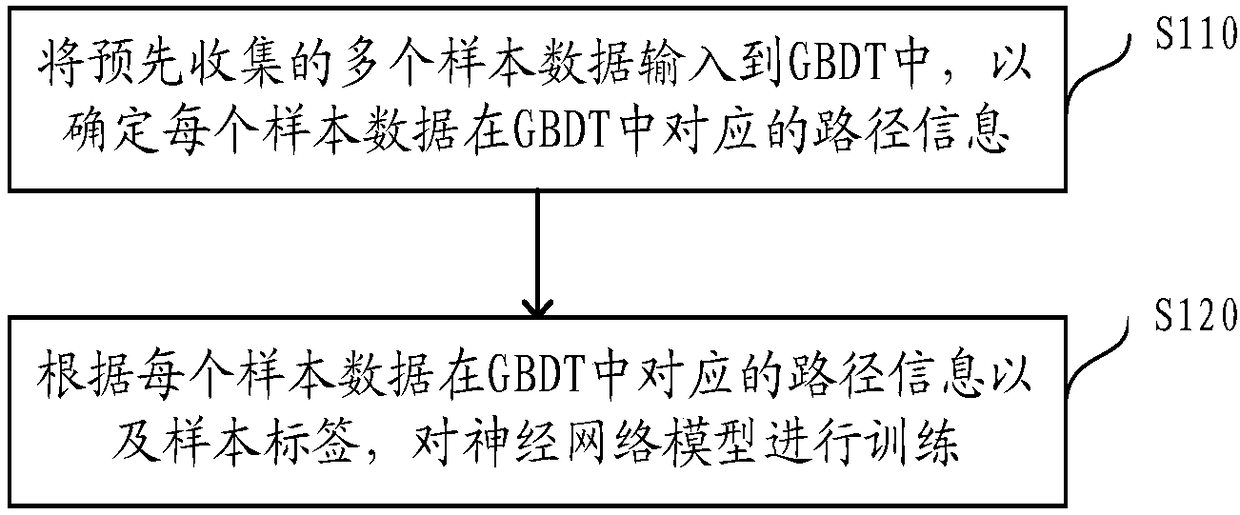

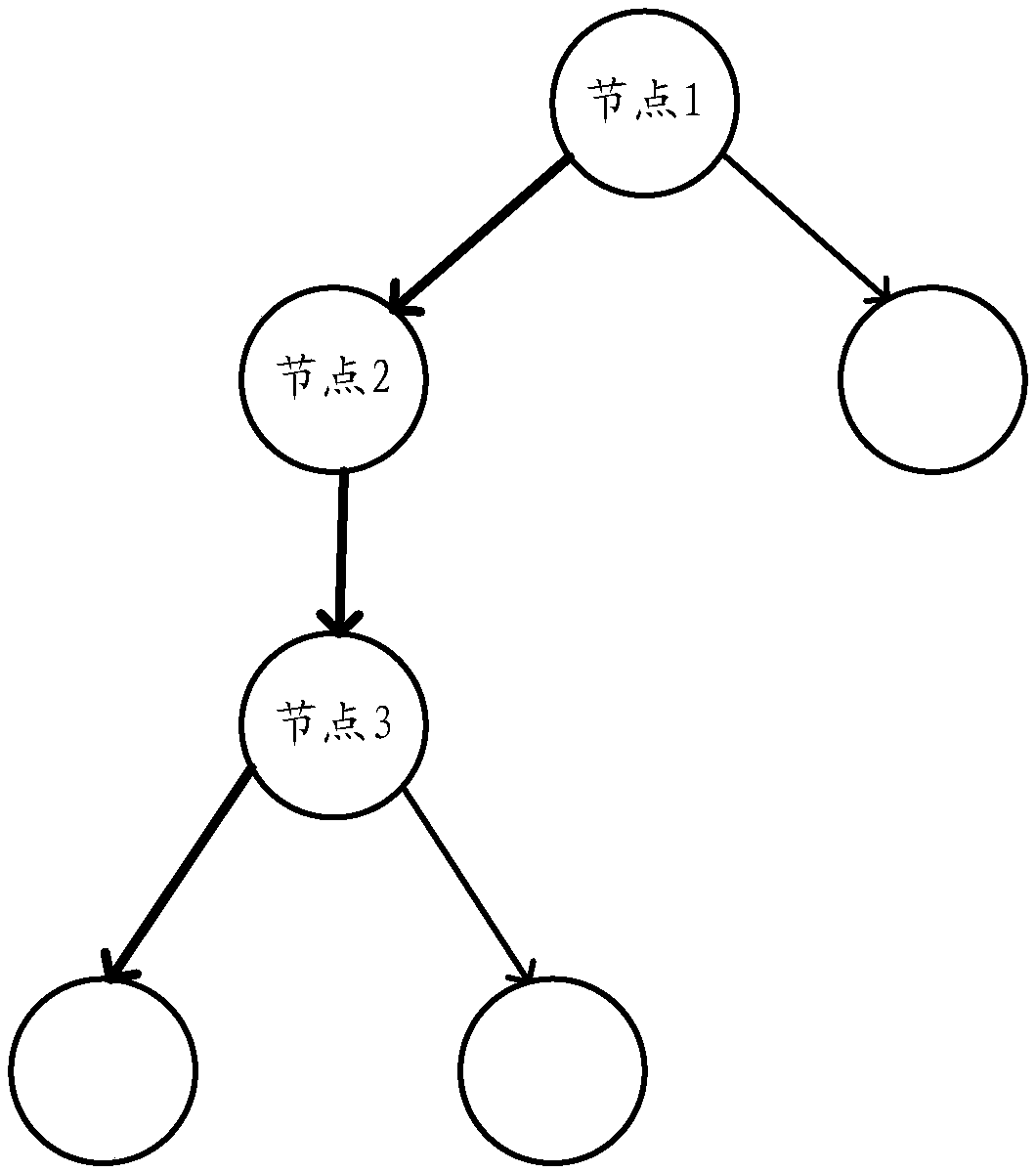

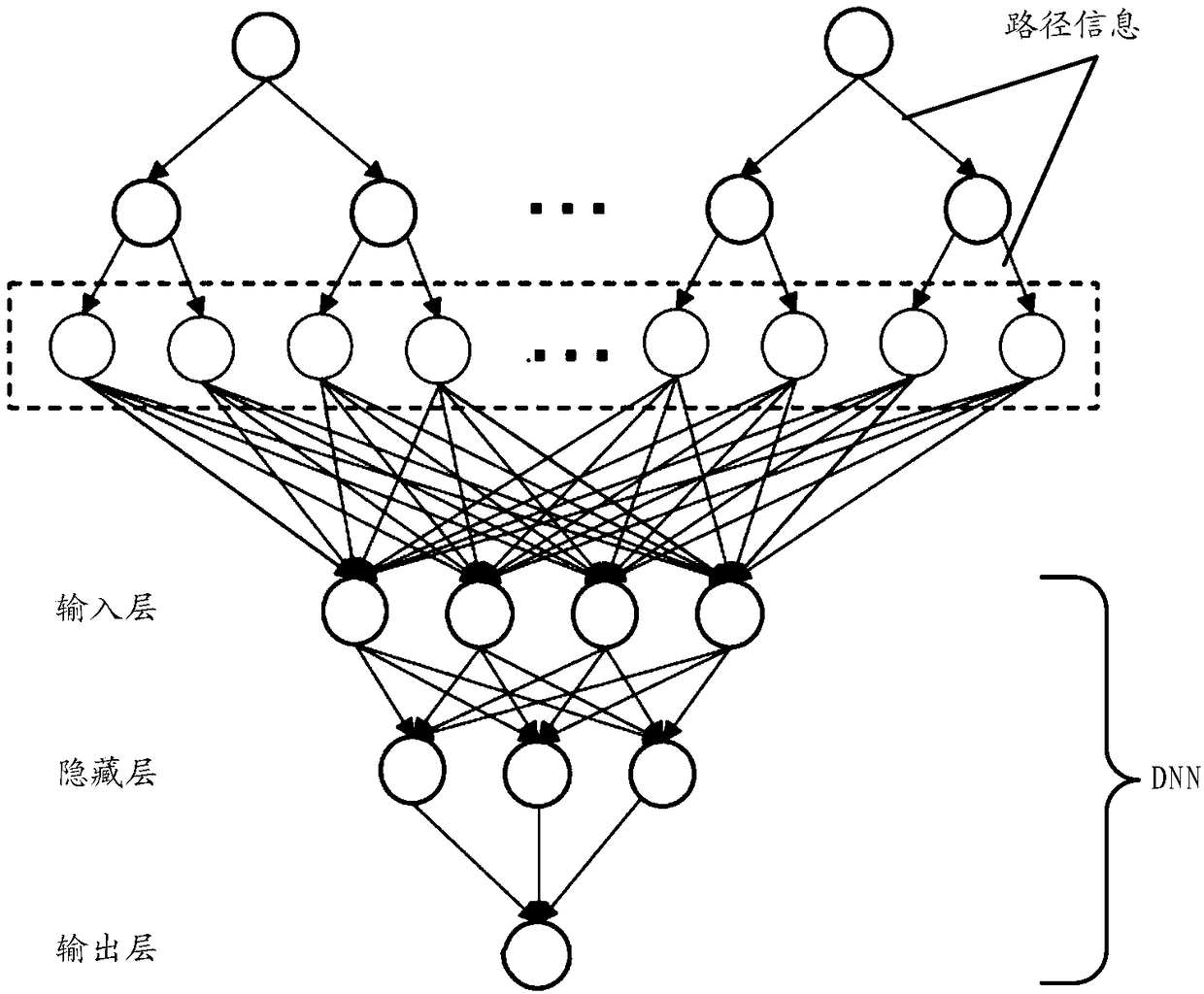

Neural network model training method and device, and transaction behavior risk identification method and device

ActiveCN108629413AImprove training efficiencyCharacter and pattern recognitionNeural learning methodsNerve networkNetwork model

The application relates to the technical field of the computer, and especially relates to a neural network model training method and device, and transaction behavior risk identification method and device. In the method for the neural network model training, multiple sample data collected in advance are inputted into the gradient boosting decision tree (GBDT), and the path information correspondingto each sample data in GBDT is determined. The training is performed on the neural network model according to the path information and the sample label corresponding to each sample data in GBDT. Thepath information is determined according to GBDT at first, then the neural network model is trained according to the path information and the sample label, one piece of the path information usually includes multiple dimension information of the sample data according to the characteristics of GBDT, and the efficiency of neural network model training can be improved.

Owner:ADVANCED NEW TECH CO LTD

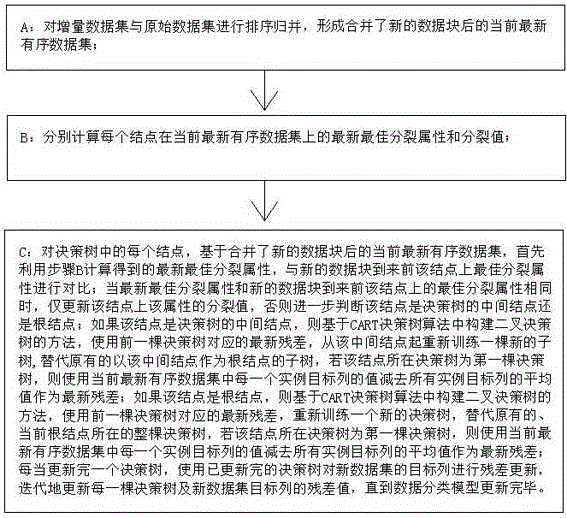

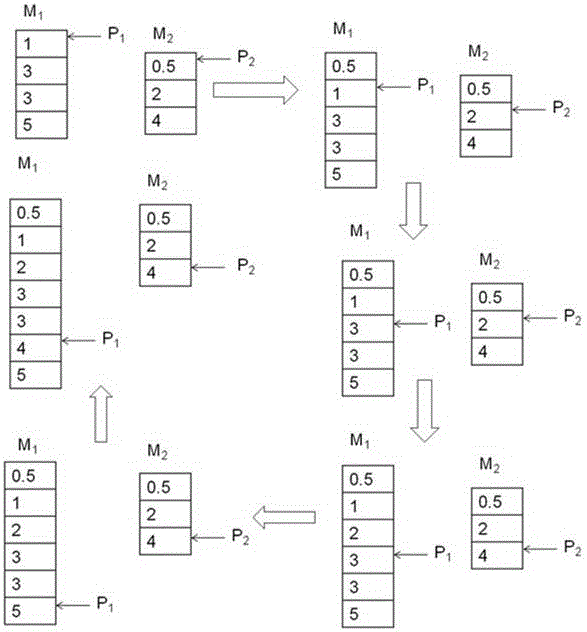

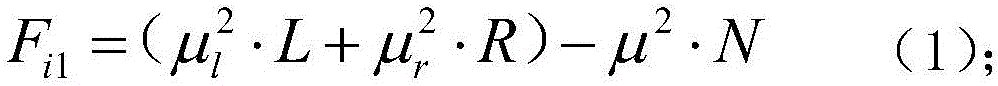

Incremental gradient improving decision-making tree updating method

ActiveCN106446964AIncrease training speedShorten the timeCharacter and pattern recognitionData setAlgorithm

The invention discloses an incremental gradient improving decision-making tree updating method. The incremental gradient improving decision-making tree updating method comprises the following steps: A, sequencing and merging an incremental data set and an original data set to acquire the current newest sequential data set; B, calculating the newest optimal splitting attribute and splitting value of each node on the current newest sequential data set separately; and C, updating data classification models by utilizing the comparison result of the newest optimal splitting attribute and the optimal splitting attribute of the node before a new data block arrives. By the incremental gradient improving decision-making tree updating method, the existing data classification models can be quickly updated by an incremental method before new data sets arrive in batches, a new gradient improving decision-making tree classification model does not need to be trained again, and updating is conducted on the basis of the existing models, so that the time of establishing the data classification models is greatly reduced, the training speed of the models is increased and a large amount of time cost is saved.

