Fully sealed constant pressure underwater camera

A camera, fully sealed technology, applied in the field of underwater cameras, can solve problems such as difficult to change positions, poor flexibility of use, damage to underwater cameras, etc., to achieve the effect of reducing the number of attitude adjustments, avoiding slow adjustment speeds, and slowing down aging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

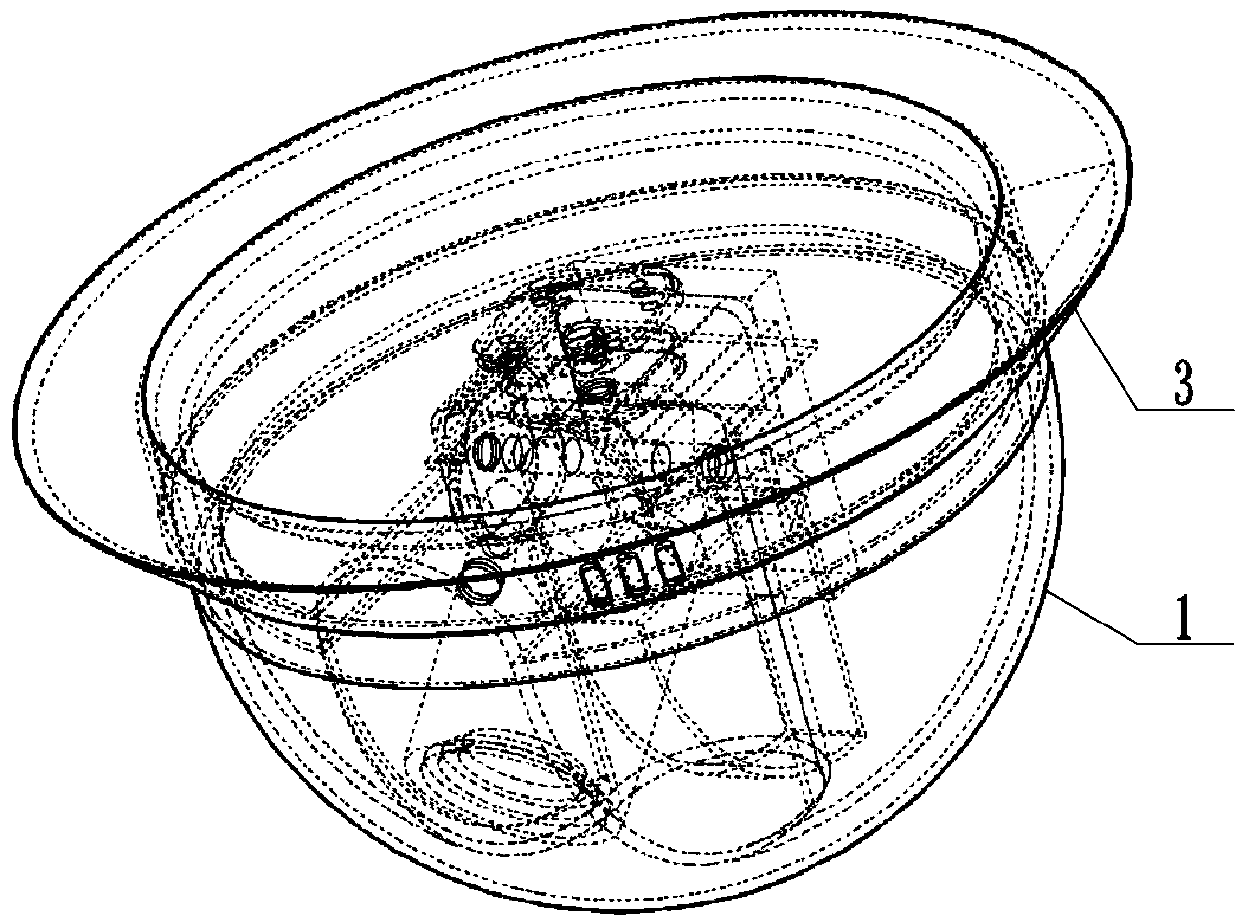

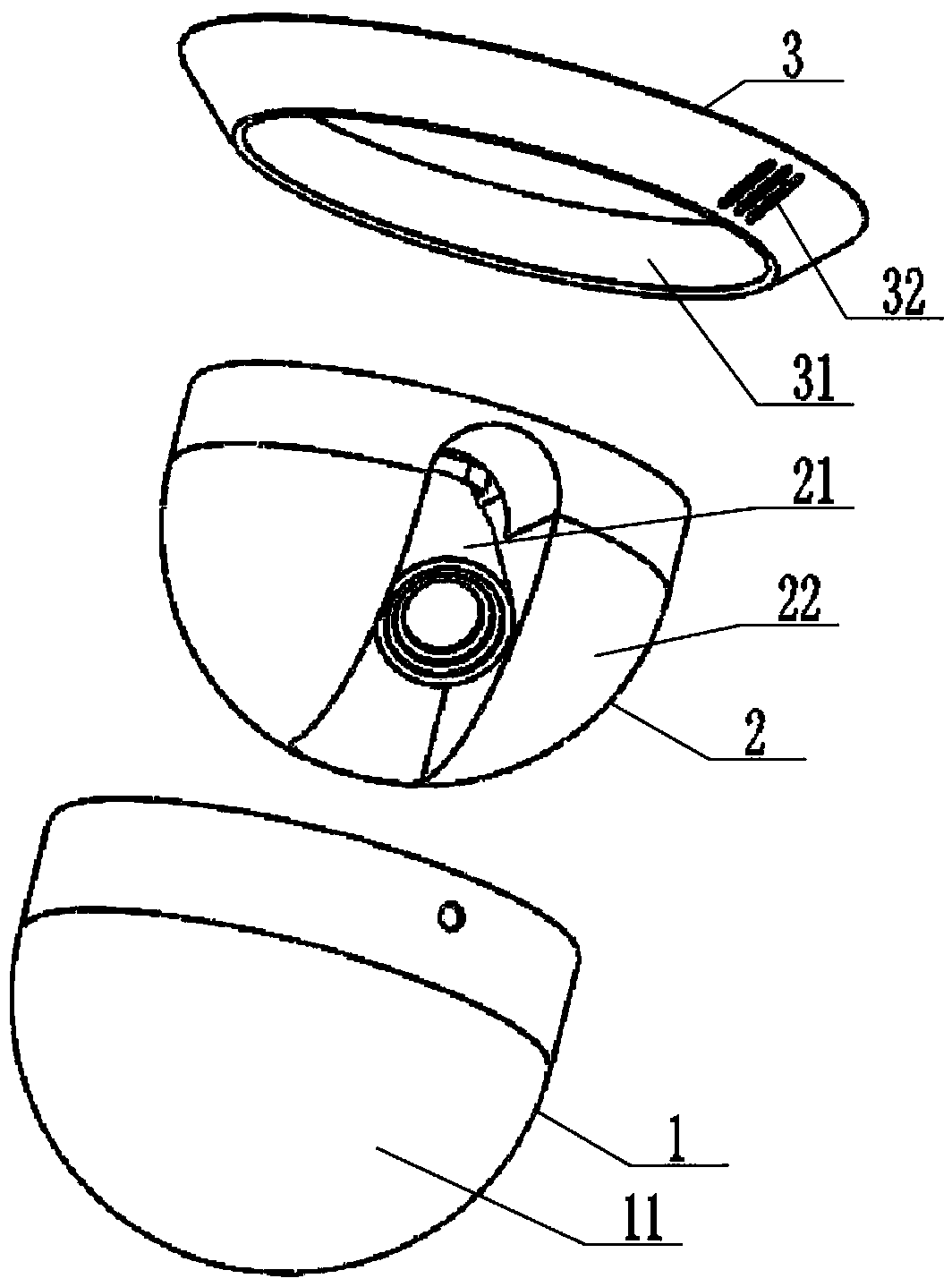

[0024] Such as figure 1 , figure 2 As shown, the fully sealed constant pressure underwater camera includes a casing assembly 1 , a camera assembly 2 and a constant pressure adjustment assembly 3 .

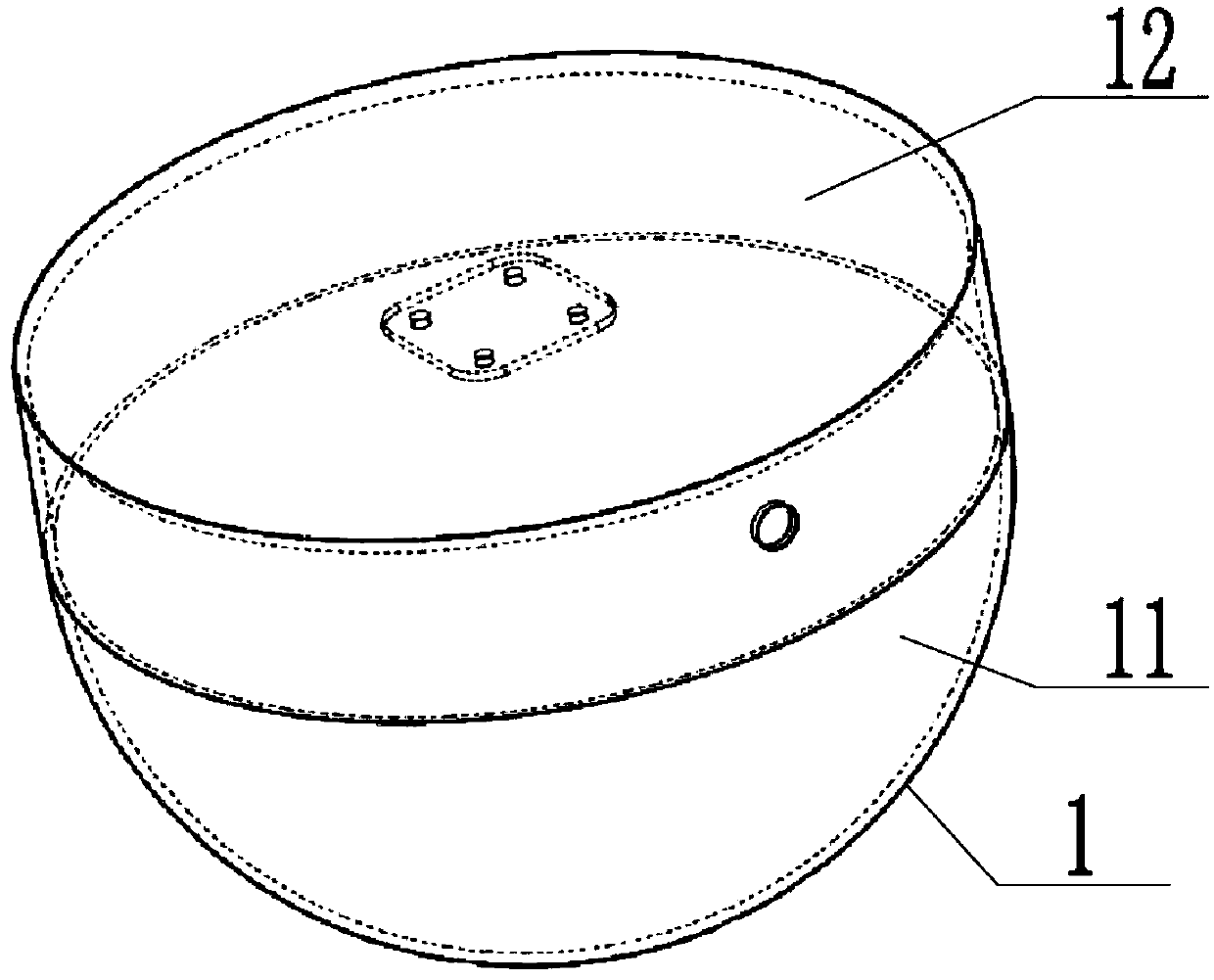

[0025] Such as image 3 As shown, the housing assembly 1 includes a hemispherical housing 11 and a housing bottom plate 12, the housing bottom plate 12 is airtightly and fixedly installed on the bottom of the hemispherical housing 11, and the spherical center projection of the hemispherical housing 11 is positioned at the The geometric center position of the shell bottom plate 12.

[0026] The camera assembly 2 is integrally packaged inside the casing assembly 1, such as Figure 4 As shown, the camera assembly 2 includes a cylindrical camera body 21, a support frame 22 and an electric control mechanism; the top end of the support frame 22 is fixedly installed on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com