Nylon wire for 3D printing and preparation method thereof

A 3D printing and nylon technology, applied in the field of nylon wire for 3D printing and its preparation, can solve the problems of high cost, shrinkage and deformation, and achieve the effects of low cost, small shrinkage and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

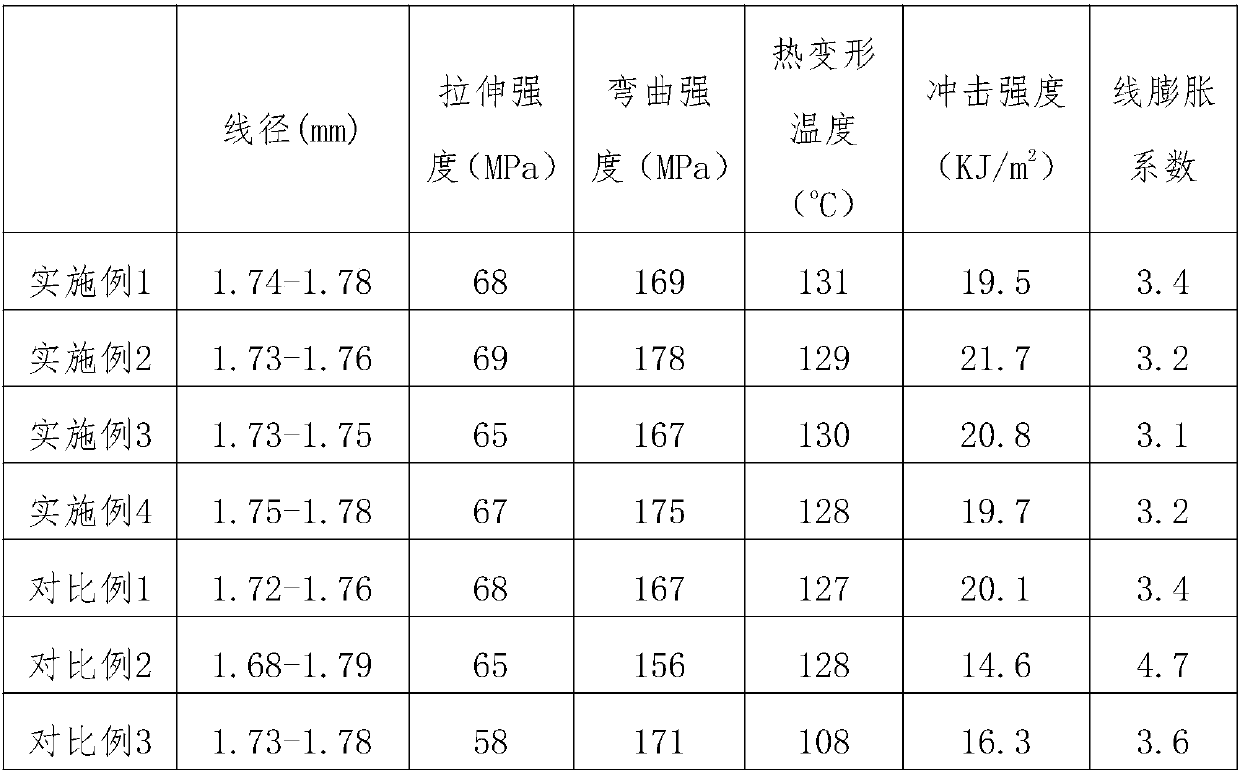

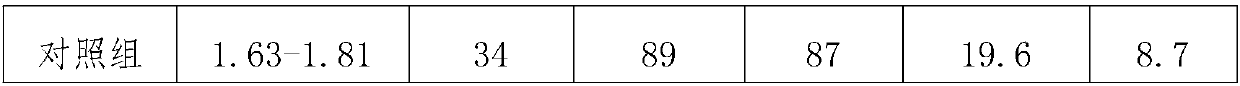

Examples

Embodiment 13D

[0028] Example 1 3D printing nylon wire

[0029] Raw materials: 50kg nylon 12 pellets, 10kg talcum powder masterbatch, 5kg maleic anhydride grafted POE, 2kg silane coupling agent KH550, 0.5kg antioxidant 1010, 0.2kg polyolefin lubricant, 1kg color masterbatch.

[0030] The particle size of the nylon 12 pellets is 3-5mm.

[0031] Preparation method of nylon wire for 3D printing:

[0032] (1) Pretreatment of talcum powder masterbatch: add silane coupling agent KH550 to the talc powder masterbatch, and remove the water produced by the reaction after the reaction is completed;

[0033] (2) Drying of raw materials: Dry nylon 12 pellets, treated talcum powder masterbatch and maleic anhydride grafted POE in a blast drying oven, set the temperature at 60°C, and dry for 12 hours;

[0034] (3) High-speed mixing: Add the nylon 12 pellets obtained in step (2), talcum powder masterbatch, maleic anhydride grafted POE, antioxidant 1010, and polyolefin lubricant to a high-speed mixer and mi...

Embodiment 23D

[0039] Example 2 3D printing nylon wire

[0040] Raw materials: 50kg nylon 12 pellets, 30kg talcum powder masterbatch, 10kg maleic anhydride grafted POE, 5kg silane coupling agent KH550, 2kg antioxidant 168, 1kg hyperdispersant, 2kg color masterbatch.

[0041] The particle size of the nylon 12 pellets is 3-5mm.

[0042] Preparation method of nylon wire for 3D printing:

[0043] (1) Pretreatment of talcum powder masterbatch: add silane coupling agent KH550 to the talc powder masterbatch, and remove the water produced by the reaction after the reaction is completed;

[0044] (2) Drying of raw materials: Dry nylon 12 pellets, treated talcum powder masterbatch and maleic anhydride grafted POE in a blast drying oven, set the temperature at 100°C, and dry for 6 hours;

[0045](3) High-speed mixing: Add the nylon 12 pellets obtained in step (2), talcum powder masterbatch, maleic anhydride grafted POE, antioxidant 168, and antioxidant 168 to a high-speed mixer and mix for 5 minutes ...

Embodiment 33D

[0050] Example 3 3D printing nylon wire

[0051] Raw materials: 60kg nylon 12 pellets, 20kg talcum powder masterbatch, 20kg maleic anhydride grafted POE, 8kg silane coupling agent KH550, 0.6kg antioxidant 1010, 1kg polyolefin lubricant, 3kg color masterbatch.

[0052] The particle size of the nylon 12 pellets is 3-5mm.

[0053] Preparation method of nylon wire for 3D printing:

[0054] (1) Pretreatment of talcum powder masterbatch: add silane coupling agent KH550 to the talc powder masterbatch, and remove the water produced by the reaction after the reaction is completed;

[0055] (2) Drying of raw materials: Dry nylon 12 pellets, treated talcum powder masterbatch and maleic anhydride grafted POE in a blast drying oven, set the temperature at 120°C, and dry for 8 hours;

[0056] (3) High-speed mixing: Add the nylon 12 pellets obtained in step (2), talc powder masterbatch, maleic anhydride grafted POE, antioxidant 1010, and polyolefin lubricant to a high-speed mixer and mix e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com