Organopolysiloxane emulsion compositon and resin composition

一种乳化组合物、聚硅氧烷的技术,应用在有机聚硅氧烷乳化组合物领域,能够解决没有均匀分散、白化、外观问题等问题,达到赋予滑动性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0241] [Preparation of composition]

[0242] The specific emulsification method of the organopolysiloxane emulsion composition of this invention is mainly as follows.

[0243] The first is to combine (A) polyoxyalkylene-modified organopolysiloxane compound, (B) polyoxyalkylene-modified organosiloxane compound, (C) surfactant and (D) organopolysiloxane The method of compounding (E) water after the mixture is emulsified.

[0244] The second is to combine (A) polyoxyalkylene modified organopolysiloxane compound, (B) polyoxyalkylene modified organosiloxane compound, (C) surfactant, (D) organopolysiloxane and ( E) A method of emulsifying a mixture of water.

[0245] The third is to compound (A) polyoxyalkylene after emulsifying a mixture of (B) polyoxyalkylene-modified organosiloxane compound, (C) surfactant, (D) organopolysiloxane and (E) water Method for modifying organopolysiloxane compounds.

[0246] The fourth is to emulsify the mixture of (A) polyoxyalkylene modified orga...

Embodiment 1

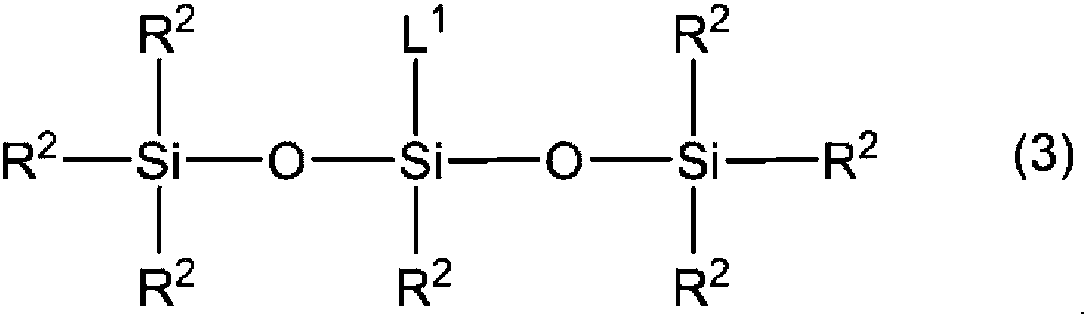

[0277] Under nitrogen atmosphere, add by following general formula (8a)

[0278] [chem 33]

[0279]

[0280] Organopolysiloxane containing silicon atoms combined with hydrogen atoms (viscosity 2,800mm 2 / s, the amount of hydrogen atoms combined with silicon atoms (0.00625mol / 100g) 79 parts by mass (79g), by the following general formula (7a)

[0281] [chem 34]

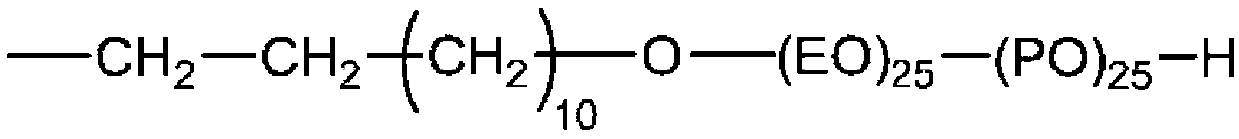

[0282] CH 2 =CHCH 2 O(CH 2 CH 2 O) 25 (CH 2 CHCH 3 O) 35 H (7a)

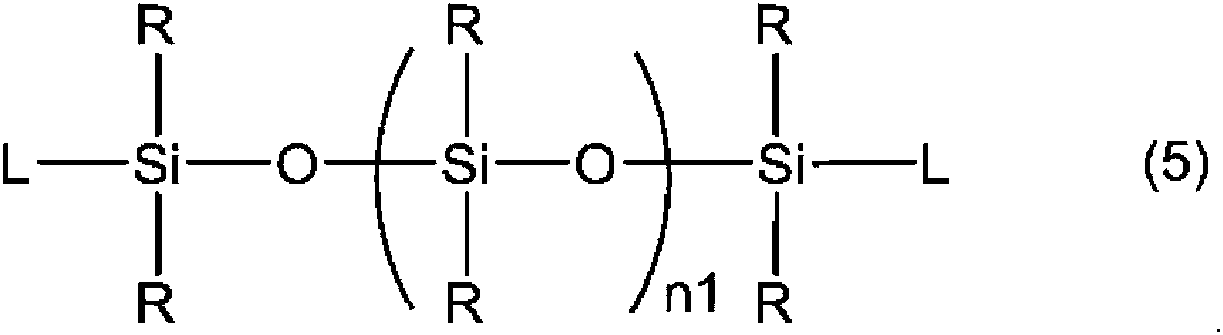

[0283] After 21 parts by mass (21 g) of the indicated unsaturated group-containing polyoxyalkylene compound and 250 parts by mass (250 g) of isopropyl alcohol were heated, the internal temperature was adjusted to 75°C. Next, a toluene solution of 5 mass ppm of platinum vinylsiloxane complex was added to siloxane in terms of platinum metal, and stirred for 8 hours to synthesize the following compound with a reaction rate of 90% or more. Polyoxyalkylene-modified organopolysiloxane compound A represented by general formula (5a) (the weight av...

Embodiment 2

[0304] will be given by the following general formula (11b)

[0305] [chemical 40]

[0306]

[0307] (k represents a number that makes the viscosity described below.)

[0308] 30 parts by mass (30 g) of the two-terminal hydroxydimethylpolysiloxane (viscosity: 30 million mPa·s) and the polyoxyalkylene-modified organopolysiloxane compound obtained in Example 1 above were dissolved in the surfactant 15 parts by mass (15 g) of compound A-1 and 5 parts by mass (5 g) of the polyoxyalkylene-modified organosiloxane compound a represented by the above general formula (3a) obtained in Example 1 were used HIVIS MIX (manufactured by PRIMIX Corporation) It stirred at 35 rpm at 20-60 degreeC for 180 minutes, and the emulsion composition B was obtained. The average particle diameter was measured with Multisizer 3 manufactured by Beckman Coulter, and was 10.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com