Owner:HENAN UNIVERSITY

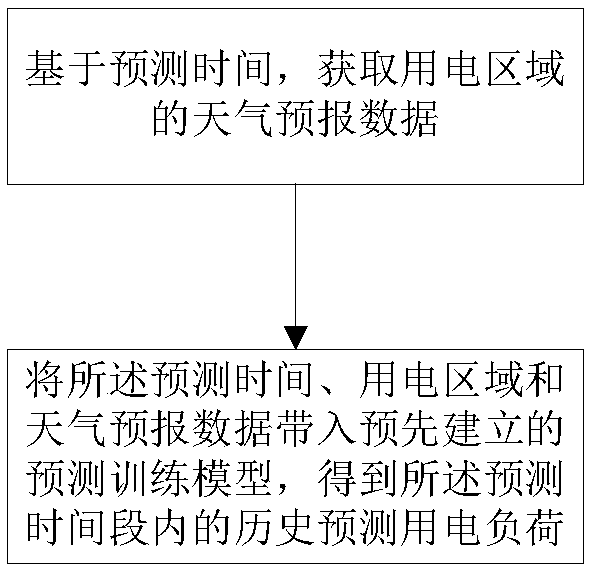

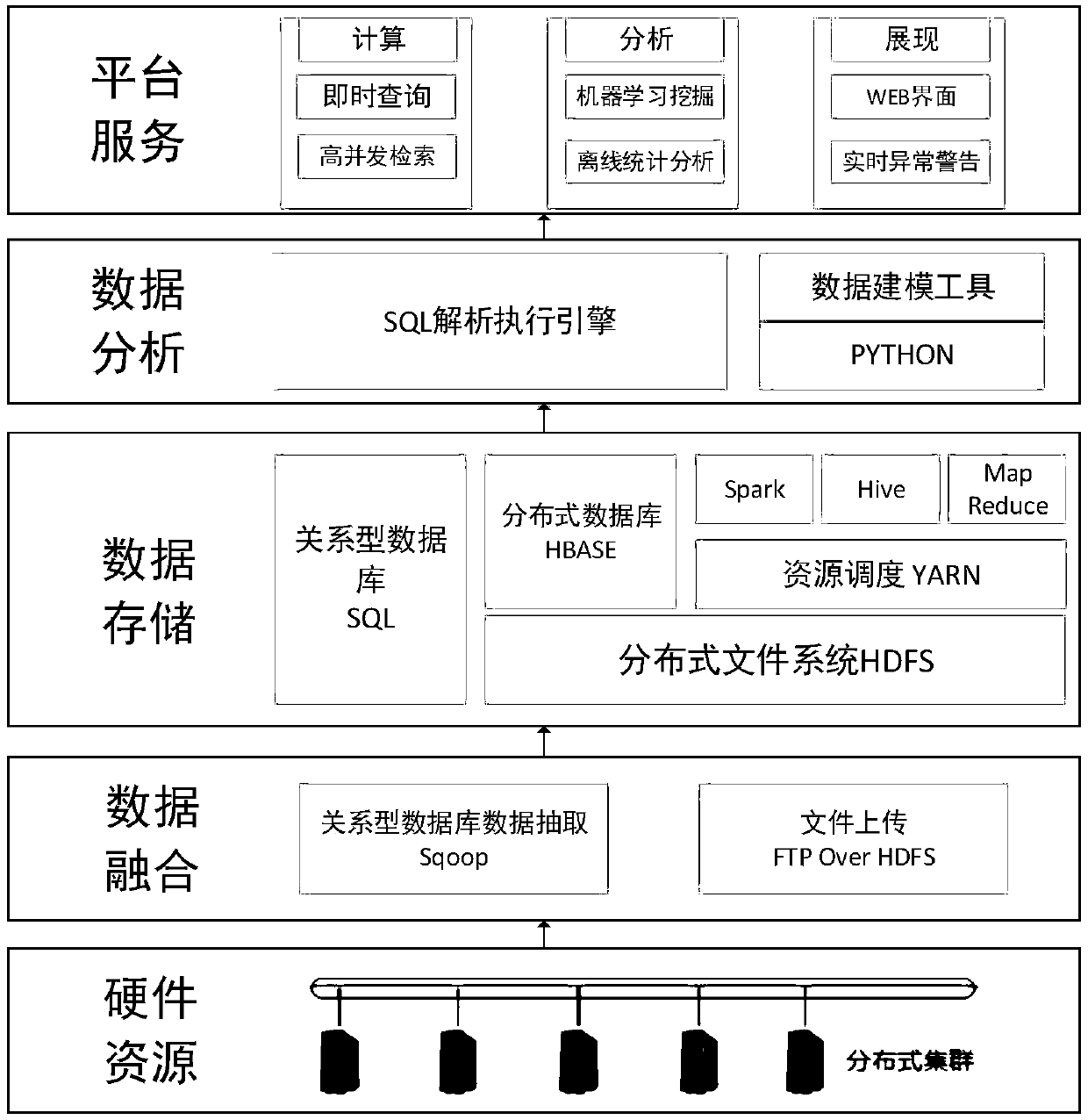

Electrical load prediction method and system based on big data

The invention provides an electrical load prediction method and system based on big data. The method comprises the steps of acquiring weather forecast data of an electrical region based on predictiontime; and substituting the prediction time, the electrical region and the weather forecast data into a pre-established prediction training model to obtain a historical prediction electrical load within the period of prediction time, wherein the prediction training model is determined by a training characteristic dataset of the electrical load, the time and the weather data based on a GBDT (Gradient Boosting Decision Tree). According to the electrical load prediction method and system based on the big data, an operation of writing intermediate data into a memory is implemented through the big data, the computational efficiency is greatly improved for the system for implementing the effect that the data are processed in real time, and the problems that the historical mass electrical load data cannot be rapidly acquired, processed, analyzed and stored in a conventional method can be well remedied through a big data analysis technology.

