Method of producing conductive coating film, and conductive coating film

A manufacturing method and conductivity technology, applied in conductive coatings, printed circuit manufacturing, cable/conductor manufacturing, etc., can solve the problems of reduced and insufficient adhesion of insulating substrates, reduce the reduction of adhesion, and improve high temperature Durability, improve the effect of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The composition of the following compounding ratio was put into the sand mill, and it dispersed at 800 rpm for 2 hours. As the media, zirconia beads with a radius of 0.2 mm were used. Apply the obtained copper paste on the resin cured layer of the polyimide film (AC-1) with a resin cured layer using an applicator so that the thickness after drying is 2 μm, and dry it with hot air at 120° C. for 5 minutes to obtain Coating films containing copper powder.

[0088]

[0089] Copolymerized polyester solution 2.5 parts

[0090] (40% by weight solution of toluene / cyclohexanone=1 / 1 (weight ratio))

[0091] Copper powder 1 (average particle size 0.12μm) 9 parts

[0092] 3.5 parts of γ-butyrolactone (diluted solvent)

[0093] 5 parts of methyl ethyl ketone (diluent solvent)

[0094] Oxetane 0.2 parts

[0095] (Copolymerized polyester: "RV290" manufactured by Toyobo Co., Ltd.

[0096] Oxetane: "OXT-221" manufactured by Toagosei Co., Ltd.)

[0097] The obtained polyimide ...

Embodiment 2~4

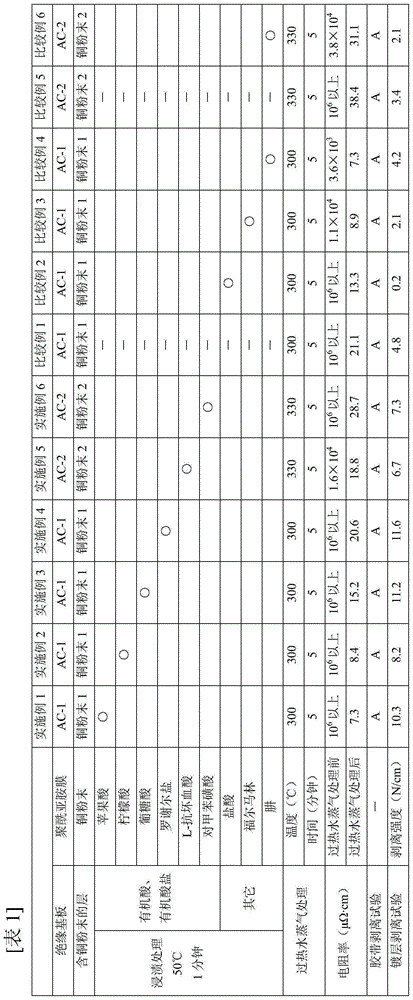

[0099] Similar to Example 1, however, the organic acid (salt) used for the organic acid (salt) treatment was changed as described in Table 1, and a conductive coating film was obtained. Table 1 shows the evaluation results of the obtained conductive coating film.

Embodiment 5~6

[0101] In the same manner as in Example 1, however, AC-2 was used on the insulating substrate, copper powder 2 was used as the copper powder, and the organic acid (salt) used for the organic acid treatment was changed as described in Table 1 to obtain electrical conductivity. coating film. In Examples 5 and 6, superheated steam treatment was performed at 330°C. Table 1 shows the evaluation results of the obtained conductive coating film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com