System for resource utilization and comprehensive treatment of organic sludge and treatment system of system

A comprehensive treatment and organic sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of insufficient process integrity, soil heavy metal pollution, high treatment cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

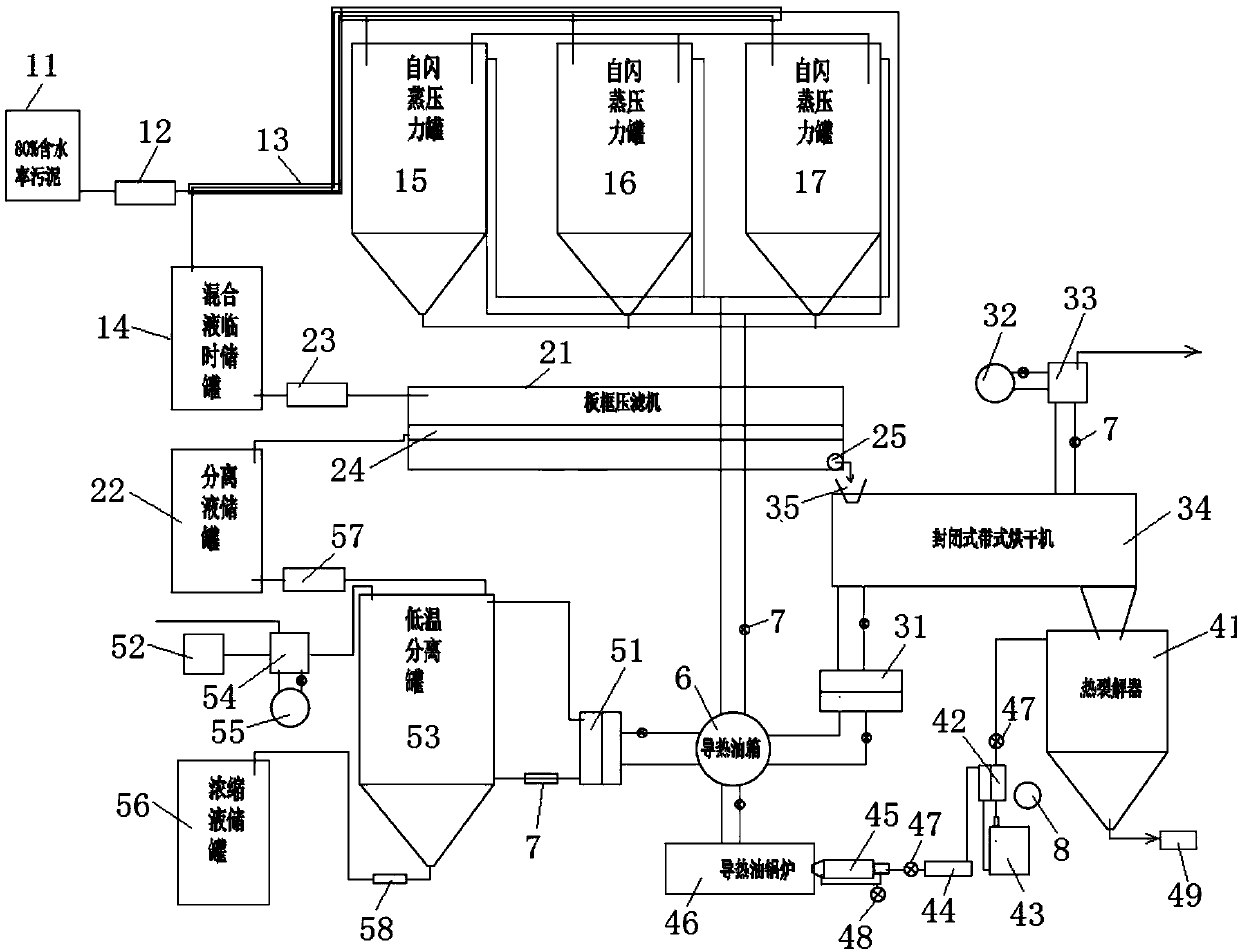

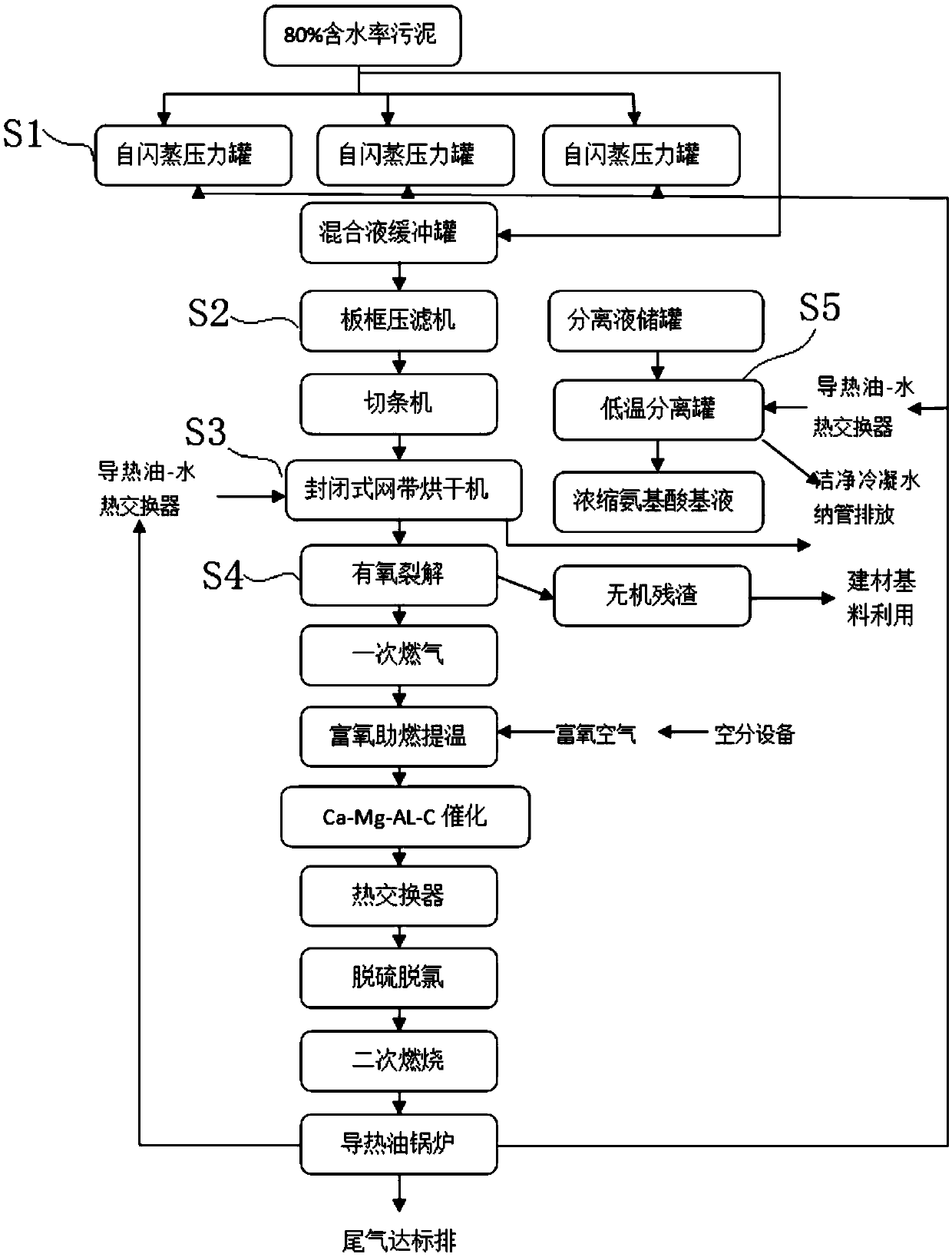

[0058] see figure 1 , an embodiment of the present invention, a comprehensive treatment system for resource utilization of organic sludge, including a thermal wall breaking process section, a plate and frame solid-liquid separation process section, a closed drying process section, a thermal cracking catalytic process section and a separation liquid low temperature Separation and concentration process section.

[0059] The thermal wall breaking process section includes a sludge feeding bin 11, a sludge conveying pump 12, a sludge conveying heat exchange conduit 13, three self-flashing pressure tanks and a mixed liquid buffer storage tank 14, and the sludge conveying heat exchange conduit 13 includes The cold material pipe and the hot material pipe, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com