Examination heating device for crank case breather pipe, breather pipe, ventilating system and automobile

A heating device and crankcase technology, which is applied in crankcase ventilation, fuel heat treatment device, charging system, etc., can solve the problems of reduced service life of the pipeline, long reaction time of the supercharger, high pressure of the intercooling system, etc. Achieve the effect of saving installation space, avoiding rapid aging, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

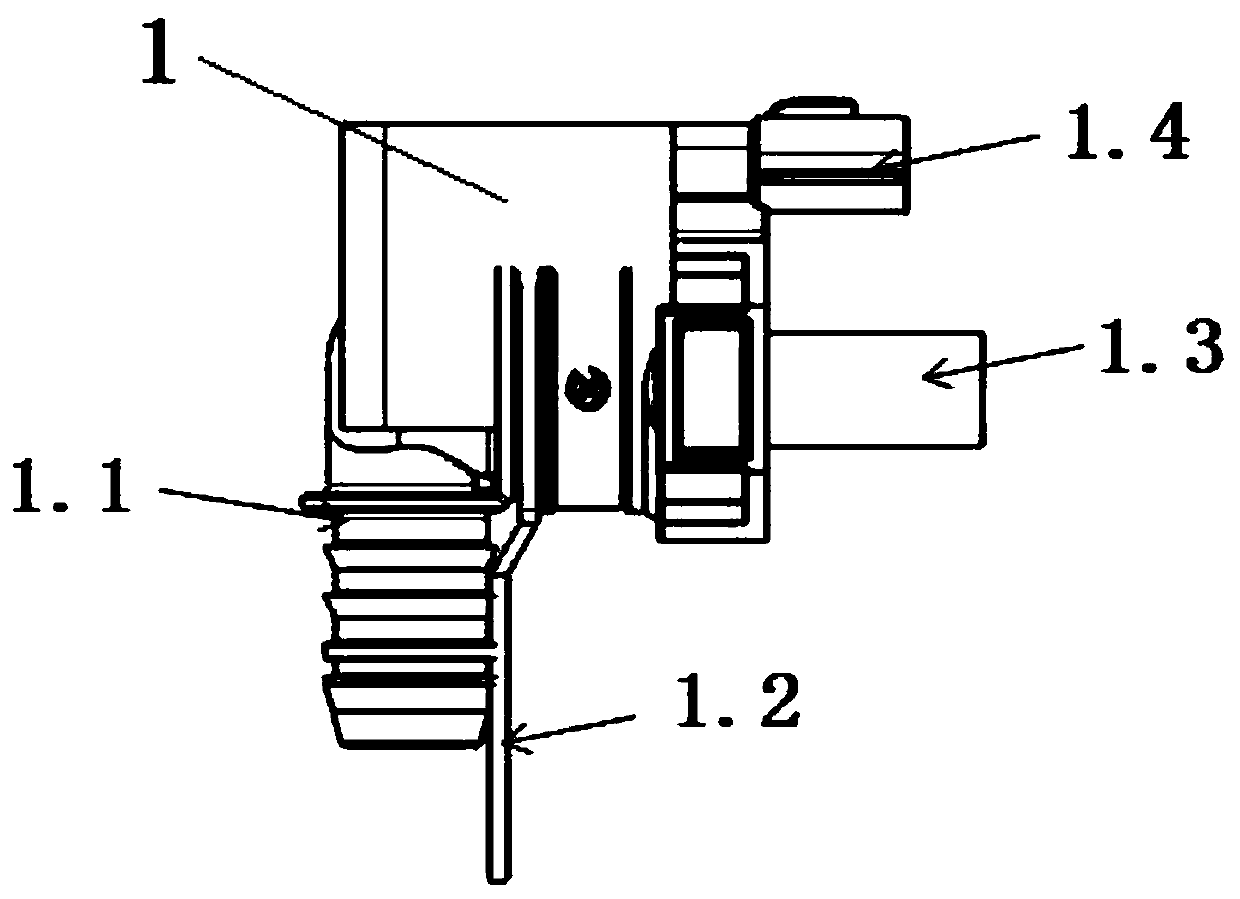

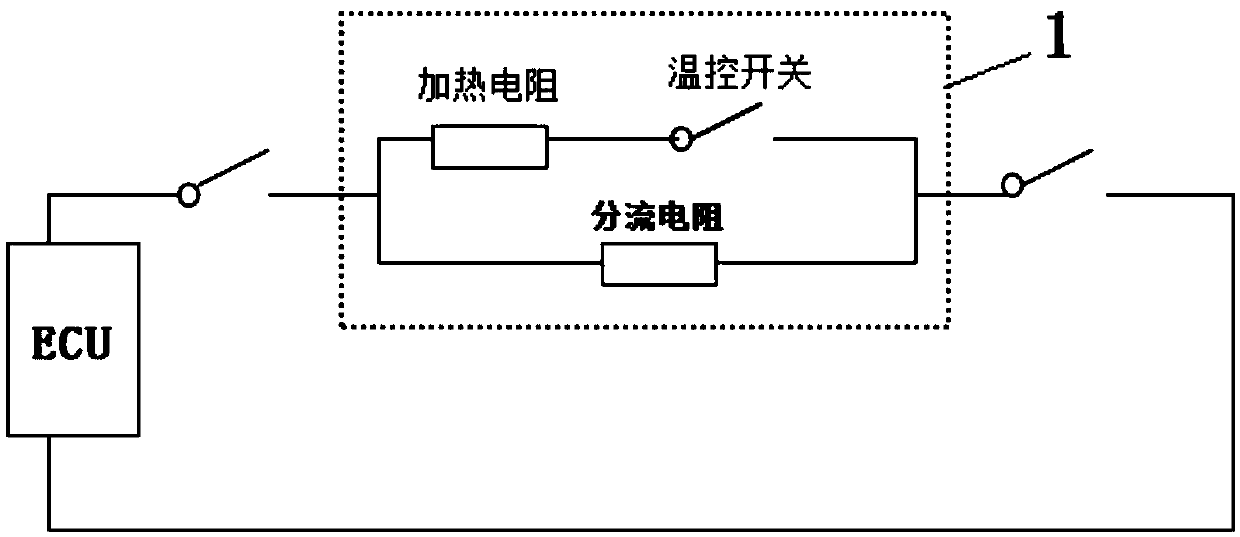

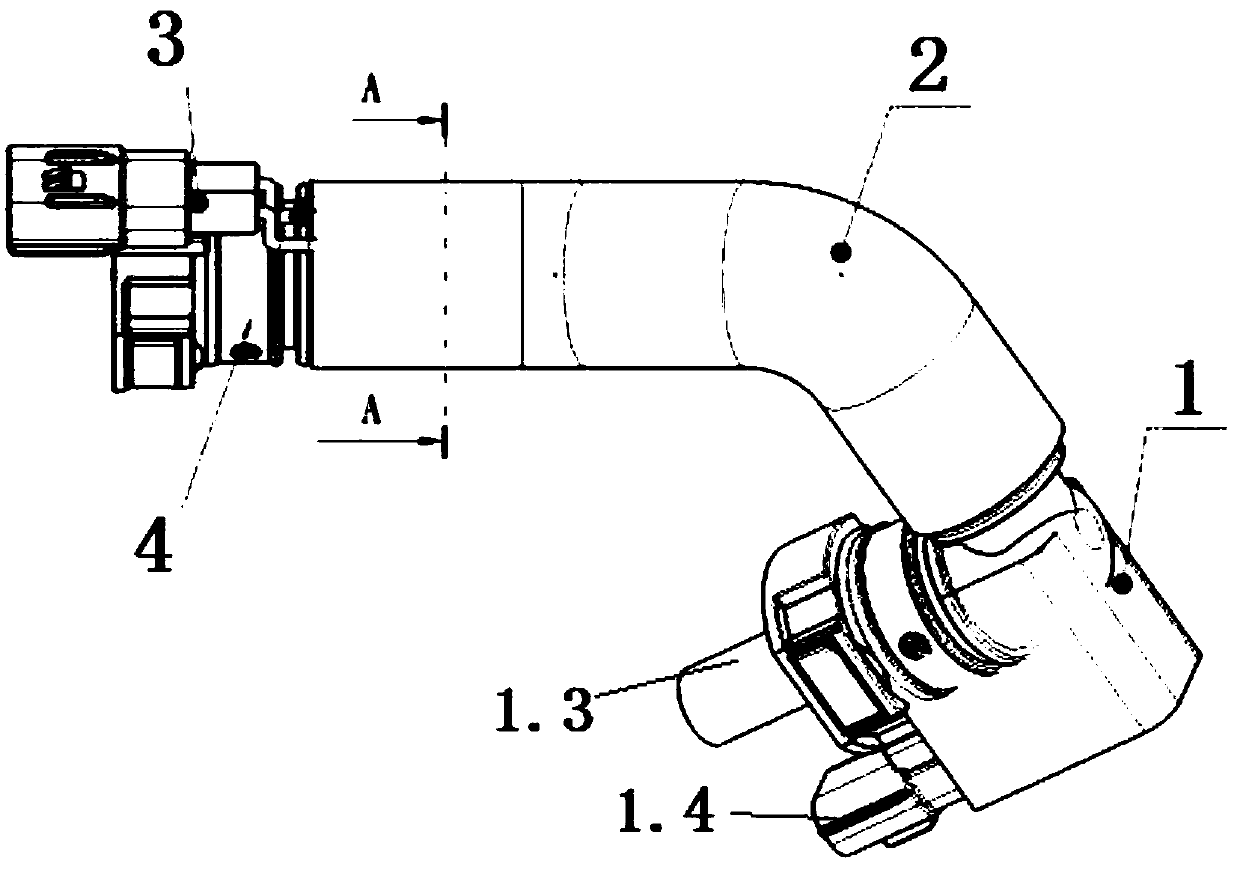

[0031]As shown in the accompanying drawings of the description, the technical solution provided by the present invention is a diagnostic heating device for crankcase ventilation pipes, which includes an outer shell 1, and the outer shell 1 is provided with an air outlet pipe 1.1 for communicating with the crankcase. It is used to connect the guide joint 1.2 of the PVC valve, the intake pipe 1.3 for connecting the engine intake main pipe and the ECU joint 1.4 for connecting the vehicle ECU, the guide joint 1.2 is electrically connected with the ECU joint 1.4, and the air outlet pipe 1.1 is communicated with the air intake pipe 1.3, The intake pipe 1.3 is made of heat-conducting material, and the outer casing 1 is provided with a parallel diagnostic circuit and a heating circuit. After the diagnostic circuit and the heating circuit are connected in parallel, they are inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com