Owner:CHINA ELECTRIC POWER RES INST +2

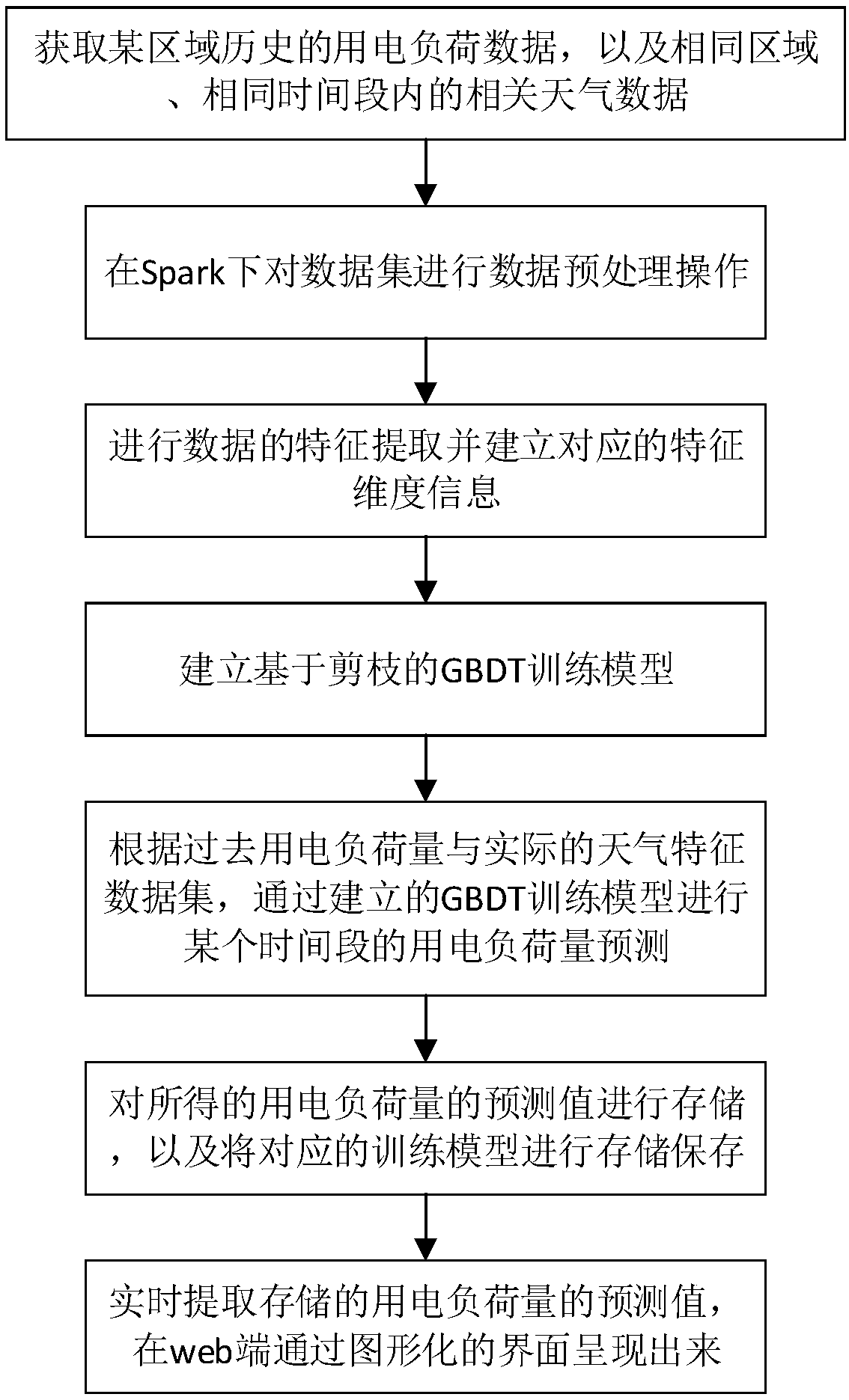

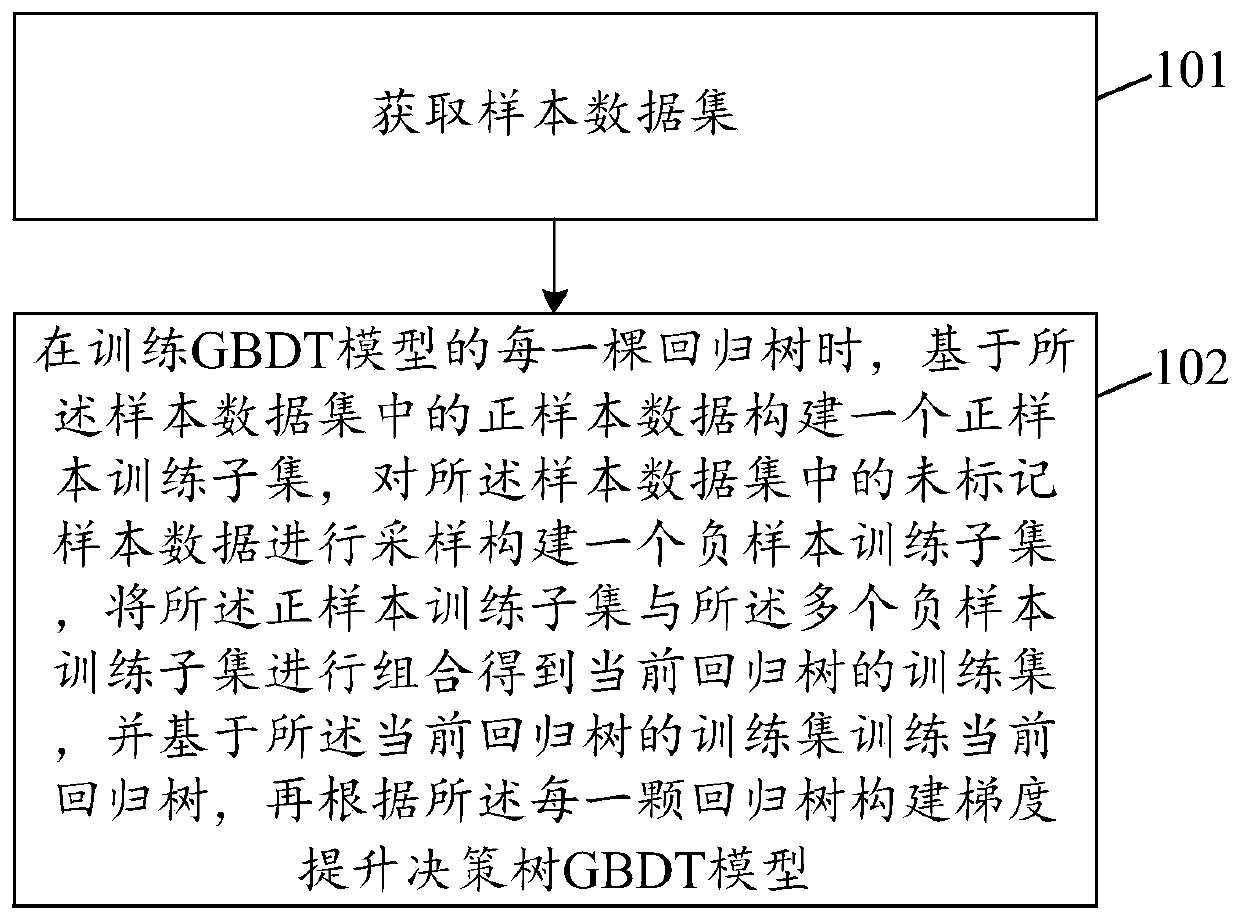

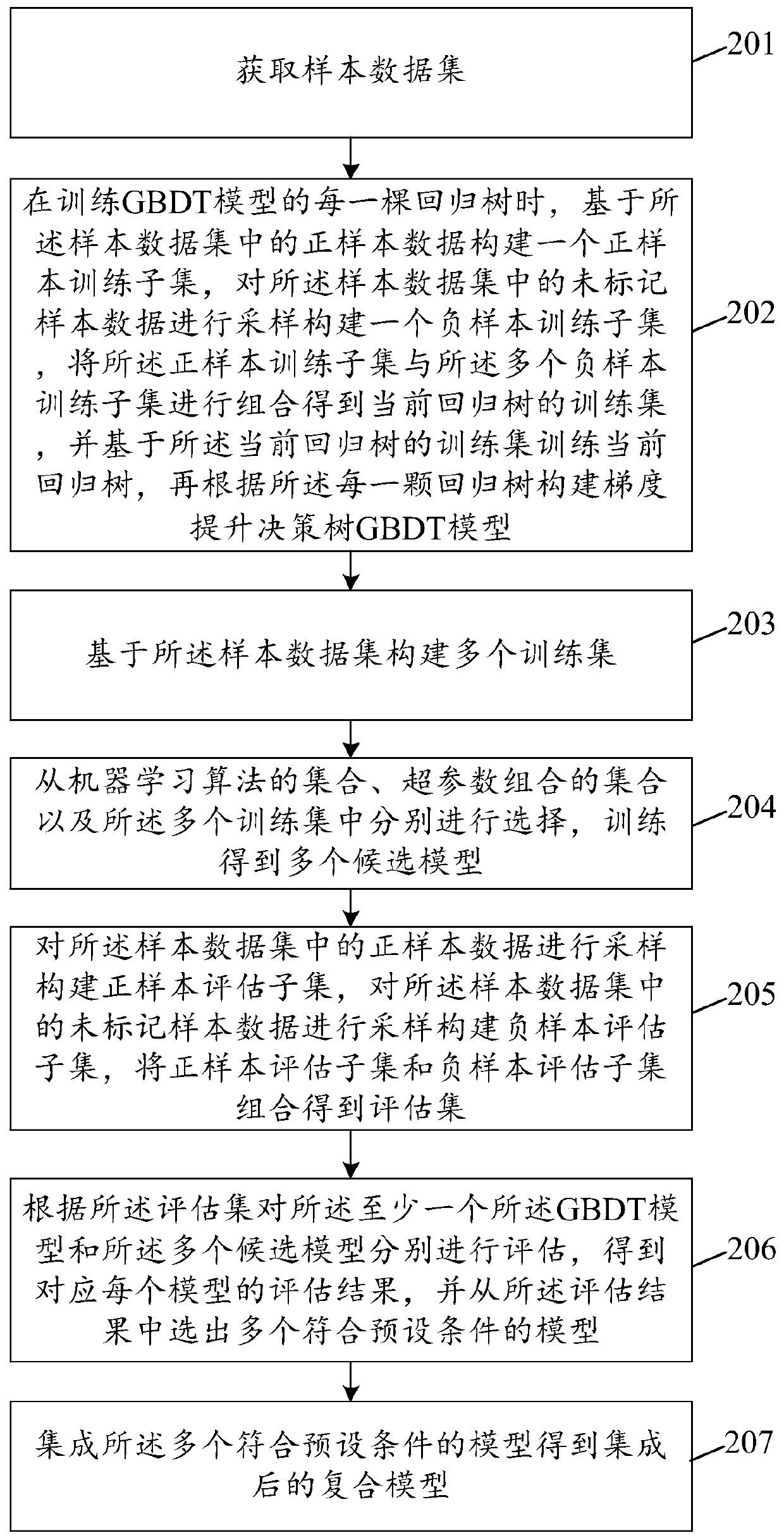

Method and device for constructing GBDT model and prediction method and device

The invention discloses a method and a device for constructing a GBDT (Gradient Boost Decision Tree) model, relates to the technical field of machine learning, and mainly aims to solve the problem oflow accuracy of the existing trained GBDT model. According to the main technical scheme, the method comprises the steps of obtaining a sample data set, wherein the sample data set comprises positive sample data with positive labels and unlabeled sample data without labels; training each regression tree of a GBDT model; constructing a positive sample training subset based on positive sample data inthe sample data set, sampling unmarked sample data in the sample data set to construct a negative sample training subset, and combining the positive sample training subset with the plurality of negative sample training subsets to obtain a training set of a current regression tree, training the current regression tree based on the training set of the current regression tree, and constructing a GBDT model according to each regression tree. The invention is used in the construction process of the gradient boosting decision tree.

Owner:THE FOURTH PARADIGM BEIJING TECH CO LTD

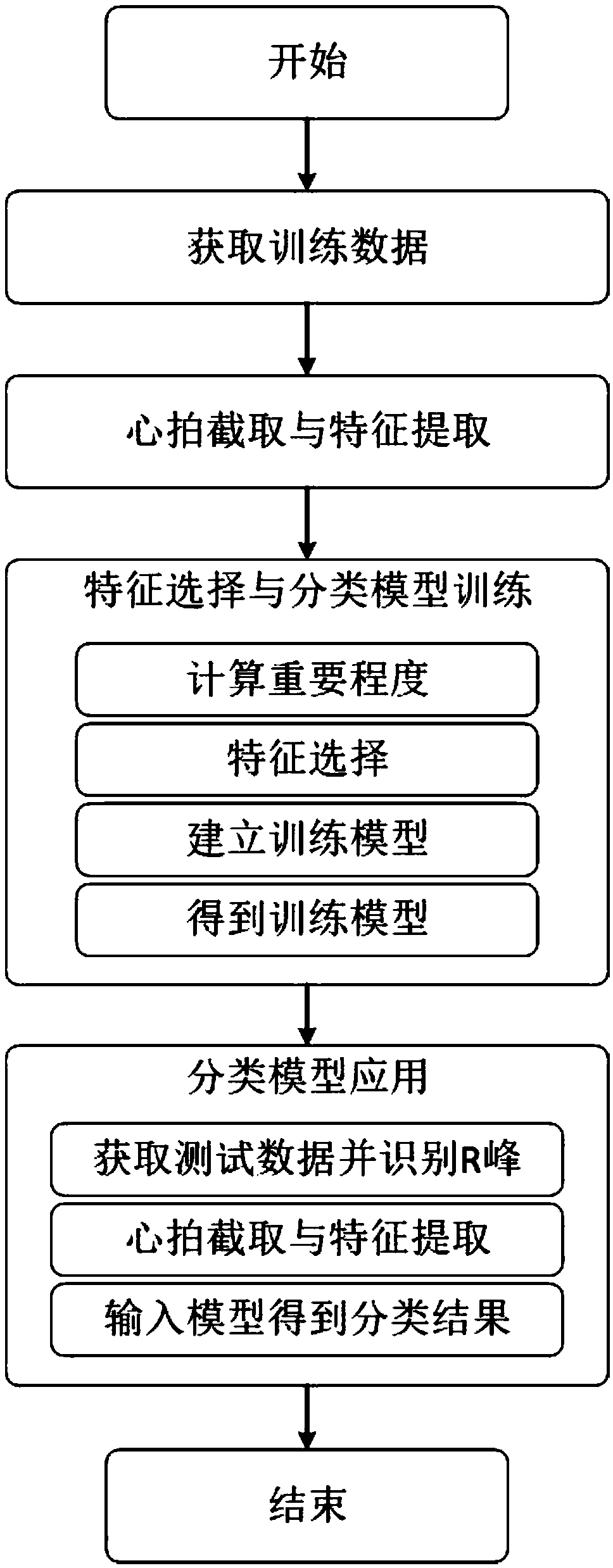

Dynamic electrocardiogram heart beat classification method based on gradient boosting decision tree

ActiveCN109303559AAccurate identificationAvoid the influence of abnormal heartbeatDiagnostic recording/measuringSensorsEcg signalSupraventricular Ectopic Beats

The invention relates to a dynamic electrocardiogram heart beat classification method based on a gradient boosting decision tree. The method comprises the steps that in actual dynamic electrocardiogram, classification is conducted on single heart beats in an electrocardiogram signal according to whether or not arrhythmia exists and the types of arrhythmia, specific classification categories comprise normal heart beats, supraventricular ectopic beat heart beats, ventricular ectopic beats, ventricular beat and normal beat fusion heart beats and pacemaker heart beats; the method comprises the following steps that 1, training data is obtained; 2, heart beat interception and feature extraction are conducted; 3, feature selection and classification model training are conducted; 4, classificationmodel application is conducted, wherein a tree-model-based feature selection method is adopted in step 3 to select features, and the classification model is trained through a gradient boosting decision tree classification method. The method is suitable for arrhythmia classification training of dynamic electrocardiogram and classification identification of different types of heart beats, and a doctor can be assisted in accurately reading and analyzing the electrocardiogram.

