Straw-powder-containing composite flame-retardant material and preparation method thereof

A composite flame retardant and straw powder technology is applied in the field of composite flame retardant materials containing straw powder and its preparation, which can solve the problems of poor flame retardancy, easy occurrence of mildew, etc. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

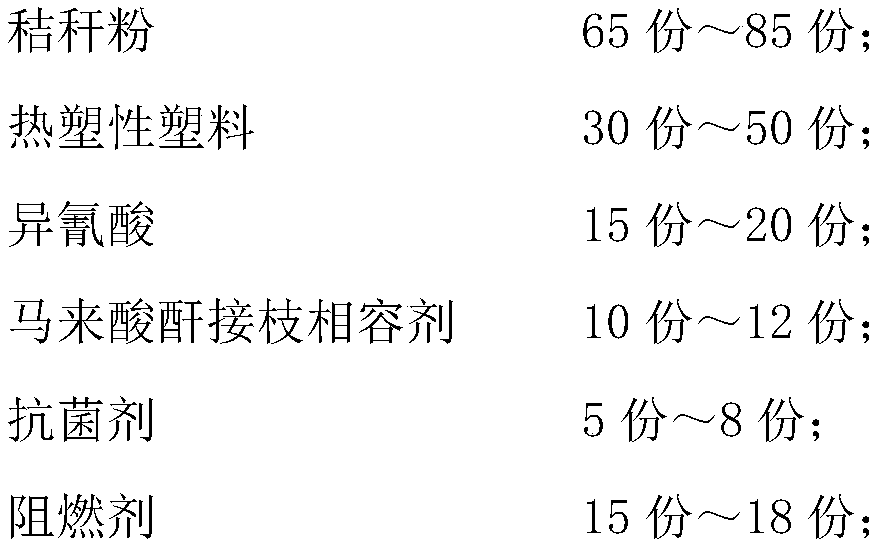

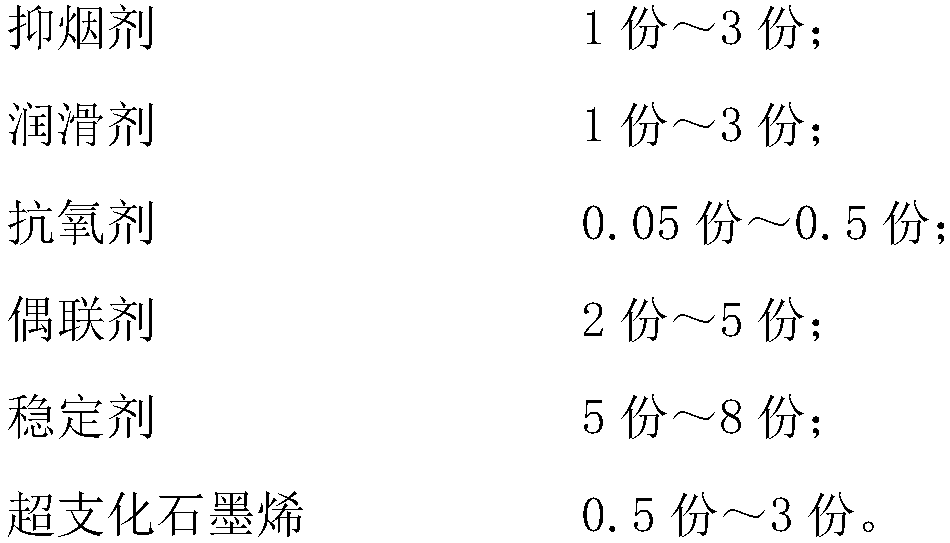

Method used

Image

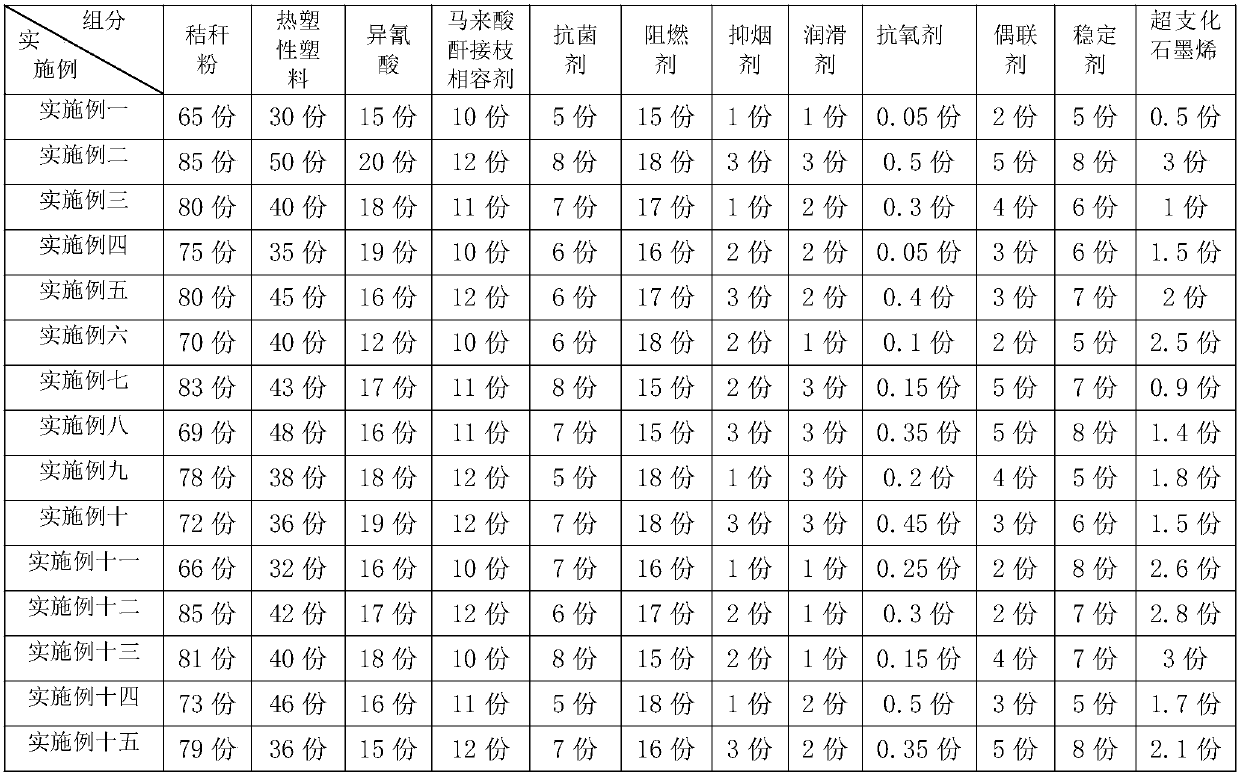

Examples

Embodiment 1

[0030] Step 1: Preparation of straw, removing the pith part of the straw, and then drying at 95°C to make the water content of the straw 4.5%; then grinding the straw, and then screening through a pore size of 0.3mm to obtain straw powder ;

[0031] Step 2: Preparation of plastic granules, placing thermoplastics in a twin-screw extruder at a temperature of 150° C. and a screw speed of 60 r / min for melting and granulation to obtain thermoplastic matrix granules;

[0032] Step 3: Take 0.5 parts of hyperbranched graphene and place it in deionized water, and disperse it with ultrasonic waves to obtain an aqueous solution of hyperbranched graphene;

[0033] Step 4: Take 65 parts of straw powder obtained in step 1 and 30 parts of thermoplastic matrix particles obtained in step 2 and put them into a high-speed mixer. During the stirring process, add 15 parts of isocyanic acid and maleic anhydride graft-compatible 10 parts of lubricant, 1 part of lubricant, 15 parts of flame retardan...

Embodiment 2

[0036] Step 1: Preparation of straw, remove the pith part of the straw, and then dry it at 100°C to make the water content of the straw 4%; then grind the straw, and then screen it through a pore size of 0.5mm to obtain straw powder ;

