Catalyst for diesel engine on basis of perovskite and modified hydrotalcite-derived oxide and preparation method thereof

A technology of perovskite and modified water, which is applied in the field of adsorption-reduction catalysts and its preparation, can solve the problems of deteriorating the adsorption performance of LNT catalysts, failing to assist in increasing the NOx saturated adsorption capacity of LNT catalysts, and frequent switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

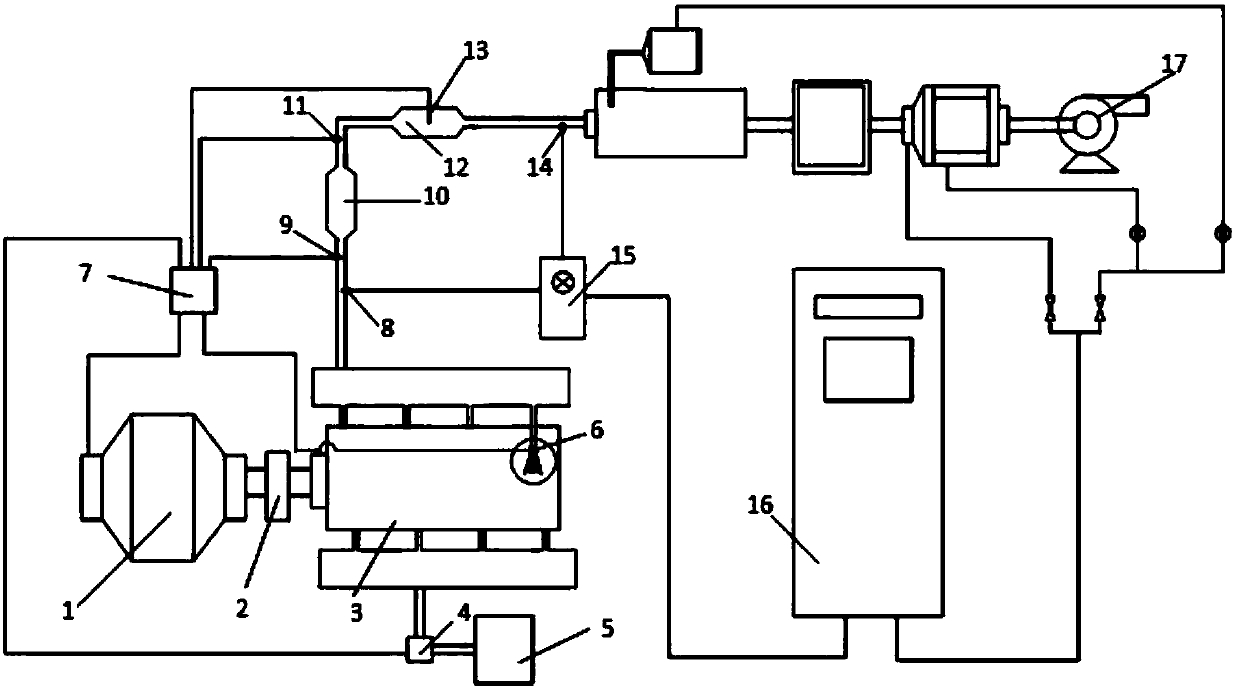

Image

Examples

preparation example Construction

[0056] The preparation method of the catalyst for diesel engine based on perovskite and modified hydrotalcite derivative oxide, its specific process comprises the following 5 steps:

[0057] (1) Determination of the catalyst raw material consumption;

[0058] (2) La x Ce (1-x) mn y Ni (1-y) o 3 Preparation of type perovskite composite oxide;

[0059] (3) Preparation of La-modified hydrotalcite-derived composite oxides;

[0060] (4) Preparation of coating slurry;