Owner:杭州质子科技有限公司

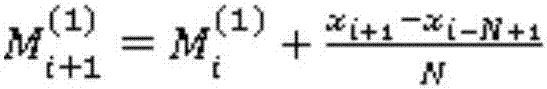

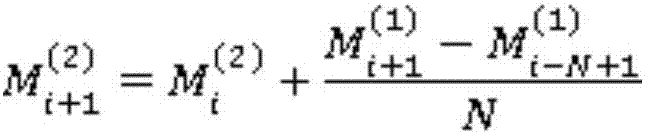

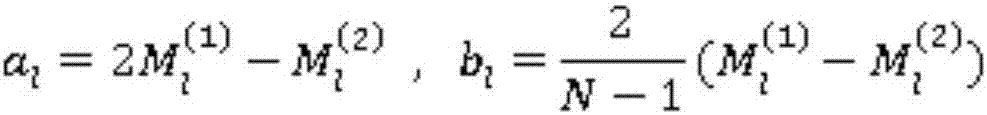

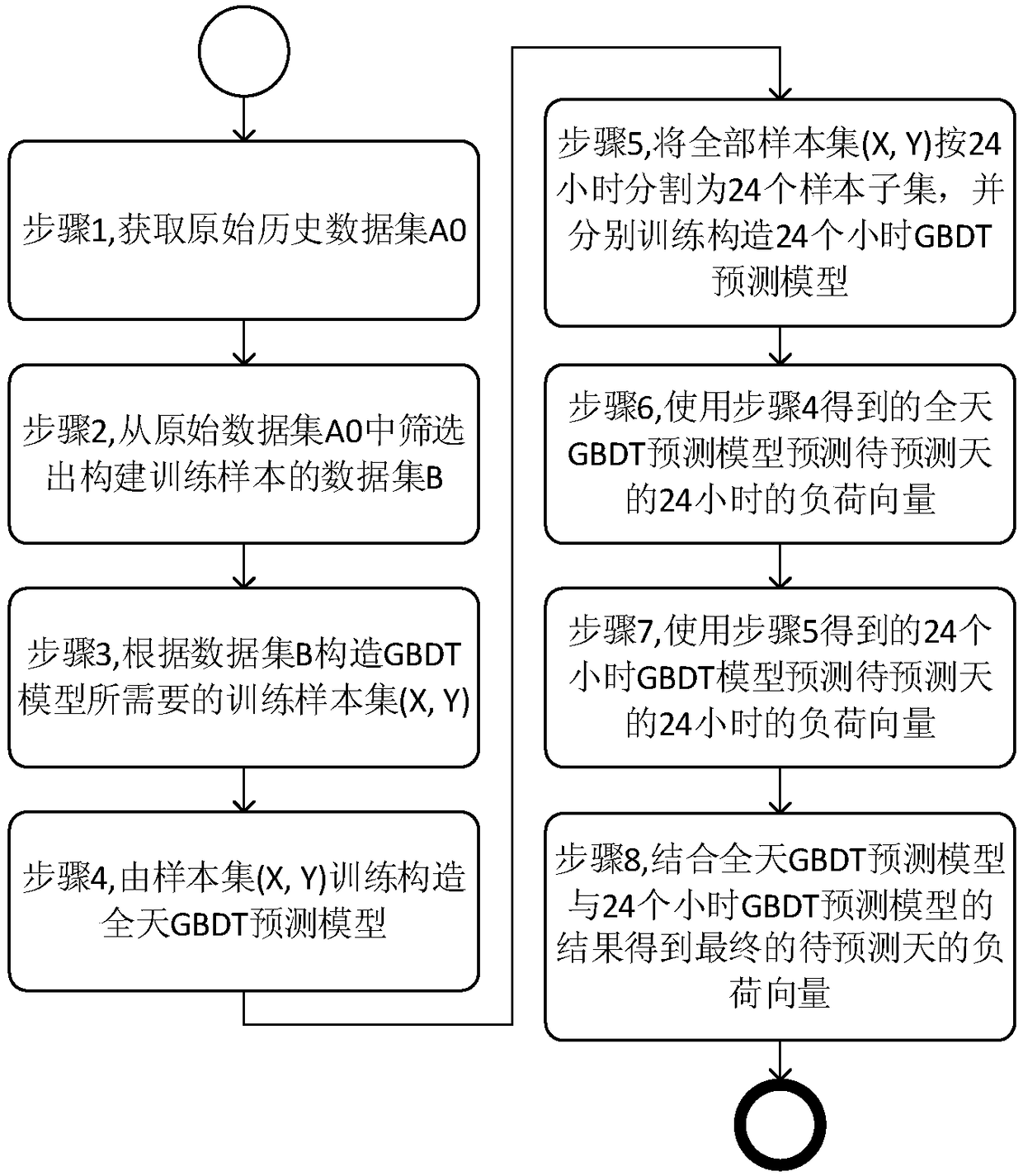

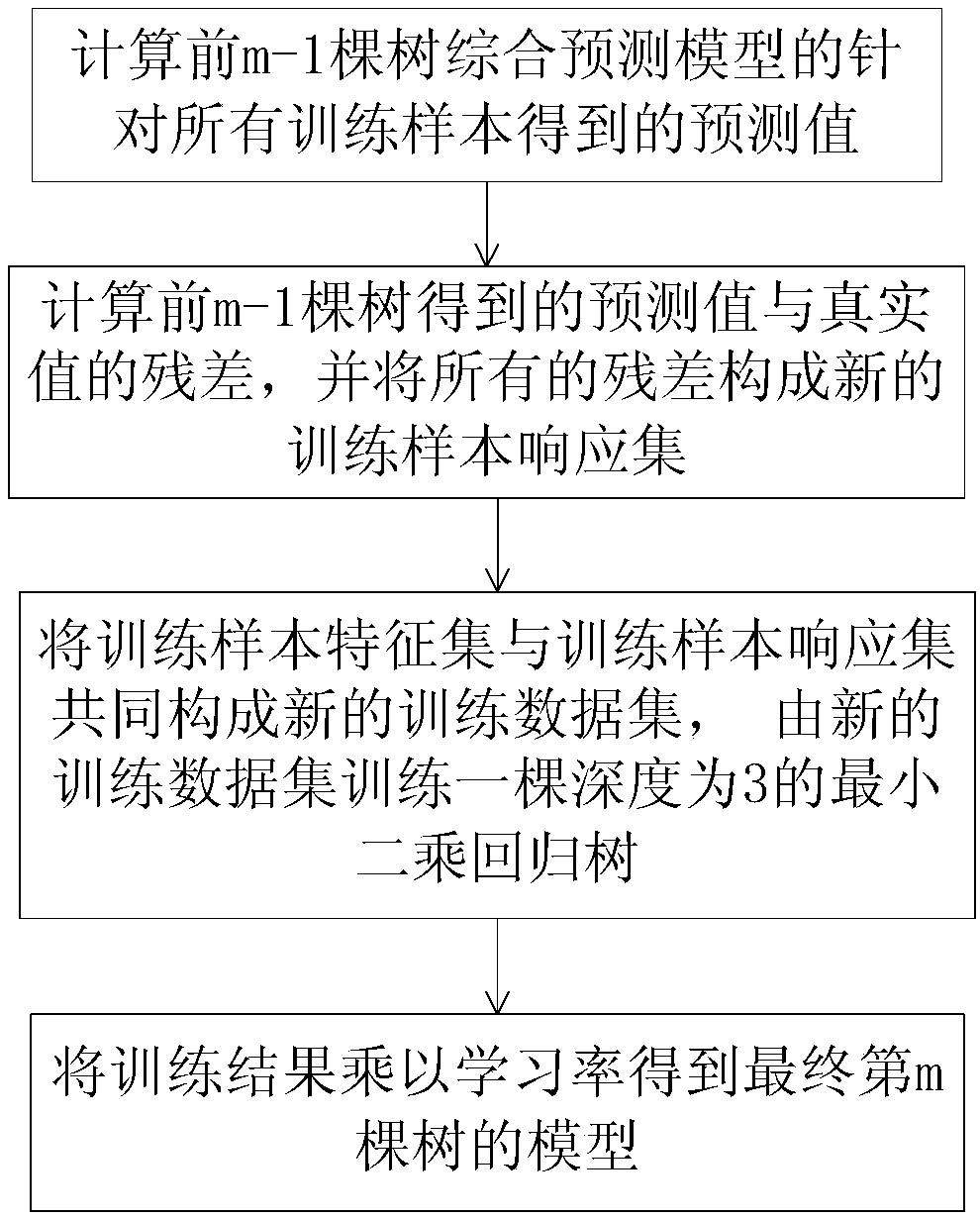

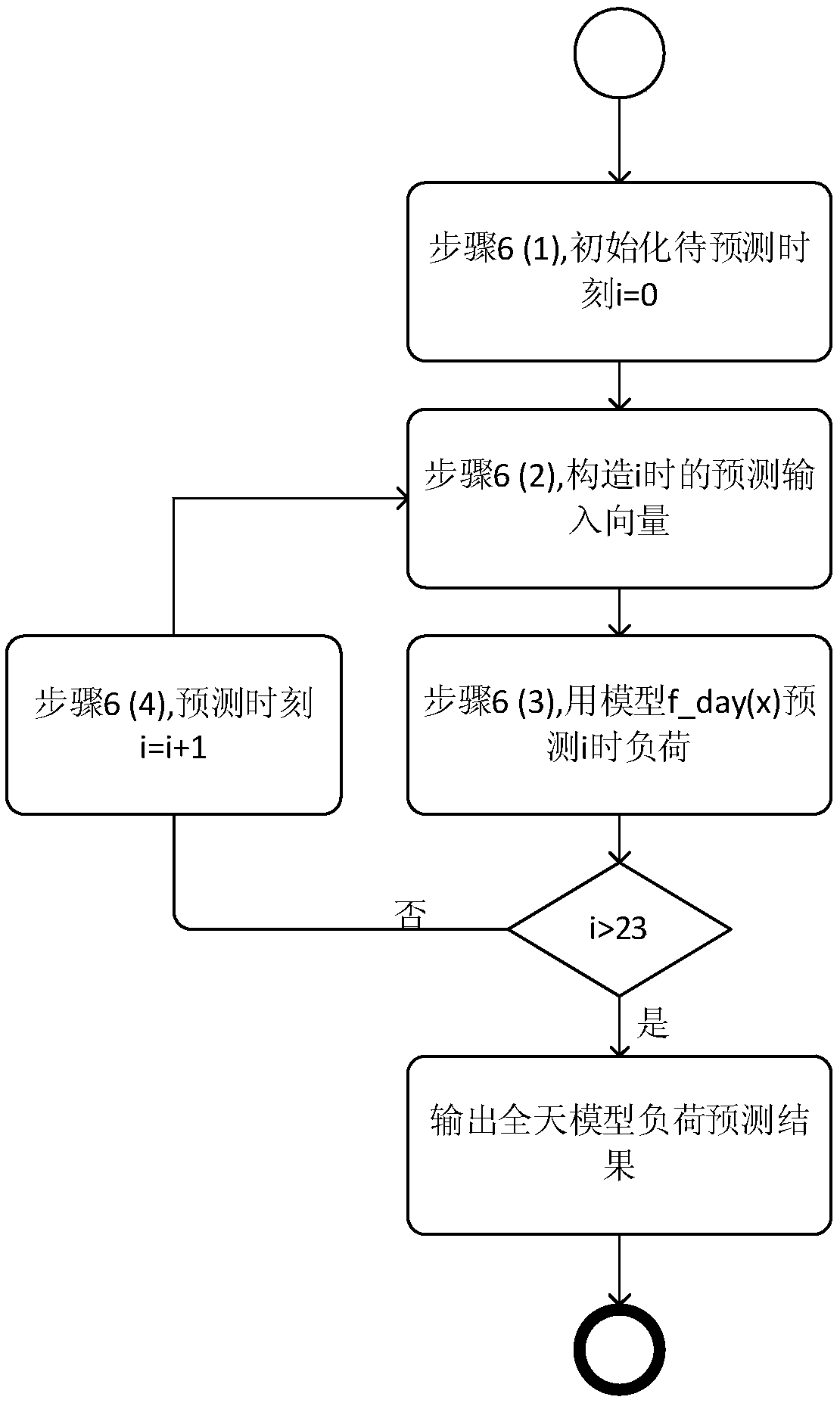

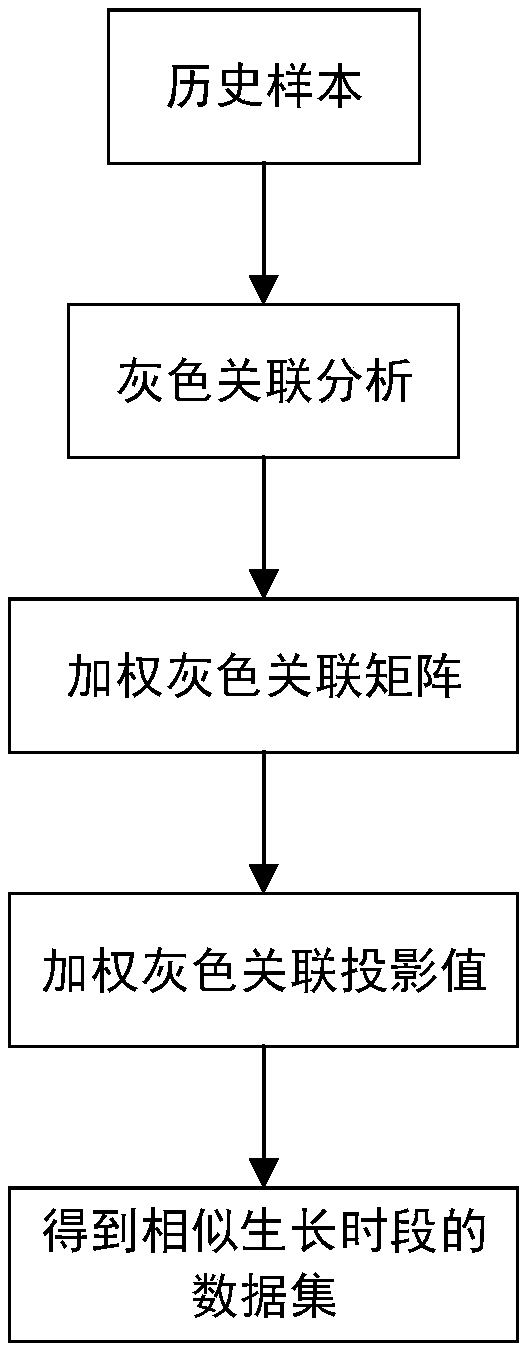

Short-term load prediction method based on GBDT (gradient boosting decision tree)

ActiveCN108539738AHigh precisionGeneralization error is controllableLoad forecast in ac networkData setOriginal data

An embodiment of the invention discloses a short-term load prediction method based on a GBDT (gradient boosting decision tree). The method comprises the following steps: acquiring historical load dataof N days before the prediction-waiting day, and forming an original data set A0; screening a data set B for constructing training samples from the original data set A0; constructing total sample set(X, Y) required for constructing a GBDT prediction model by the data set B; training and constructing a whole-day GBDT prediction model by the total sample set (X, Y), and prediction whole-day load vector of the prediction-waiting day according to the whole-day GBDT prediction model; segmenting the total sample set (X, Y) into 24 sample subsets by the hour, training and constructing hour GBDT prediction models respectively, and predicting 24-hour load vectors of the prediction-waiting day according to the hour GBDT prediction models; predicting the final load vector of the prediction-waitingday according to combination of the whole-day load vector and the 24-hour load vectors. The short-term load prediction precision is improved by sufficiently mining characteristics in the historical load data and constructing the different GBDT models.

