Hydrotalcite-derived oxide-based nitrogen oxide trapping catalyst as well as preparation method and application thereof

A technology based on oxides and nitrogen oxides, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of sulfur resistance, coking resistance, and thermal aging resistance Poor sintering performance, difficult LNT technology, poor coating performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

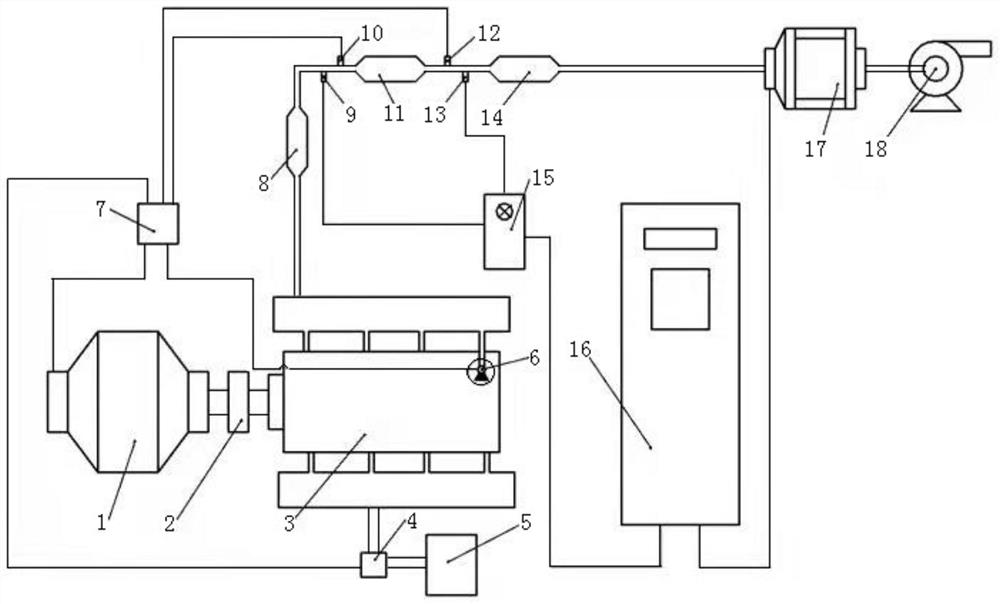

Image

Examples

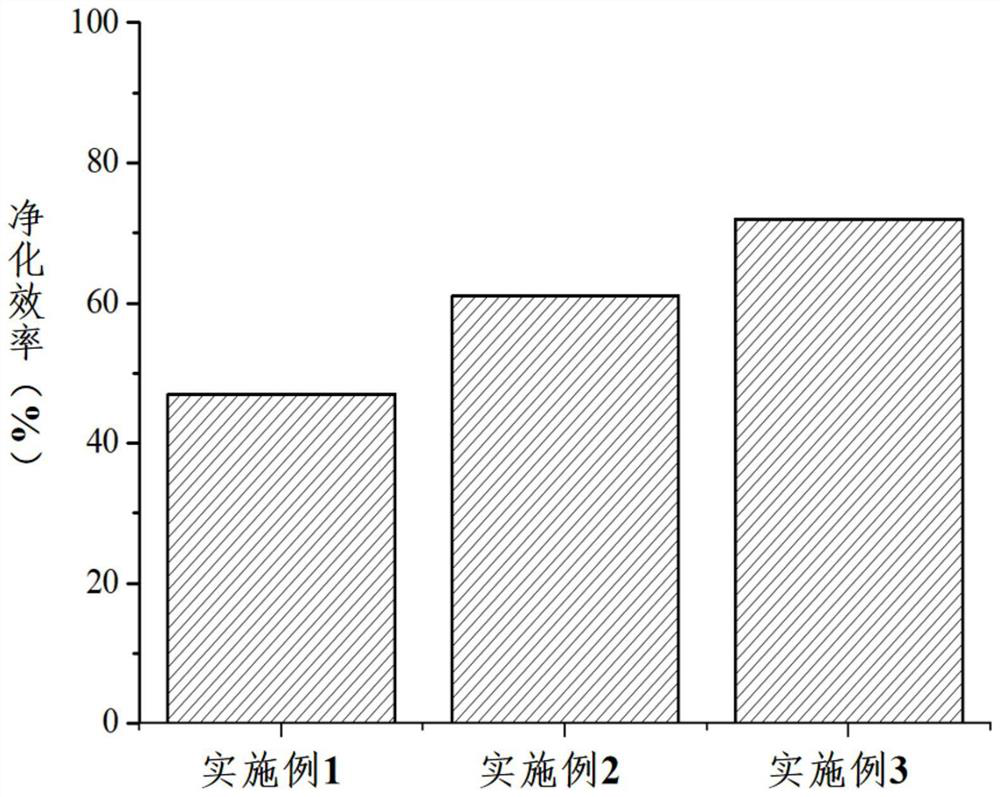

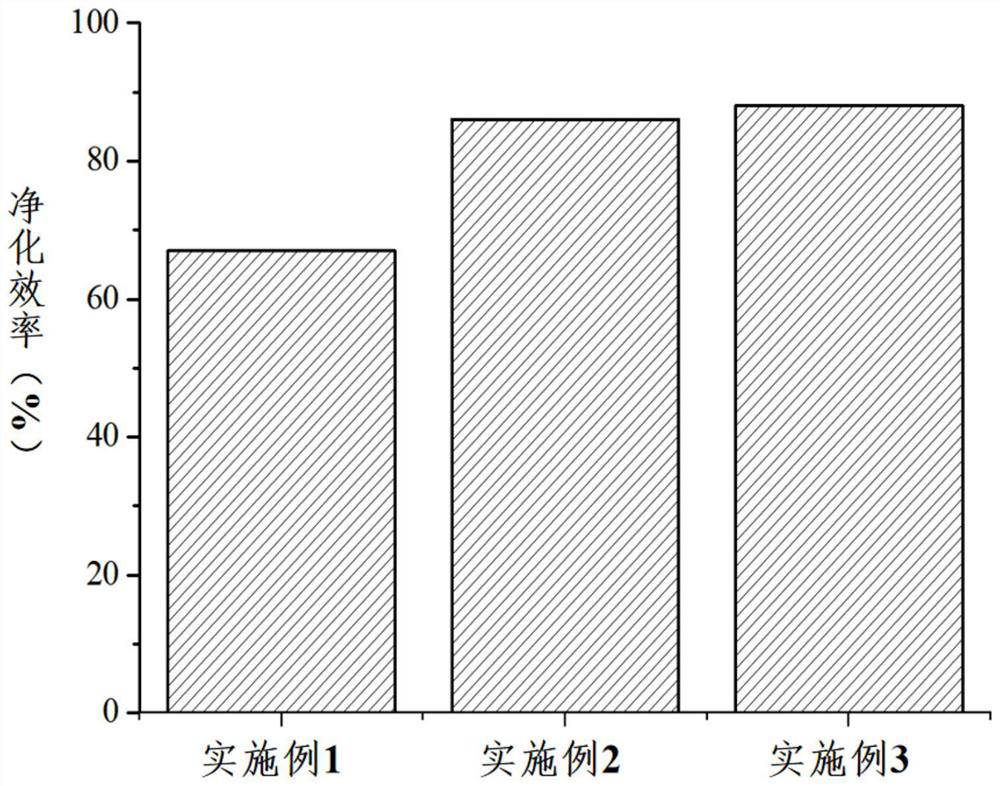

Embodiment 1

[0031] (1) Catalyst composition design

[0032] The following ratios are designed respectively: CeO 2 -PtO 2 / ZrO 2 CeO in Composite Catalytic Nanoparticles 2 and PtO 2 The mass percentage is: 99% / 1%, the mole percentage of Mg element and Mn element in the Mn-Fe modified hydrotalcite-derived composite oxide is: 25% / 75%, the mole percentage of Al element and Fe element is: 90 % / 10%, γ-Al in coating accessories 2 O 3 and La 2 O 3 The mass percentage is: 25% / 75%, the mass percentage of the main catalytic active components, co-catalysts, adsorption-coating materials and coating accessories is: 5% / 10% / 65% / 20%, and the planned configuration The coating slurry can generate 2000g of catalytic coating.

[0033] (2) CeO 2 / ZrO 2 Preparation of composite oxide nanoparticles

[0034] Weigh 249.8g Ce(NO 3 ) 3 ·6H 2 O, 696.9g Zr (NO 3 ) 4 ·5H 2 O and 800g median particle size (D 50 particle size) is carbon black of 472nm, the three kinds of raw materials are added togethe...

Embodiment 2

[0046] (1) Catalyst composition design

