Preparation method of chili-flavor spicy and hot potato chip seasoner and chili-flavor spicy and hot potato chip seasoner

A technology of spicy flavor and seasoning, which is applied in the field of peppery spicy potato chip seasoning and peppery spicy potato chip seasoning, can solve the problem of coarse chili powder and pepper powder particles, poor adhesion fastness on the surface of potato chips, Seasoning powder falls and other problems, to achieve the effect of maintaining flavor and taste, good adsorption fastness, and improving adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

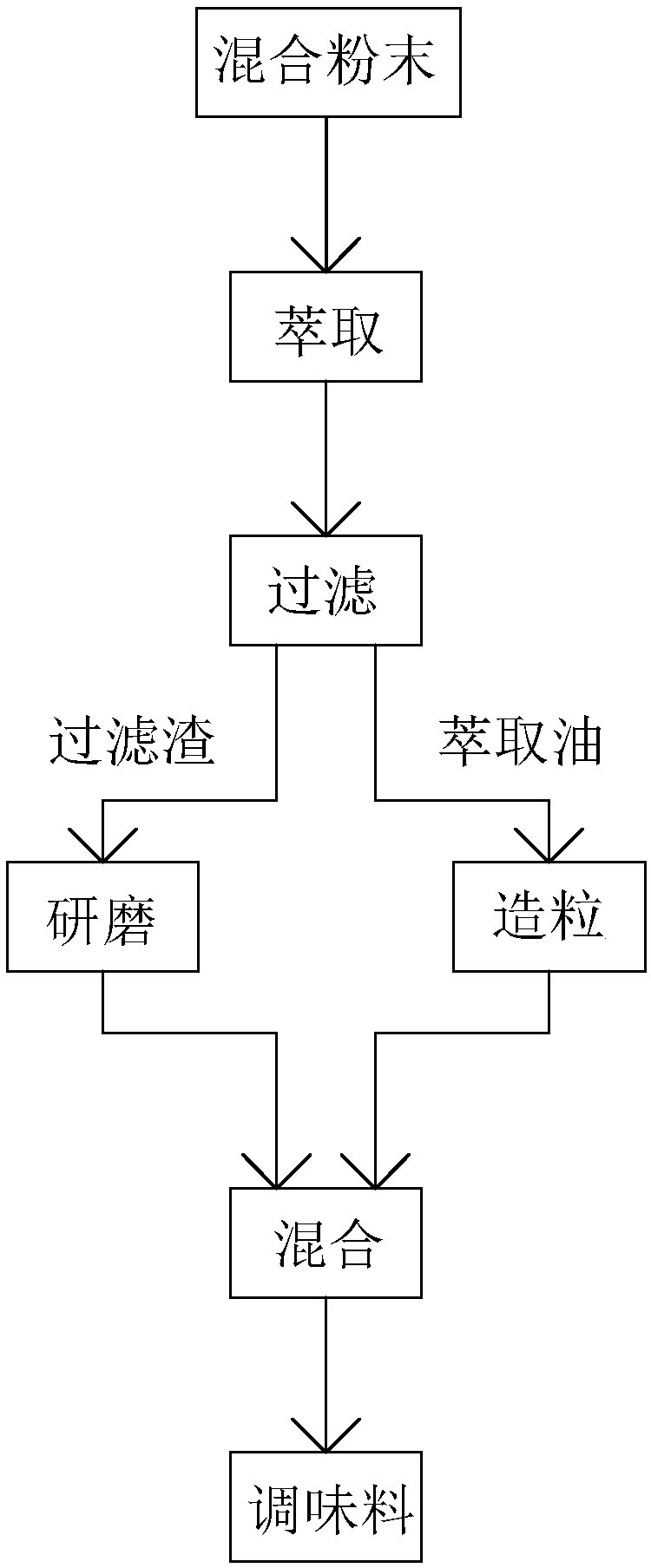

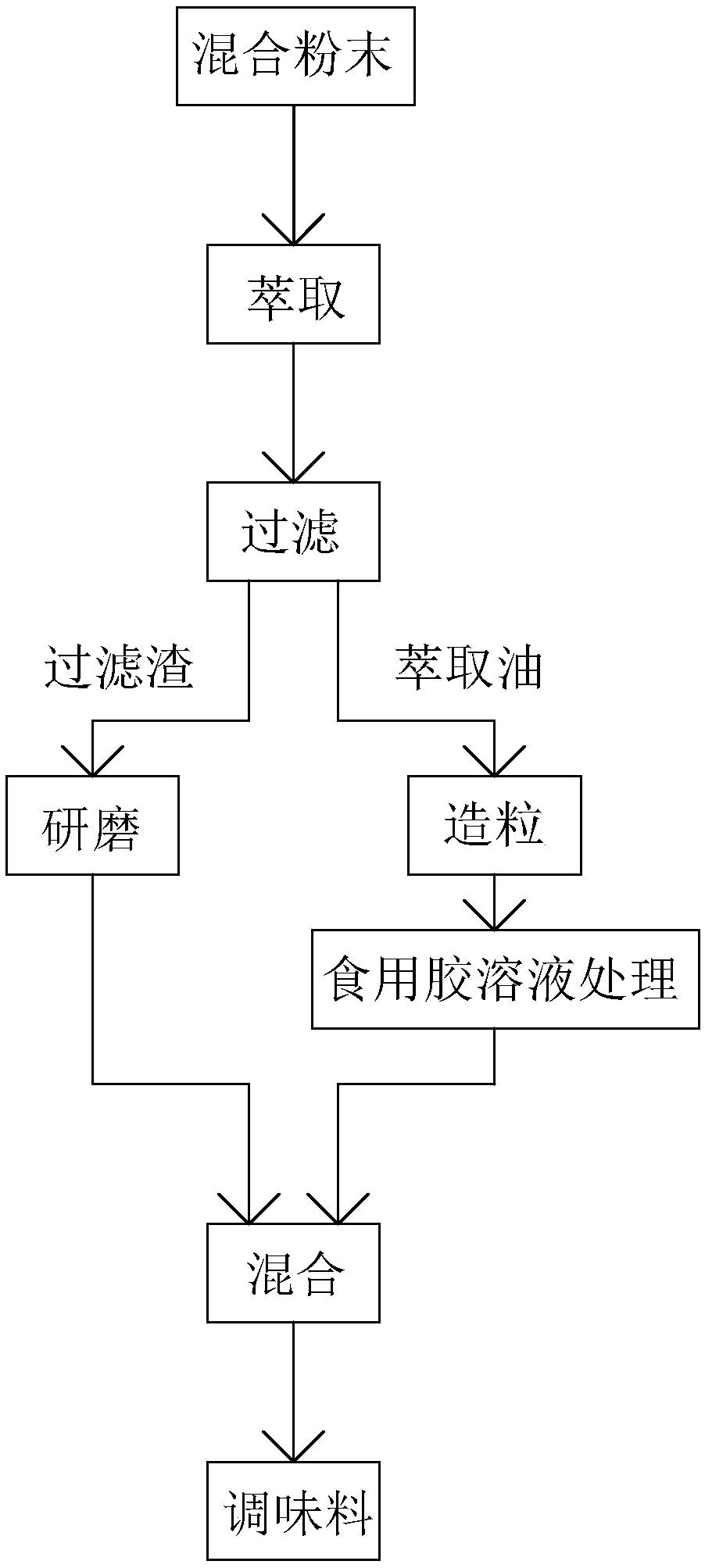

[0052] A preparation method of peppery and spicy potato chip seasoning, which uses dried chili powder, dried pepper powder, salt, monosodium glutamate, palm oil, edible silicon dioxide, edible calcium carbonate, tertiary butyl hydroquinone and vitamin E as Raw material, its technological process such as figure 1 As shown, specifically include the following steps,

[0053] Extraction: Add the mixed powder formed by mixing dried chili powder and dried Zanthoxylum bungeanum powder in the mass ratio of 1:0.8 to palm oil to obtain a mixed powder-palm oil mixture, the mass ratio of mixed powder and palm oil is 1:1.5 . Heat the mixed powder-palm oil mixture to 80°C and keep it warm for 35 minutes. In order to reduce the destruction of nutrients in dried chili powder and dried pepper powder by heating, the palm oil is also mixed with 0.1% tert-butyl hydroquinone by mass percentage.

[0054] Filtration: After the heat preservation is completed, use a vacuum filter to filter the mixe...

Embodiment 2

[0059] A preparation method of peppery and spicy potato chip seasoning, which uses dried chili powder, dried pepper powder, salt, monosodium glutamate, palm oil, edible silicon dioxide, edible calcium carbonate, tertiary butyl hydroquinone and vitamin E as Raw material, its technological process such as figure 1 As shown, specifically include the following steps,

[0060] Extraction: Add the mixed powder formed by mixing dried chili powder and dried Zanthoxylum bungeanum powder in a mass ratio of 1:1 to palm oil to obtain a mixed powder-palm oil mixture, and the mass ratio of mixed powder to palm oil is 1:1.8 . Heat the mixed powder-palm oil mixture to 90°C and keep it warm for 30min. In order to reduce the destruction of nutrients in the dried chili powder and dried pepper powder by heating, the palm oil is also mixed with 0.15% tert-butyl hydroquinone by mass percentage.

[0061] Filtration: After the heat preservation is completed, use a vacuum filter to filter the mixed...

Embodiment 3

[0066] A preparation method of peppery and spicy potato chip seasoning, which uses dried chili powder, dried pepper powder, salt, monosodium glutamate, palm oil, edible silicon dioxide, edible calcium carbonate, tertiary butyl hydroquinone and vitamin E as Raw material, its technological process such as figure 1 As shown, specifically include the following steps,

[0067] Extraction: Add the mixed powder formed by mixing dried chili powder and dried Zanthoxylum bungeanum powder in a mass ratio of 1:1.2 to palm oil to obtain a mixed powder-palm oil mixture, and the mass ratio of mixed powder to palm oil is 1:2.0 . Heat the mixed powder-palm oil mixture to 100°C and keep it warm for 25 minutes. In order to reduce the destruction of nutrients in dried chili powder and dried pepper powder by heating, 0.2% tert-butyl hydroquinone is also mixed with the palm oil.

[0068] Filtration: After the heat preservation is completed, use a vacuum filter to filter the mixed powder-palm oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com