Split type uncooled infrared core assembly

An uncooled infrared, split-type technology, applied in the field of infrared imaging, to achieve the effects of increased flexibility, reduced volume and power consumption, and easy low-noise design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the following implementation links are included:

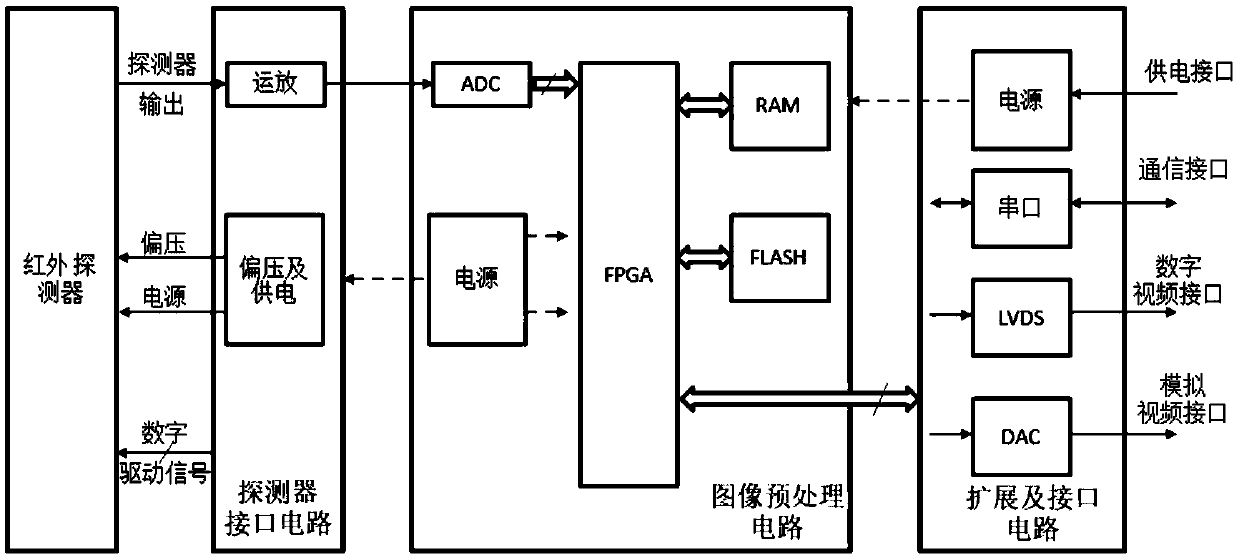

[0042] Step 1. Press the uncooled infrared movement assembly circuit figure 1 The circuit function is divided. The circuit is divided into uncooled infrared detector, infrared detector readout, infrared image preprocessing, power supply and interface output.

