Last stage orbit remaining application subsystem attitude control method

A technology for applying subsystems and attitude control, which is applied in the directions of space navigation vehicle guidance devices, space navigation equipment, space navigation aircraft, etc. Design difficulty and other issues, to achieve the effect of being beneficial to ground imaging and data communication, improving attitude control accuracy, and eliminating the influence of time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

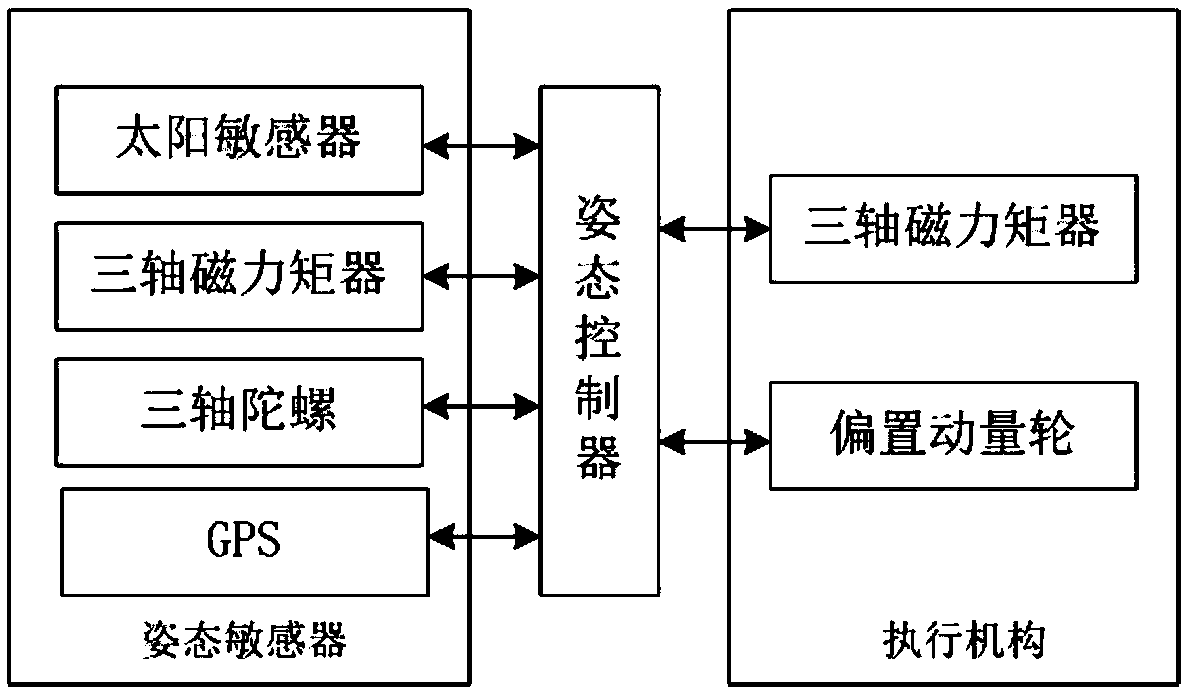

[0084] figure 1 It is a schematic diagram of the system structure of a last-stage track keeping application subsystem in a preferred embodiment of the present invention.

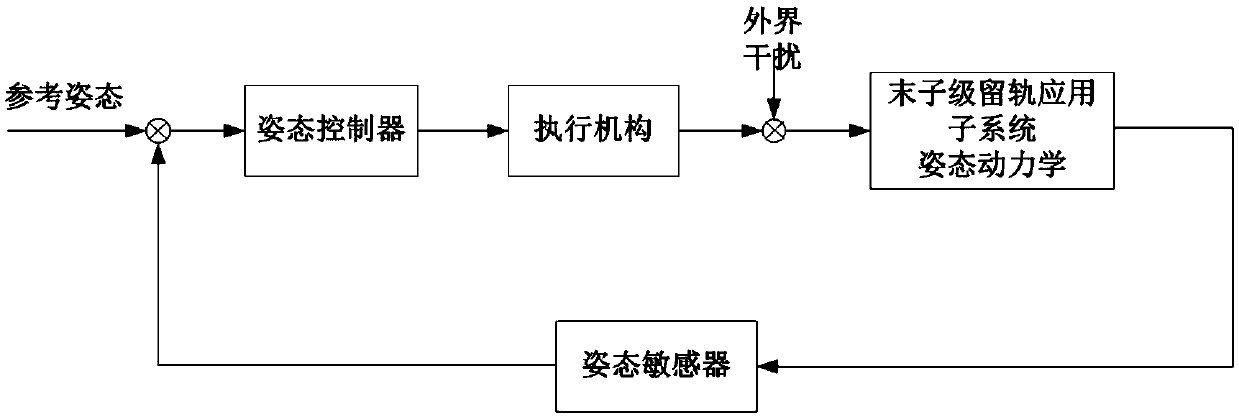

[0085] like figure 1 As shown, this embodiment provides an attitude control system of the last sub-level track keeping application subsystem, which includes: an attitude sensor, an attitude controller, and an actuator.

[0086] The attitude sensor is used to obtain the attitude information of the last sub-level track keeping application subsystem, and output a signal that is a function of the attitude parameters. Attitude sensors include sun sensors, three-axis magnetic torque devices, GPS and three-axis gyroscopes.

[0087] An attitude controller, connected in communication with the attitude sensor, is used to determine the current state of the last-level track-keeping application subsystem according to the attitude information of the last-level track-keeping application subsystem, and the current state i...

Embodiment 2

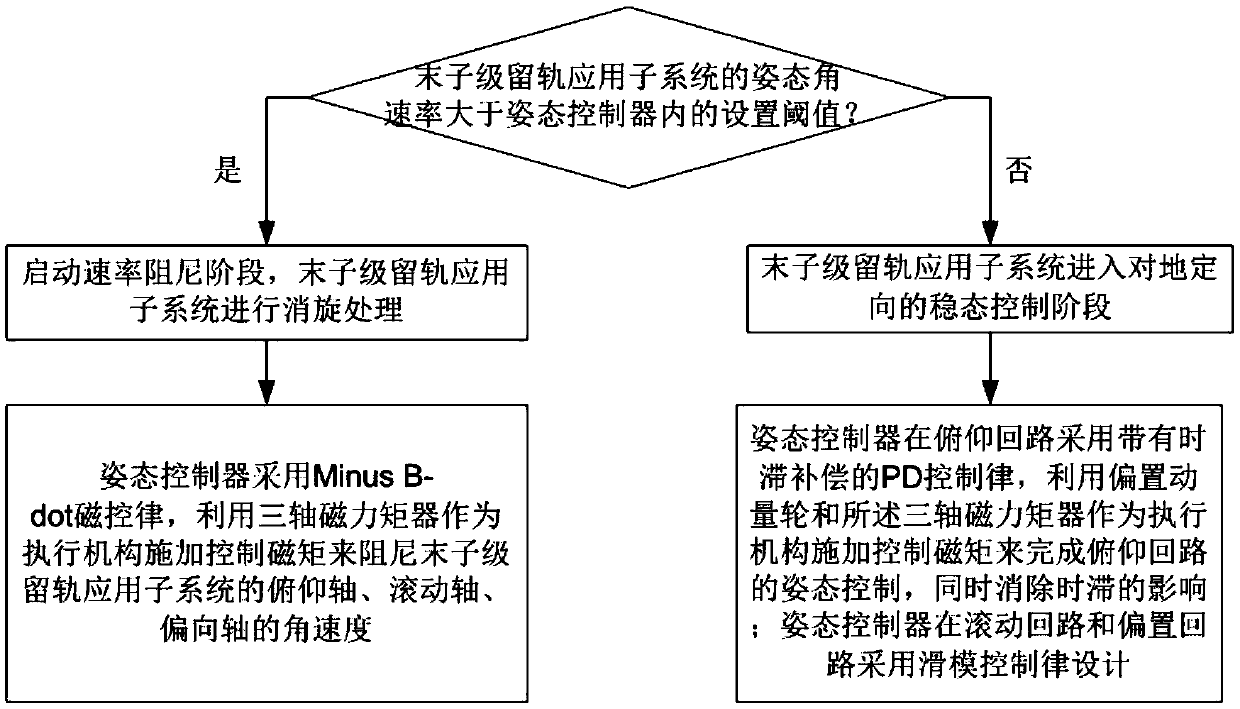

[0091] image 3 It is a flow chart of an attitude control method of the last sub-stage track keeping application subsystem in a preferred embodiment of the present invention.

[0092] like image 3 As shown, a method for attitude control of the last sub-level orbit application subsystem, including:

[0093] After the last sub-level orbit-keeping application subsystem enters the task setting orbit, the attitude controller pre-stores the setting threshold of the attitude angular rate of the last sub-level orbit-keeping application subsystem. When the attitude angular rate is greater than the attitude controller Set the threshold within the threshold, start the rate damping stage, and perform derotation processing on the last sub-level orbit-keeping application subsystem; when the attitude angular rate is less than or equal to the setting threshold in the attitude controller, the last sub-level orbit-staying application The subsystem enters the ground-oriented steady-state cont...

Embodiment 3

[0170] Simulation example:

[0171] The on-orbit flight stage of the last sub-level application subsystem for orbital retention is simulated, and the simulation input conditions are:

[0172] a) Running track

[0173] Orbit Type: Sun Synchronous Orbit

[0174] Orbit height: 539km

[0175] Orbit inclination: 97.5553deg

[0176] Orbit eccentricity: 0

[0177] b) Satellite mass characteristics

[0178] Satellite mass: 8.3±0.5kg

[0179] Satellite size: 110mm×231.7mm×346mm

[0180] Satellite inertia: I xx =0.088kg·m 2 , I yy =0.116kg·m 2 , I xx =0.044kg·m 2

[0181] 1) B-dot damping simulation

[0182] Taking the rate damping stage as an example, the simulation is carried out. The specific parameters and simulation results are as follows:

[0183] a) Initial pose

[0184] Attitude angle: [10; 10; 10] deg

[0185] Angular speed of rotation: [-3; -3; -3] deg / sec

[0186] b) Control parameters

[0187] Control cycle: 1sec

[0188] Damping Gain: 3e5

[0189] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com