Double-coating catalyst for diesel engine on basis of modified hydrotalcite-derived oxide and preparation method

A technology of hydrotalcite and oxides, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of different, different exhaust components, functional components underdistribution etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

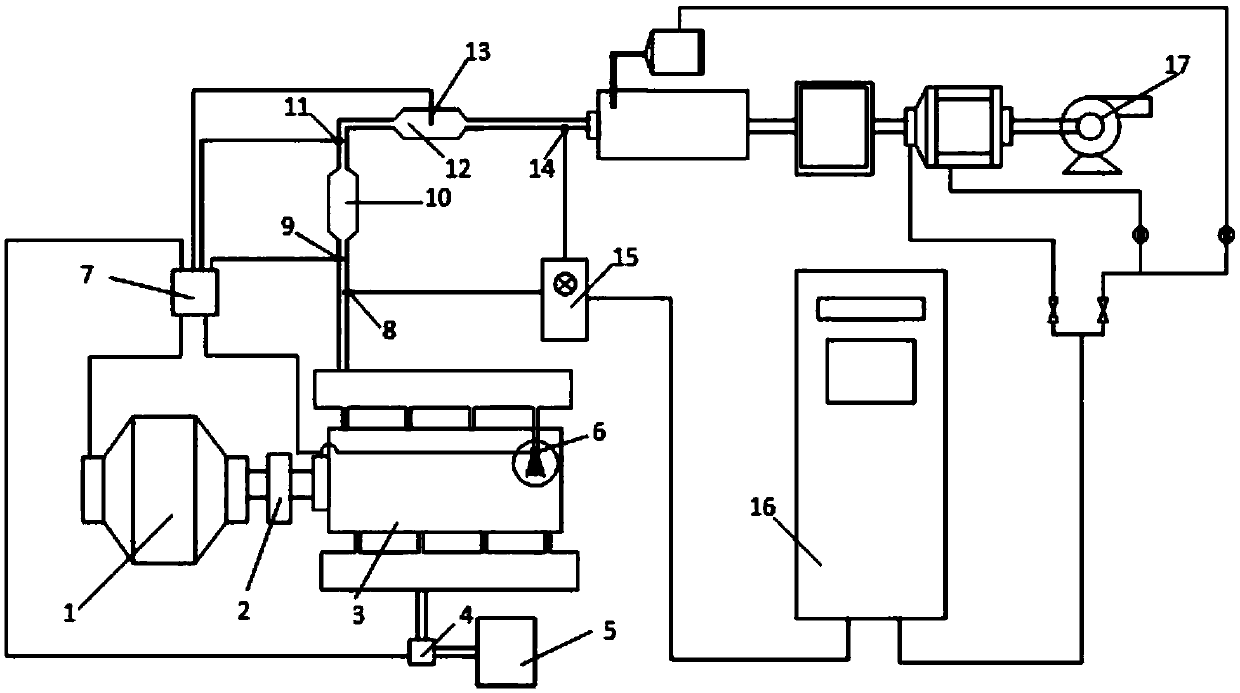

Method used

Image

Examples

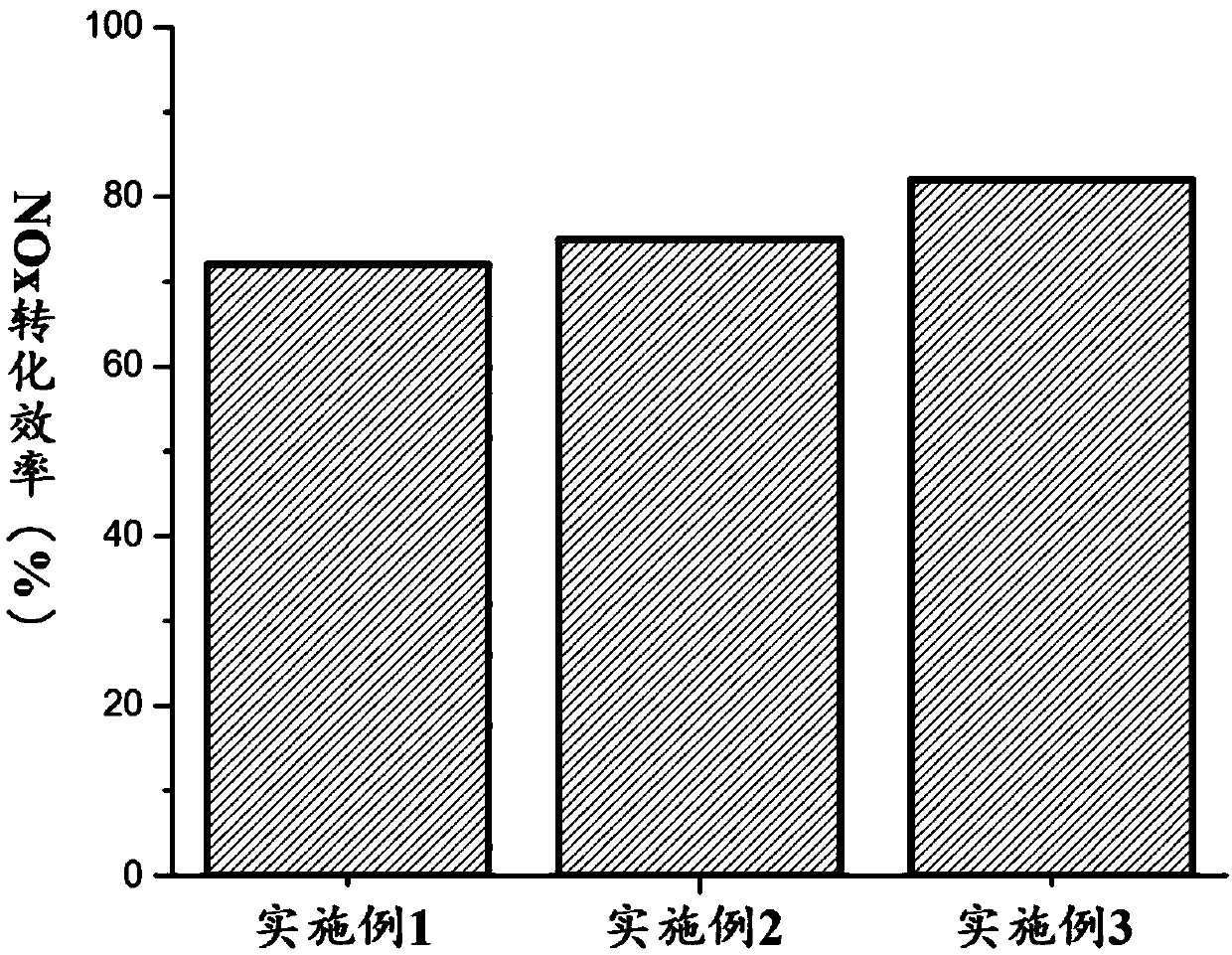

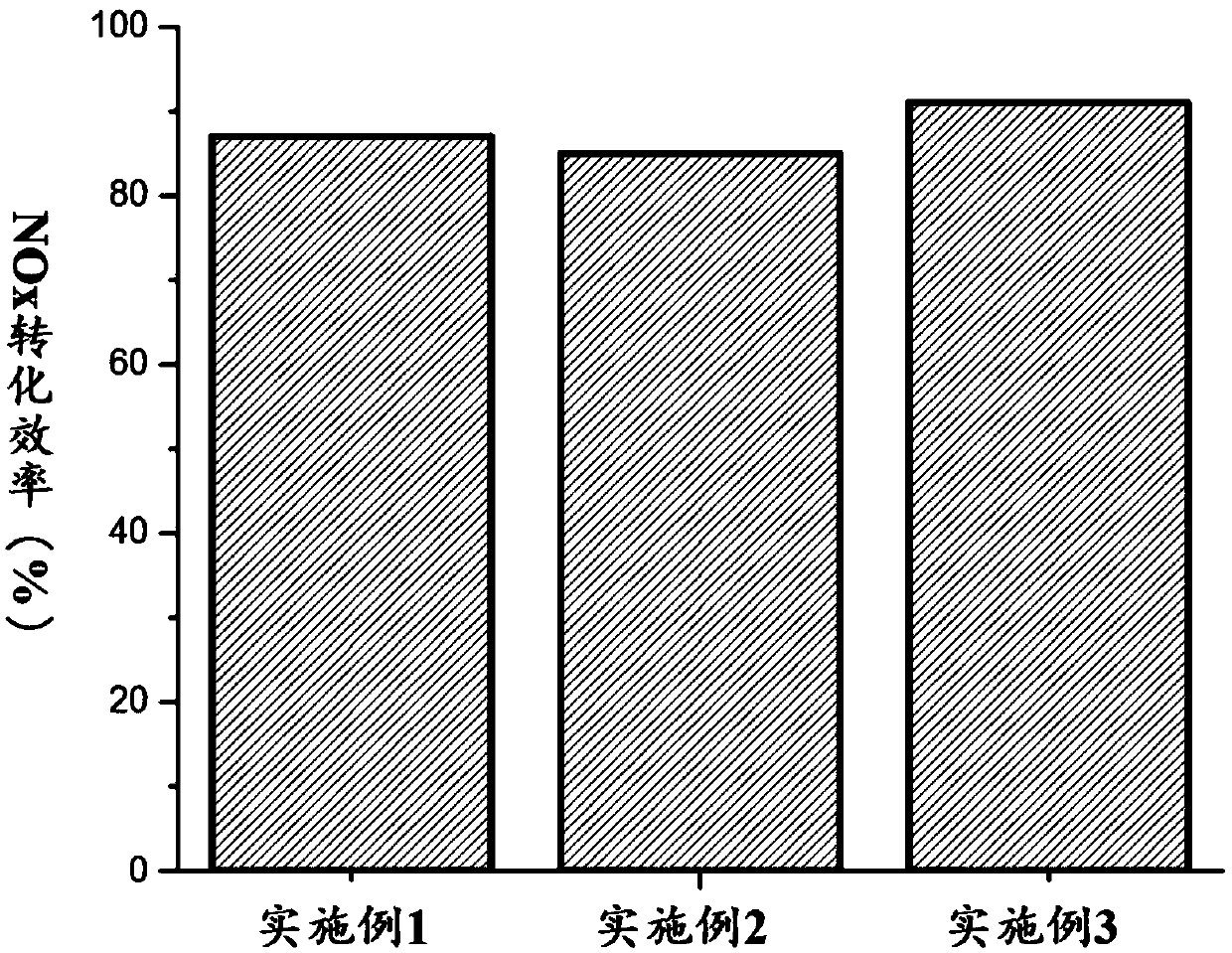

Embodiment 1

[0056] (1) Catalyst composition design

[0057] The main active components of Pt and La in the outer catalytic coating were designed respectively. x Sr (1-x) mn y co (1-y) o 3 The mass percentage of the type perovskite composite oxide is: 2% / 98%; the mass percentage of the main active component of the outer catalytic coating, the outer catalytic coating adsorbent, the outer catalytic coating co-catalyst and the outer catalytic coating base material is : 15% / 10% / 10% / 65%; Bi-Ni bimetallic modified hydrotalcite-derived composite oxide, γ-Al in the base material of the inner catalytic coating 2 o 3 and SiO 2 The mass percentage of the inner catalytic coating is: 85% / 