Iron-base alloy and preparation method thereof, outer sleeve and inner heater

An iron-based alloy and outer casing technology, which is applied in immersion heating devices, ohmic resistance heating parts, etc., can solve the problems of high production cost and complicated preparation process, achieve low production cost, simple preparation method, and benefit large-scale production. The effect of mass industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

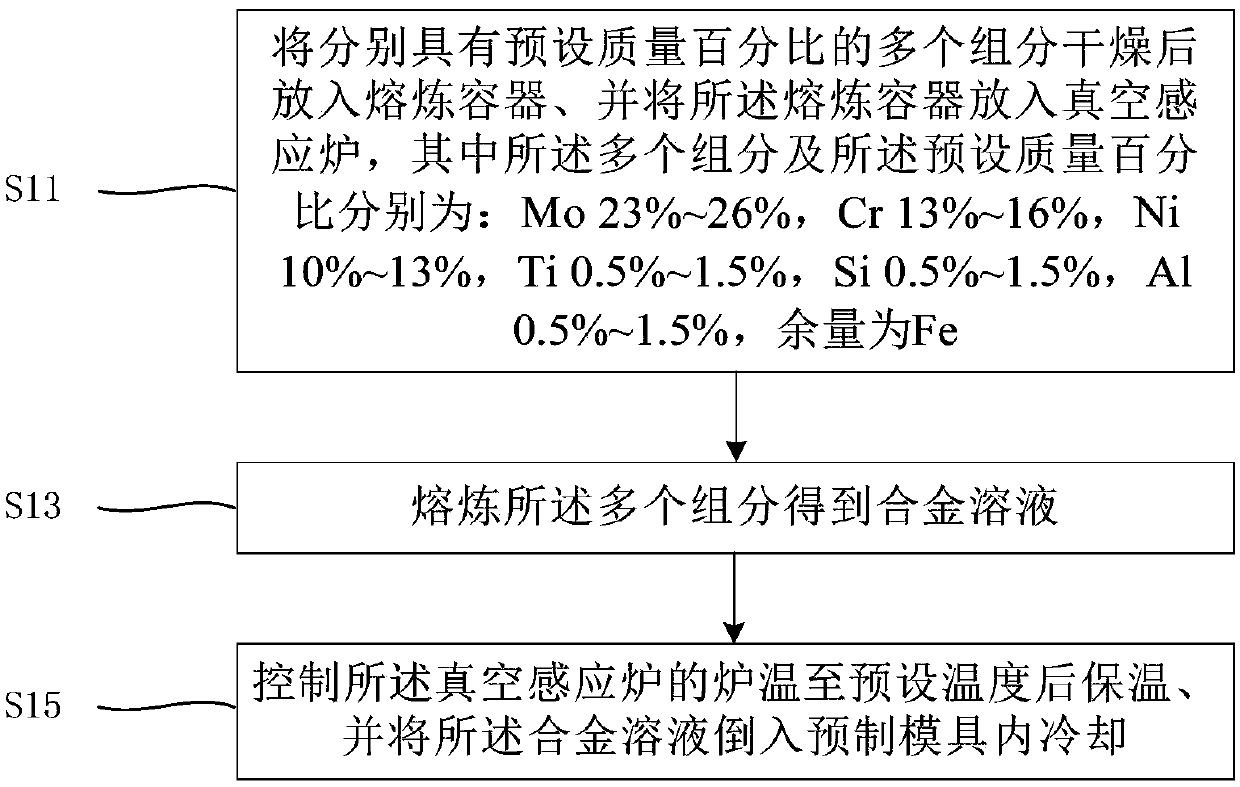

[0027] see figure 1 , which is a schematic flow chart of a method for preparing a molten zinc corrosion-resistant iron-based alloy based on Laves phase strengthening provided in the first embodiment of the present invention. The Laves phase here is a chemical formula mainly AB 2 (A, B represent two chemical elements) type close-packed cubic or hexagonal intermetallic compounds. The atomic radius ratio r of two chemical elements A and B in Laves phase A / r B About between 1.1 and 1.6. The Laves phase-strengthened iron-based alloy prepared by the iron-based alloy preparation method provided in the embodiment of the present invention uses Laves as the strengthening phase and α-Fe as the matrix. Among them, the Laves strengthening phase is, for example, Fe 2 Mo is a matrix and a multi-element Laves phase in which Ni, Cr, Al, Si and other elements are solid-dissolved.

[0028] Specifically, the method for preparing an iron-based alloy provided in an embodiment of the present ...

no. 2 example

[0053] The second embodiment of the present invention provides a Laves phase-strengthened iron-based alloy resistant to molten zinc corrosion. The molten zinc corrosion-resistant iron-based alloy based on Laves phase strengthening can be prepared by the method of the first embodiment of the present invention. Fe-based alloys with Fe 2 Mo is a strengthening phase, and α-Fe is used as a matrix. See Table 1 for the composition and mass percentage of the iron-based alloy, specifically: Mo 23%-26%, Cr 13%-16%, Ni 10%-13%, Si 0.5%-1.5%, Ti 0.5%- 1.5%, Al0.5% ~ 1.5%, the balance is Fe.

