Automatic filling sealing line for lubricating oil

An automatic filling and lubricating oil technology, applied in the direction of packaging, bottling machines, synchronous devices, etc., can solve the problems of not having water removal and controlling metering and discharging, not suitable for mechanized assembly line production, low production efficiency, etc., to achieve liberation The effects of manpower, high degree of mechanization and fast filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

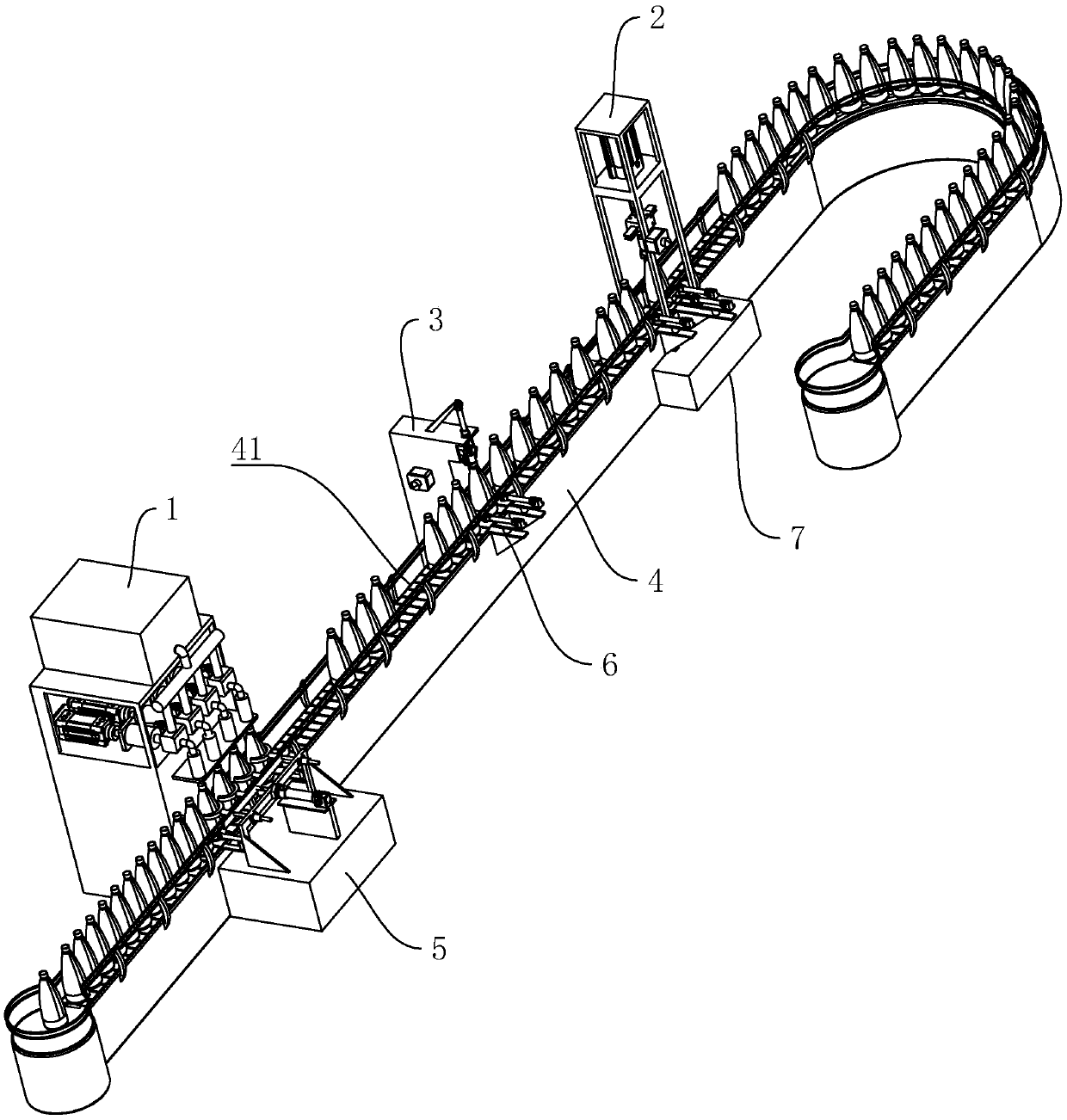

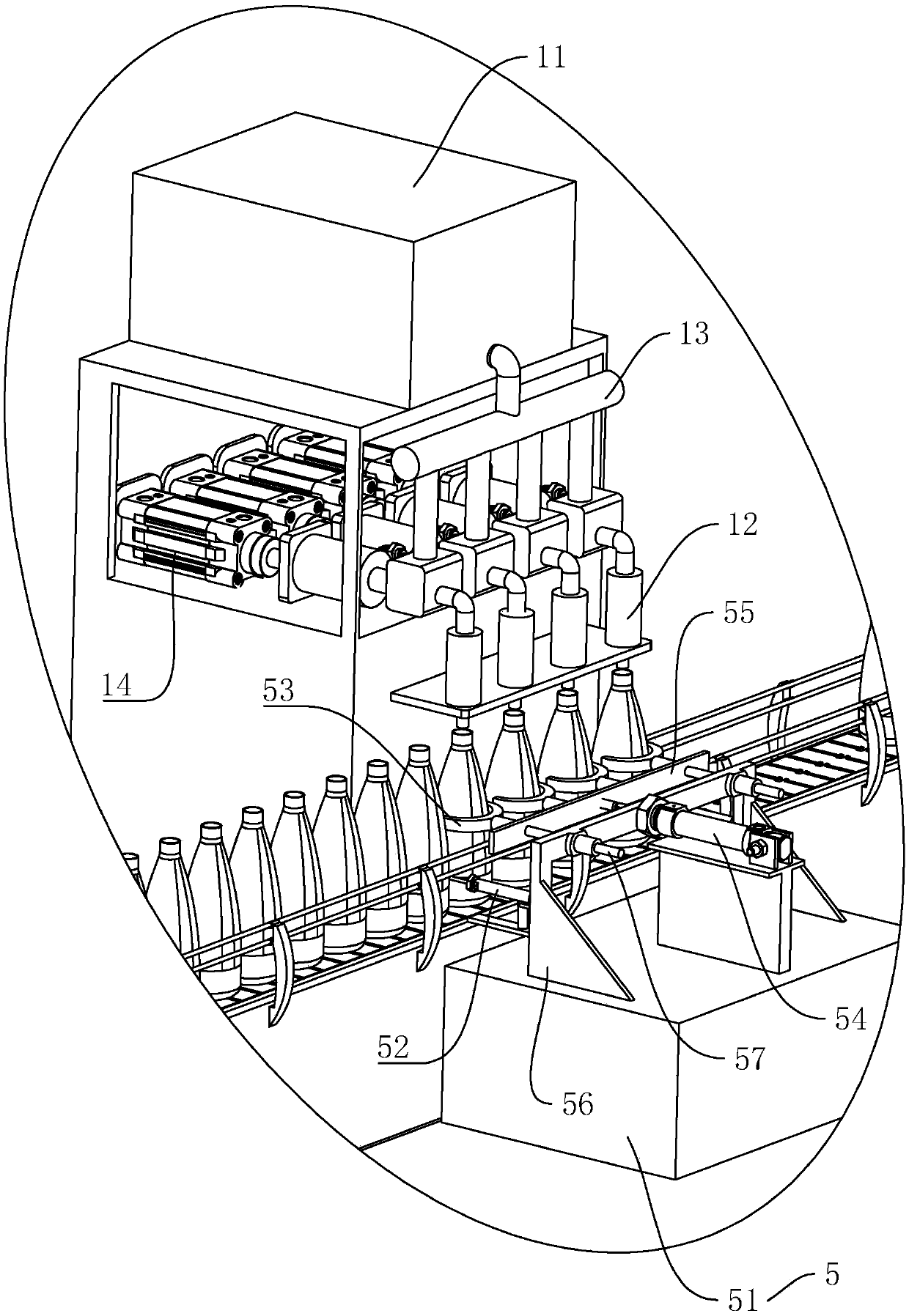

[0031] An automatic lubricating oil filling line provided in this embodiment has a structure such as figure 1 and figure 2 As shown, the filling machine 1 is included, and the filling machine 1 is equipped with a conveying line 4 on one side. The conveying line 4 is in the shape of a hook as a whole. And a sealing machine 2 for capping and sealing the lubricating oil drum.