Owner:国网山东省电力公司营销服务中心(计量中心) +2

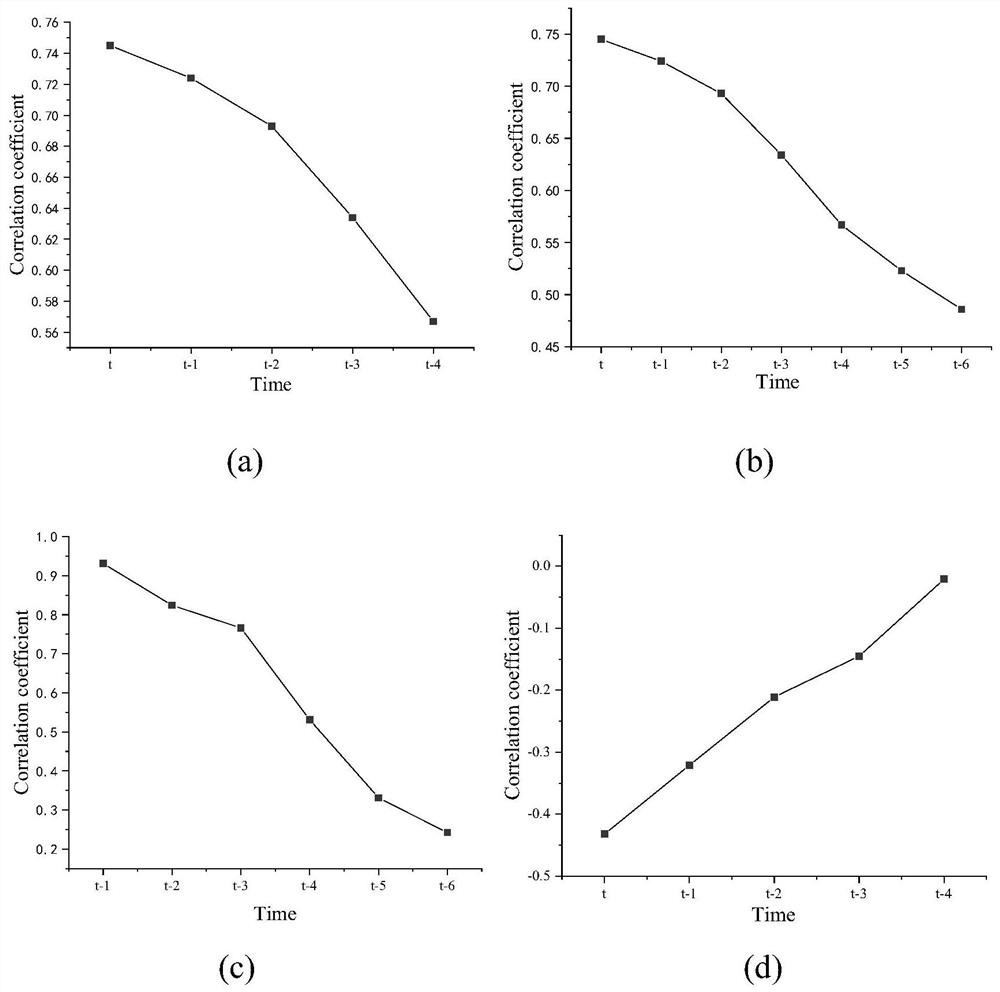

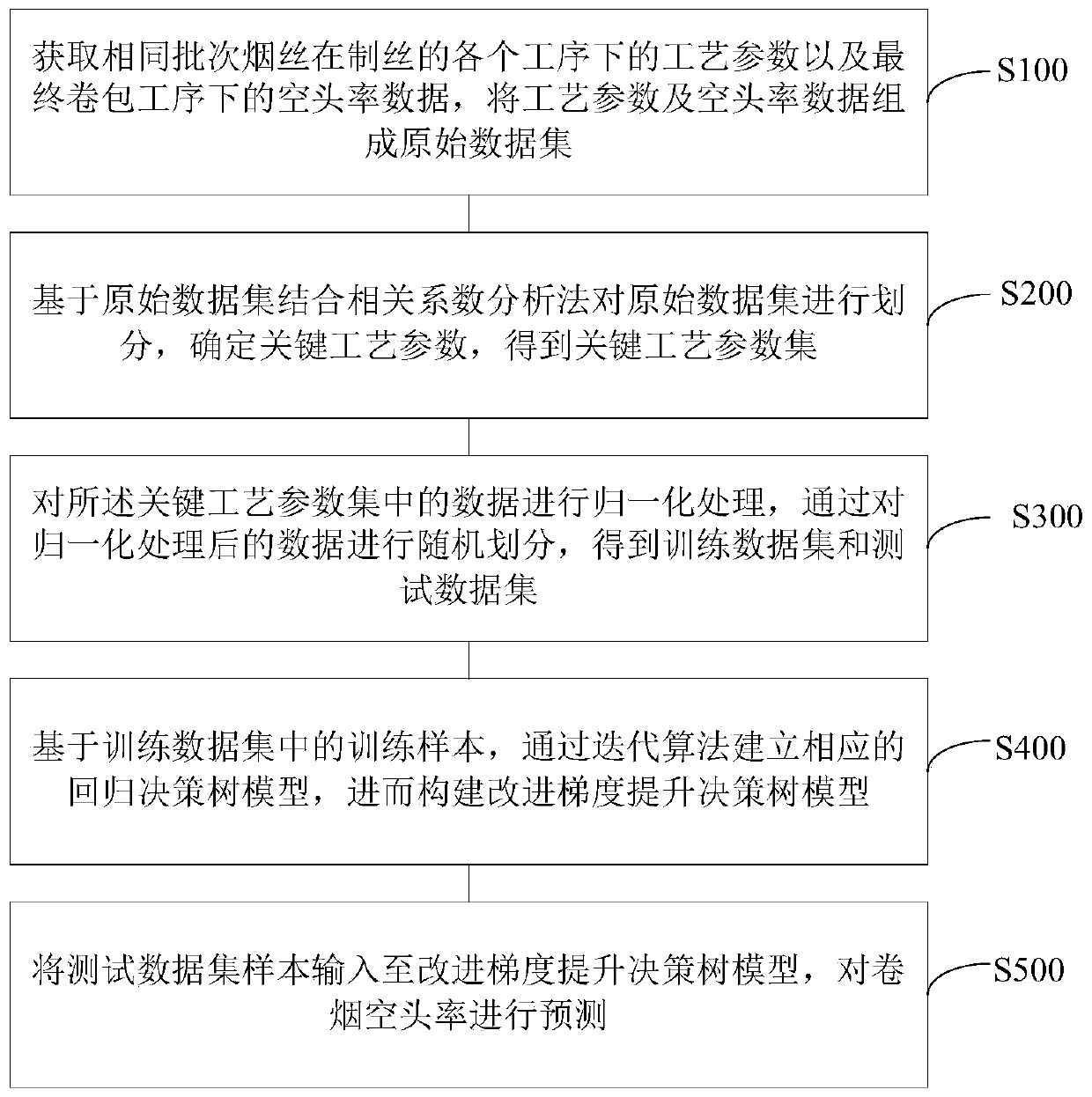

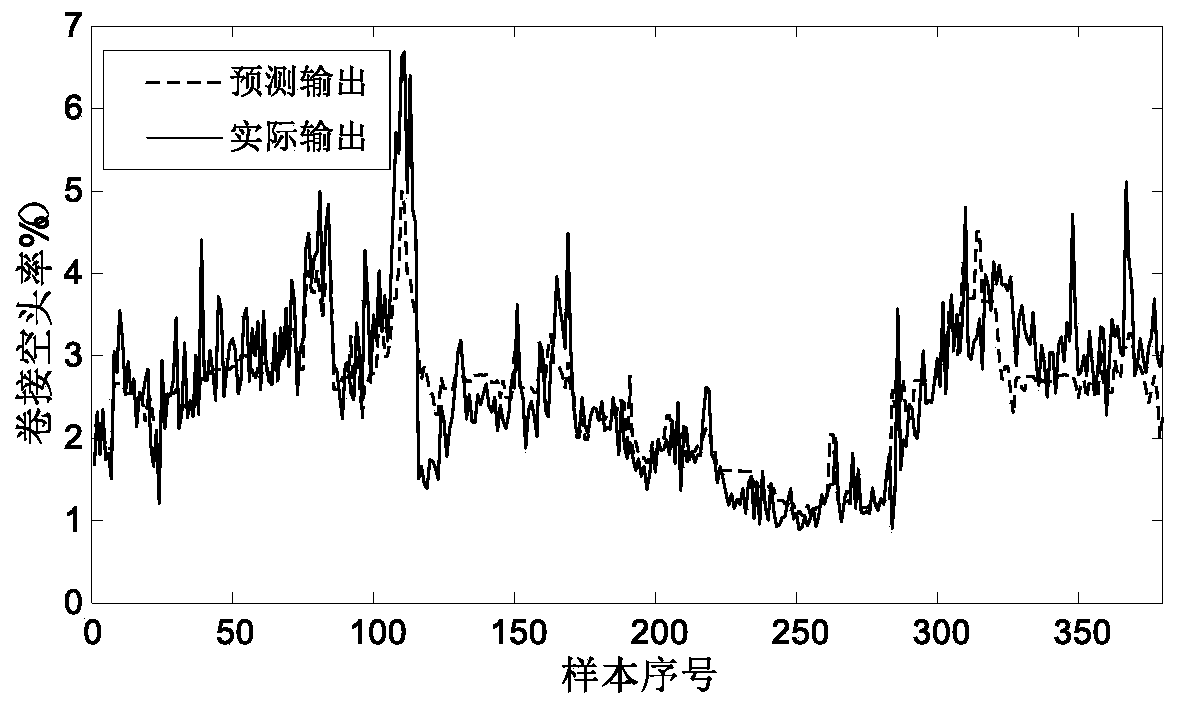

Cigarette loose end rate prediction method and system based on improved gradient improvement decision tree

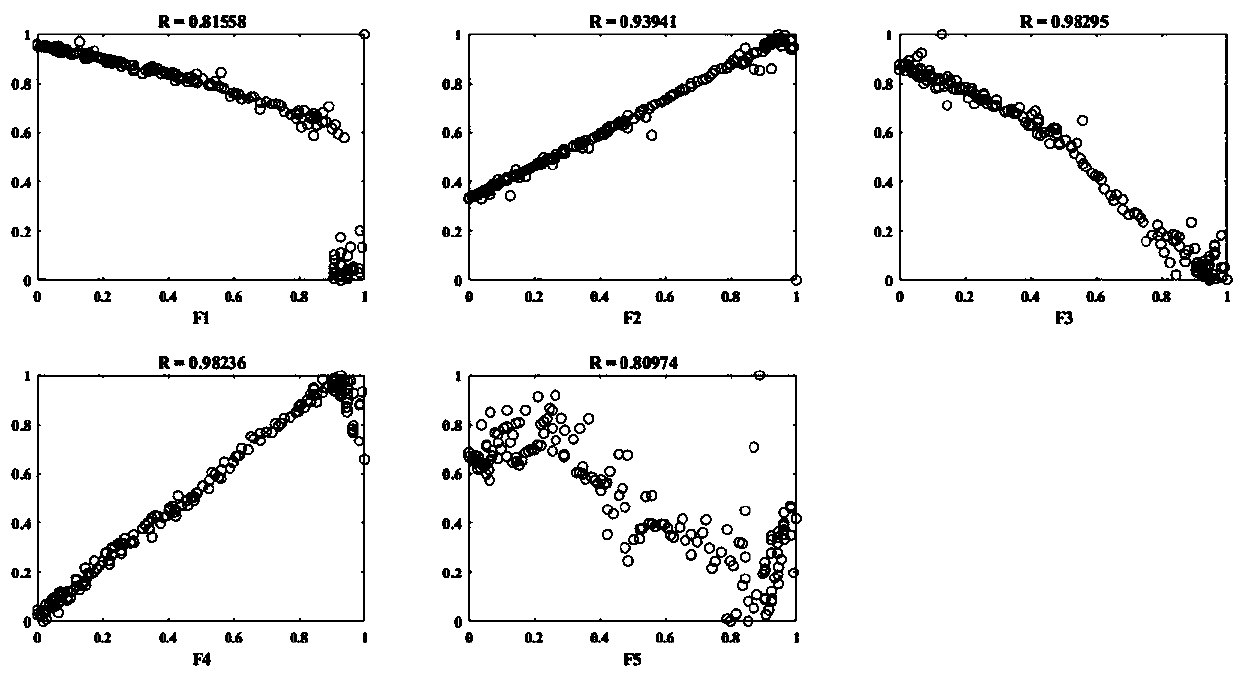

ActiveCN110245802AAccurate predictionExplanatoryForecastingCharacter and pattern recognitionCorrelation coefficientData set

The invention discloses a cigarette loose end rate prediction method based on an improved gradient improvement decision tree, which comprises the following steps: acquiring process parameters of tobacco shreds in the same batch in each process of tobacco shred making and loose end rate data in a final package process, and forming an original data set by the process parameters and the loose end rate data; dividing the original data set based on the original data set in combination with a correlation coefficient analysis method to obtain a key process parameter set; performing normalization processing on the data in the key process parameter set, and performing random division on the normalized data to obtain a training data set and a test data set; on the basis of training samples in the training data set, constructing an improved gradient improvement decision tree model; and inputting the test data set sample into the improved gradient improvement decision tree model, and predicting the cigarette empty head rate. A connection is established between each process parameter of the tobacco shred making process and the index of the cigarette packet vacancy rate, so that more accurate prediction of the cigarette vacancy rate is realized.