[0054] Table 1 Fe-based alloy components and their mass percentages (wt.%)

[0055]

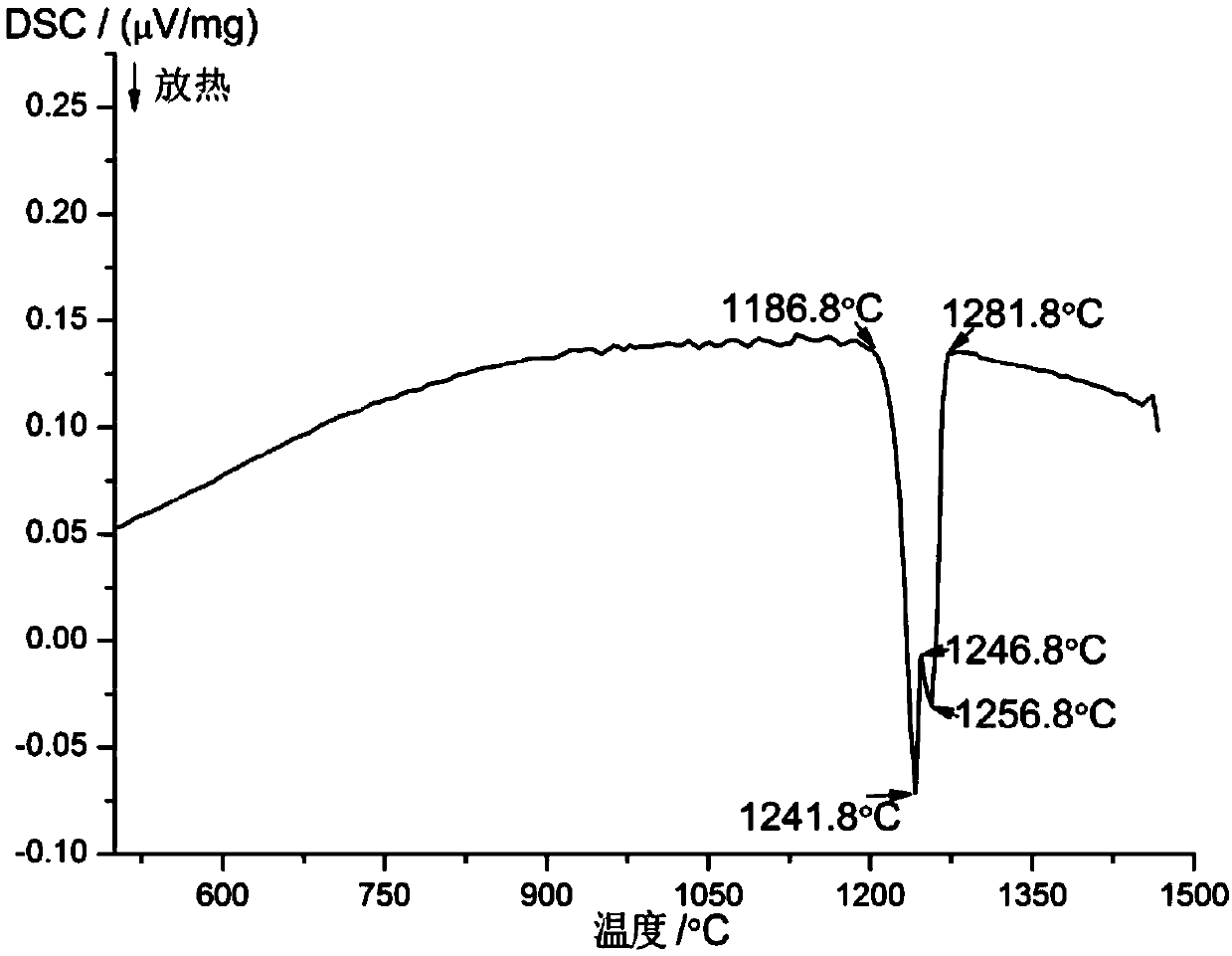

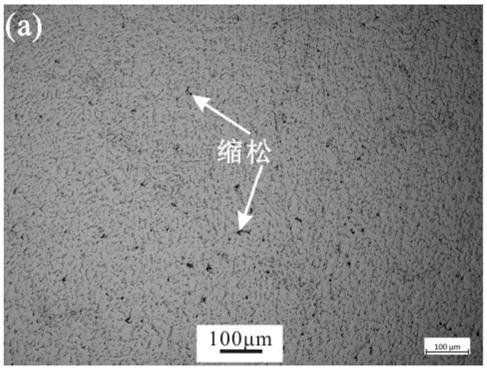

[0056] In order to test various properties of the iron-based alloy provided in the embodiment of the present invention, five samples were made from the iron-based alloy (denoted as DEG) for testing in the embodiment of the present invention. In addition, two existing alloys (denoted as D1, D2) were used to ma...

no. 3 example

[0097] See eg Figure 7 , which is a schematic structural diagram of an internal heater 10 provided in the third embodiment of the present invention. During the production of hot-dip galvanizing and die-casting, it is necessary to use the internal heater 10 to heat molten metal such as molten zinc. The internal heater 10 is mainly used in hot-dip galvanizing, aluminum plating and zinc / aluminum thermal processing. The usage form of the internal heater 10 is that the internal heater 10 is inserted into the metal melt to be melted or heated like "heating quickly", and then energized for continuous heating.

[0098] Such as Figure 7 As shown, the internal heater 10 includes, for example, an outer casing 110 , a stainless steel extension pipe 140 , a flange 120 connecting the outer casing 110 and the extension pipe 130 , an electric heating tube 140 and a terminal post 150 .

[0099] Specifically, such as Figure 8 As shown, the outer sleeve 110 may be, for example, in the sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Macro hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap