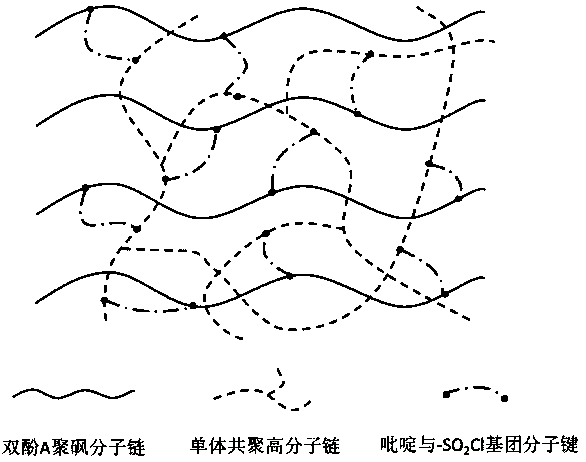

Preparation method of cation exchange membrane with multiple crosslinked structures

A cation exchange membrane and anion exchange membrane technology, applied in cation exchange, ion exchange, chemical instruments and methods, etc., can solve the problems affecting the mechanical properties and electrochemical properties of the membrane, improve the anti-swelling performance, expand the application range, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Bisphenol A polysulfone sulfonylation:

[0034] Add 60.0g bisphenol A polysulfone to a dry four-necked flask, then add 500.0ml dichloroethane, stir to completely dissolve bisphenol A polysulfone; put 3.6818g sulfuryl chloride and 10ml dichloroethane into the dropping funnel At room temperature, the liquid in the dropping funnel was slowly added dropwise to the dichloroethane solution of bisphenol A polysulfone, and the dropping time was 10 minutes. Scrape the modified bisphenol A polysulfone solution on a flat plate and dry it at 60°C to remove the solvent to obtain a modified bisphenol A polysulfone solid.

[0035] (2) Monomer solution preparation:

[0036] Add 7.8245g of N-methylpyrrolidone, 3.1854g of divinylbenzene, 0.1429g of 4-vinylpyridine and 9.8555g of ethyl methacrylate sulfonate into the beaker, then add 0.0552g of azobisisobutyronitrile and stir until completely dissolved to obtain a monomer solution.

[0037] (3) Membrane solution preparation:

[00...

Embodiment 2

[0049] (1) Bisphenol A polysulfone sulfonylation:

[0050] Add 60.0g bisphenol A polysulfone to a dry four-necked flask, then add 500.0ml dichloroethane, stir to completely dissolve bisphenol A polysulfone; put 3.6818g sulfuryl chloride and 10.0ml dichloroethylene into the dropping funnel At room temperature, the liquid in the dropping funnel was slowly added dropwise to the dichloroethane solution of bisphenol A polysulfone, and the dropwise addition time was 10 minutes. After the dropwise addition was completed, the reaction was continued at room temperature for 4 h; after the reaction was completed, Modified bisphenol A polysulfone solution: scrape the modified bisphenol A polysulfone solution on a flat plate and dry it at 60°C to remove the solvent to obtain a modified bisphenol A polysulfone solid.

[0051] (2) Monomer solution preparation:

[0052] Add 6.5205g N-methylpyrrolidone, 3.1854g divinylbenzene, 0.2144g 4-vinylpyridine and 9.8555g ethyl methacrylate sulfonate i...

Embodiment 3

[0061] (1) Bisphenol A polysulfone sulfonylation:

[0062] Add 60.0g bisphenol A polysulfone to a dry four-necked flask, then add 500.0ml dichloroethane, stir to completely dissolve bisphenol A polysulfone; put 2.7614g sulfuryl chloride and 10.0ml dichloroethylene into the dropping funnel At room temperature, the liquid in the dropping funnel was slowly added dropwise to the dichloroethane solution of bisphenol A polysulfone, and the dropwise addition time was 10 minutes. After the dropwise addition was completed, the reaction was continued at room temperature for 4 h; after the reaction was completed, Modified bisphenol A polysulfone solution, drying the modified bisphenol A polysulfone solution at 60° C. to remove the solvent to obtain a modified bisphenol A polysulfone solid.

[0063] (2) Monomer solution preparation:

[0064] Add 6.4118g of N-methylpyrrolidone, 2.1467g of divinylbenzene, 0.1445g of 4-vinylpyridine and 8.5395g of ethyl methacrylate sulfonate into the beake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| transference number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com