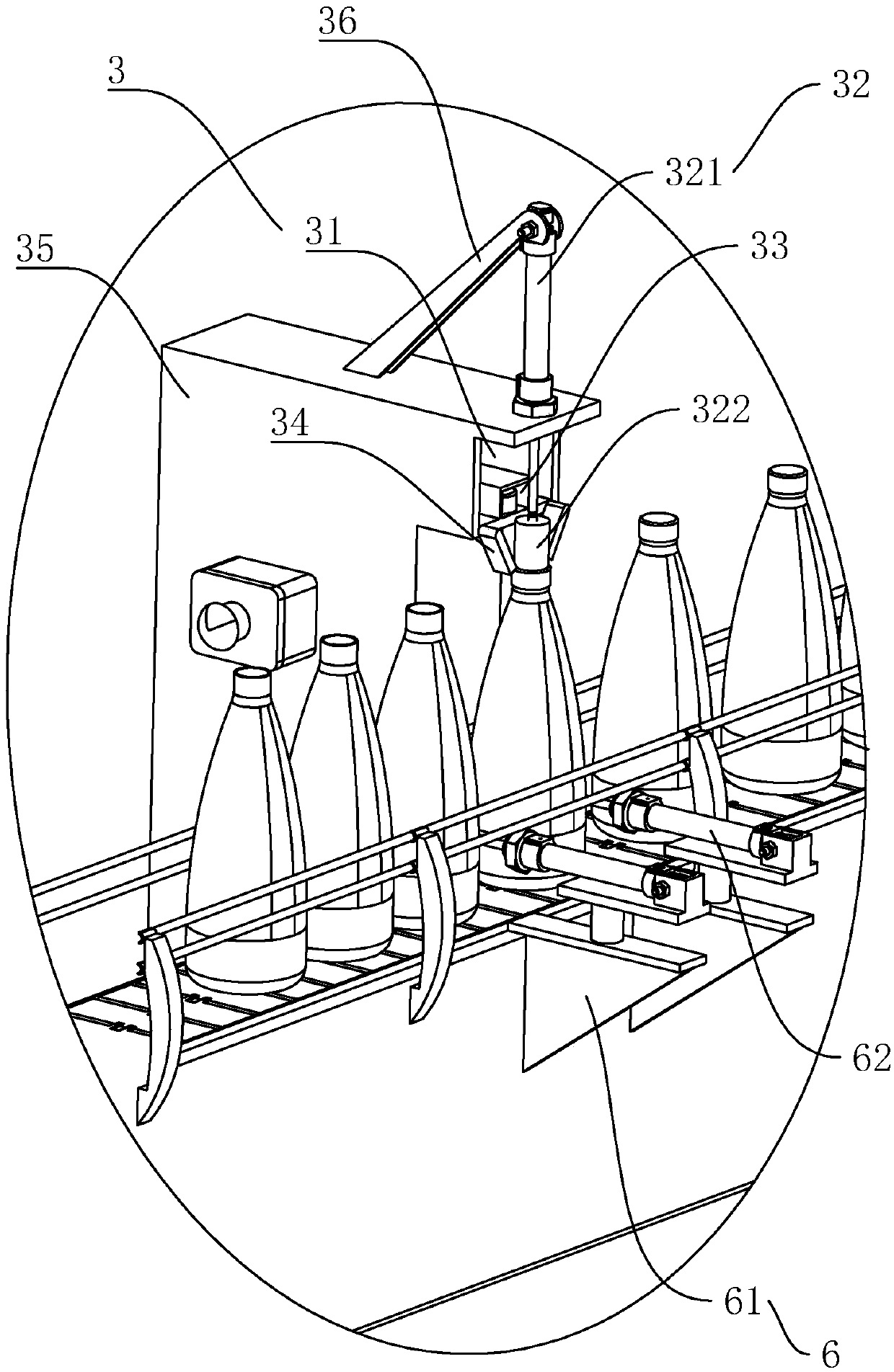

[0032] Such as figure 1 and figure 2 As shown, the conveying line 4 at the position of the filling machine 1 is provided with a first limit assembly 5, the corresponding position of the capping machine 3 is provided with a second limit assembly 6, and the corresponding position of the sealing machine 2 is provided with a third limit assembly 7. For limiting the lubricating oil drum, the first limiting component 5, the second limiting component 6 and the third limiting component 7 are all equipped with laser sensors for sensing the position of the lubricating oil barrel.

[0033] Such as figure 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com