High Alkalinity High Strength Sulphoaluminate Cement

A technology of sulfoaluminate cement and sulfoaluminate clinker, applied in cement production and other directions, can solve the problems of steel corrosion, low alkalinity, slow hydration speed, etc. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

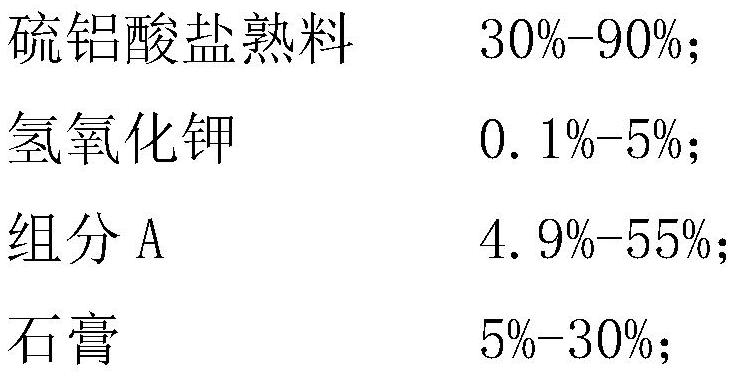

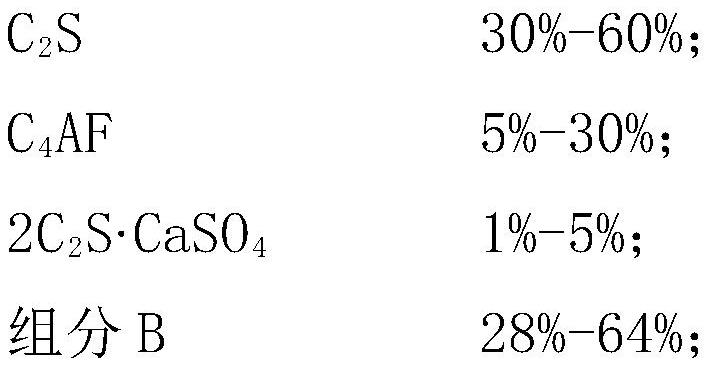

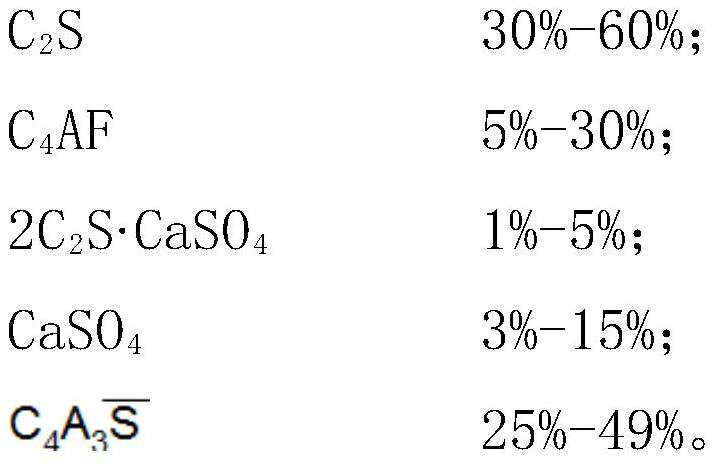

Method used

Image

Examples

Embodiment 1- Embodiment 3 and comparative example 1- comparative example 3

[0061] Prepare the sample of sulphoaluminate clinker according to the formula listed in Table 1 below, and measure the alkalinity of the sulphoaluminate clinker hydration system according to GB20472-2006. The test results are shown in Table 1, and the ratio in the table For weight percent wt%.

[0062] Formulation and properties of table 1 sulfoaluminate clinker

[0063]

[0064]

[0065] It can be seen from the data listed in the above table 1 that when the C of the sulfoaluminate clinker 2 S includes 30% α' type C 2 S, the alkalinity of the sulfoaluminate clinker hydration system increases, and its pH value increases by 0.7, see the data of Example 1 and Comparative Example 1.

[0066] It can be seen from the data listed in the above table 1 that when the C of the sulfoaluminate clinker 2 S includes 53.3% of α'-type C 2 When S, the alkalinity of the sulfoaluminate clinker hydration system increases, and its pH value increases by 1.1, see the data of Example 2 and C...

Embodiment 4- Embodiment 7 and comparative example 4- comparative example 7

[0070] Select the formula of the above-mentioned sulphoaluminate clinker with the highest alkalinity in the early stage, that is, the sulphoaluminate cement of Example 2, and prepare samples of sulphoaluminate cement according to the formula listed in Table 2 below, according to the standard GB20472-2006 Measure the alkalinity of the hydration system of the sulphoaluminate cement, measure the compressive strength of the sulphoaluminate cement according to the standard GB / T17671-1999, the test results are shown in Table 2, and the ratio in the table is by weight Percent wt%.

[0071] Formulation and properties of table 2 sulphoaluminate cement

[0072]

[0073] As can be seen from the data listed in the above table 2, in comparative example 4-comparative example 7, potassium hydroxide is not added, only anhydrite, silica-alumina material (such as slag powder and / or phosphorus slag powder) and / or Or siliceous materials (such as silica fume powder and / or nano-silica), which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com