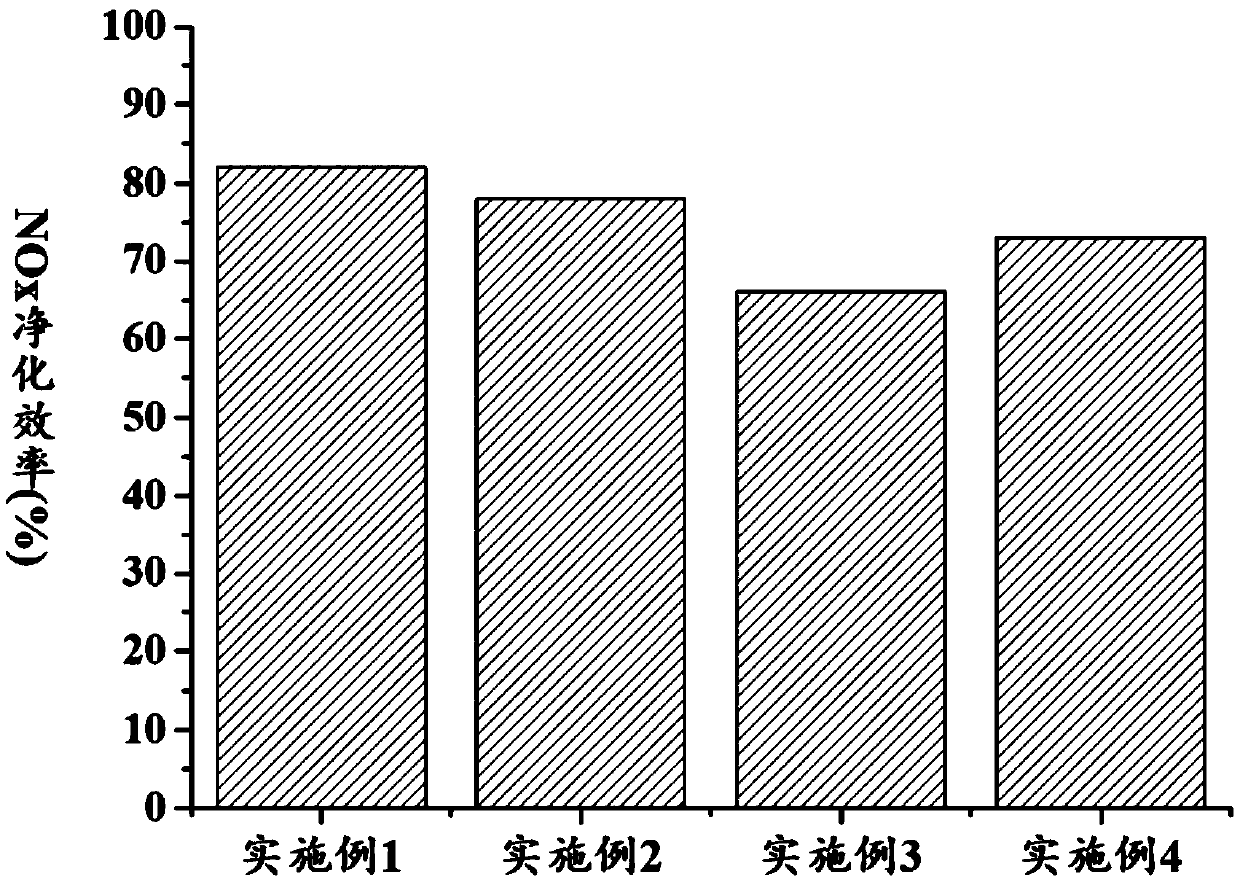

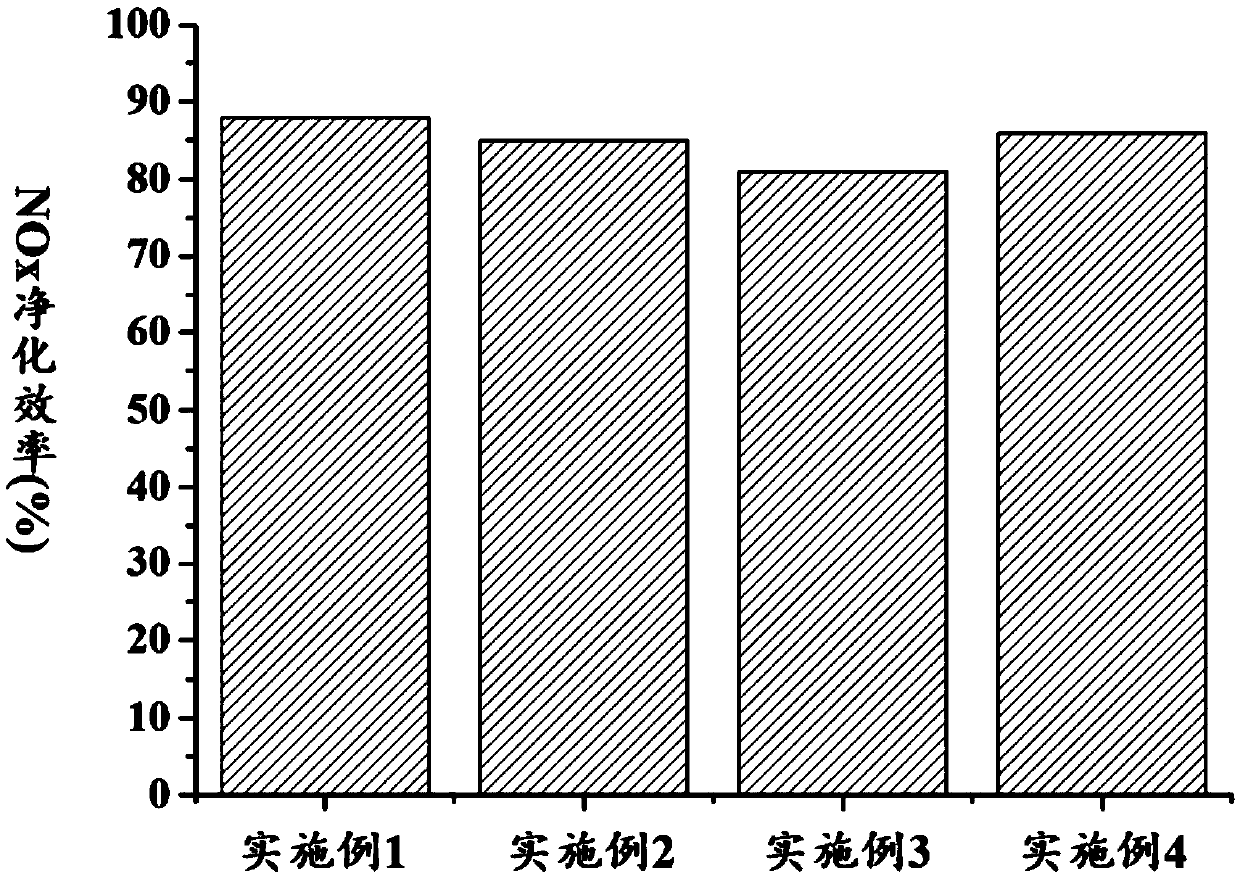

Embodiment 1

[0076] (1) Determination of the amount of catalyst raw material used

[0077] In the main active component of the catalyst prepared in Design Example 1, La x Ce (1-x) mn y Ni (1-y) o 3 The mass ratio of type perovskite composite oxide and noble metal Pt-Pd is: 90%:10%; La x Ce (1-x) mn y Ni (1-y) o 3In the type perovskite composite oxide, the molar percentage of La ion and Ce ion at A site is: 75% / 25%, and the molar percentage of Mn ion and Ni ion at B site is: 50% / 50%; noble metal Pt-Pd In, the mass percentage of Pt and Pd is: 25% / 75%; CeO in cocatalyst 2 and ZrO 2 The mass ratio is: 80%:20%; La modified hydrotalcite derived composite oxide and γ-Al in the coating additive 2 o 3 The mass ratio is: 75%:25%; Al in La modified hydrotalcite derived composite oxide 2 o 3 and La 2 o 3 The mol percentage example is: 50%:50%; the mass ratio of the main active ingredient, adsorbent, co-catalyst and coating aid in the catalytic coating is: 15% / 20% / 15% / 50%; every 100g ca...

Embodiment 2

[0088] (1) Determination of the amount of catalyst raw material used

[0089] In the main active component of the catalyst prepared in Design Example 2, La x Ce (1-x) mn y Ni (1-y) o 3 The mass ratio of type perovskite composite oxide and noble metal Pt-Pd is: 90%:10%; La x Ce (1-x) mn y Ni (1-y) o 3 In the type perovskite composite oxide, the molar percentage of La ion and Ce ion at A site is: 50% / 50%, and the molar percentage of Mn ion and Ni ion at B site is: 25% / 75%; noble metal Pt-Pd In, the mass percentage of Pt and Pd is: 75% / 25%; CeO in cocatalyst 2 and ZrO 2 The mass ratio is: 90%:10%; La modified hydrotalcite derived composite oxide and γ-Al in the coating additive 2 o 3 The mass ratio is: 80%:20%; Al in La modified hydrotalcite derived composite oxide 2 o 3 and La 2 o 3 The mol percentage example is: 20%:80%; the mass ratio of the main active ingredient, adsorbent, co-catalyst and coating aid in the catalytic coating is: 10% / 15% / 10% / 65%; every 100g c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com