10% / 5%; the mass percentage of the main active ingredient of the inner catalytic coating, the inner catalytic coating adsorbent, the inner catalytic coating co-catalyst and the inner catalytic coating base material is: 10% / 10% / 10% / 70%; La x Sr (1-x) mn y co (1-y) o 3 The molar percentage of La ion and Sr i...

Embodiment 2

[0067] (1) Catalyst composition design

[0068] The main active components of Pt and La in the outer catalytic coating were designed respectively. x Sr (1-x) mn y co (1-y) o 3 The mass percentage of the type perovskite composite oxide is: 5% / 95%; the mass percentage of the main active component of the outer catalytic coating, the outer catalytic coating adsorbent, the outer catalytic coating co-catalyst and the outer catalytic coating base material is : 10% / 10% / 5% / 75%. Bi-Ni Bimetallic Modified Hydrotalcite-Derived Composite Oxide, γ-Al in Basic Material of Internal Catalytic Coating 2 o 3 and SiO 2 The mass percentage of the inner catalytic coating is: 80% / 10% / 10%; the mass percentage of the main active ingredient of the inner catalytic coating, the inner catalytic coating adsorbent, the inner catalytic coating co-catalyst and the inner catalytic coating base material is: 5% / 10% / 5% / 80%. La x Sr (1-x) mn y co (1-y) o 3 The molar percentage of La ion and Sr ion i...

Embodiment 3

[0078] (1) Catalyst composition design

[0079] The main active components of Pt and La in the outer catalytic coating were designed respectively. x Sr (1-x) mn y co (1-y) o 3 The mass percentage of the type perovskite composite oxide is: 5% / 95%; the mass percentage of the main active component of the outer catalytic coating, the outer catalytic coating adsorbent, the outer catalytic coating co-catalyst and the outer catalytic coating base material is : 15% / 10% / 5% / 70%; Bi-Ni bimetallic modified hydrotalcite-derived composite oxide, γ-Al in the base material of the inner catalytic coating 2 o 3 and SiO 2The mass percentage of the inner catalytic coating is: 85% / 10% / 5%; the mass percentage of the main active ingredient of the inner catalytic coating, the inner catalytic coating adsorbent, the inner catalytic coating co-catalyst and the inner catalytic coating base material is: 10% / 10% / 10% / 70%; La x Sr (1-x) mn y co (1-y) o 3 The molar percentage of La ion and Sr ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com