Ultraviolet LED epitaxial preparation method and ultraviolet LED

A technology of LED structure and epitaxy, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of low luminous efficiency of ultraviolet LEDs and single luminous layer of ultraviolet LEDs, and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

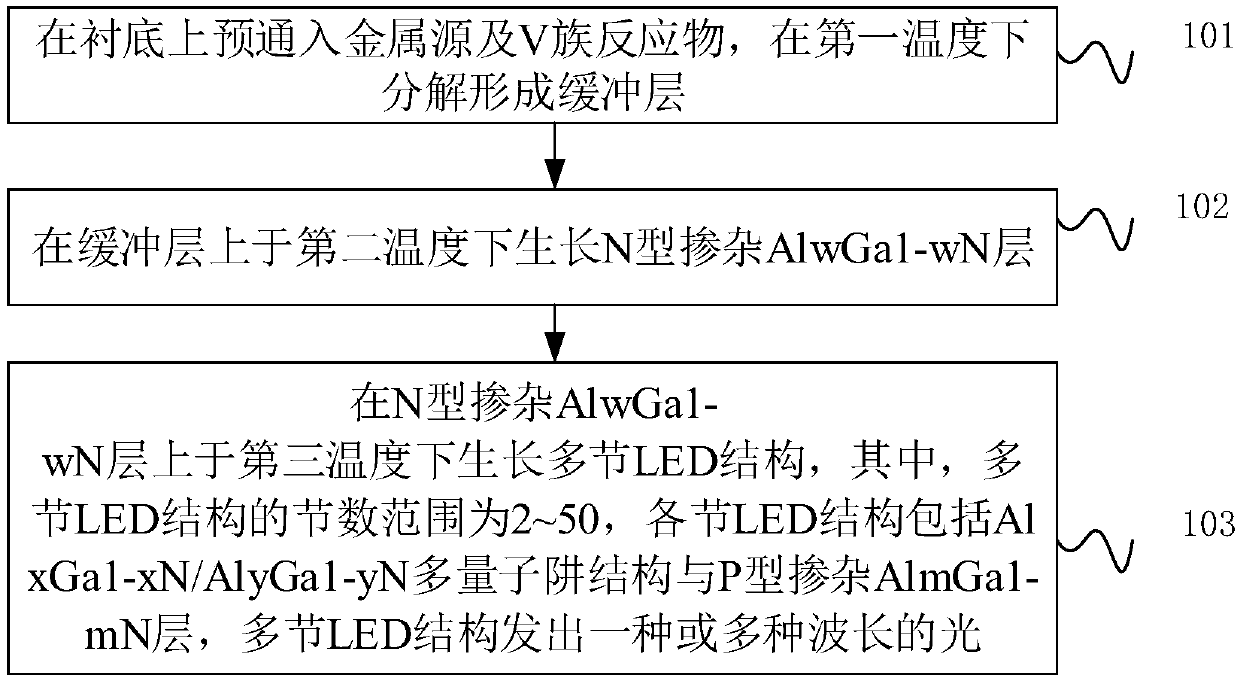

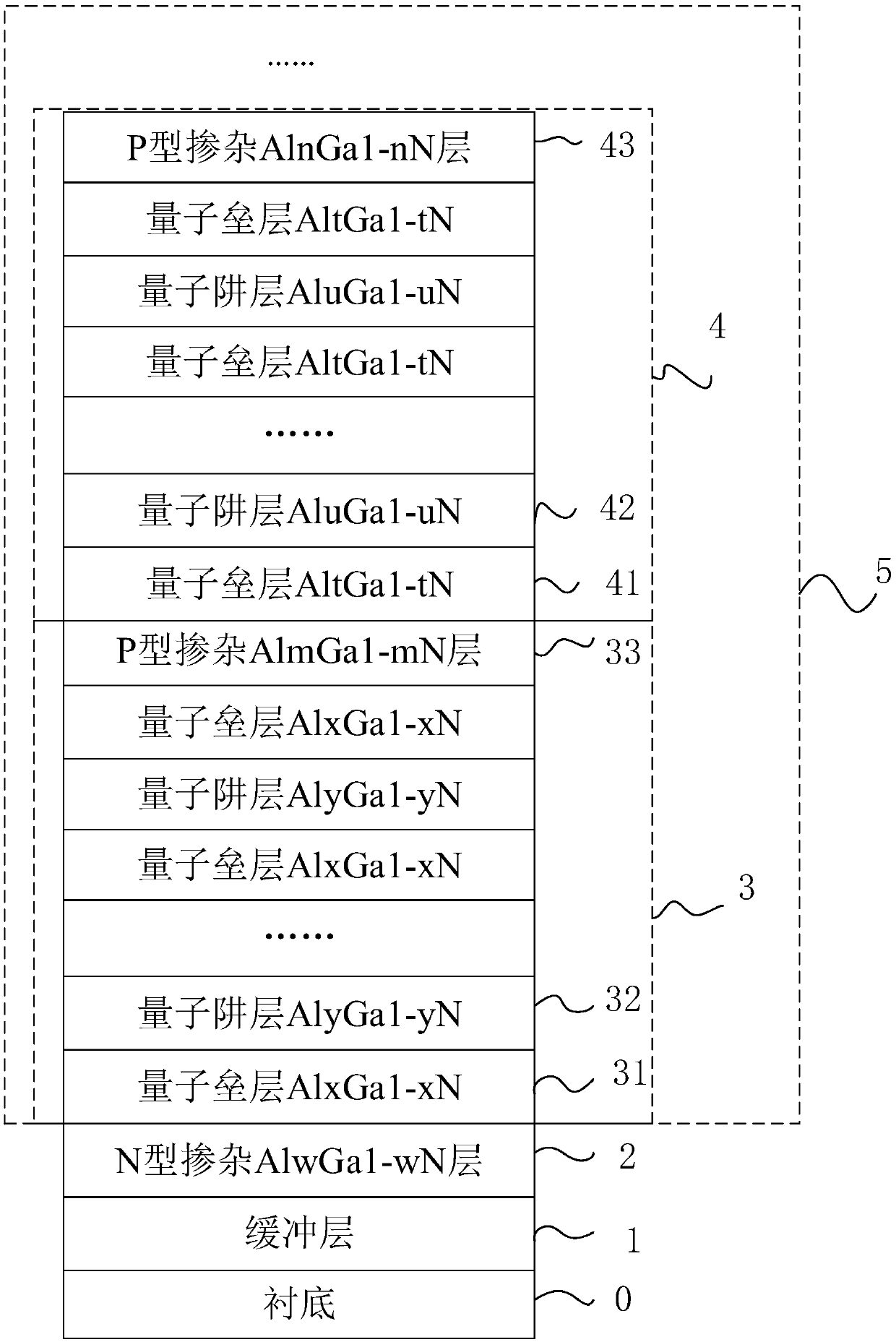

[0055] figure 1 It is a flow chart of the ultraviolet LED epitaxial preparation method provided by Embodiment 1 of the present invention, figure 2 It is a schematic structural diagram of the ultraviolet LED epitaxy provided by Embodiment 1 of the present invention, as figure 1 and figure 2 As shown, the method in this embodiment may include:

[0056] Step S101: pre-flowing metal sources and group V reactants on the substrate, and decomposing them at a first temperature to form a buffer layer.

[0057] The substrate 0 is mainly used to support and improve the film properties. The film is grown on the substrate 0, the material properties of the substrate 0 and the surface shape of the substrate 0 have a great influence on the characteristics of the film, because the thickness of the film is generally between nanometers and microns, and the surface of the substrate 0 is required to have an ultra-high flatness The combination of film and substrate O is also a very important ...

Embodiment 2

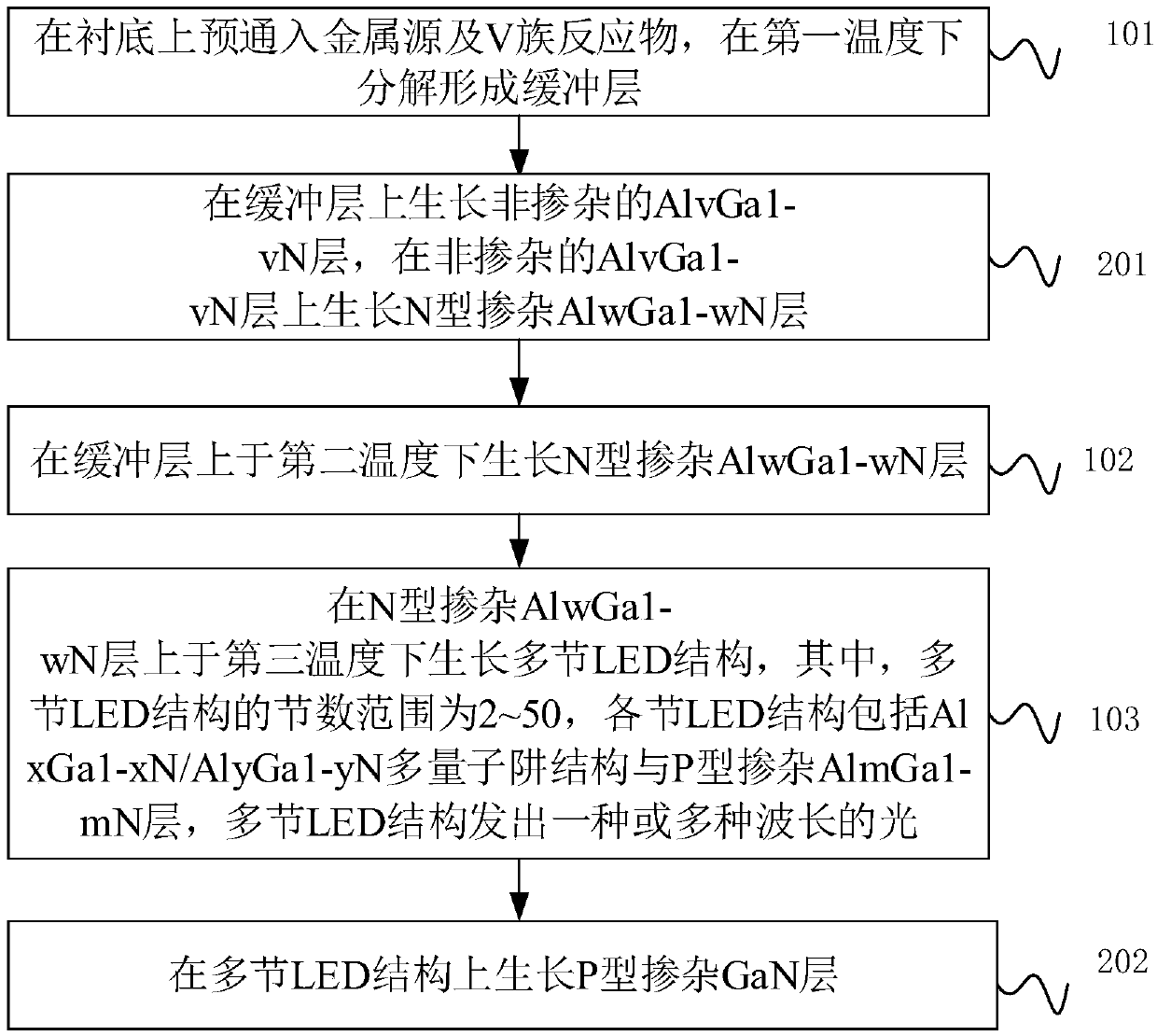

[0077] On the basis of the first embodiment above, in order to ensure the quality of the N-type doped AlwGa1-wN layer, image 3 It is a schematic flow chart of the method for preparing ultraviolet LED epitaxy provided by Embodiment 2 of the present invention, Figure 4 It is a schematic structural diagram of the ultraviolet LED epitaxy provided by Embodiment 3 of the present invention, such as image 3 and Figure 4 As shown, the ultraviolet LED epitaxial preparation method provided by the embodiment of the present invention may also include:

[0078] S201: growing a non-doped AlvGa1-vN layer on the buffer layer, and growing an N-type doped AlwGa1-wN layer on the non-doped AlvGa1-vN layer.

[0079] Specifically, the undoped AlvGa1-vN layer 6 can be grown by adjusting the temperature of the reaction chamber while feeding trimethylaluminum, trimethylgallium and NH3, and then growing on the undoped AlvGa1-vN layer 6 N-type doped AlwGa1-wN layer 2 . The embodiment of the prese...

Embodiment 3

[0085] Ultraviolet LEDs can be used in the field of sterilization. In order to realize the preparation of ultraviolet LEDs with ultra-high bactericidal functions, on the basis of the above-mentioned embodiment 1 and embodiment 2, the preparation method of three-section ultraviolet 280nm band ultraviolet LEDs will be described below as an example. A UV LED with a single wavelength of 280nm can include the following steps:

[0086] Step 1: In the MOCVD reaction chamber of metal organic chemical vapor deposition equipment, the temperature is raised to 900°C, the pressure is 400mbar, and trimethylaluminum (150 milliliters per minute (ml / min)) and ammonia gas are introduced at the same time for 3 minutes, and the sapphire A reaction occurs on the substrate to form a 25nm AlN buffer layer.

[0087] The second step: the temperature is raised to 1200°C and the pressure is lowered to 200mbar, the AlN buffer layer undergoes a decomposition reaction, and after the AlN buffer layer is dec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap