Processing method of machine-made sophora japonica bud stir-fried tea

A technology for tea processing and locust rice, which is applied in the field of machine-made locust rice frying and tea processing, can solve the problems of inability to realize industrialized production and stay in hand-made production, and achieve the effects of high sensory score, clear and golden tea soup, and burnt taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

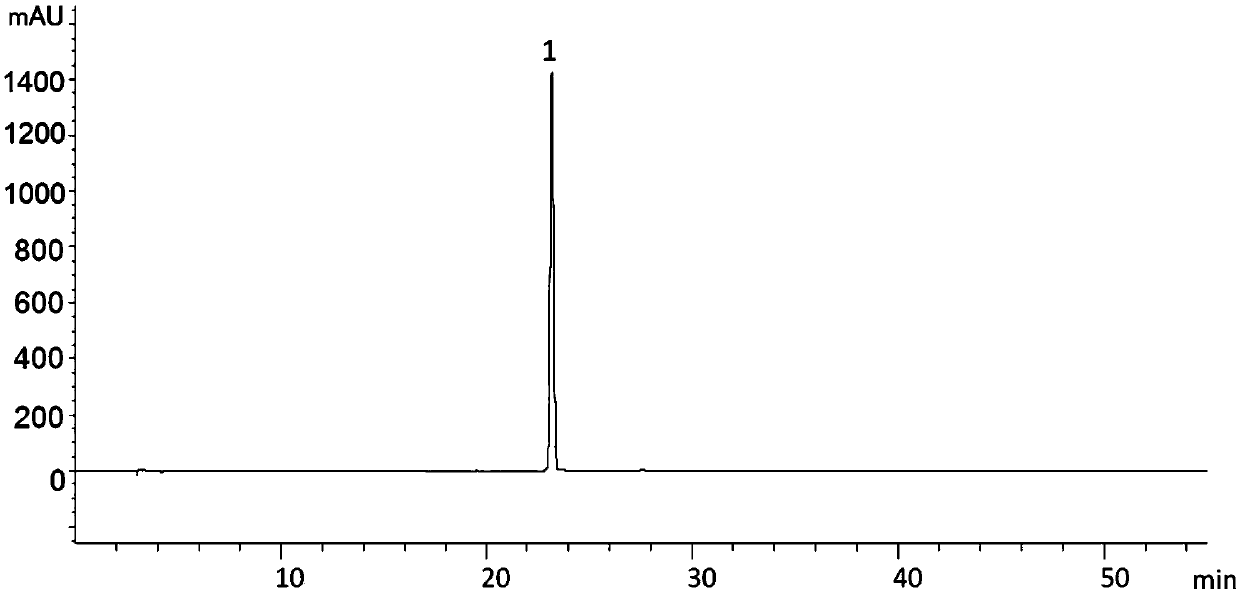

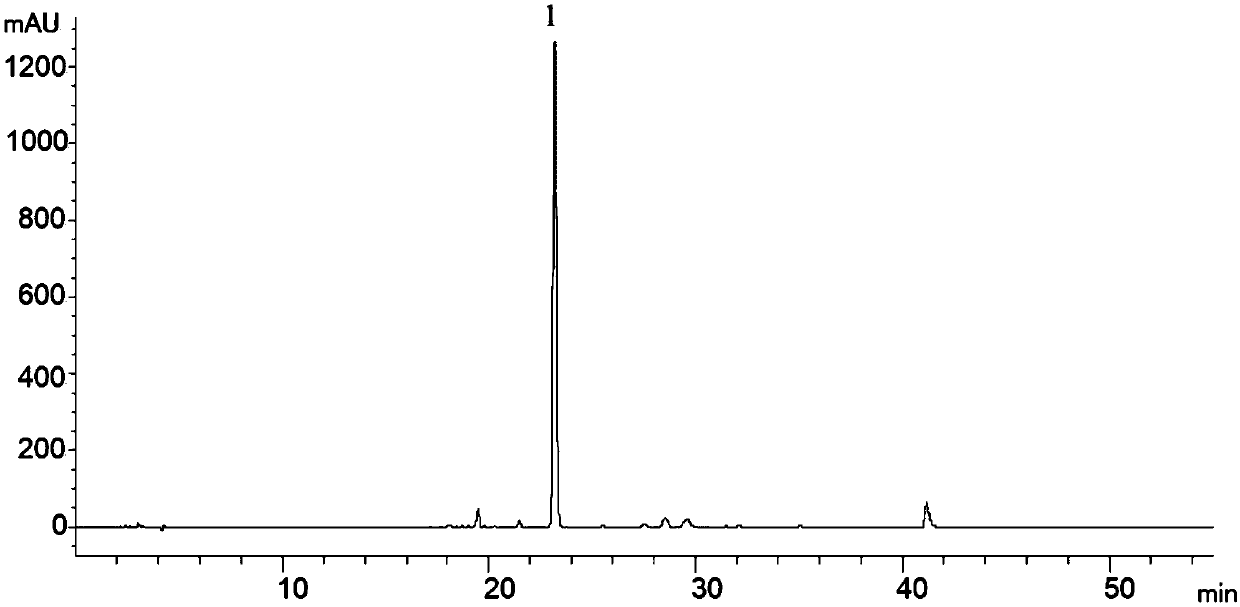

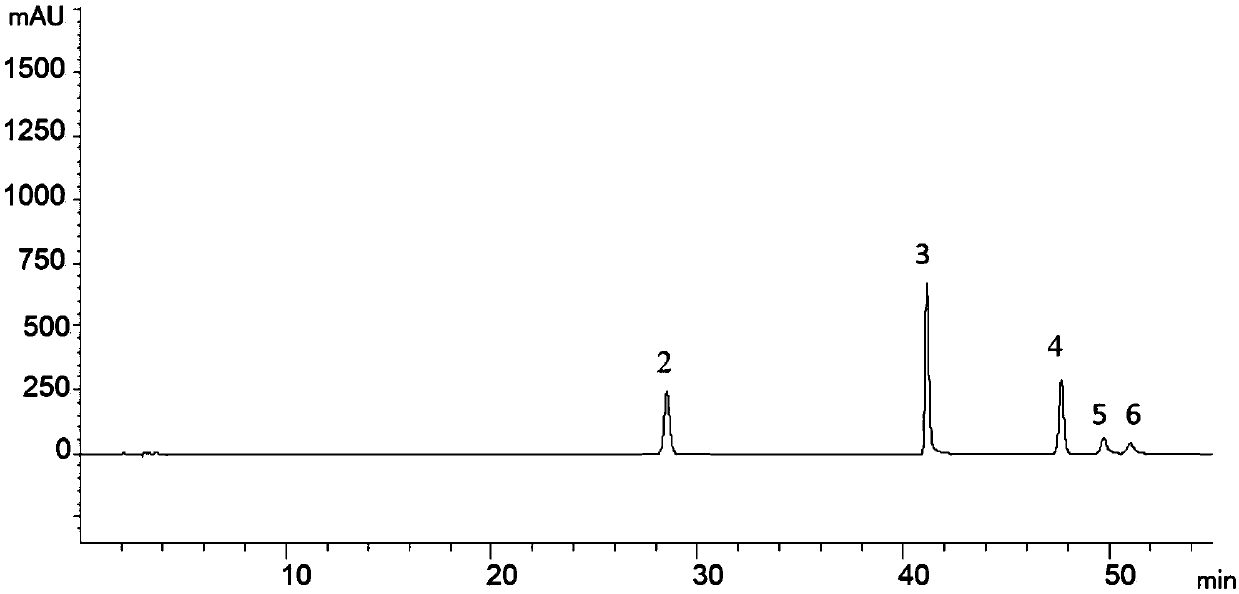

Image

Examples

Embodiment 1

[0057] The processing method of machine-made Sophora japonica fried tea is specifically carried out according to the following methods:

[0058] (1) Harvesting: Select the branches of Sophora japonica with full grains and larger grains.

[0059] (2) Finishing and drying: stack the branches of Huai Mi in a steamer with a thickness of 4-6cm on a multi-compartment steaming rack for steaming. After the water boils, continue steaming for 15-20 minutes, and then put the obtained Huai Mi in a sunny day. dry in the sun outside;

[0060] (3) Stir-frying: under the conditions of a frying amount of 34kg / time and a frying speed of 400r / min, evenly heat from room temperature to 125°C for 15 minutes, and add stevia with a mass fraction of 1% to Sophora japonica Glycoside solution, the dosage of steviol glycoside solution is to add 120ml of steviol glycoside solution to every 34kg Sophora japonica, and then continue frying at 125°C for 6 minutes;

[0061] (4) Cooling: Put the fried sophora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com