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

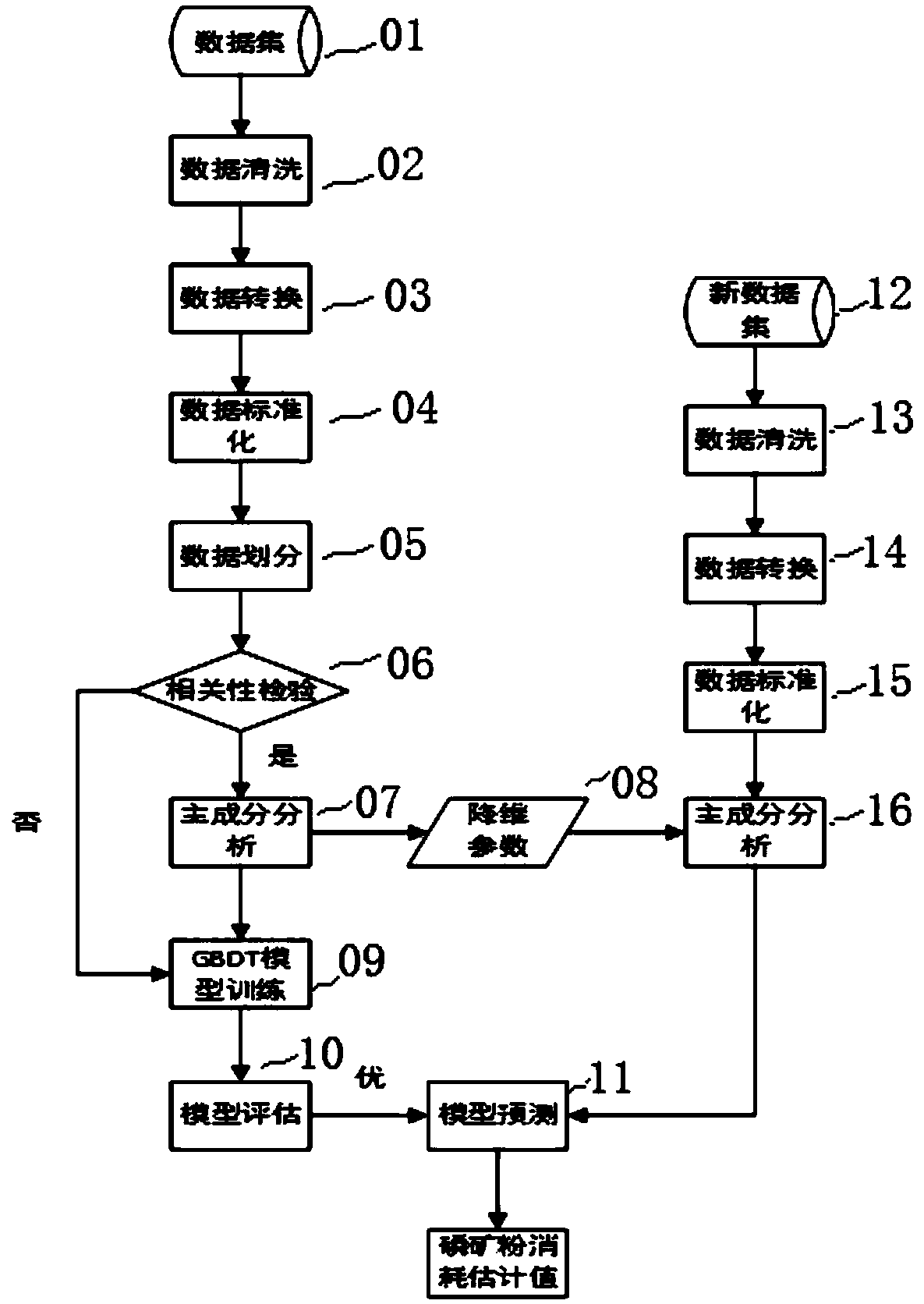

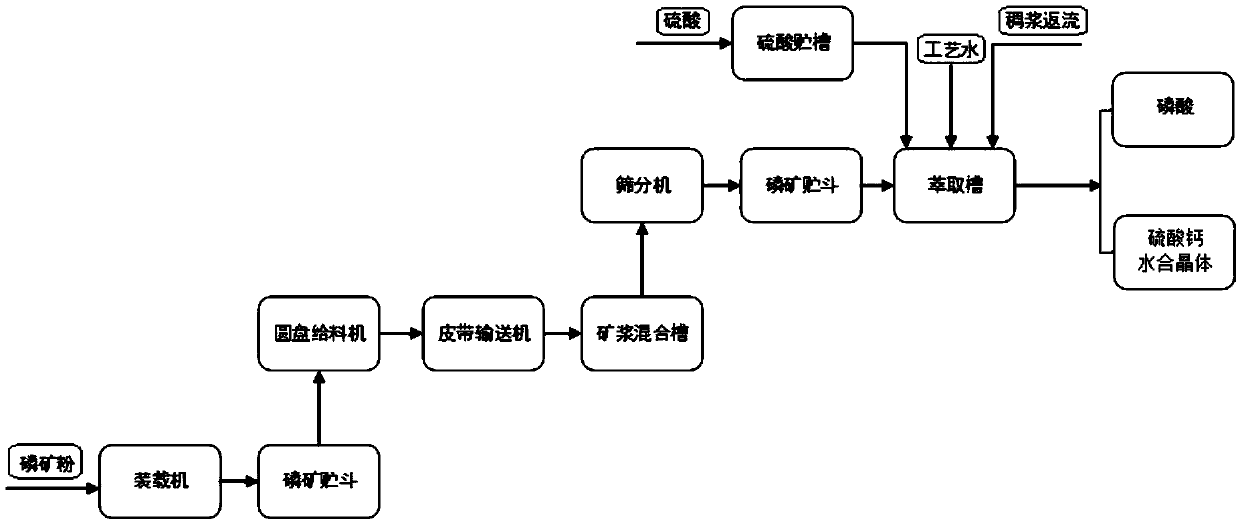

Phosphoric acid production parameter control method based on gradient boosted decision tree

ActiveCN108873829AImprove stabilityReduce cost of measurementTotal factory controlProgramme total factory controlPython languageMeasurement device

The present invention provides a method for software measurement of ground phosphate rock consumption and a phosphoric acid production parameter control method in a feed-grade calcium hydrophosphate production process. The phosphoric acid production parameter control method comprises the steps of: analyzing relevant factors for influencing consumption, based on the method theory of machine learning, transmitting and storing pulp flow real-time data and vitriol flow real-time data automatically collected by an internet-of-things collection device and pulp flow data manually collected by a lab to a cloud platform, allowing a python language-based analysis platform to be directly connected with a database to extract features based on time sequence data to perform analysis and modeling, and establishing a real-time soft measurement technology for the ground phosphate rock consumption to replace a ground phosphate rock physical measurement device with high investment and easy damaging. Theimplementation process of the method mainly comprises the steps of: pulp flow collection, vitriol flow, pulp storage tank intensity, mineral powder consumption historical data, data preprocessing, training of a gradient boosted decision tree (GBDT) regression model, and prediction of the mineral powder consumption to control phosphoric acid for generation of parameters through adoption of the trained GBDT regression model.

Owner:上海新增鼎数据科技有限公司

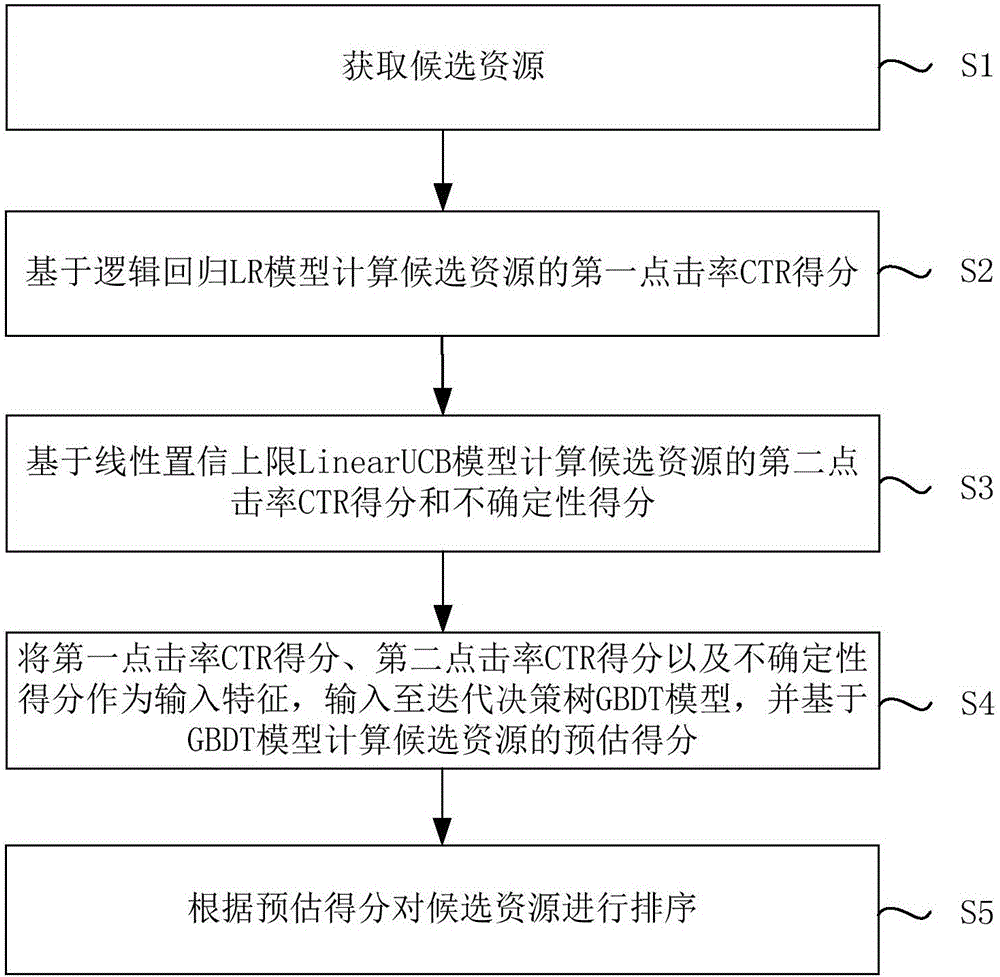

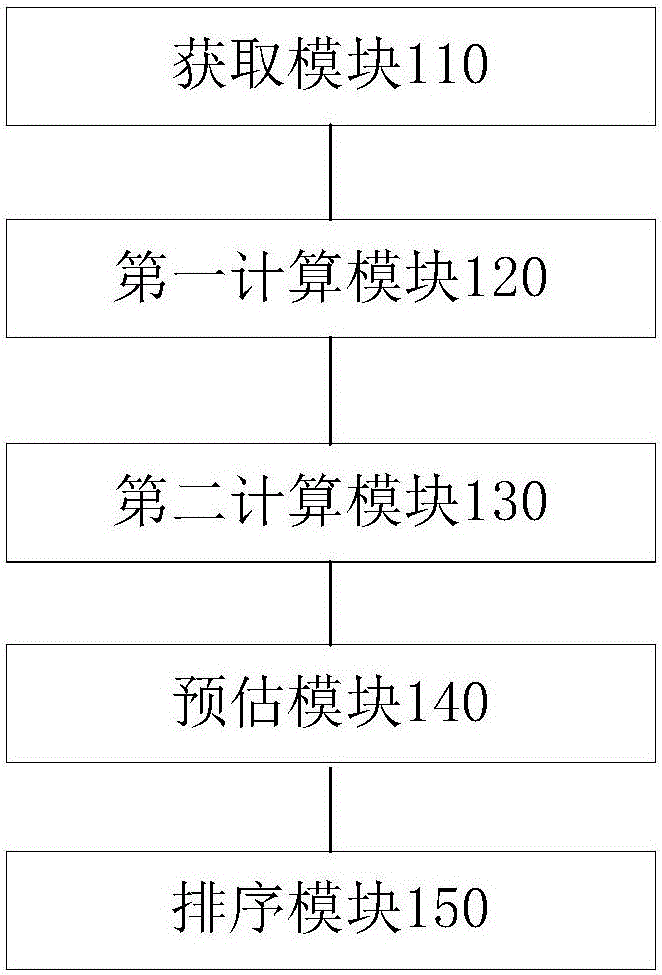

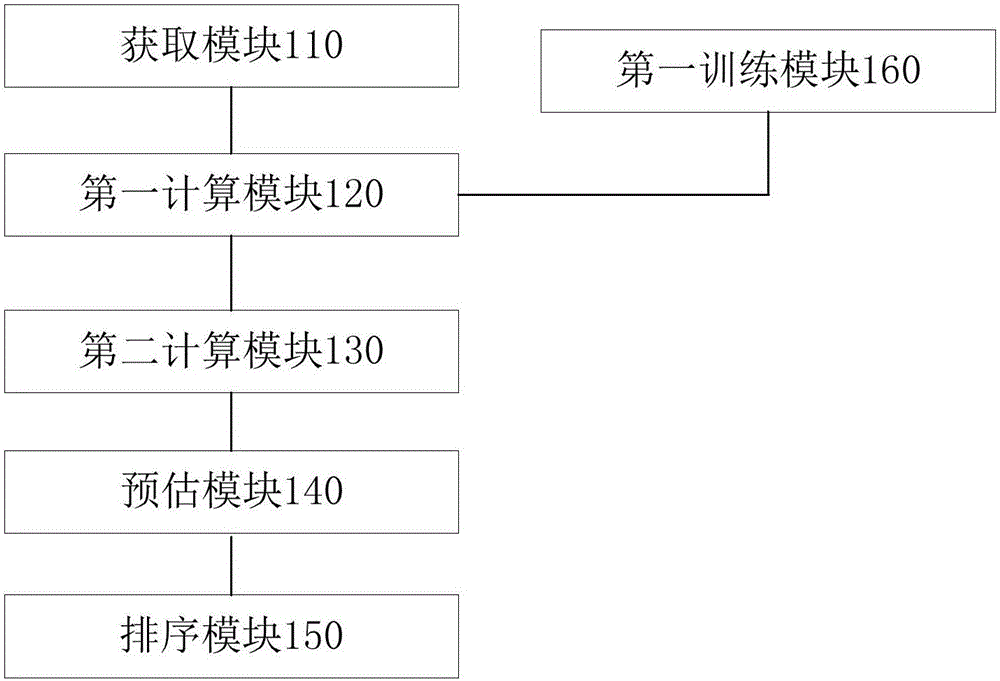

Resource sequencing method and device

ActiveCN105808762AEasy to sortHigh precisionSpecial data processing applicationsResource basedData mining

The invention discloses a resource sequencing method and device. The resource sequencing method comprises the following steps: acquiring candidate resources; calculating first click through rate (CTR) scores of the candidate resources based on a logistic regression (LR) model; calculating second CTR scores and uncertainty scores of the candidate resources based on a linear confidence upper limit LinearUCB model; inputting the first CTR scores, the second CTR scores and the uncertainty scores serving as input features into a gradient boosting decision tree (GBDT) model, and calculating pre-estimated scores of the candidate resources based on the GBDT model; and sequencing the candidate resources according to the pre-estimated scores. Through adoption of the resource sequencing method, the accuracy of CTR pre-estimation can be increased effectively, so that sequencing optimization of the candidate resources is realized; candidate resources more preferred by a user are presented preferentially; and the user experience is improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

