Preparation method of silver-based catalyst for degrading VOCs

A catalyst, H2O2 technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve the effect of enhancing load stability and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

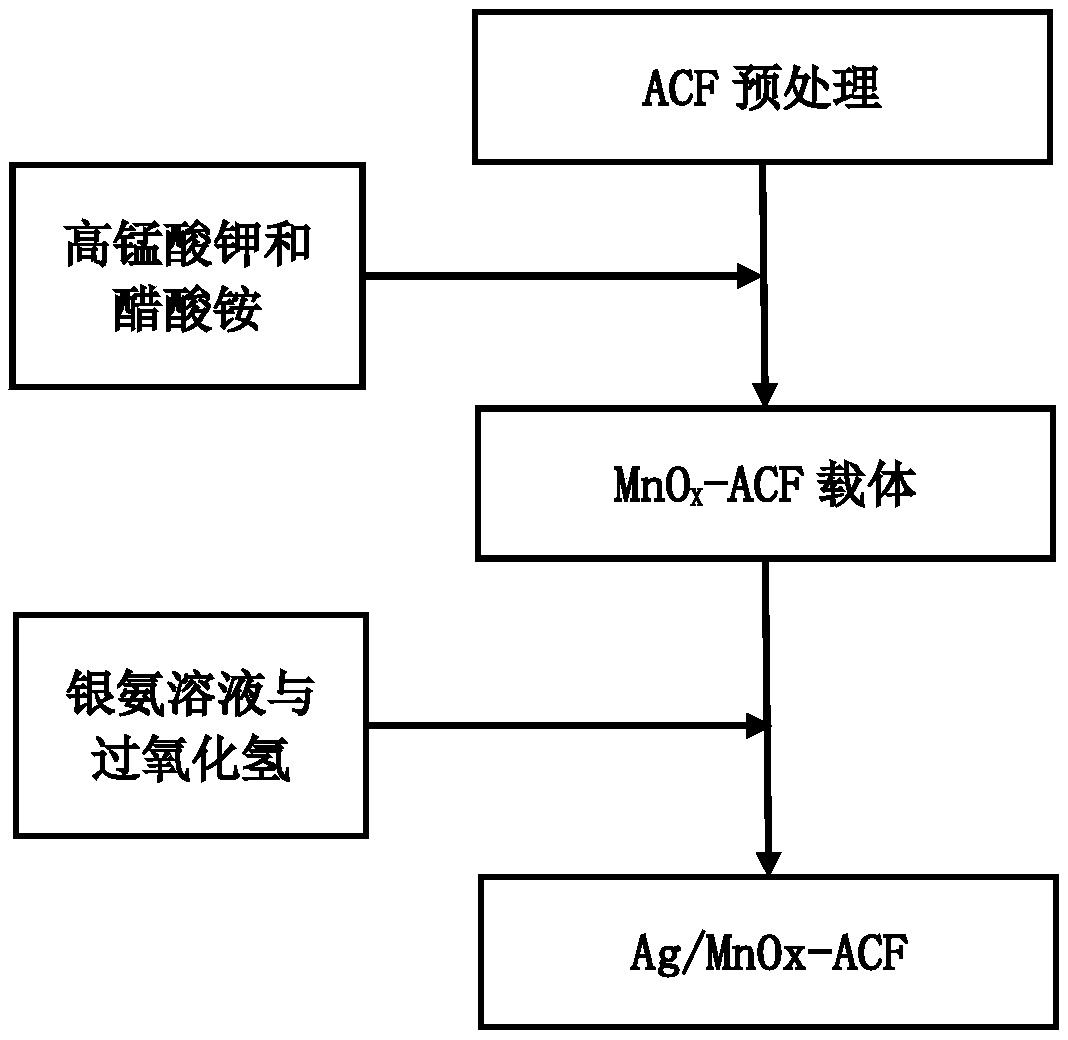

[0022] Based on the above principles, a method for preparing a catalyst for adsorption and degradation of VOCs of the present invention comprises the following steps:

[0023] (1) Soak the activated carbon fiber sheet in a methanol solution with a concentration of 0.1-0.2mol / L for 3-5min, then wash it with deionized water for 3-5min to remove possible residues on the surface, take it out and put it in a beaker and place it in an oven at 55-65°C 20-30min, then take it out and put it in a NaOH solution with a concentration of 0.5-1mol / L for 2-3min, then place the activated carbon fiber sheet stained with NaOH solution in a beaker, and heat it in an oven at 100-120°C for 30-40min Promotes hydrolysis of activated carbon fiber surfaces.

[0024] (2) (NH with a mass ratio of (1-1.5): 4) 4 ) 2 C 2 o 4 ·H 2 O and KMnO 4 Dissolved in deionized water to form a mixed solution, the KMnO 4 The solid-to-liquid ratio with deionized water is (0.015g-0.020g): 1ml. Put the activated car...

Embodiment 1

[0029] (1) Soak 0.1g of activated carbon fiber sheets in a methanol solution with a concentration of 0.1mol / L for 3 minutes, then wash with deionized water for 3 minutes to remove possible residues on the surface, take them out and put them in a beaker and place them in a 55°C oven for 20 minutes, then take them out and put them in Concentration of 0.5mol / L NaOH solution for 2min, then place the activated carbon fiber sheet dipped in NaOH solution in a beaker, place it in an oven at 100°C and heat for 30min to promote the hydrolysis of the activated carbon fiber surface.

[0030] (2) Take (NH with a mass ratio of 1:4 4 ) 2 C 2 o 4 ·H 2 O and KMnO 4 Dissolved in deionized water to form a mixed solution, the KMnO 4 The solid-to-liquid ratio with deionized water is 0.015g:1ml. Put the activated carbon fiber sheet obtained in step (1) into the mixed solution and add 0.2mol / L hydrochloric acid to adjust the pH of the mixed system to 7, then place the mixed system in a 90°C co...

Embodiment 2

[0035] (1) Soak 0.1g of activated carbon fiber sheets in a methanol solution with a concentration of 0.15mol / L for 4 minutes, then wash with deionized water for 4 minutes to remove possible residues on the surface, take them out and put them in a beaker and place them in a 60°C oven for 25 minutes, then take them out and put them in Concentration of 0.8mol / L NaOH solution for 2.5min, then place the activated carbon fiber sheet dipped in NaOH solution in a beaker, and heat in an oven at 110°C for 35min to promote the hydrolysis of the activated carbon fiber surface.

[0036] (2) Take (NH with a mass ratio of 1.2:4 4 ) 2 C 2 o 4 ·H 2 O and KMnO 4 Dissolved in deionized water to form a mixed solution, the KMnO 4 The solid-to-liquid ratio with deionized water is 0.018:1ml. Put the activated carbon fiber sheet obtained in step (1) into the mixed solution and add 0.3mol / L hydrochloric acid to adjust the pH of the mixed system to 7.2, then place the mixed system in a constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com