[0037] Step 2: Preparation of plastic granules, placing thermoplastics in a twin-screw extruder with a temperature of 155° C. and a screw speed of 70 r / min for melting and granulation to obtain thermoplastic matrix granules;

[0038] Step 3: taking 3 parts of hyperbranched graphene and placing it in deionized water, and dispersing it with ultrasonic waves to obtain an aqueous solution of hyperbranched graphene;

[0039] Step 4: Take 85 parts of straw powder obtained in step 1 and 50 parts of thermoplastic matrix particles obtained in step 2 and put them into a high-speed mixer. During the stirring process, add 20 parts of isocyanic acid and maleic anhydride graft compatible 12 parts of lubricant, 3 parts of lubricant, 18 parts of flame retarda...

Embodiment 3

[0042] Step 1: Preparation of straw, remove the pith part of the straw, and then dry at 105°C to make the water content of the straw 3%; then grind the straw, and then screen through a pore size of 0.2mm to obtain straw powder ;

[0043] Step 2: Preparation of plastic granules, placing thermoplastics in a twin-screw extruder at a temperature of 150° C. and a screw speed of 60 r / min for melting and granulation to obtain thermoplastic matrix granules;

[0044] Step 3: Take 1 part of hyperbranched graphene and place it in deionized water, and disperse it with ultrasonic waves to obtain an aqueous solution of hyperbranched graphene;

[0045] Step 4: Take 80 parts of straw powder obtained in step 1 and 40 parts of thermoplastic matrix particles obtained in step 2 and put them into a high-speed mixer. During the stirring process, add 18 parts of isocyanic acid and maleic anhydride graft-compatible 11 parts of lubricant, 2 parts of lubricant, 17 parts of flame retardant, 4 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com