Sintering method for reducing light degradation of P-type solar cell and application thereof

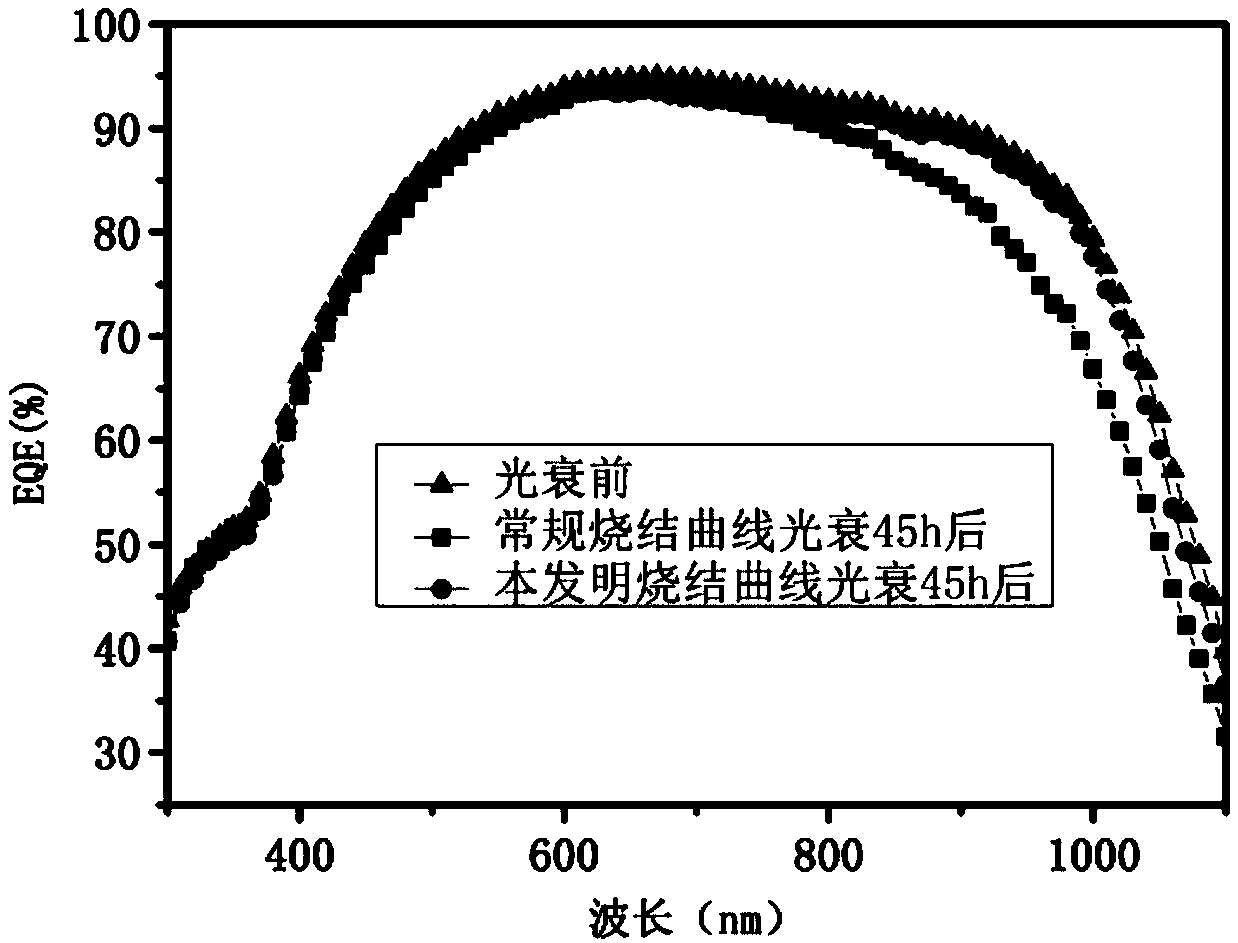

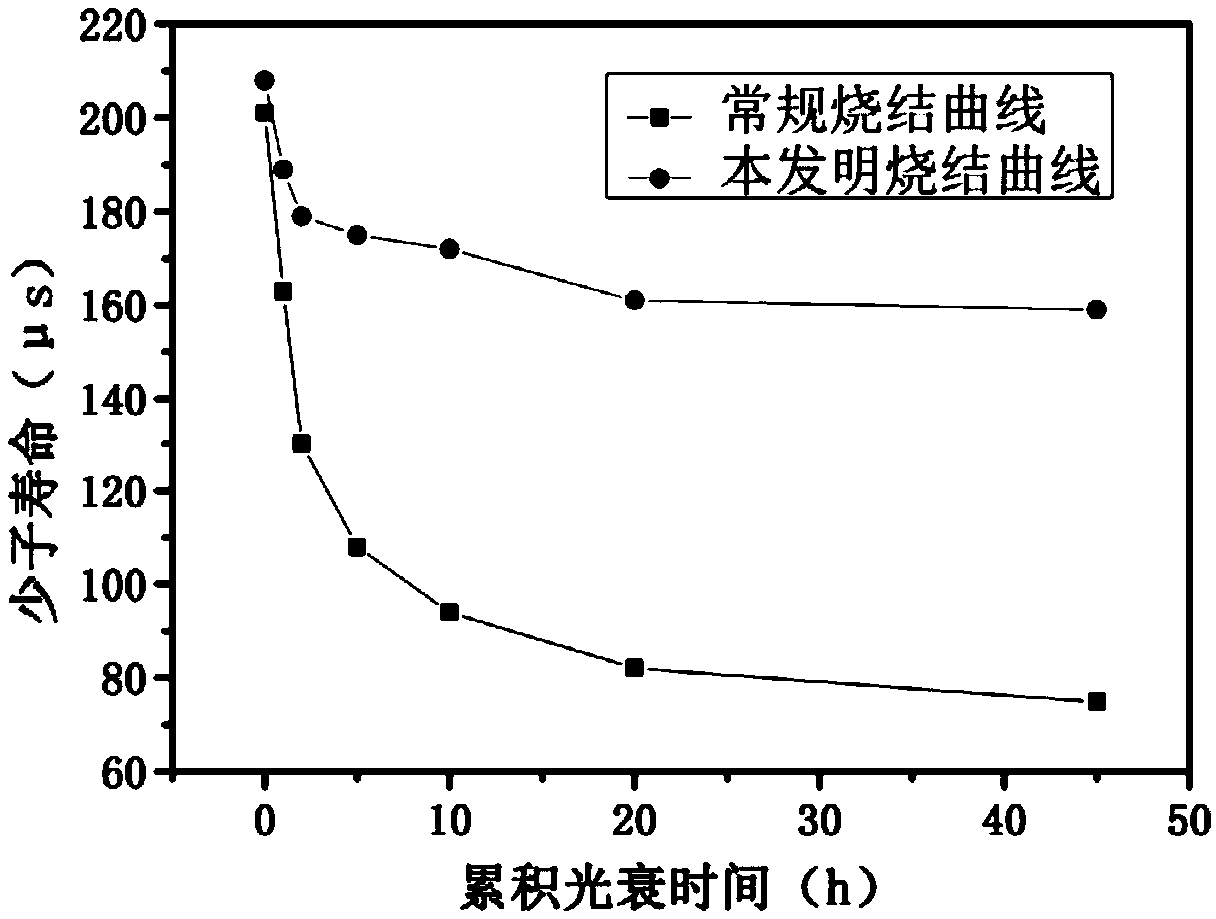

A solar cell and light-induced attenuation technology, which is applied in the field of solar cells, can solve the problems that restrict the development prospects of PERC technology, the large-scale light decay of polycrystalline PERC cells, and the lack of large-scale industrialization, so as to suppress the light decay effect and reduce the light intensity. Attenuation range, the effect of reducing the number of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

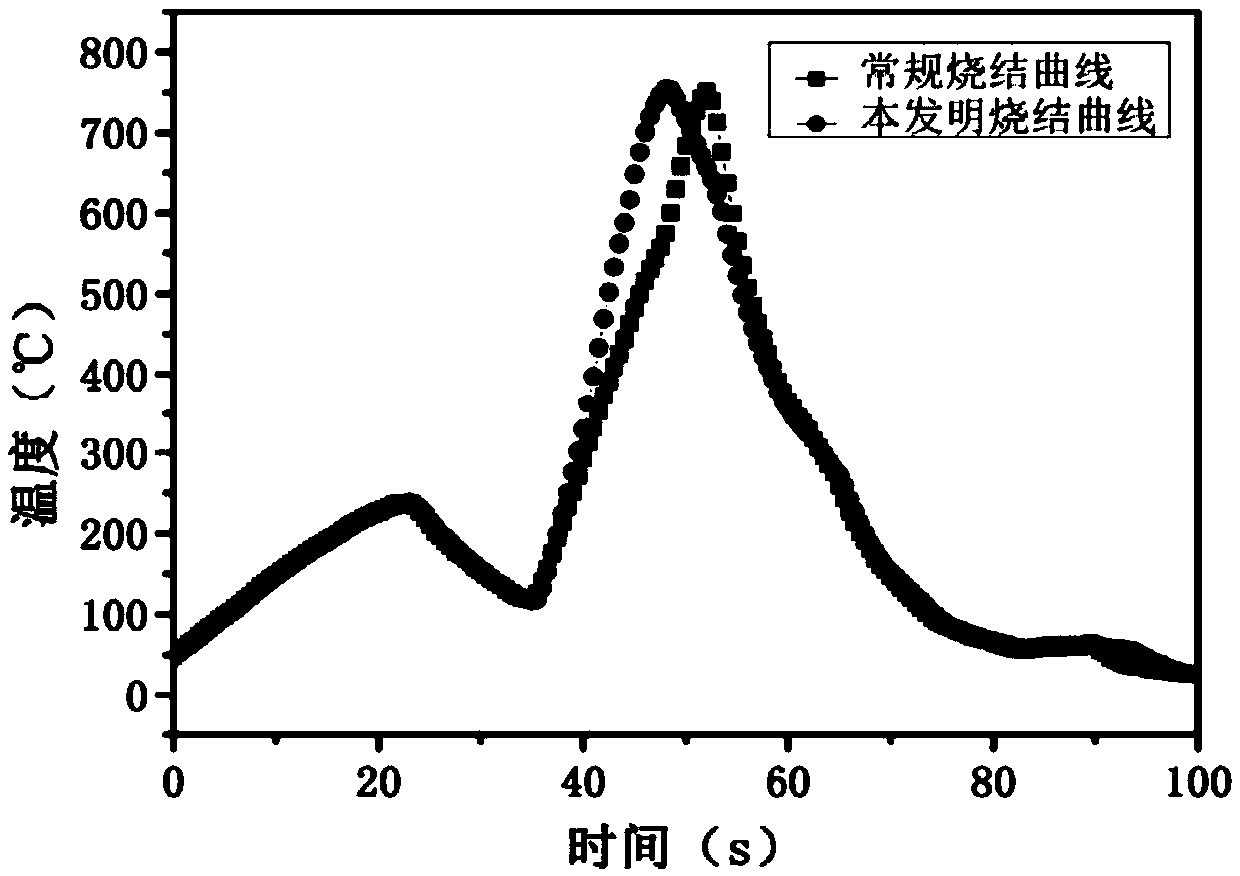

[0028] This embodiment provides a sintering method for reducing the light-induced attenuation of a P-type solar cell, including:

[0029] The screen-printed cells are placed on the sintering furnace belt in the sintering zone and transported at a rate of 200 inches / min. First dry in the drying zone with a temperature of 260°C, and then heat up and sinter in the sintering zone. After reaching the sintering peak temperature of 740°C, perform cooling and sintering at a cooling rate of 5K / s to the sintering activation temperature of 675°C. After sintering, the The cells are cooled in a cooling zone with a temperature of 80°C.

Embodiment 2

[0031] This embodiment provides a sintering method for reducing the light-induced attenuation of a P-type solar cell, including:

[0032] The screen-printed cells are placed on the sintering furnace belt in the sintering zone and transported at a speed of 260 inches / min. Firstly dry in the drying zone with a temperature of 300°C, then heat up and sinter in the sintering zone. After reaching the sintering peak temperature of 790°C, perform cooling and sintering at a cooling rate of 40K / s to the sintering activation temperature of 675°C. After sintering, the The cells are cooled in a cooling zone with a temperature of 100°C.

Embodiment 3

[0034] This embodiment provides a sintering method for reducing the light-induced attenuation of a P-type solar cell, including:

[0035] The screen-printed cells are placed on the sintering furnace belt in the sintering zone and transported at a speed of 230 inches / min. First dry in the drying zone with a temperature of 280°C, and then heat up and sinter in the sintering zone. After reaching the sintering peak temperature of 760°C, perform cooling and sintering at a cooling rate of 25K / s to the sintering activation temperature of 675°C. After sintering, the The cells are cooled in a cooling zone with a temperature of 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com