Active bio-based chlorine-containing s-triazine type macromolecular dye preparation method

A macromolecular dye and bio-based technology, which is applied in the field of preparation of active bio-based chlorine-containing s-triazine-type macromolecular dyes, can solve the problems of being unable to be used as a macromolecular colorant and having no color, so as to improve the brightness of the coating, Good heat resistance, deep color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

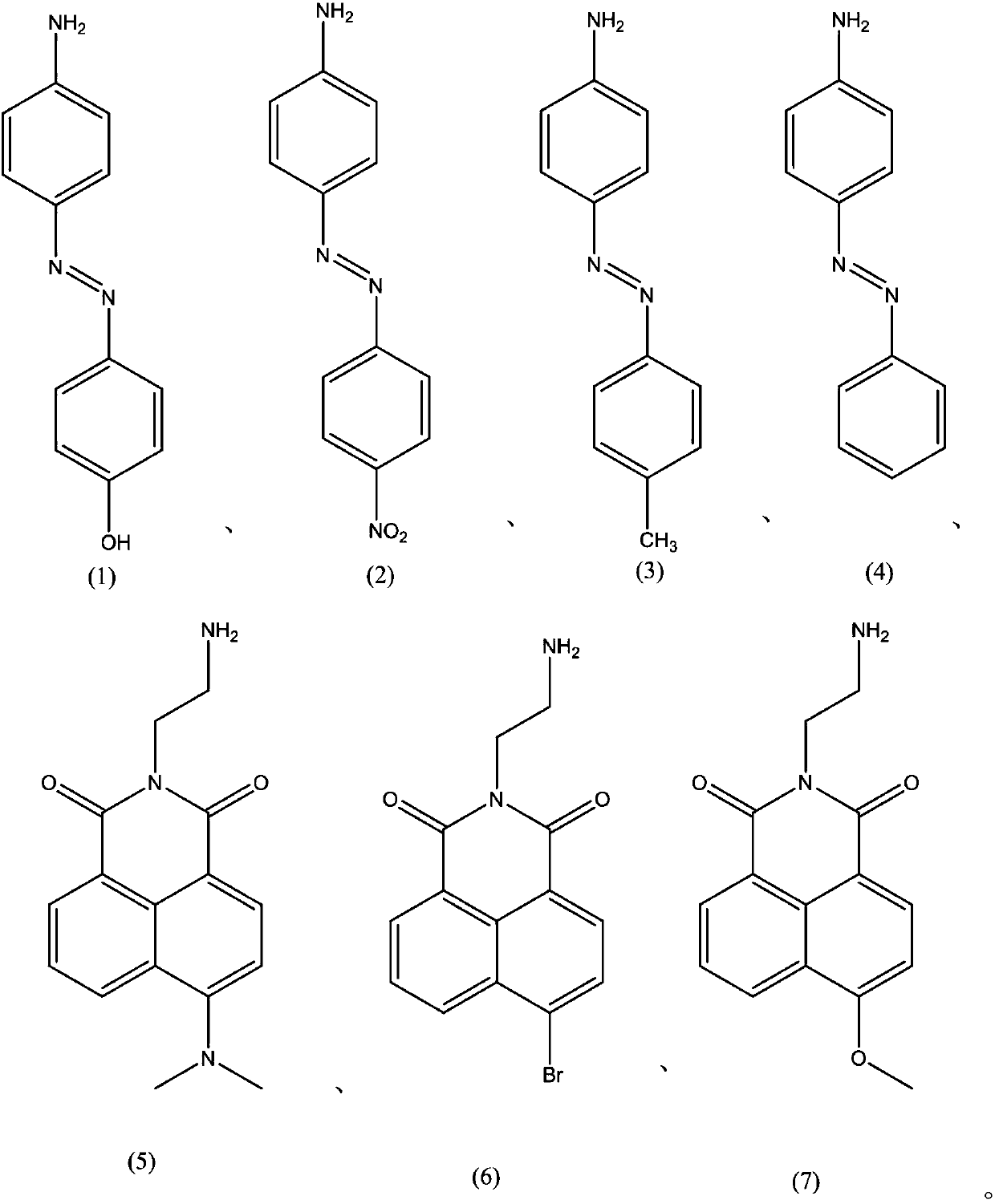

Embodiment 1

[0032] First add water to cyanuric chloride and stir evenly, add prepared 15% soda ash water to adjust pH=8.0 or so, then add refined small molecule dye precursor formula (1), wherein cyanuric chloride and small molecule dye precursor mole The ratio is 0.95:1, heat up to 75-80°C, keep pH = 5.0-6.0 and react for 4-6h to obtain dichloro-s-triazine dye monomer, wash with warm water at 80°C, and dry at 100°C Use DMF-H again 2 The pure dye monomer can be obtained after recrystallization and purification.

[0033] 1 g of dye monomer synthesized above and 10 g of chitosan compound were reacted in DMF phase at 50° C. for 5 h, and then water was added to precipitate and filter to obtain the final product.

Embodiment 2

[0035] First add water to cyanuric chloride and stir evenly, add prepared 15% soda ash water to adjust pH=8.0 or so, then add refined small molecule dye precursor formula (2), wherein cyanuric chloride and small molecule dye precursor mole The ratio is 0.95:1, heat up to 75-80°C, keep pH = 5.0-6.0 and react for 4-6h to obtain dichloro-s-triazine dye monomer, wash with warm water at 80°C, and dry at 100°C Use DMF-H again 2 The pure dye monomer can be obtained after recrystallization and purification.

[0036] The 1g dye monomer synthesized above and 10gH 2 N-PEG-NH 2 (α,ω-diaminopolyethylene glycol amine, molecular weight 1000), reacted in the water phase at 50°C for 10 hours, then added water to precipitate and filter to obtain the final product.

Embodiment 3

[0038] First add water to cyanuric chloride and stir evenly, add prepared 15% soda ash water to adjust pH=8.0, then add refined small molecule dye precursor formula (7), wherein cyanuric chloride and small molecule dye precursor mole The ratio is 0.95:1, heat up to 75-80°C, keep pH = 5.0-6.0 and react for 4-6h to obtain dichloro-s-triazine dye monomer, wash with warm water at 80°C, and dry at 100°C Use DMF-H again 2 The pure dye monomer can be obtained after recrystallization and purification.

[0039] The 1g fluorescent dye monomer synthesized above and 10gH 2 N-PEG-NH 2 (α,ω-diaminopolyethylene glycol amine, molecular weight 2000), reacted in the water phase at 50°C for 10h, then filtered and dried to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com