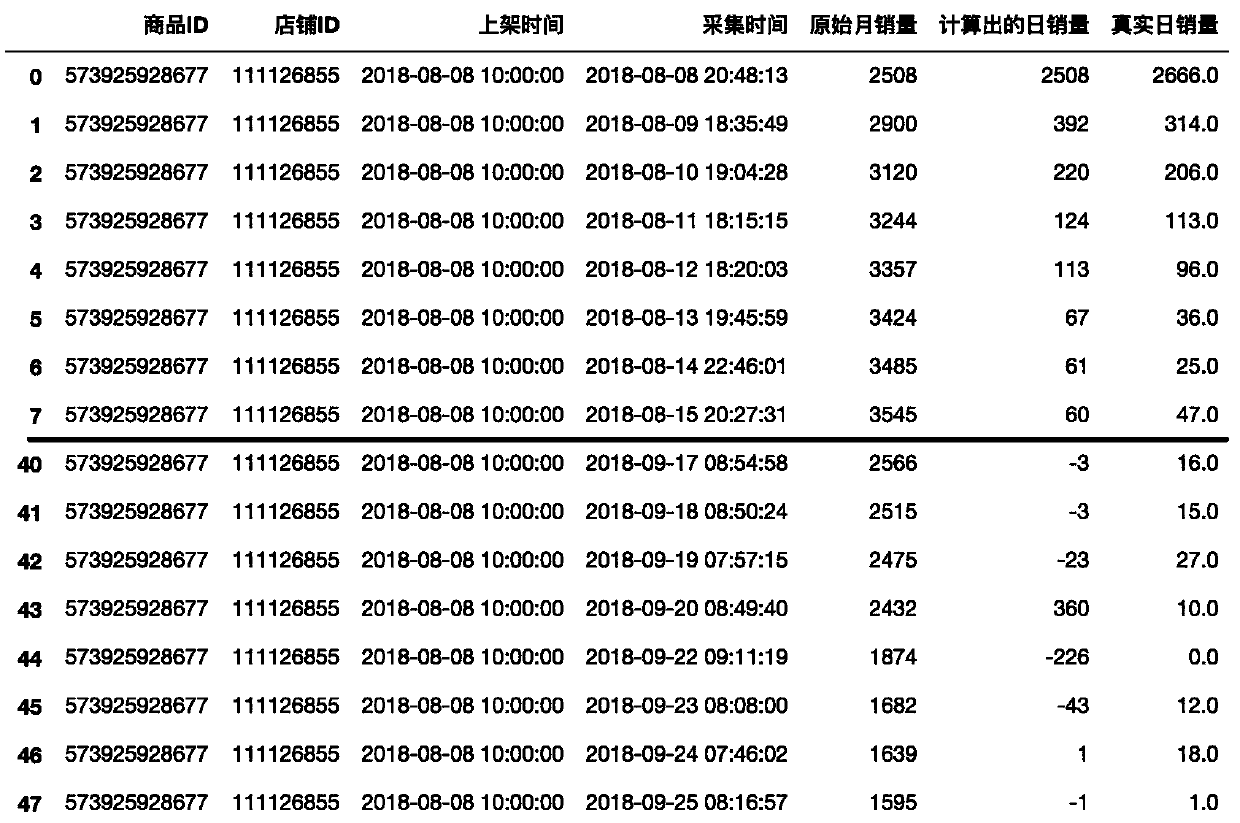

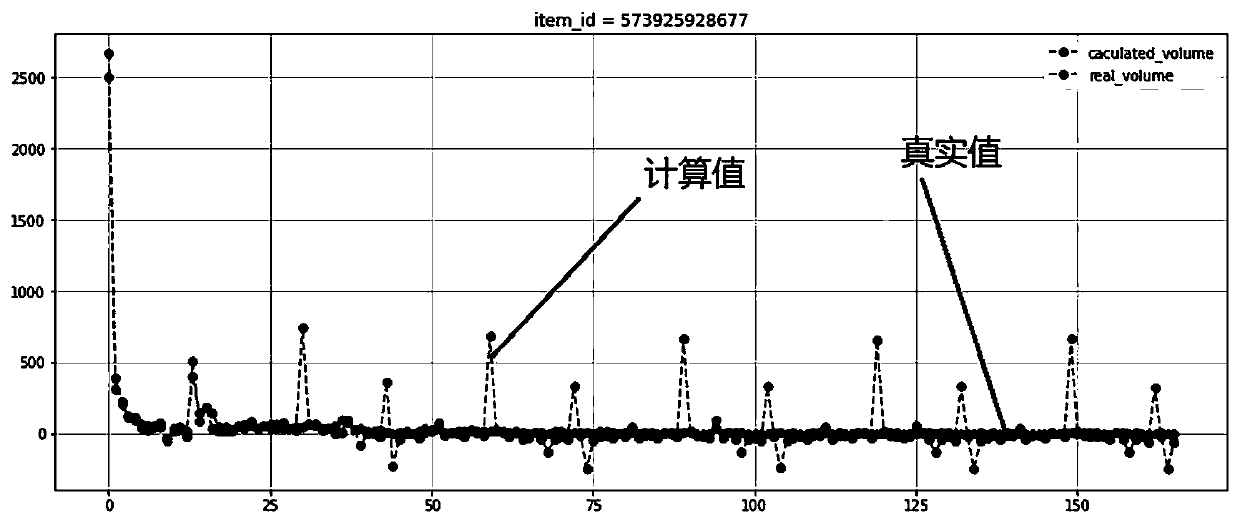

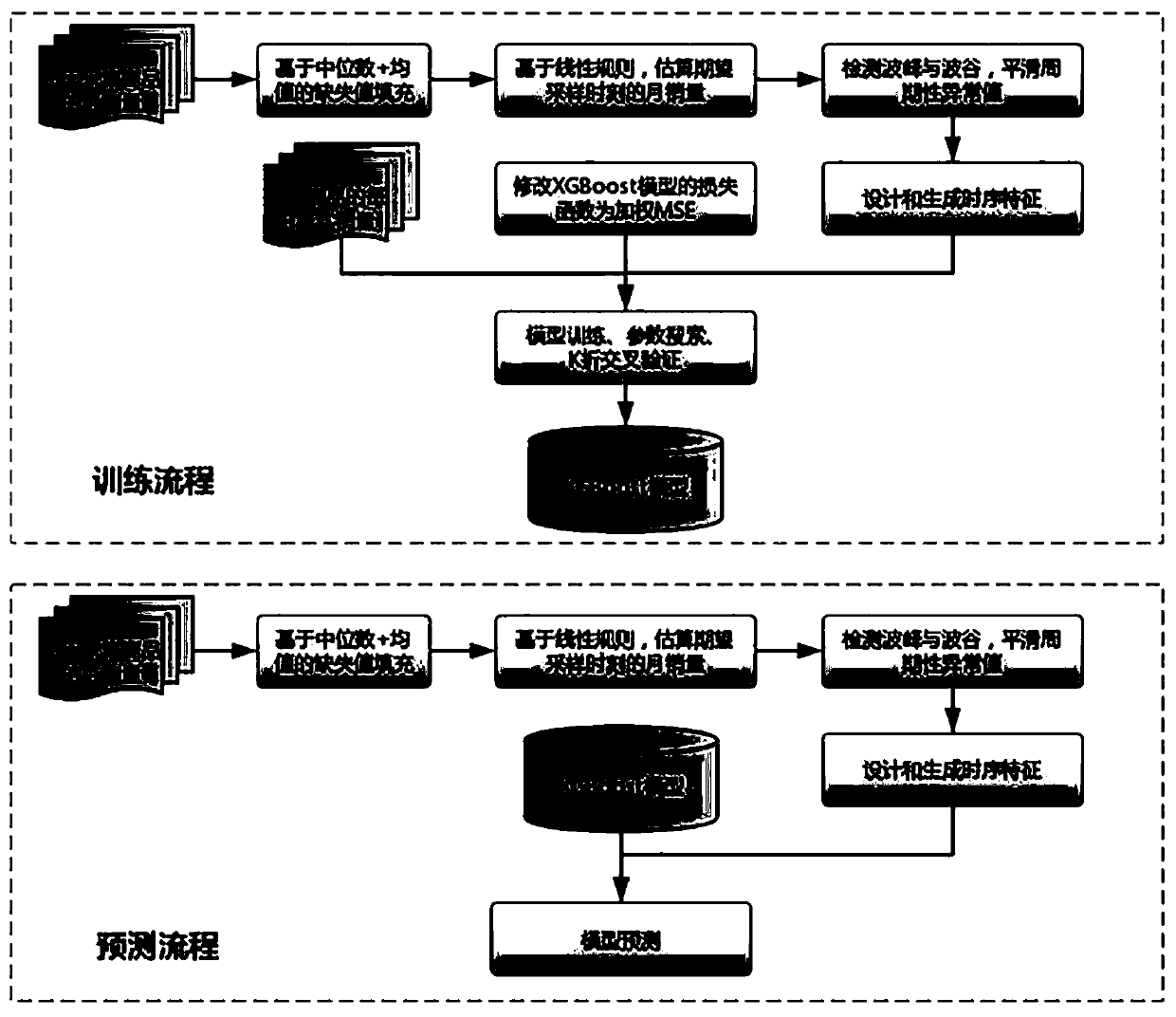

Time series data filling and restoring method based on machine learning

ActiveCN110457867ARaise the upper limit of forecast performanceReduce data noiseMachine learningSpecial data processing applicationsAlgorithmData filling

The invention relates to the technical field of computer time series data analysis and prediction, in particular to a time series data filling and restoring method based on machine learning. The method includes: filling the missing value by using a domain-based median and mean value filling method; estimating a true value of an expected sampling moment through a linear rule; detecting wave crestsand wave troughs of the time sequence, and smoothing abnormal values; taking hundreds of thousands of collected real data as samples, designing and generating time sequence characteristics, taking real results as labels, and training a machine learning model based on an XGBoost (Extreme Gradient Boost) for predicting a large number of unknown data. According to the method, the problems of multiplemissing values, large volatility, error accumulation and the like of specific time sequence data are solved, and the accuracy of data filling and restoring is effectively improved; moreover, the complexity of a machine learning model is well controlled, the filling and restoration of hundreds of millions of data records can be completed within an hour level, and the method has a high practical value.

Owner:杭州知衣科技有限公司

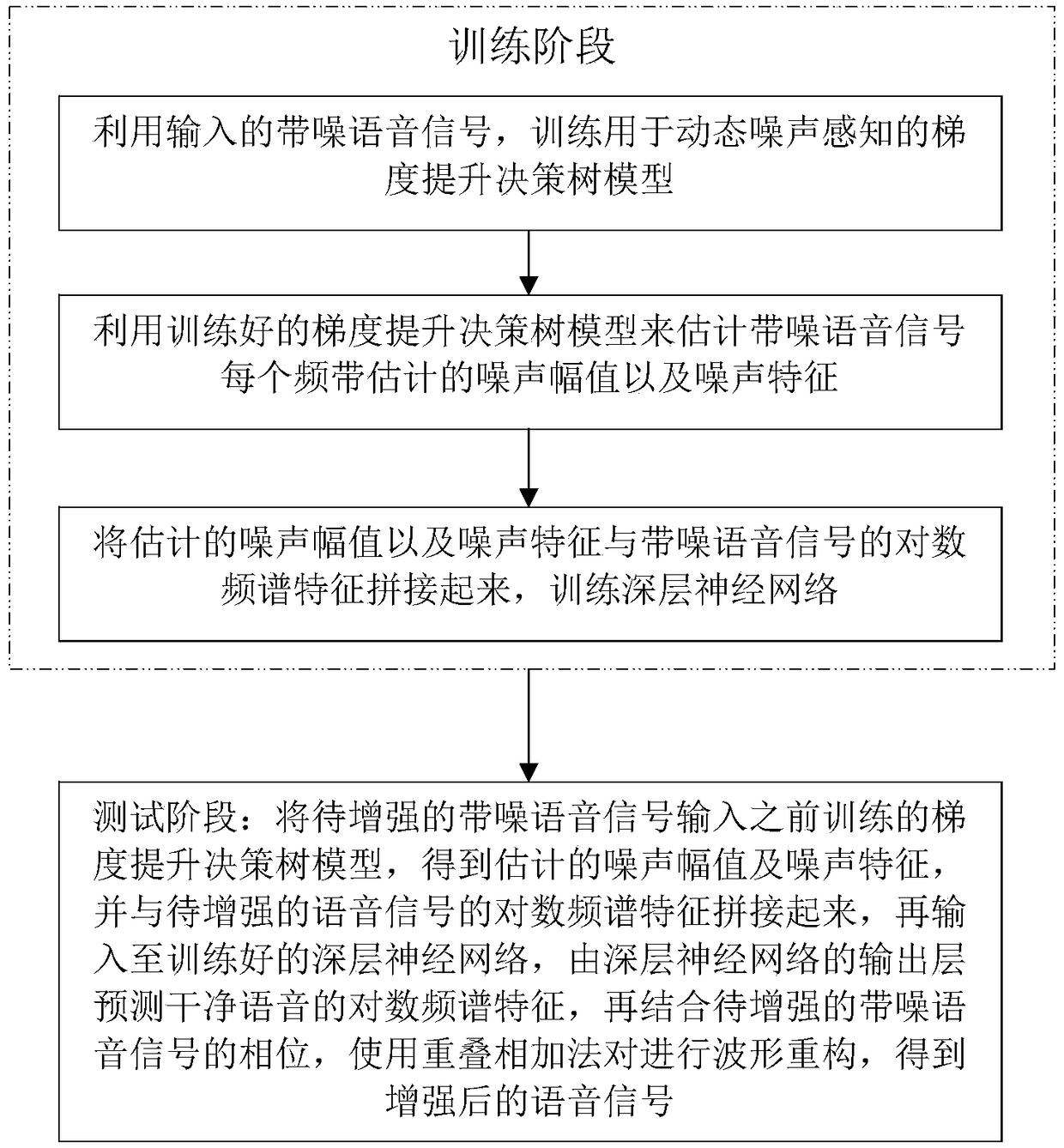

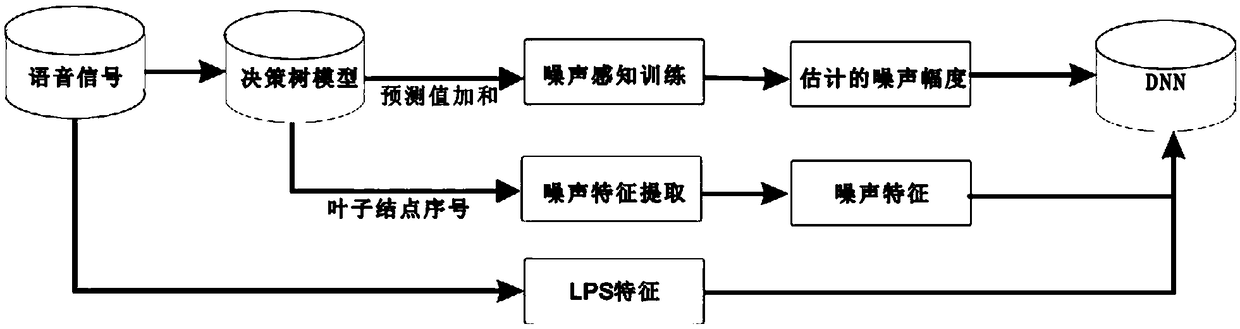

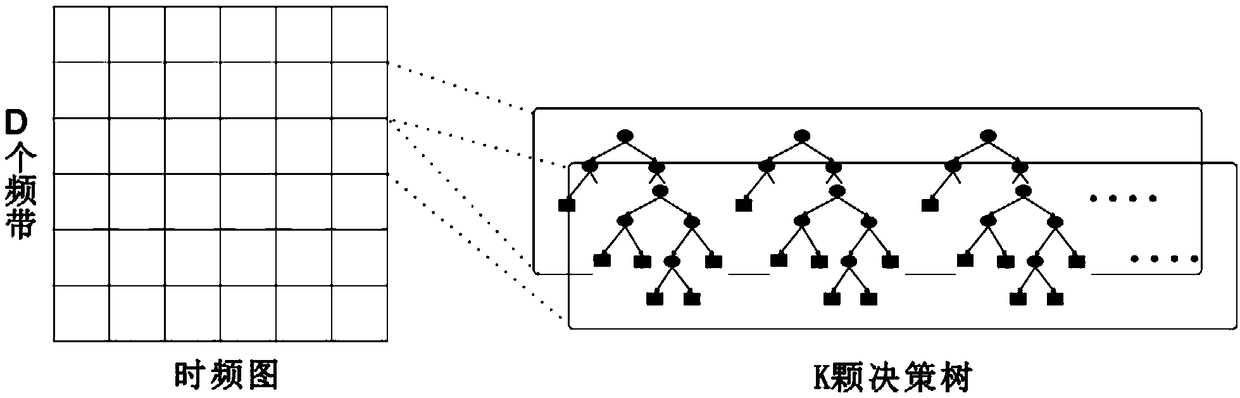

Speech enhancement method based on ensemble learning and noise sensing training

The invention discloses a speech enhancement method based on ensemble learning and noise sensing training. Compared with the static noise sensing training, the speech enhancement method provided by the invention has the advantage that non-stable noises can be accurately tracked, meanwhile, by utilizing the feature that a gradient boosted decision tree can spontaneously extract characteristics, noise scene coding for each time-frequency unit is obtained, then additional information of noises is provided for the deep neural network, while the traditional noise sensing training method only can obtain the amplitude information of noises. Seen from the experimental result, the method is superior to the speech enhancement method adopting static noise sensing training.

Owner:UNIV OF SCI & TECH OF CHINA

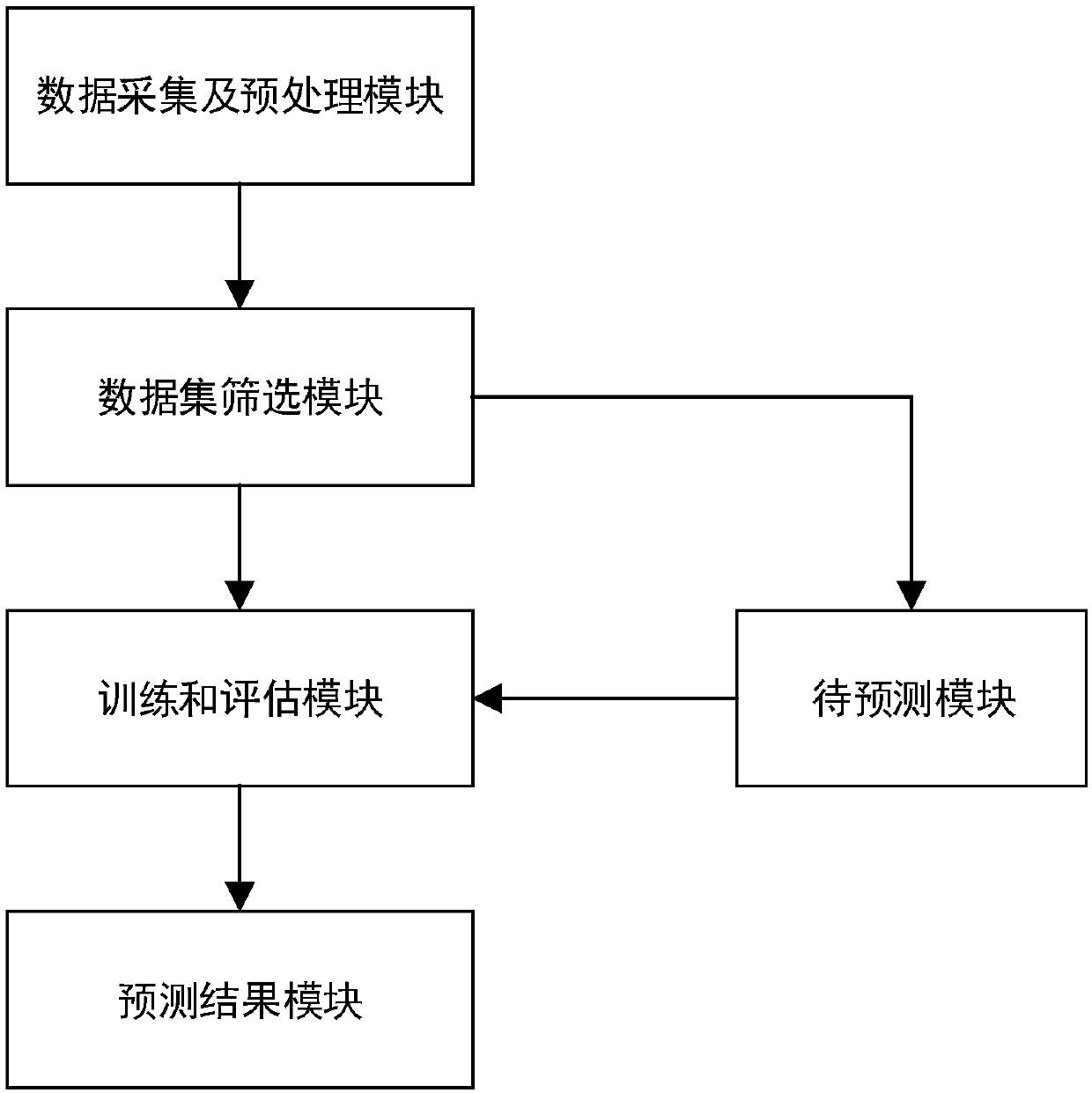

A silicon rod growth rate prediction model in polysilicon reduction furnace is presented

ActiveCN109543916AQuality assuranceGuaranteed growth rateForecastingNeural learning methodsChemical reactionData set

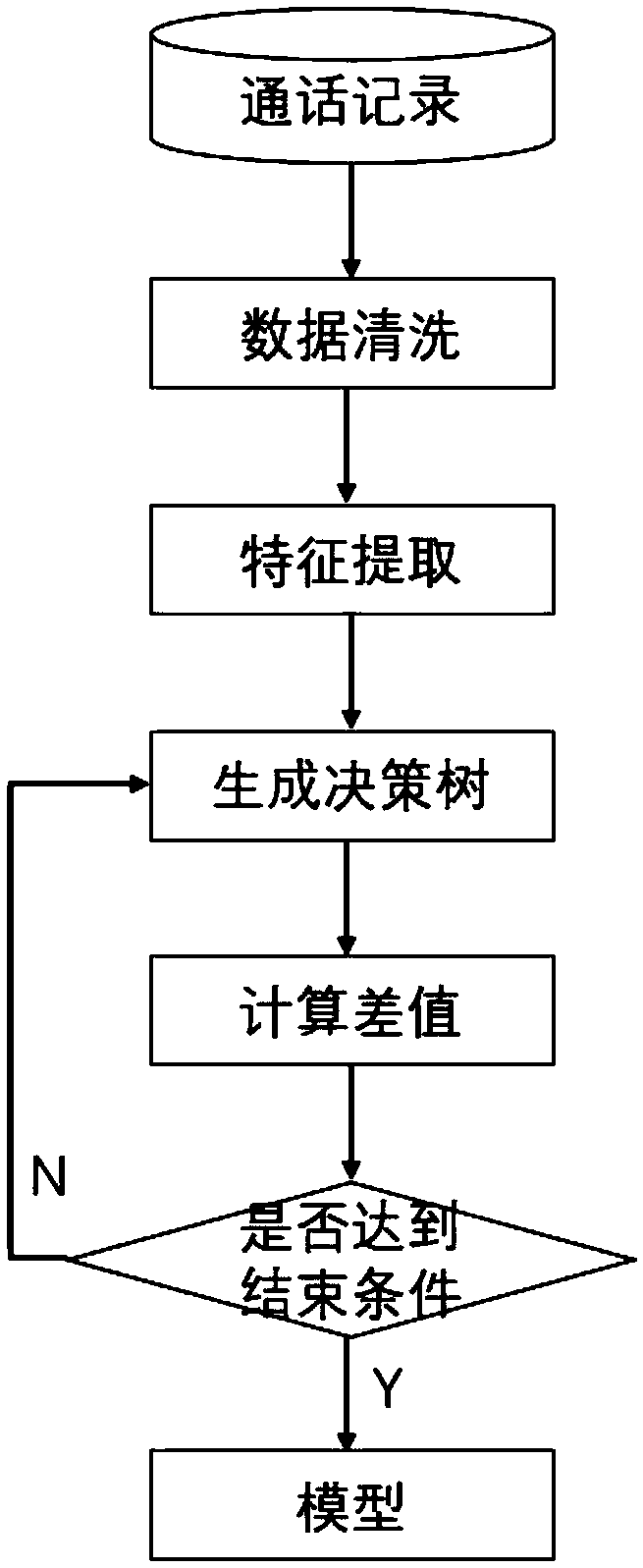

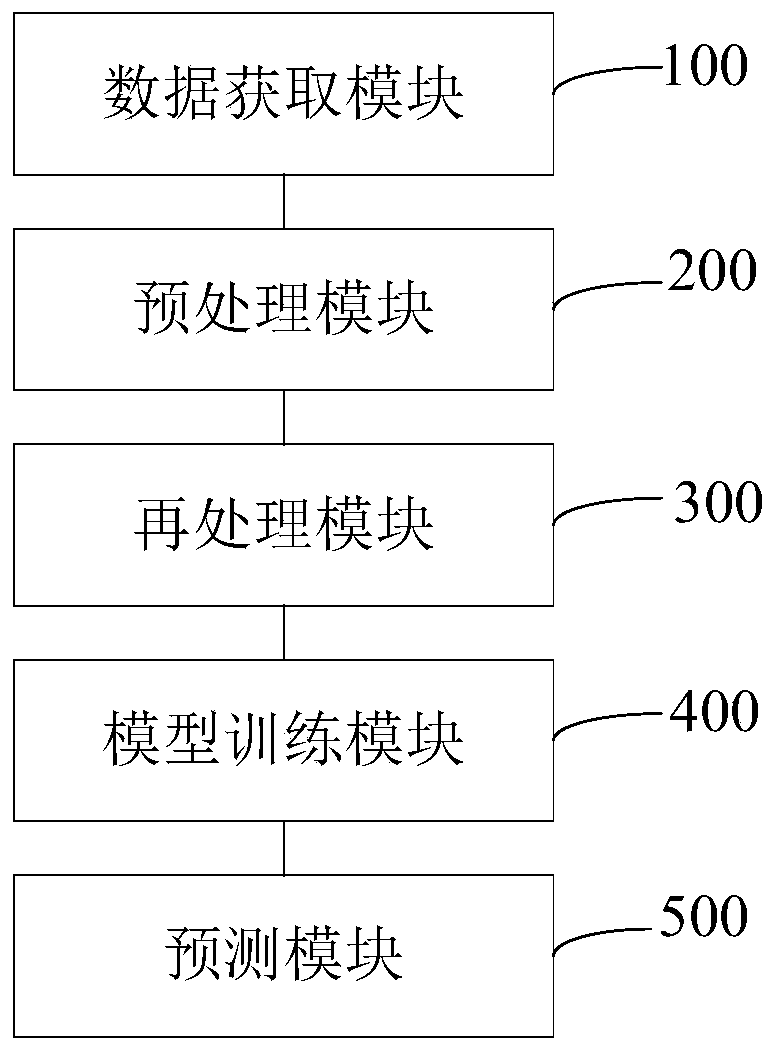

The invention discloses a silicon rod growth rate prediction model in a polycrystalline silicon reduction furnace, comprising a data acquisition and preprocessing module, which is used for acquiring data related to the silicon rod growth rate through a sensor and cleaning the acquired data; The data set screening module used for screening the data set after data collection and data cleaning of thedata collection module to obtain a training set and a test set; The Training and evaluating module, which is used for training the gradient lifting decision tree model and evaluating the model by using the average relative error and the eligibility rate; a prediction module, which is used for inputting the feature vector to be predicted; The prediction result module used for inputting the featurevector to be predicted into the prediction model and outputting the prediction result. The invention abandons the influence of complex chemical reaction on the growth rate in the traditional theoretical research, does not need to consider the complex chemical reaction, realizes the prediction of the growth rate of polysilicon, and provides guidance for improving the production efficiency and shortening the production cycle.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com