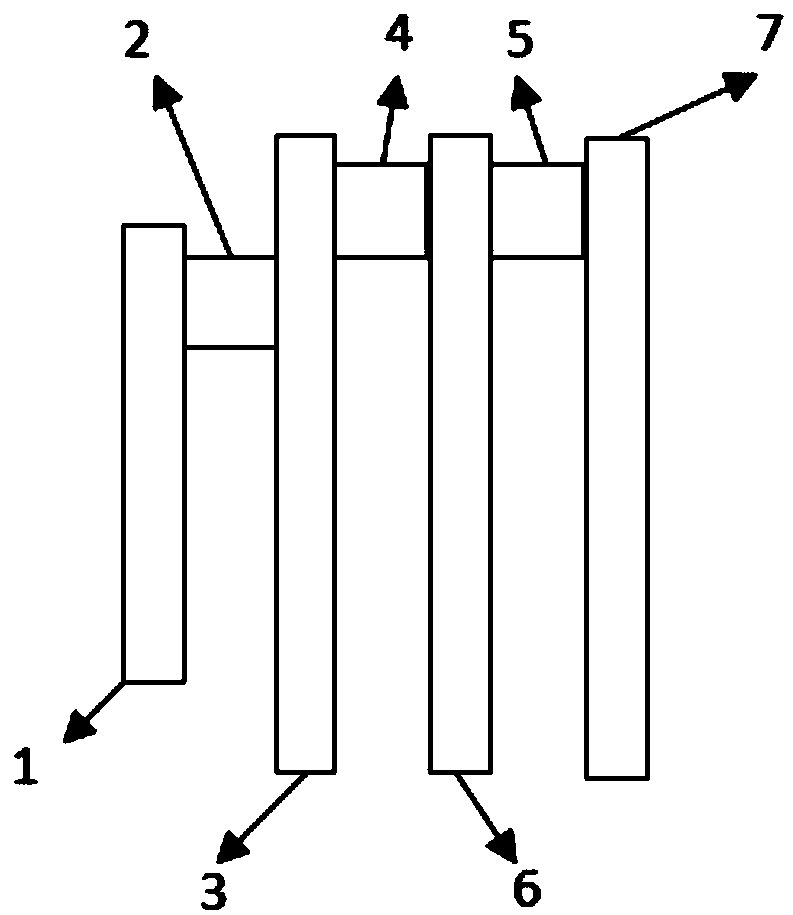

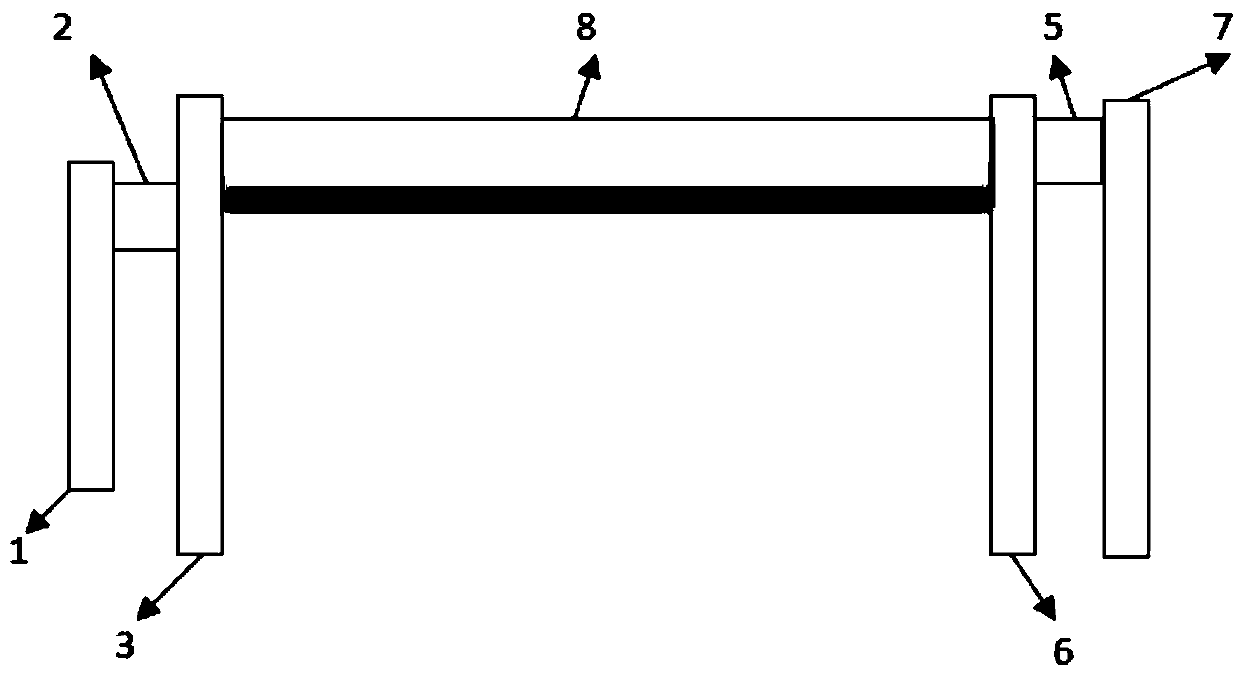

[0043] Step 2. Determine the relative layout of the detector and its readout circuit board, image preprocessing and power supply expansion interface circuit board, and determine the circuit board type of the front-end circuit, flexible connection part, and back-end circuit.

[0044] Step 3. Determine the infrared detector readout circuit according to the required size of the front end of the imager diagram 2-1 and Figure 2-2 Functions of parts 1, 2, and 3 in the book and develop circuit design. In order to improve the anti-interference ability of the front-end circuit, it is recommended to place the ADC circuit on the infrared detector readout circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com