Ship sanitary water system utilizing condensate water of air conditioner

A sanitary water and ship technology, applied in the field of ship sanitary water system, can solve the problems of poor sterilization and filtration effects, inconvenient cleaning or replacement, and poor anti-corrosion effect, so as to improve the anti-corrosion effect and facilitate cleaning or replacement , Good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

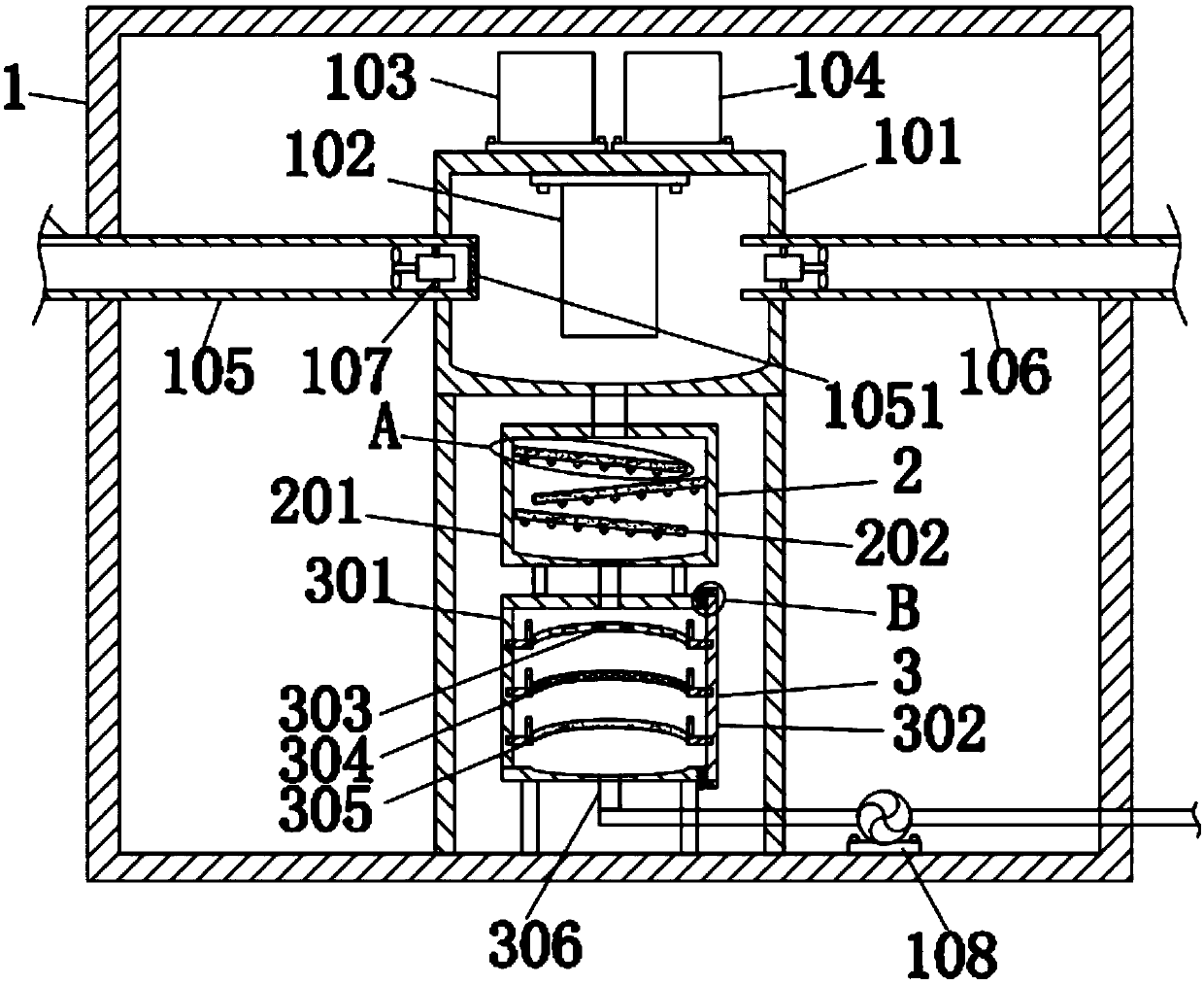

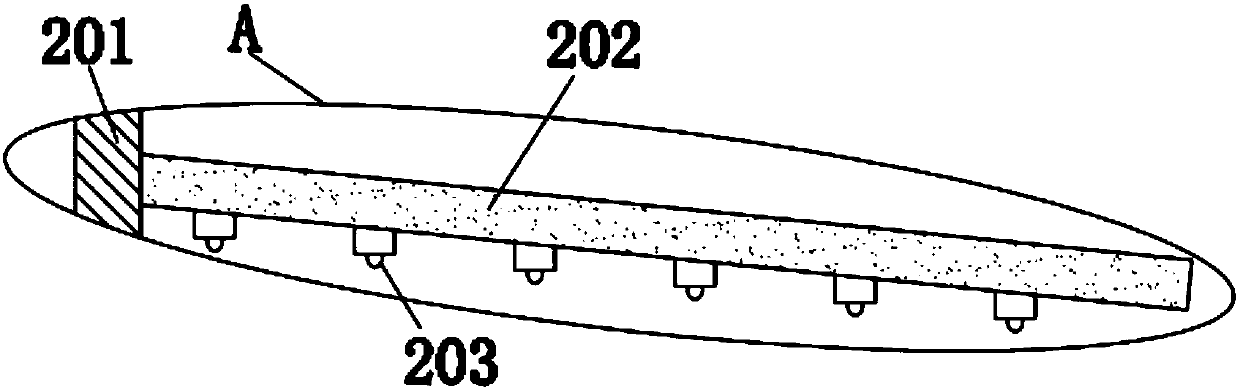

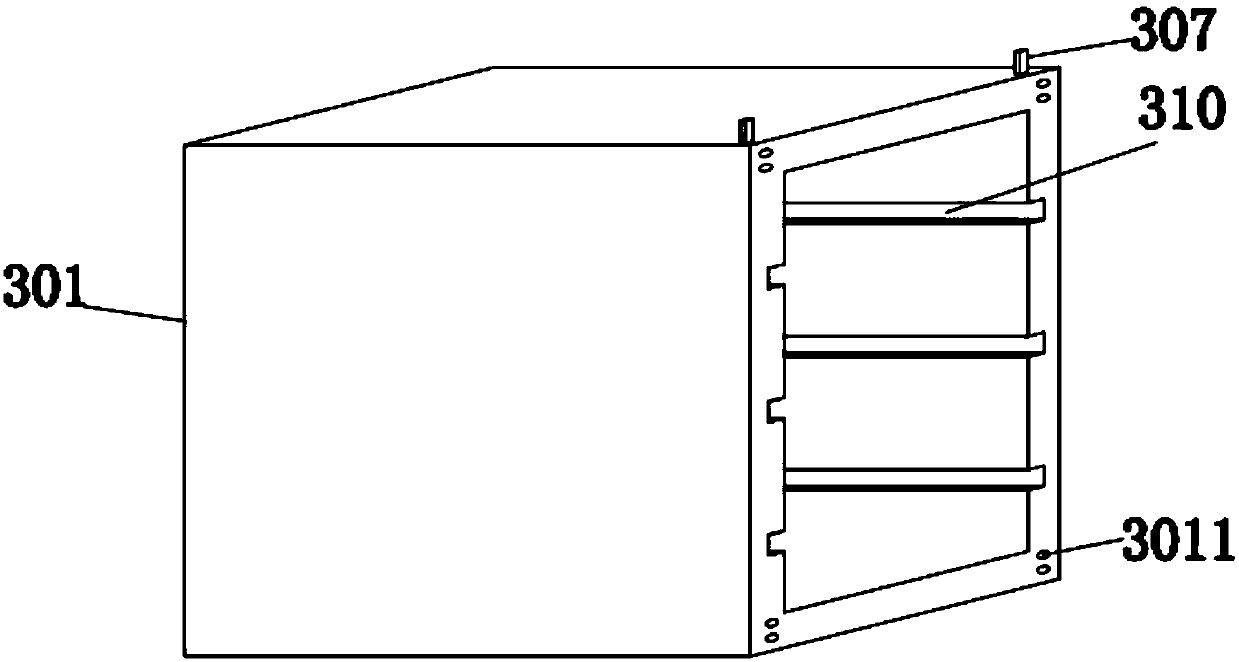

[0050] Such as figure 1 As shown, a ship sanitation water system utilizing air-conditioning to condense water includes an air-conditioning room 1, and the interior of the air-conditioning room 1 is fixedly installed with a refrigeration box 101, a sterilizing mechanism 2 and a filtering mechanism 3 sequentially through brackets from top to bottom;

[0051] Such as figure 1 As shown, the top of the refrigeration box 101 is fixed with an evaporator 102 through bolts, and the top of the refrigeration box 101 is fixed with a compressor 103 and a condenser 104 through bolts in turn from left to right. The compressor 103 is connected to the evaporator through pipelines 102 communicates with the condenser 104, and the evaporator 102 and the condenser 104 are communicated through a capillary tube. The middle part of the left and right side walls of the refrigeration box 101 is respectively equipped with an outlet pipe 105 and an inlet pipe 106, and the outlet pipe 105 and the inlet pi...

Embodiment 2

[0078] The difference from Example 1 is that the outer wall of the evaporator 102 is sprayed with an anti-corrosion layer, and the anti-corrosion layer is prepared by the following method:

[0079] Take the following raw materials and weigh them by weight: 3 parts of zinc oxide powder, 5 parts of amino resin powder, 7 parts of aluminum powder, 11 parts of modified phenolic resin, 4 parts of polyvinyl acetate, 6 parts of polyisocyanate, dodecyl sulfonate 9 parts of sodium acid emulsion, 7 parts of silicon acrylic emulsion, 10 parts of binder, 6 parts of defoamer, 80 parts of distilled water;

[0080] S1, material preparation: first weigh the above raw materials;

[0081]S2. Preliminary mixing: first pour distilled water into the mixer, then pour the modified phenolic resin, polyvinyl acetate, polyisocyanate, sodium dodecyl sulfonate emulsion, and silicone acrylic emulsion into the mixer, and then stir and mix. material, control the rotating speed of the stirrer at 40r / min, the...

Embodiment 3

[0089] The difference with embodiment 2 is the preparation of anti-corrosion layer, and its specific preparation method is as follows:

[0090] Take the following raw materials and weigh them by weight: 5 parts of zinc oxide powder, 7 parts of amino resin powder, 9 parts of aluminum powder, 13 parts of modified phenolic resin, 6 parts of polyvinyl acetate, 8 parts of polyisocyanate, dodecyl sulfonate 11 parts of sodium acid emulsion, 9 parts of silicon acrylic emulsion, 14 parts of binder, 8 parts of defoamer, 100 parts of distilled water;

[0091] S1, material preparation: first weigh the above-mentioned raw materials;

[0092] S2. Preliminary mixing: first pour distilled water into the mixer, then pour the modified phenolic resin, polyvinyl acetate, polyisocyanate, sodium dodecyl sulfonate emulsion, and silicone acrylic emulsion into the mixer, and then stir and mix. material, control the rotating speed of the stirrer at 60r / min, the temperature is 65 degrees Celsius, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com