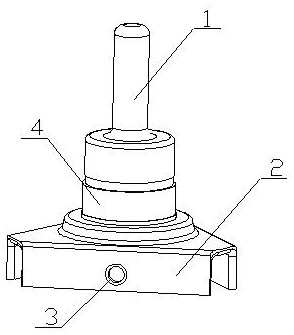

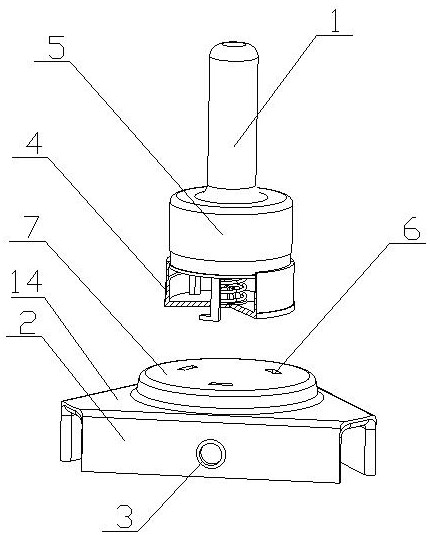

A modular intelligent logistics center transmission plate disassembler and its accessories

A technology of intelligent logistics and conveying boards, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of combination assembly, installation difficulty, insufficient suction, etc., and achieve the effects of easy installation, positioning and alignment, avoiding leakage damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

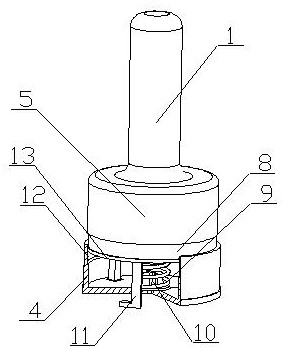

[0016] A modularized intelligent logistics center transfer plate disassembler and its accessories are realized in this way, consisting of a grip (1), a sliding sleeve (4), a pressing block (5), a sliding groove (8), and a compression spring (9), positioning buckle (10), hanging claw (11), accommodating groove (12) and limit ring (13), the pressing block (5) is placed at one end of the handle (1), and the handle The surface of the handle (1) is provided with anti-slip lines, the anti-slip lines can be netted lines, crow's feet and wavy lines, preferably netted lines, the press block (5) is a cylindrical structure, the press block (5) There is a sliding groove (8) on the outside, and extends to the bottom of the pressing block (5), the sliding groove (8) is an annular groove, and the width of the sliding groove (8) is a quarter of the height of the pressing block (5) One, the limit ring (13) is placed on the outside of the pressure block (5), and is located in the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com