Laser welding equipment used for battery cell tab and pole piece

A laser welding and tab technology, applied in other manufacturing equipment/tools, circuits, electrical components, etc., can solve the problems of high cost of ultrasonic welding equipment, low tab strength, etc., to avoid virtual welding problems and improve tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are further explanations and supplements to the present invention, and will not constitute any limitation to the present invention.

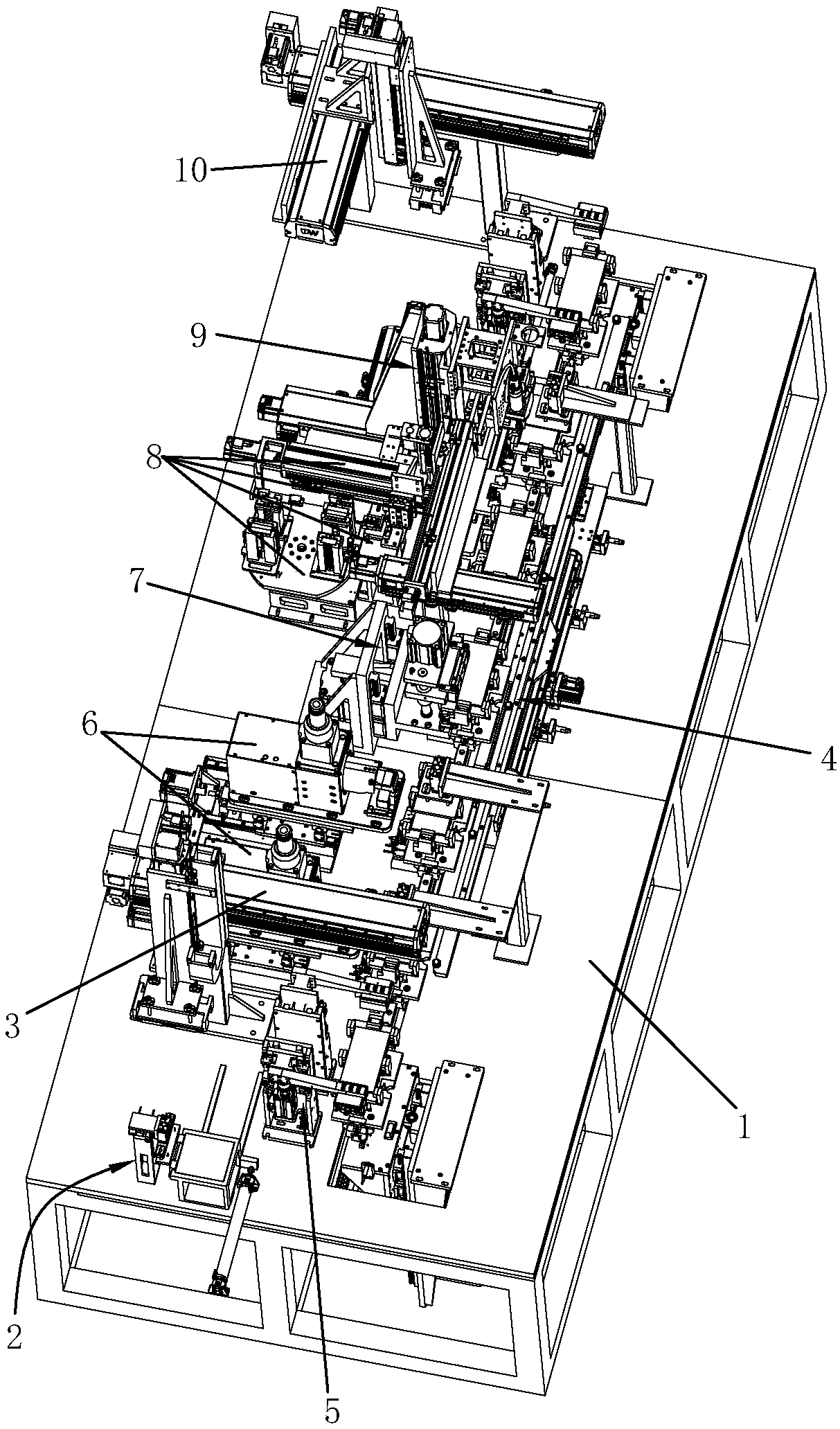

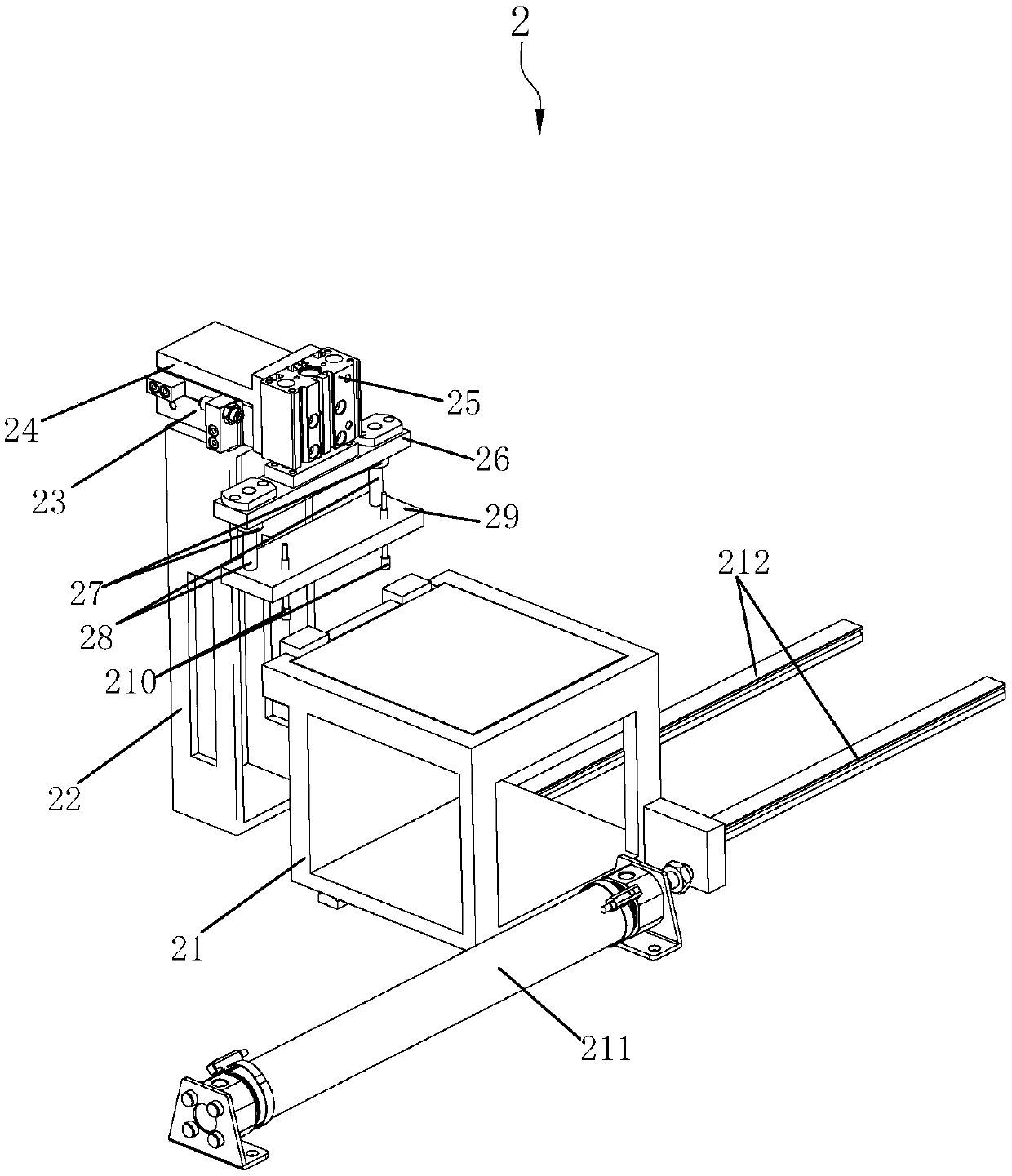

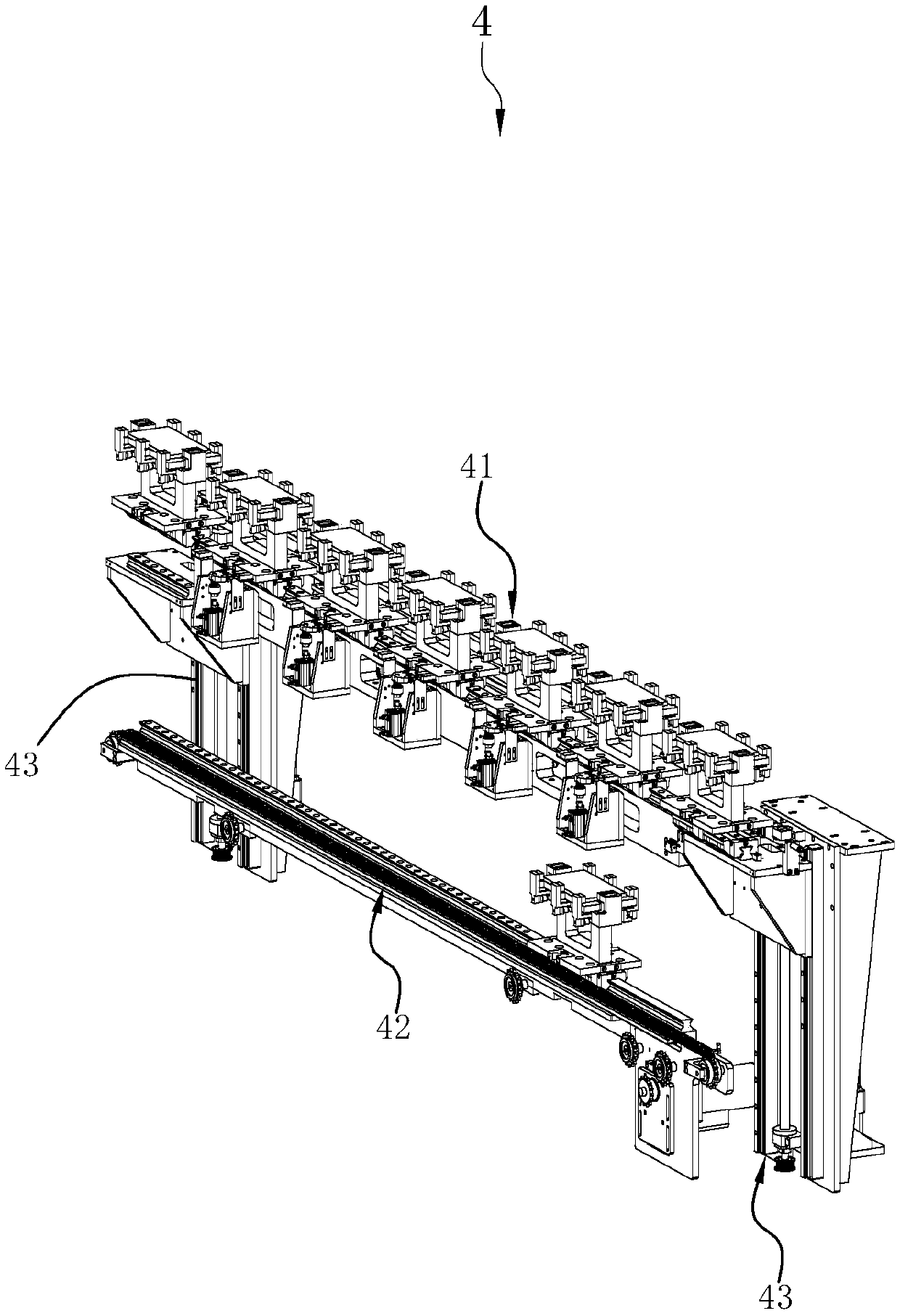

[0029] like Figure 1 to Figure 12 As shown, the laser welding equipment for battery tabs and pole pieces of the present invention uses a laser welding machine to weld the battery tabs and pole pieces of the pouch power battery. The equipment includes a workbench 1, The short-circuit detection components 2 are respectively arranged on the workbench 1 for short-circuit detection of the cells, and the cells that pass the short-circuit detection are grabbed to the feeding manipulator 3 for the fixture, and are respectively set on the workbench The top and bottom are used to circulate the upper and lower return line assembly 4 of the fixture up and down, and the fixture unlocking assembly 5, pre-welding assembly 6, Tab cutting assembly 7 , adapter piece feeding assembly 8 , welding assembly 9 and unloading manipulator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com