[0047] The following ratios are designed respectively: CeO 2 -PtO 2 / ZrO 2 CeO in Composite Catalytic Nanoparticles 2 and PtO 2 The mass percentage is: 95% / 5%, the mole percentage of Mg element and Mn element in the Mn-Fe modified hydrotalcite-derived composite oxide is: 75% / 25%, the mole percentage of Al element and Fe element is: 40 % / 60%, γ-Al in coating accessories 2 O 3 and La 2 O 3 The mass percentage is: 75% / 25%, the mass percentage of the main catalytic active components, co-catalysts, adsorption-coating materials and coating accessories is: 1% / 2% / 87% / 10%, and the planned configuration The coating slurry can generate 2000g of catalytic coating.

[0048] (2) CeO 2 / ZrO 2 Preparation of composite oxide nanoparticles

[0049] Weigh 47.9g Ce(NO 3 ) 3 ·6H 2 O, 139.4g Zr (NO 3 ) 4 ·5H 2 O and 280g D 50 For carbon black with a particle size of 373 nm, the three raw materials were added to 3 L of deionized water, foll...

Embodiment 3

[0059] (1) Catalyst composition design

[0060] The following ratios are designed respectively: CeO 2 -PtO 2 / ZrO 2 CeO in Composite Catalytic Nanoparticles 2 and PtO 2 The mass percentage is: 96% / 4%, the mole percentage of Mg element and Mn element in the Mn-Fe modified hydrotalcite-derived composite oxide is: 50% / 50%, the mole percentage of Al element and Fe element is: 50 % / 50%, γ-Al in coating accessories 2 O 3 and La 2 O 3 The mass percentage is: 50% / 50%, the mass percentage of the main catalytic active components, co-catalysts, adsorption-coating materials and coating accessories is: 3% / 6% / 76% / 15%, and the planned configuration The coating slurry can generate 2000g of catalytic coating.

[0061] (2) CeO 2 / ZrO2 Preparation of composite oxide nanoparticles

[0062] Weigh 145.3g Ce(NO 3 ) 3 ·6H 2 O, 418.1g Zr (NO 3 ) 4 ·5H 2 O and 600g D 50 For carbon black with a particle size of 373 nm, the three raw materials were added together in 12 L of deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com