Microbial feed fermentation equipment

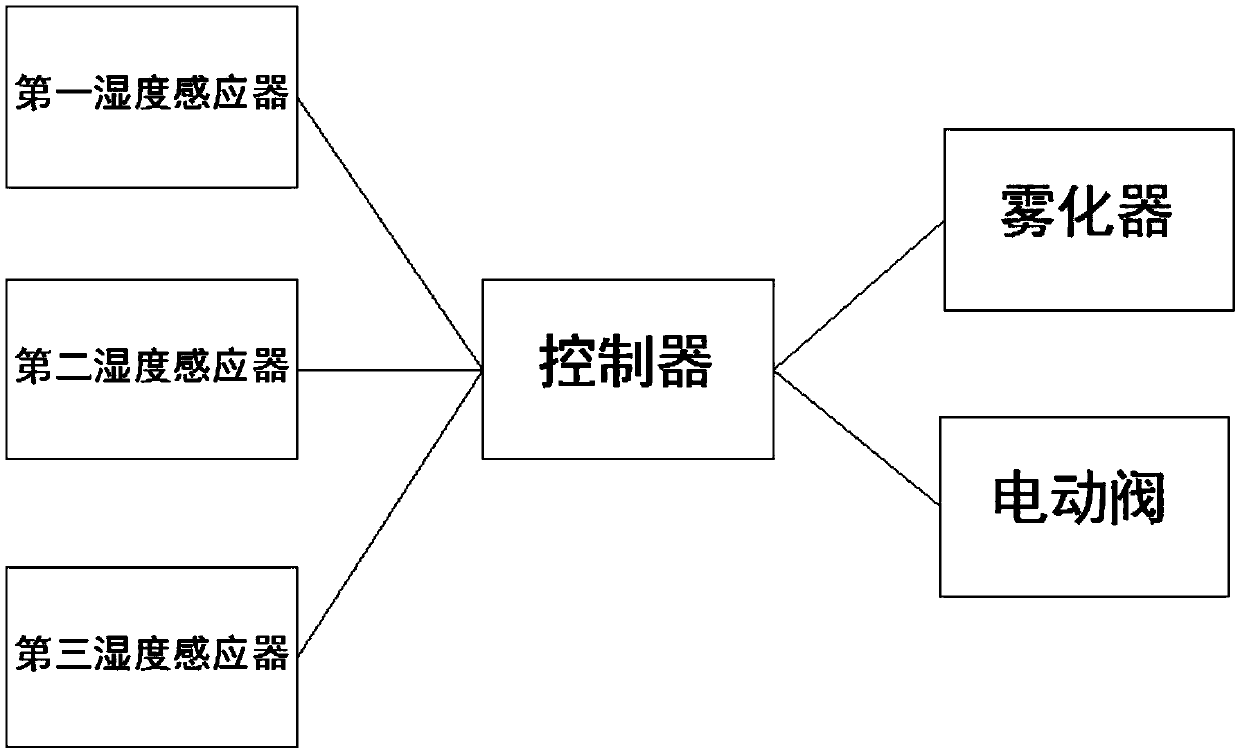

A technology of microbial feed and fermentation equipment, applied in the field of fermented feed production equipment, can solve the problems of affecting the quality of feed fermentation, limited cooling effect, growth of aerobic microorganisms, etc., so as to solve the problem of slow humidity regulation and inability to automatically adjust humidity and reduce heat. The effect of passing, speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

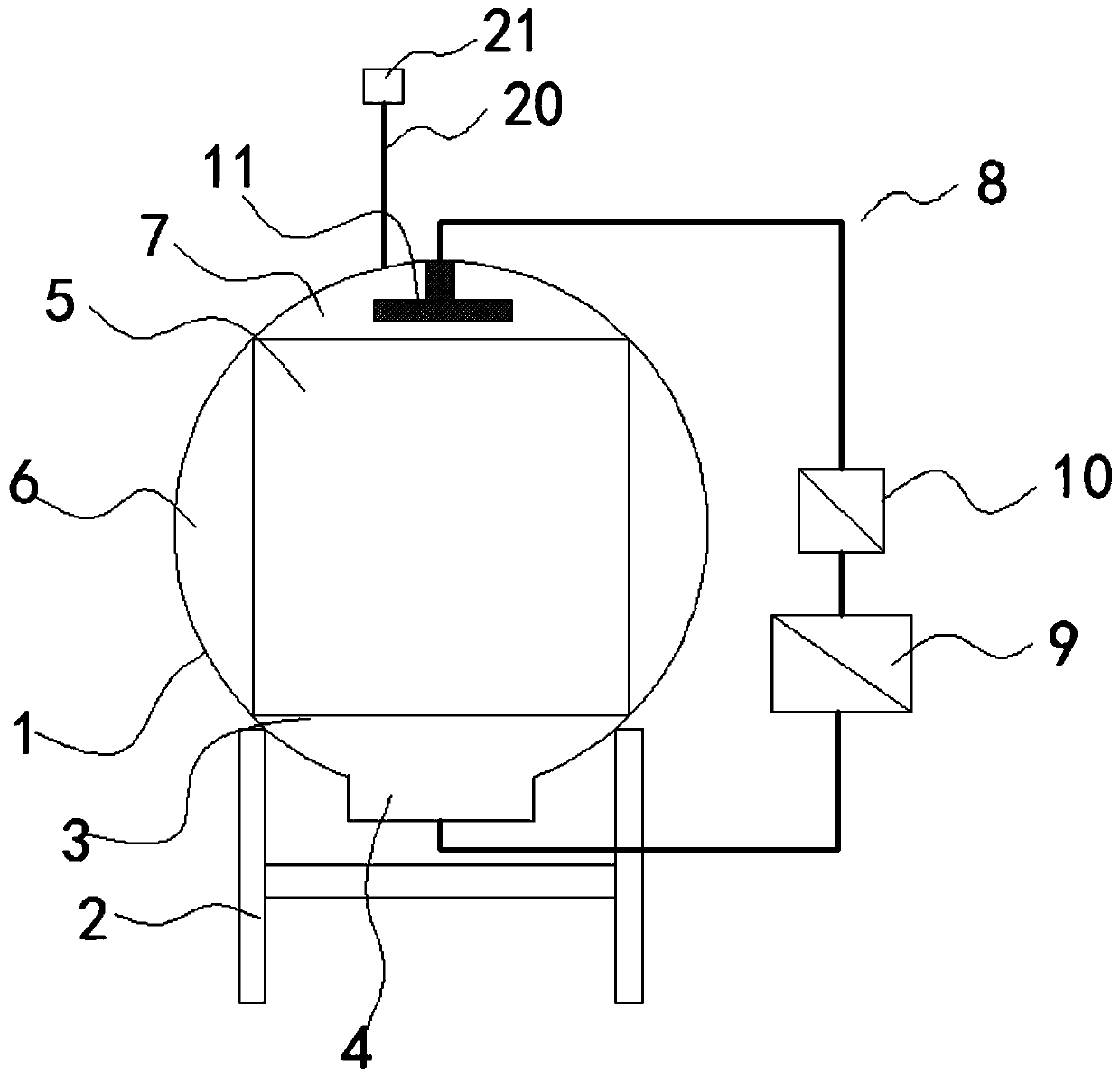

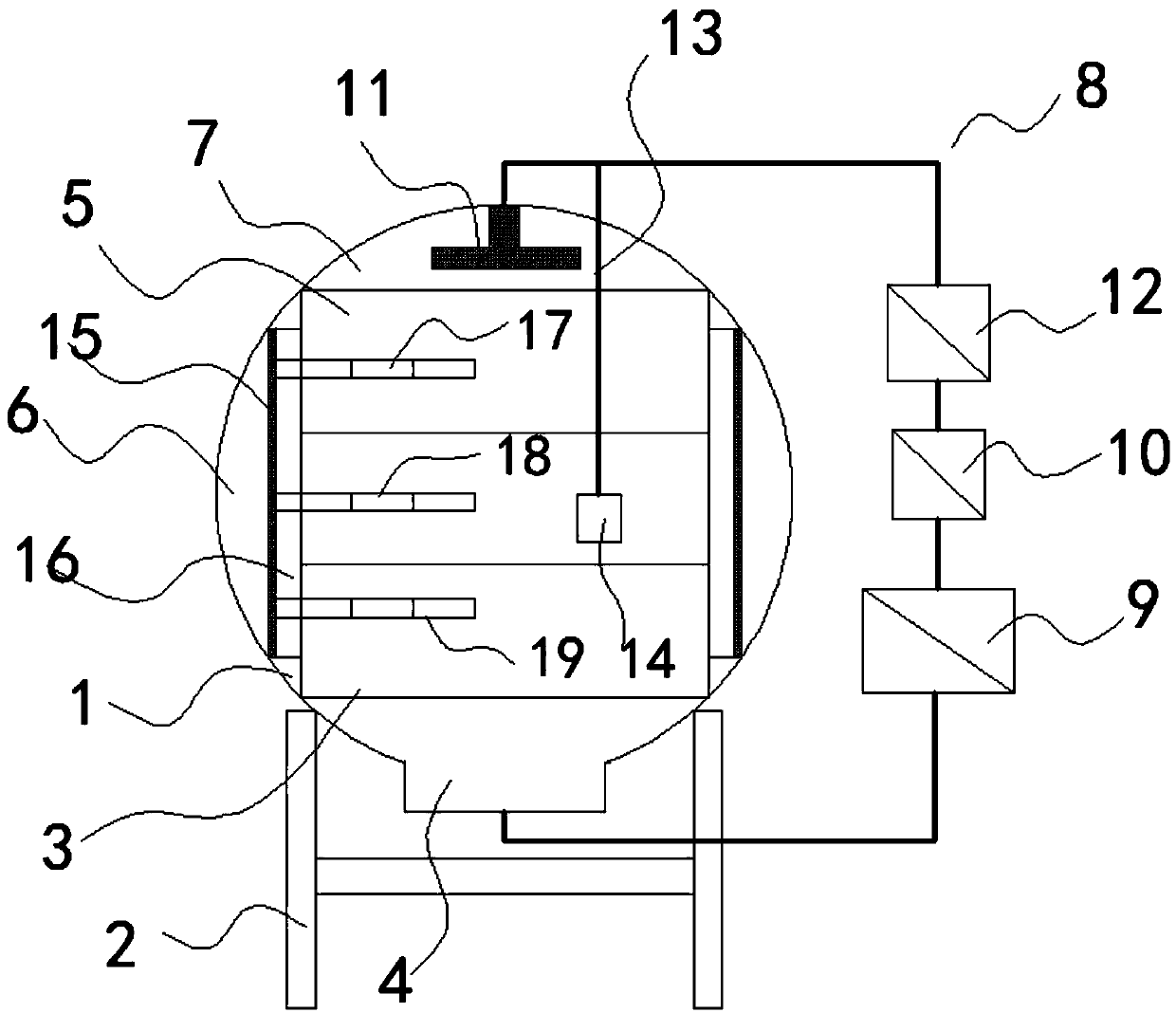

[0038] In the first embodiment, if figure 1 Shown, a kind of microbial feed fermentation equipment comprises:

[0039] The tank body 1 is horizontally arranged on the bracket 2. There is an accommodation space inside the tank body 1. Doors for entering and exiting the accommodation space are respectively provided at both ends of the tank body 1. The door body is equipped with a door leaf , The door leaf can open and close the door body to facilitate material transportation. The bottom side of the tank body is provided with a water collection tank 4, the water collection tank 4 is arranged along the length direction of the tank body, and the cross section of the tank body is circular.

[0040] An external spraying device, which includes: a pole 20 vertically arranged above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com